Demon International STORM 1 User manual

STORM

PRESSURE WASHER

OPERATOR MANUAL

Clemas & Co. Unit 5 Ashchurch Business Centre, Alexandra Way, Tewkesbury,

Gloucestershire, GL20 8NB.

Tel: 01684 850777 Fax: 01684 850707

DemonStormManual—Issue10/07 Page1

DEMONSTORMRANGE

STORM1

STORM2

STORM500

STORMSTATICWALLMOUNTEDRANGE

WM1

WM4

STORMSTATICFREESTANDINGRANGE

FS1

FS4

DeclarationofConformity

(E.H.S.R)

We,DemonInternationalLimitedofAbbotsClose,LeeMillIndustrialEstate,Ivybridge,

Devon,PL219GADeclarethismachinemustbeoperatedinaccordancewiththe

operationandsafetyinstructionsassuppliedwiththismachine.Thismachineis

manufacturedinaccordancewiththefollowingstandards.

HSEPVBPM‐BS415Part1‐BS5415Section2.41986

Thisinstructionmanualisrelevantonlytothefollowingmachineandwillnotbekept

updatedunlessspecificallyrequestedbythecustomer.Howeveranychangestothe

operatingprocedureorchangeswhichmightaffectthesafetyofthismachinewillbe

notifiedtotheregisteredownerofthismachineonly.

