demig DE-BT 1000 User manual

demig Prozessautomatisierung GmbH

Manual

Terminal DE-BT 1000

By demig Prozessautomatisierung GmbH

from version 12.1.1 (2017)

demig Prozessautomatisierung GmbH

Manual Terminal DE-BT 1000

This manual was produced using ComponentOne Doc-To-Help.™

demig Prozessautomatisierung GmbH

Manual Terminal DE-BT 1000 Content • i

Content

1. Cha ter: Introduction ....................................................................................... 1

1.1 Basic Information ............................................................................................. 1

1.1.1. General Handling .........................................................................................1

1.1.2. CE-Conformity .............................................................................................1

1.1.3. Installation Instructions ................................................................................1

1.1. . Structure of the Operating Instructions .........................................................2

1.1.5. Security Symbols .........................................................................................2

1.1.6. Disclaimer....................................................................................................2

1.2 Brief Explanation of the Industrial Terminal DE-BT 1000 ................................. 3

1.2.1. General Explanation ....................................................................................3

1.3 General Handling of the DE-BT 1000 .............................................................. 3

1.3.1. Commands ..................................................................................................

1.3.2. Status Line ..................................................................................................7

1.3.3. Menu ...........................................................................................................8

1.3. . Service Menu ..............................................................................................9

2. Cha ter: Service and Technical Data ............................................................ 11

2.1 General maintenance .................................................................................... 11

2.1.1. Cleaning and care of the keypad and of the screen .................................... 11

2.1.2. Direct Support............................................................................................ 11

2.2 Update of the System Software ..................................................................... 13

2.2.1. Necessary Material .................................................................................... 13

2.2.2. Starting the Update .................................................................................... 13

2.2.3. Update History ........................................................................................... 1

2.3 Technical Data .............................................................................................. 15

2.3.1. Control System Unit ................................................................................... 15

2.3.2. Installation and mounting ........................................................................... 15

2.3.3. PIN Assignments ....................................................................................... 16

2. Installation Dimensions and Measurements of Rack-Housing ........................ 17

2. .2. Connections .............................................................................................. 18

3. Cha ter: A endix .......................................................................................... 19

3.1 License Note ................................................................................................. 19

Index ......................................................................................................................... 21

demig Prozessautomatisierung GmbH

Manual Terminal DE-BT 1000 Cha ter: Introduction • 1

1. Cha ter: Introduction

1.1 Basic Information

1.1.1. General Handling

Please read the operating instruction carefully before installing or handling the

industrial terminal DE-BT 1000, in order to avoid dangerous situations and damages

due to operating errors. This operating manual is limited to the handling of the

DE-BT 1000 and does not include all different applications.

1.1.2. CE-Conformity

The industrial terminal DE-BT 1000 corresponds to the standards and guidelines

named in the conformity declaration. To make sure these are observed, please pay

attention to the following:

• It is the responsibility of the installing person to observe all the standards and

guidelines for the usage and installation of the industrial terminal DE-BT 1000.

• Make sure that only qualified staff installs the industrial terminal DE-BT 1000.

• Make sure that all the precautions stated in the chapter "Information for the

installation" are observed.

• Reparations of the industrial terminal DE-BT 1000 by the customer are not

allowed.

• By using the industrial terminal DE-BT 1000 for unintended purposes as well

violating the regulations mentioned above, demig Prozessautomatisierung GmbH

assumes no responsibility. The conformity declaration then loses its validity.

1.1.3. Installation Instructions

Please check the process control system immediately upon receipt. In case of any

damages, the device must not be installed. Pay attention to the terms of installation in

chapter service and technical data.

demig Prozessautomatisierung GmbH

2 • Cha ter: Introduction Manual Terminal DE-BT 1000

1.1.4. Structure of the O erating Instructions

All security advices in this operating manual are marked with this symbol:

Further information is shown in a frame with the headline information. Security

functions are marked with the following symbol:

1.1.5. Security Symbols

The following security symbols are shown on the terminal:

Attention! An incorrect connection of the device may lead to system

disturbances, - damages, quality losses as well as danger to persons

and environment. The connections not marked directly at the

controller are explained in the corresponding documentation

(Operating Instructions, Pin Assignment Cards).

