Page 2

WARNING: TO AVOID PERSONAL INJURY OR DEATH, OBSERVE THE FOLLOWING

INSTRUCTIONS:

Never overload the wagon. The rating of the GF450 gear is 30,000 lbs. or the rating of

the tires, whichever is less.

Ensure that anybody present is clear before applying power to any machinery used in

conjunction with the wagon box or when moving the box.

Never allow anyone in, near, or on the gravity box during the transporting, loading, or

unloading of grain. Moving grain is dangerous and can cause entrapment, resulting in

severe injury or death by suffocation.

Do not exceed 20 miles per hour when towing the wagon.

TABLE OF CONTENTS

General information, Warranty Policy & Registration & Table of Contents...........................2

For your safety................................................................................................................... 3-9

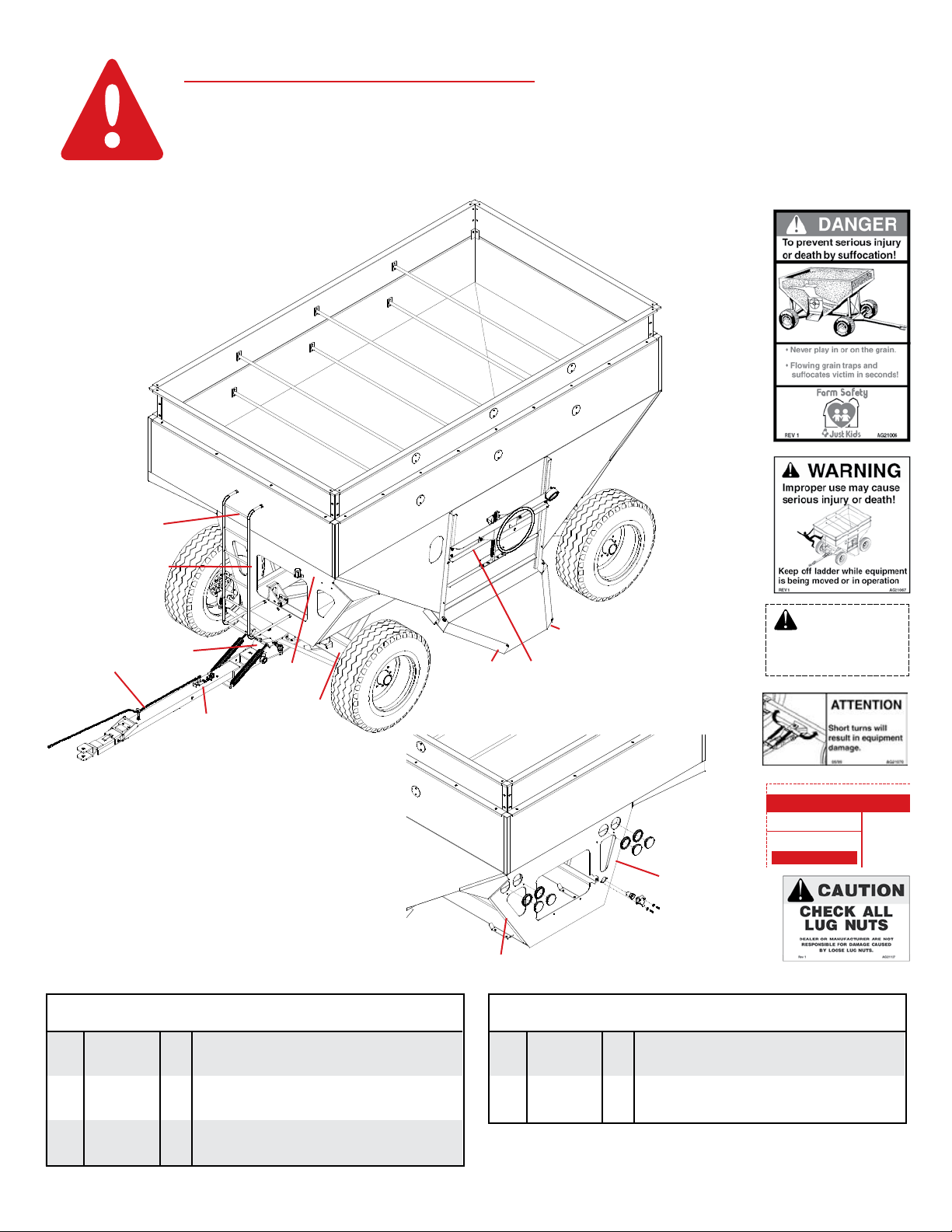

Safety Sign Locations.........................................................................................................10

Bolt Torque & Wheel Bearing Adjustment...........................................................................11

Running Gear Parts Breakdown.........................................................................................12

Running Gear Parts List and Assembly Instructions ..........................................................13

Brake Tongue Maintenance and Adjustment ......................................................................14

Brake Tongue Parts Breakdown and Parts List ..................................................................15

13” Brake Cluster Parts Breakdown and Parts List ............................................................16

Running Gear Brake Line Parts Breakdown, Parts List, and Assembly Instructions..........17

Brake System Maintenance and Repair .......................................................................... 18-19

Gravity Flow Box Parts Breakdown ....................................................................................20

Gravity Flow Box Assembly Instructions and Parts List......................................................21

Maintenance and General Operation .................................................................................22

Gravity Box to Running Gear Assembly Instructions and Parts List...................................22

Gravity Flow Light Kit Parts Breakdown, Parts List, and Wiring Schematic .......................23

Thank you for purchasing a Demco Gravity Flow Wagon. We feel you have made a wise choice and hope you are completely

satisfied with your new piece of equipment. Proper care and use will result in many years of service.

INTRODUCTION

GENERAL INFORMATION

1. Unless otherwise specified, high-strength (grade5)

(3 radial-line head markings) hex head bolts are used

throughout assembly of this piece of equipment.

2. Whenever the terms “LEFT” and “RIGHT” are used in

this manual it means from a position behind the wagon

box and facing forward.

3. When placing a parts order, refer to this manual for proper

part numbers and place order by PART NUMBER,

DESCRIPTION and COLOR.

4. Read the assembly instructionscarefully. Study the assembly

procedures and all illustrations before you begin assembly.

Note which parts are used in each step. This unit must

be assembled in the proper sequence or complications

will result.

WARRANTY POLICY, OPERATOR MANUALS & REGISTRATION

Go online to www.demco-products.com to review Demco warranty policies, operator manuals and register your Demco product.