MachineType

SerialNumber

Voltage

WorkingPressure

DateofSupply

DemonStormManual—Issue10/07 Page2

TechnicalSpecifications

Storm1

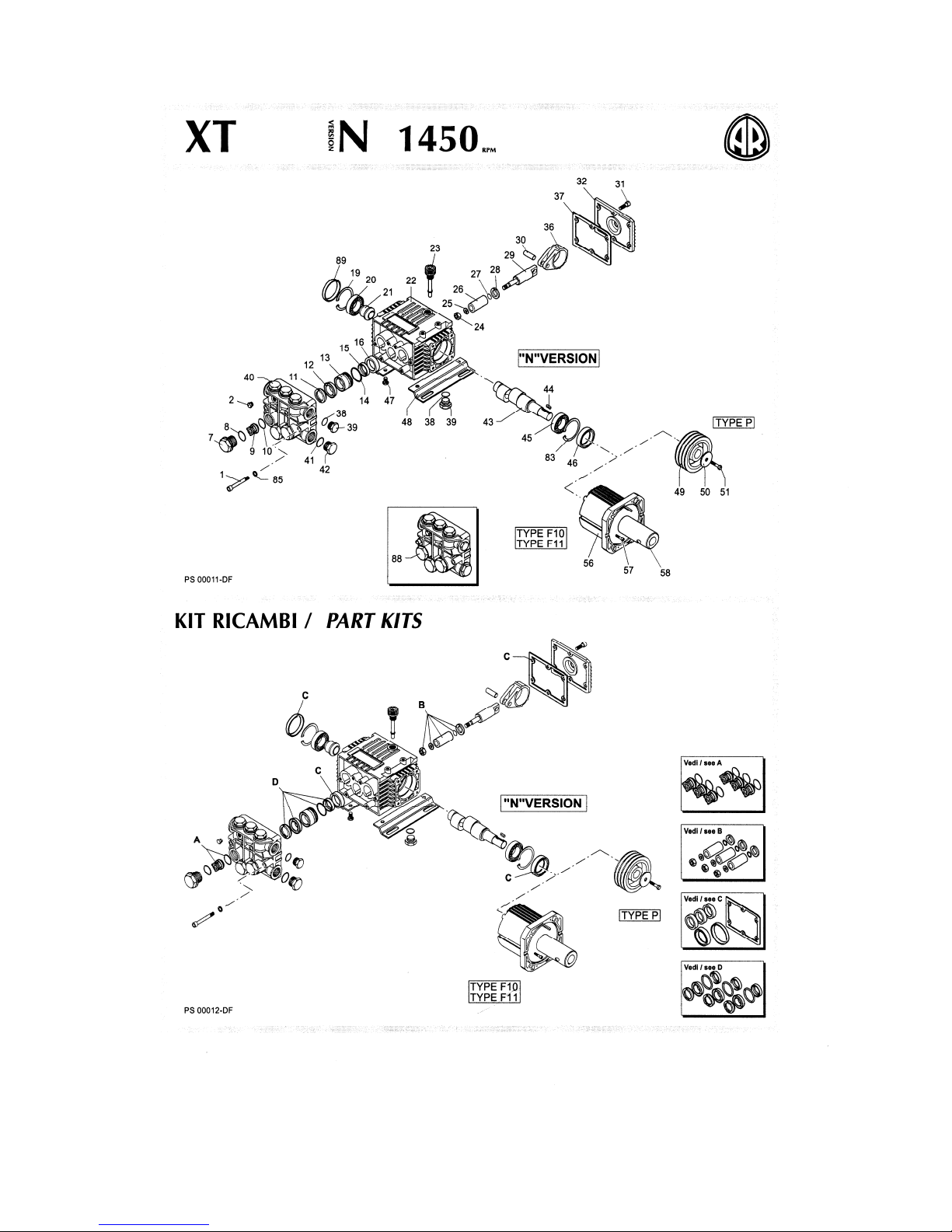

PumpARXT11.14 Motor MTR00100

Pumppressure 100bar 1500psi Motoroutput P12.2KW

Flowrate 11lpm 2.45gpm Motorinput P23.0KW

Maxbypasssetting120bar 1750psi Maxcurrent12.5amps

H.PNozzle 15045 Voltage 230V+or‐10V

Pumpoil 10W40 Insulation ClassF

Unloadervalve ARMM4B/C Dutycycle 100%

NoiseProtection IP54

Storm2

PumpXT11.14 Motor MTR00301

Pumppressure 100bar 1500psi MotoroutputP12.2KW

Flowrate 11lpm 2.45gpm MotorinputP23.0KW

Maxbypasssetting120bar 1750psi Maxcurrent 24amps

H.PNozzle 15045 Voltage 110v+or‐5V

Pumpoil 10W40 Insulation ClassF

Unloadervalve ARMM4B/C Dutycycle 100%

NoiseProtection IP54

Storm500

PumpARHSHP15.50 Motor N/a

Pumppressure 500bar725psi MotorOutput15Kw

Flowrate 15lpm3.3gpm MotorInput

Maxbypasssetting510bar7450psi Maxcurrent

H.P.Nozzle 1503Voltage 415v+or‐15v

PumpOil 10W40 Insulation ClassF

Unloadervalve VB16DutyCycle100%

SafetyValve V5500 Protection IP54

Noise

DemonStormManual—Issue10/07 Page3

StormWallmounted1

PumpXT11.14 Motor MTR00100

Pumppressure 100bar 1500psi MotorOutputP12.2W

Flowrate 111pm 2.45gpm MotorInputP23.0KW

Maxbypasssetting120bar Maxcurrent12.5amps

H.P.Nozzle 15045 Voltage 230V+or‐10V

PumpOil 10W/40 Insulation ClassF

Unloadervalve ARMM4B/CTSS DutyCycle100%