Protective ground wire (min. 6mm² cross section!)

1.1.6. Disclaimer

Possible errors cannot be excluded. demig Prozessautomatisierung GmbH

assumes neither a legal res onsibility nor the liability for mis rints, wrong

information and/or omissions or the resultant damages. Suggestions for

im rovement and advice are always welcome.

All rights reserved!

W ar ni ng :

!

Notice:

!

!

demig Prozessautomatisierung GmbH

Manual Terminal DE-BT 1000 Cha ter: Introduction • 3

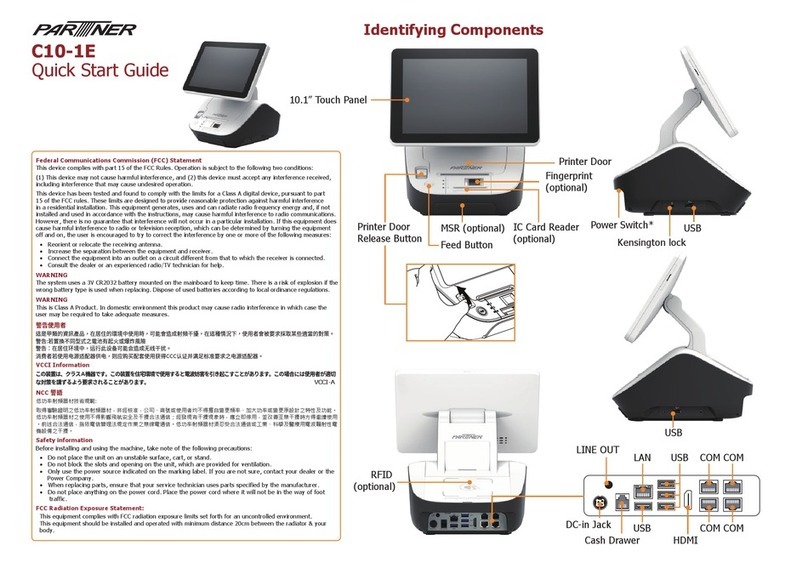

1.2 Brief Ex lanation of the Industrial

Terminal DE-BT 1000

1.2.1. General Ex lanation

The industrial terminal DE-BT 1000 is a display and input terminal. As it is only a

terminal, a further host system for the control is needed (e.g.: process supervisory

system prosys/2). The host system transmits the messages/commands via different

communication systems to the DE-BT 1000.

After receiving a message, the display is updated for the user. In case of an input mask

on the screen, the keypad can be used to enter the data which then will be requested

by the host system.

1.3 General Handling of the DE-BT 1000

The DE-BT 1000 has a main display, which is shown immediately after the start. This

is also the range for masks and texts. Furthermore, it has a status line in which different

information can be shown. From this main display, different instructions can be carried

out by key shortcuts. The instructions and the corresponding key shortcuts are

described in the menu point „Commands“.

Use the tab keys and to switch between the different input parts in a menu.

The entry can be selected with the arrow keys after marking a selection field. Buttons

can be confirmed by „ENTER“ and selections change the status with the space bar

„

“. Inputs in a text field are done by the keypad.

demig Prozessautomatisierung GmbH

4 • Cha ter: Introduction Manual Terminal DE-BT 1000

1.3.1. Commands

1.3.1.1. Delete Messages

Messages or errors in the status line can be blanked out by mouse click or by key

shortcut [SHIFT] + [F7] ausgeblendet werden.

1.3.1.2. Configuration Menu

By the shortcut [SHIFT] + [F8] the configuration menu of the DE-BT 1000 is reached.

First you have to answer the security request „Do you really want to open the DE-BT

1000 configuration?“ with „ es“. In case of „No“ as answer, the user returns to the main

display.

