4-1 OPERATOR’S MANUAL

4 SAFETY

Improper operation of this equipment can cause death or serious injury. Before using this

equipment, make certain that every operator:

• Is instructed in safe and proper use of machine.

• Reads and understands the manual(s) pertaining to the machine.

• Reads and understands all safety decals on the machine.

• Clears area of other persons.

• Learns and practices safe use of machine controls in a safe, clear area before operating this machine.

Personal Protective Equipment (PPE) is required when working with this equipment. Wear

the appropriate protective shoes, eye and face protection, hearing protection, and any other PPE appropriate for the

work being conducted. Failure to comply could result in death or serious injury.

Crushing hazard. Follow lifting procedures for the grain cart and track module. Use

proper capacity lifting equipment and suitable jack stands to support the grain cart Failure to comply could result in

death or serious injury.

Never install, do maintenance, or repairs on the track system unless the machine on which

it is mounted is turned off and the key is in the possession of the person doing the work.

Maintain travel speeds such that complete control and stability is practiced at all times.

Reducing the speed when turning, crossing slopes and on rough, slick or muddy terrain will aid in controlling and

stabilizing the vehicle.

Stay off slopes too steep for safe operation.

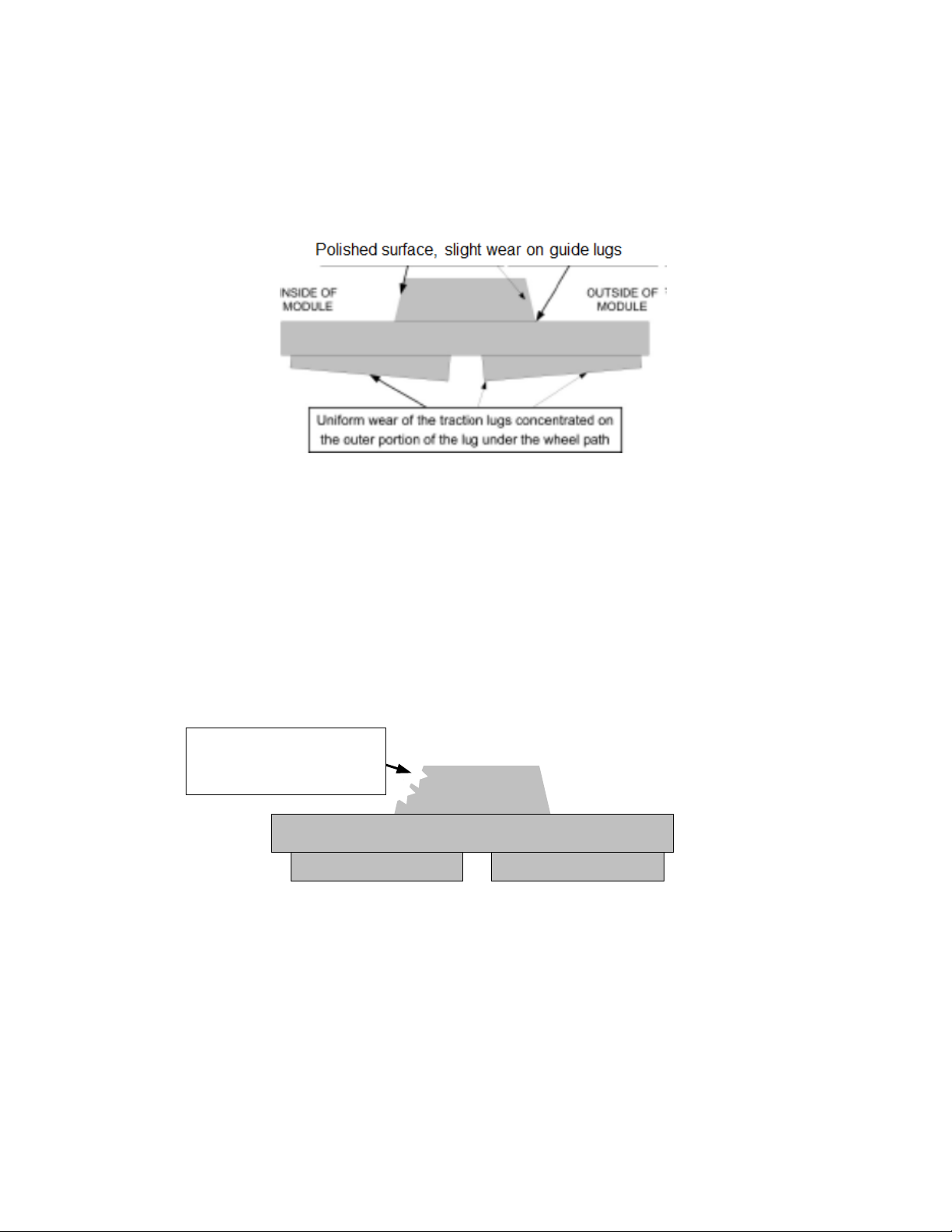

DO NOT pull the cart with hard mud or debris lodged inside the module against rubber surfaces.

After operating in muddy conditions clear the frame and wheels of mud and debris build up.

Never use tracks or frame as a step or standing platform to access or work on the

grain cart or equipment. Failure to comply could result in death or serious injury.

Before starting vehicle, walk around to check for other people, tools, loose parts, etc.

Keep everyone clear of the track modules when the tractor and grain cart are moving. Be aware of those persons

working in the vicinity of the vehicle. Failure to comply could result in death or serious injury.