NoiseProtection IP54

StormWallmounted4

PumpRK15.20 MotorMTR00220

Pumppressure 200bar 2900psi MotorOutputP15.5W

Flowrate 15lpm 3.3gpm MotorInputP26.6KW

Maxbypasssetting210bar Maxcurrent12.6ampsphase

H.P.Nozzle 1505Voltage 415V+or‐10V

PumpOil 10W/40 Insulation ClassF

Unloadervalve ARMM4B/CTSS DutyCycle100%

NoiseProtection IP54

StormFreeStanding1

PumpXT11.14 Motor MTR00100

Pumppressure 100bar 1500psi MotorOutputP12.2W

Flowrate 111pm 2.45gpm MotorInputP23.0KW

Maxbypasssetting120bar Maxcurrent12.5amps

H.P.Nozzle 15045 Voltage 230V+or‐10V

PumpOil 10W/40 Insulation ClassF

Unloadervalve ARMM4B/CTSS DutyCycle100%

NoiseProtection IP54

StormFreeStanding4

PumpRK15.20 MotorMTR00220

Pumppressure 200bar 2900psi MotorOutputP15.5W

Flowrate 15lpm 3.3gpm MotorInputP26.6KW

Maxbypasssetting210bar Maxcurrent12.6ampsphase

H.P.Nozzle 1505Voltage 415V+or‐10V

PumpOil 10W/40 Insulation ClassF

Unloadervalve ARMM4B/CTSS DutyCycle100%

NoiseProtection IP54

DemonStormManual—Issue10/07 Page4

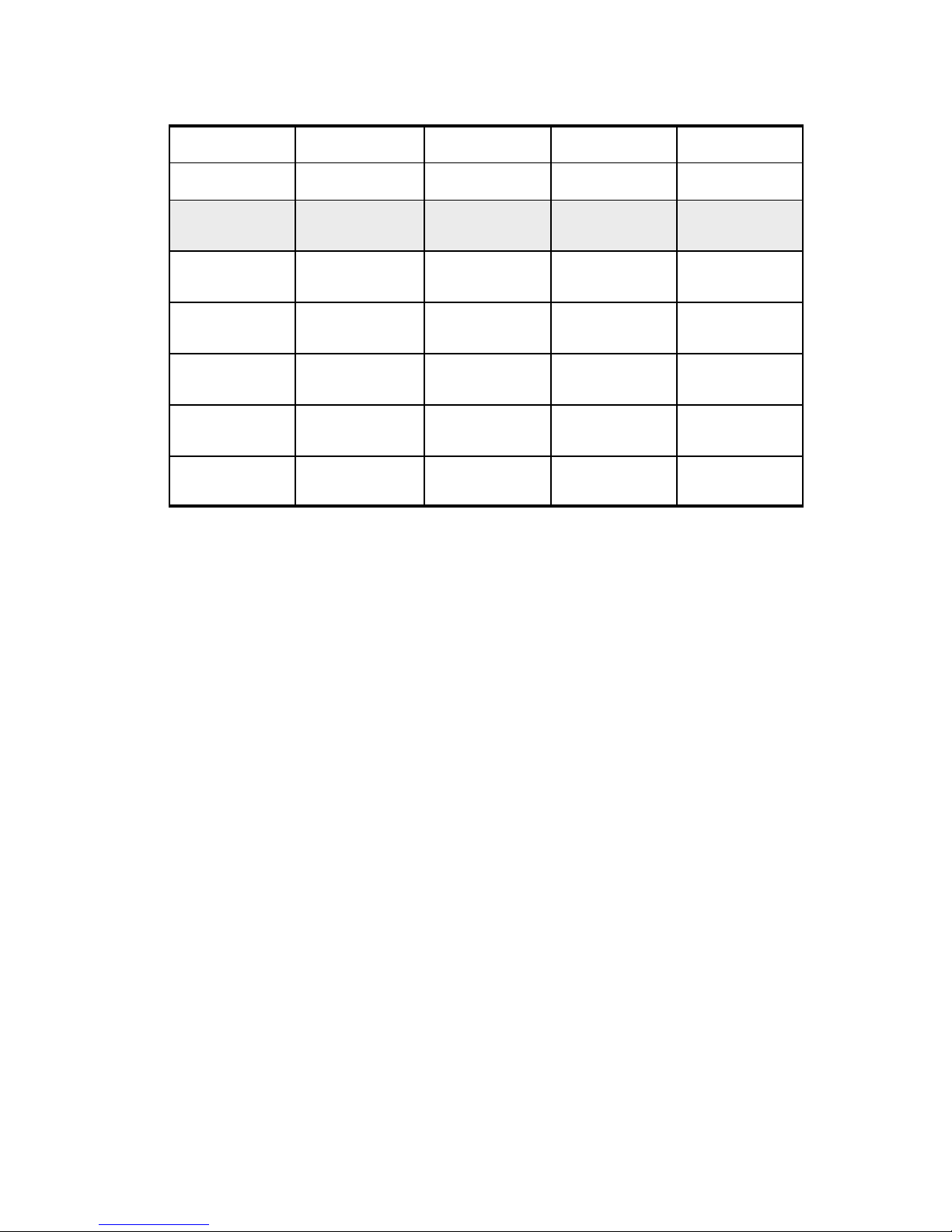

ValveKitPistonKitOilSealKitWaterSealKit

STORM11864262918721874

STORM21864262918721874

WM11864262918721857

WM41828275718561857

FS11864262918721857

FS41828275718561857

STORM500

CommonPartNumbers

ChemicalFilterMTM86010

InletQRCouplingMTM73001(ToTap)3/4Female(Nito)

InletQRCouplingMTM73020(ToTap)3/4Male(Nito)

ElectricalBoxonStormDEM101111

DemonStormManual—Issue10/07 Page5