Different settings can be done in the configuration menu. The following list gives a

short overview of the setting possibilities. In case of a selection field, the possible

options are shown in the square brackets.

• GID (device ID) [0-9]

• UID (user ID) [0-9]

• Baud rate RS 85 [300, 600, 1200, 2 00, 800, 9600, 19200, 38 00]

• Parity RS 85 [o=Odd, e=Even, n=None]

• Stop bits RS 85 [1, 2]

• Baud rate RS232 [300, 600, 1200, 2 00, 800, 9600, 19200, 38 00]

• Parity RS232 [o=Odd, e=Even, n=None]

• Stop bits RS232 [1, 2]

• Active [RS232, RS485, NET]

• Port number [102 -65535]

• DHCP

• IP address

• Subnet mask

• Default gateway

The GID and UID are used for the device addressing. Furthermore, the interface

configuration can be determined. That includes the serial interfaces RS232 and

RS 85, as well as the IP configuration. Moreover, the interface, which should be used

for the communication with the host system, can be selected in the selection field

„Active“. For a communication via network (NET) the selected Port is used.

demig Prozessautomatisierung GmbH

Manual Terminal DE-BT 1000 Cha ter: Introduction • 5

1.3.1.3. Factory Settings

To set the terminal back to factory setting, use the shortcut [SHIFT] + [F1] in the

configuration menu. In case the security request is answered with „ es“ the DE-BT

1000 is set back to factory settings. The factory settings are as follows:

• GID = 1

• UID = 1

• Baud rate RS 85 = 9600

• Parity RS 85 = o

• Stop bits RS 85 = 2

• Baud rate RS232 = 9600

• Parity RS232 = o

• Stop bits RS232 = 2

• Active = RS 85

• Port number = 50000

• DHCP = Yes

• IP address = 0.0.0.0

• Subnet mask = 255.255.255.0

• Default gateway = 0.0.0.0

1.3.1.4. Information Dis lay

Information about the preset configuration can be displayed by [SHIFT] + [F2] in the

configuration menu in case, the request was confirmed with „ es“. Besides this

information, also the current network configuration is shown.

demig Prozessautomatisierung GmbH

6 • Cha ter: Introduction Manual Terminal DE-BT 1000

1.3.1.5. Keyboard Test

The keyboard test can be called by [SHIFT] + [F4] and the following confirming with

„ es”. In the now appearing window the keys to be pressed on the softkeyboard are

highlighted in color. After the successful pressing of a key, it will be deleted in the

display. The keyboard test is closed automatically when no further key is shown.

highlighted key

1.3.1.6. Exit terminal mode

To exit the terminal mode and go to the menu (see chapter 1.3.3) use the key

combination [SHIFT] + [F8] in the configuration menu. You only reach the service

menu after confirming the following request with „ es“.

1.3.1.7. U date

The update program is started with [SHIFT] + [F9] from the configuration menu and by

confirming the appearing request with „ es“. After that the update can be installed by

the File Transfer Manager (FTM).

demig Prozessautomatisierung GmbH

Manual Terminal DE-BT 1000 Cha ter: Introduction • 7

1.3.2. Status Line

At the upper edge of the display is the status range of the DE-BT 1000. This range is

consisting of one line and directly after the start it looks as follows:

version communication channel messages

Then the version and the communication channel are updated.

The communication channel shows on which interface the communication with the

host system is expected. A red highlightning shows an inactive communication. An

active communication is shown in green.

Messages can contain information or errors. They are shown in a ticker right to the

communiction channel. To mark an error, the text is shown in red letters instead of

white letters.

demig Prozessautomatisierung GmbH

8 • Cha ter: Introduction Manual Terminal DE-BT 1000

1.3.3. Menu

After leaving the terminal surface (see chapter 1.3.1.6) the menu follows, which looks

as follows:

In this menu the user can select between three menu points.

Description of the menu points:

1.3.3.1. START start BT1000

Selecting the first menu point „start BT1000“ the menu is left and the DE-BT 1000

application is started.