PREPARATION

WaterSupply:

a.Ensurethereisanadequatewatersupplyeitherfromthemainsorareservoir.

b.Attachwatersupplyhosestosuitabletaporimmerseendofhoseintoreservoir.

NOTE:ONLYCLEANFILTEREDWATERSHOULDBEUSED.

Hoses:

a.Attachthehighpressurehosetothepumpconnection.

b.Attachthesprayguntooppositeendofthehighpressurehose.

c.EnsurethattheregulatornozzleontheendofthespraylanceisCLOSED.

OPERATION

(Checkthatelectricmotorisswitched‘OFF’)

a.Plugintoasuitableelectricalsource.(Notanextensionlead)

b.Turnonwatersupply.

c.Ensurethatthetriggeris‘OPEN’toventairfromthepump.

d.Switch‘ON’electricmotor.

e.Openregulatornozzleslightlyanddirectlanceonsurfacetobecleaned.Press

operatingtrigger.

f.Adjustpressureregulatorasrequiredtoobtainworkingpressure.

g.NOTE:Thehighpressurewaterwillcausethegunto‘kick’.Makesureyouhavea

firmgripofthegunandlance.

h.Oncompletionoftheoperationswitch‘OFF’electricmotorandunplugfrompower

supply.

i.Turn‘OFF’watersupply.

j.Releaseresidualpressureingunandlancebyoperatingtrigger.

DemonStormManual—Issue10/07 Page6

OPERATINGHINTS

a.Duringverycoldweatheritismostimportanttoprotectthemachineagainstfreezing.DO

NOToperatemachineshoulditbecomefrozen.Moveittoawarmareaandallowtothaw

naturally.

b.Checkallhosesandcouplingsforleaks,tightenwherenecessary.

WHENUSINGCLEANINGAGENTS

a.Setmachineupforwateronly.

b.Connectdetergenthosetomachineandplacefilterendintodetergentreservoir.Unscrewthe