1.3.3.2. LOG show logfile

The second menu point „show logfile“ serves to show the last log-entries. They are

shown in a new window.

1.3.3.3. SERVICE maintenance

By selecting the last menu point „maintenance“ the service menu is opened.

demig Prozessautomatisierung GmbH

Manual Terminal DE-BT 1000 Cha ter: Introduction • 9

1.3.4. Service Menu

In this dialog maintenance work at the DE-BT 1000 can be done. The dialog is as

follows:

When leaving this dialog with “Cancel” you return to the menu. Furthermore, you

have the possibility to select one of the following nine menu points with “OK”.

1.3.4.1. DHCP activate DHCP

Selecting this menu point, the DHCP-server assigns a new IP address to the terminal.

Thus, the terminal is achievable with the new IP address.

1.3.4.2. SHOW_NET show network settings

In this menu point, you can see the current network configuration. The IP-address, the

subnetmask and the network status are shown.

1.3.4.3. UPD_MOD start u date mode

To install new updates, the terminal can be set in the update mode (in addition to the

way described in 1.3.1.7) by means of the menu point „start update mode“. The update

can be installed with the File Transfer Manager (FTM).

1.3.4.4. INST_UPD install u date

In case the update was transferred to the terminal and not directly installed you can do

the now with the menu point „install update [ ]“. Between the square brackets is the

update´s file name.

1.3.4.5. SHOW_UPD show u date history

The update history (installation dates of the updates) can be shown by the menu point

„show update history.

demig Prozessautomatisierung GmbH

10 • Cha ter: Introduction Manual Terminal DE-BT 1000

1.3.4.6. RMMSK remove ALL mask files

All masks existing in the storage are deleted with this menu point. Therefore, all masks

have to be sent again to the terminal.

1.3.4.7. DATETIME set date/time

To set the date and the time manually use the menu point „set date/time“. In the now

following dialog enter first the date and in a further dialog the time.

1.3.4.8. REBOOT reboot

After selecting this menu point the terminal reboots .

1.3.4.9. HALT halt

This menu point shuts down the terminal.

demig Prozessautomatisierung GmbH

Manual Terminal DE-BT 1000 Cha ter: Service and Technical Data • 11

2. Cha ter: Service and

Technical Data

2.1 General maintenance

2.1.1. Cleaning and care of the key ad and of the screen

The front panel with the keypad is a laminated surface (according to DIN 0050 IP

protection 65). This surface, as well as the screen of the monitor, may be cleaned with

a damp cloth and customary neutral detergent (glass cleaning agent).

2.1.2. Direct Su ort

We offer the following possibilities for a direct support:

a) Tele hone Su ort

Many malfunctions are caused by incorrect settings or improper handling. They

may often be corrected in cooperation with the service technician via telephone.

b) E-Mail Su ort

Use the direct support by e-mail with our service technician.

c) Service on site

You may request the help of a service technician directly at demig or at the

manufacturer. This relates to all software and hardware questions.

Absolutely to be avoided:

• Dripping wet treatment

• Aggressive cleaning agents

• Treatment of the keypad with peaked things

Wa rning:

!

demig Prozessautomatisierung GmbH

12 • Cha ter: Service and Technical Data Manual Terminal DE-BT 1000

2.1.2.1. Contact:

Telephone: + 9 271 77202-25 or + 9 271 77202-29

Fax: + 9 271 7 70

E-Mail: service@demig.de

URL: www.demig.com

demig Prozessautomatisierung GmbH

Manual Terminal DE-BT 1000 Cha ter: Service and Technical Data • 13

2.2 U date of the System Software

2.2.1. Necessary Material

• External PC or Laptop with FTM (File Transfer Manager) and a connection to the

DE-BT 1000. This connection can be serial or via network.