adjustablenozzleontheendofthelancetoreducethepressureto500psi.Thechemicalwill

nowbeautomaticallyinjectedintothewater.

c.Oncompletionofwork,flushthroughhoseandgunwithcleanwatertoremoveanyresidual

detergent.

SERVICING

TheStormrangerequirelittlemaintenanceapartfromcheckingtheoillevelatleasteveryweekand

changingtheoilshoulditturnwhiteoritissixmouthsold.Iftheoilturnswhiteitisdueonlytowater

enteringthepumpviathedipstick,whichhasabreatherholedrilledthrough.Thedesignofthepump

doesnotallowwaterfromthepumptogainaccesstothegearboxdrive.

Shouldtheperformancebereducedtoalevelwherethejetisineffectivecontacttheservicedepart‐

menttoascertainthecorrectremedialrepairwork.

DemonStormManual—Issue10/07 Page7

OPERATINGINSTRUCTIONS

SAFETY

i.AResidualCurrentDevice(R.C.D.)orEarthLeakageTripmustbeusedwiththismachine.

ii.Waterathighpressureisdangerousandcancauseseriousinjury.Thismachineistobeused

withgreatcaution.

a.NEVERpointthehighpressuresprayjetatanyperson,animal,glassoranyothermaterialwhich

mayshatter.

b.PREVENTanyover‐sprayfrominjuringotherpeopleordamagingproperty.

c.DONOTeventrytouseapressurewasheronmachineryorelectricalequipmentthatis

connectedinanywaytothemainssupply.(allswitchesintheoffposition,pulloutallplugsandif

possibleremovefuses).Coverorsealelectricmotorsandfittingstoprevententryofwater.

d.ALWAYSwhenusingmachine:‐

‐wearsafetygogglesandhelmetorhelmetwithavisor.

‐wearwaterproofclothingandgloves.

‐takeparticularcarewithdetergentsandchemicals.

e.NEVERattempttodisconnectanyhosewithpressureinitorallowthehosetobeflattenedor

kinked.

f.DONOTuseahighpressurehosefromaladder.Useaplatformtowerorproperscaffolding.

g.CHECKthatyoursupplyvoltageagreeswiththatshownonthemachine.

h.Ifanextensionleadisusedunwindallcableoffthedrumtostopoverheating.Therightsize

ofextensionleadmustbeused,failuretodosowillresultinswitchfailureormotordamage.

Demonstronglyrecommendtheuseofextensionhosesopposedtoextensionleads.Warranty

claimsfordamagedswitchesandmotorsusedonextensionleadswillnotbeallowed.Askthe

servicedepartmentifindoubt.

I.DOALLyoucantokeepplugsandsocketsinadryplaceorcoveredtoprevententryofwater.

j.Whereacableisfoundtobedamaged,thepowermustbeswitchedoffandtheplugremoved

beforeattemptingtoremovetheequipment.

DemonStormManual—Issue10/07 Page8

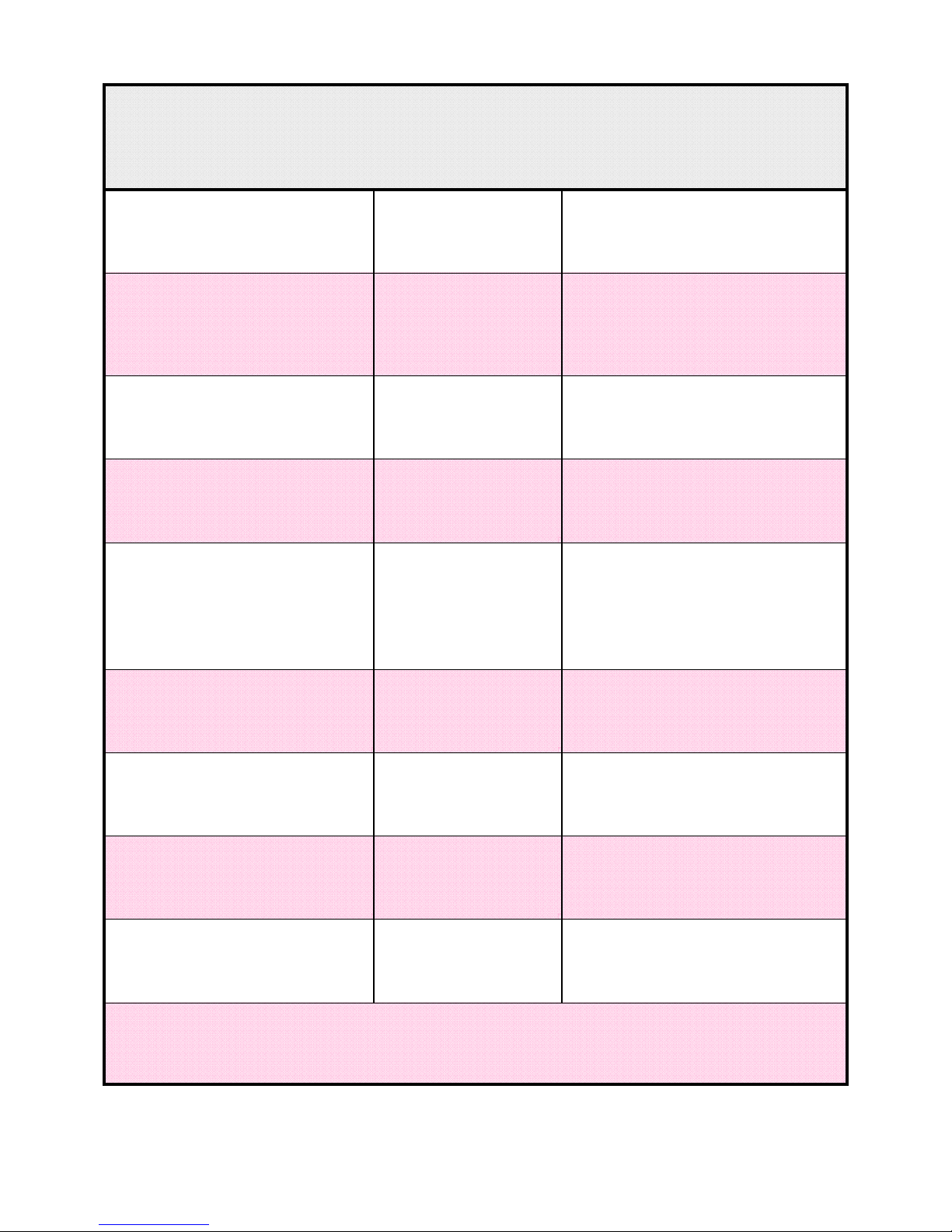

FAULTFINDER

FAULT

CAUSE

REMEDY

Machinestopssuddenly

Orwillnotstart.

Blownfuse.Checkmainspowersupply,re‐

placefuse.Waituntilunitcools

downbeforeresettingswitch.

Suddenpressureloss.Watersupplyfailed.Checkwatersupply.

LowpressureHPnozzlewornor

unloaderset

Incorrectly.

ReplaceHPnozzle.Setunloader

tocorrectsetting.

Lowpressurewithnoiseand

vibration.

Valveswornor

blocked.Pistonseals

worn.

Pumpsuckingair.

Clean/replaceasrequired.

Replace.

Checkwatersupplypipeandun‐

ions.

Pumpwillnotby‐pass.Nonreturnvalve

dirtyorjammed.

Cleanorreplace.

Waterdripsfrompumpbox.Pumpsealsworn.Replace.

Oildripsfrompumpbottom.Oilsealworn.Replace.

Oilismilkyincolour.Wateringress

throughoilfilter

plug.

Rinsepumpoutandreplaceoil.