• Update file (e.g. via E-Mail) from demig Prozessautomatisierung GmbH. There

are 3 different update types:

•

File name:

•

u date for:

•

200727os.tbz

•

Operating system and Kernel modules

•

200727xs.tbz

•

Surface

•

200735bt.tbz

•

Terminal Application

• The first 6 figures of the file name describe the release date (year and calendar

week) of the update. Depending on the current software status of the DE-BTk

1000 it is not necessary to install all 3 update types. In case of several updates

the following sequence of the updates should be noted:

• *os.tbz → *xs.tbz → *bt.tbz

2.2.2. Starting the U date

1. Start the FTM on the computer.

2. Set the DE-BT 1000 in the update mode, see chapter 1.3.1.7.

3. Now connect the FTM with DE-BT 1000. As it is the same procedure as for the

controller, see the operation manual of the FTM.

. Transmit then, by the FTM, the update to the DE-BT 1000. The question whether

to send the files or also to start the update has to be answered with „Make update

“. The update is then transmitted and automatically installed!

5. For the installation of further updates please repeat steps 1- .

demig Prozessautomatisierung GmbH

14 • Cha ter: Service and Technical Data Manual Terminal DE-BT 1000

2.2.3. U date History

Delivery date ex works: ______________________________

Software version at delivery: ______________________________

No: Date Installed File Software Version after

U date

01

02

03

0

05

06

07

08

09

10

11

12

13

1

15

16

17

18

19

20

21

22

23

2

25

demig Prozessautomatisierung GmbH

Manual Terminal DE-BT 1000 Cha ter: Service and Technical Data • 15

2.3 Technical Data

2.3.1. Control System Unit

• COM-Express CPU module

• AMD G-Series 1,6 GHz

2.3.1.1. Storage

• 2 GB RAM (operating store)

• 8 GB Industrial Grade Flash for operating program and configuration storage

2.3.1.2. O tional mass storage

• USB mass storage

2.3.1.3. Interfaces/Connections

• All interfaces are galvanically isolated from the supply and system potential.

• DIN-RS232, up to 38 00 Baud

• DIN-RS 22/RS 85, compatibel up to BT 85, half and full duplex, up to 38 00

Baud

• 2x USB, for keyboard, printer, scanner, etc.

• Power supply unit: 2 V DC, ± 15%, max. eo W, protective earth connection

• Gigabit-Ethernet interface

2.3.1.4. Dis lay

• 6,5" TFT LCD-color display with extra large viewing angle

• resolution 6 0x 80 pixles

2.3.1.5. O eration

• Membrane keyboard (according to DIN EN 60529 IP protection 65)

• Extern connectable PC keyboard and mouse

2.3.2. Installation and mounting

• Ambient temperature 0...+ 5°C

• Relative humidity 0 - 90% non condensing at + 0°C and below 3000m

• Supply voltage 2 V DC, ± 15%, power consumption 20W (normal mode)

• Storing temperature -20...+60°C

• Integrated seal at the rear of the front panel

• Mounting space in the switch gear cabinet to the top and the bottom 15 cm

demig Prozessautomatisierung GmbH

16 • Cha ter: Service and Technical Data Manual Terminal DE-BT 1000

2.3.2.1. Potentials

In order to guarantee an undisturbed operation (electromagnetic compatibility EMC), it

is important to connect the protective grounding cable (min. diameter 6 mm2, superiorly

earth wire).

2.3.3. PIN Assignments

2.3.3.1. Serial Interfaces

Male Connector: Female Connector:

Pin: RS232 RS485/422

1 DCD 5V

2 RXD GND

3 TXD -

DTR -

5 GND -

6 DSR Y Sender

7 RTS Z

8 CTS A Receiver

9 RI B

2.3.3.2.

2.3.3.3. Power Su ly

Pin:

1 2 V

2 Ground

3 PE

Table of contents

Popular Touch Terminal manuals by other brands

Interflex

Interflex IF-80 Series manual

Ingenico group

Ingenico group Move 3500 BLUETOOTH quick start guide

FingerTec

FingerTec TA300 quick start guide

Hisense

Hisense HK560 user manual

Beijer Electronics

Beijer Electronics VICPAS EXTER Series Service and maintenance manual

Roger

Roger PRT-EM Series Installation and programming guide