IFINDOUBTASK—OURADVICEISFREEANDCANSAVEYOUMONEY

DemonStormManual—Issue10/07 Page9

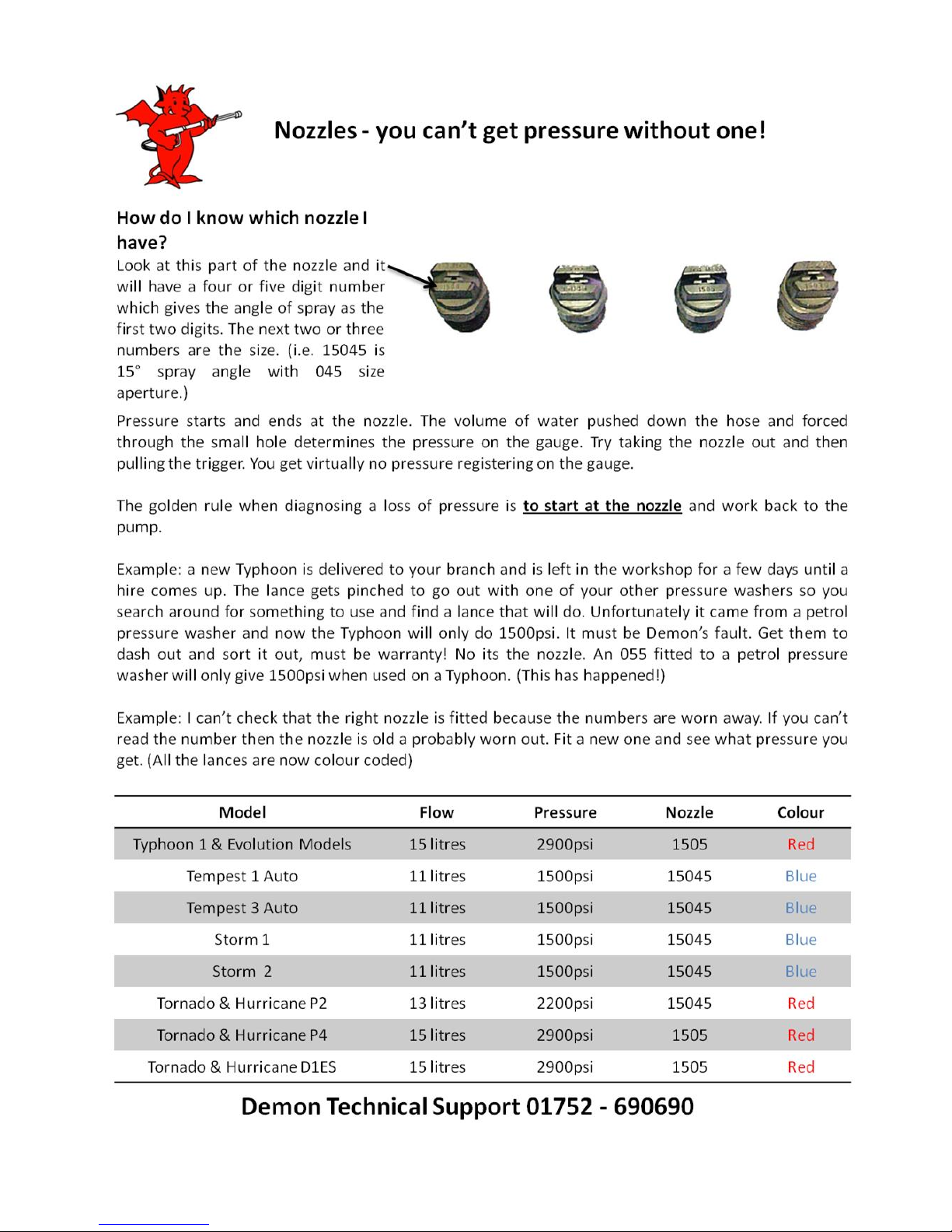

DemonStormColdWaterRange—GeneralArrangement

WheelCap

Wheel25

On/OffSwitch

KR411107

Wheel

WHEEL200

PressureGuage

DEM20620

Cover

DEM20181

HandleFrame

DEM10226

DetergentPipeDEM10115

Plug13ampDEM10180

Contactor30ampDEM101102

L/PInlet MTM73001FemaleSteppedNipple

L/PInletMTM73020MaleNito

ChemicalFilter

MTM86010

Outlet

MTM70013Female3/8

KnobKit

DEM102255

DemonStormManual—Issue10/07 Page10

DemonStorm1—EasyStartValve

ChemicalIntake

PA00100

EasyStartValve

MTM39001

StormEasyStarttoWaterInletPipe

DEM10321

1/4BSPChemicalBarb1/4Hose

DEM20410

DemonStormManual—Issue10/07 Page11

DemonStormWallmountedRange—GeneralArrangement

PressureGuage

KR15039

ColdWaterButton

H6442B

ElectricsBox

ElectricMotor

MTR00100(WM1)

MTR00200(WM4)

CompletePump&

Motor

MTR00101(WM1)

UnloaderValve

ARMM4B/CTSS

Pump

ARXT11‐14(WM1)

ARXR15‐20H(WM4)

DemonStormManual—Issue10/07 Page12

DemonStormFreeStandingRange—GeneralArrangement

PressureGuage

KR15039

ColdWaterButton

H6442B

ElectricsBox

ElectricMotor

MTR00100(WM1)

MTR00200(WM4)

CompletePump&

Motor

MTR00101(WM1)

UnloaderValve

ARMM4B/CTSS

Pump

ARXT11‐14(WM1)

ARXR15‐20H(WM4)

DemonStormManual—Issue10/07 Page13

WARRANTY

Thiswarrantycoversthecostofallreplacementpartsandlabourcharges

incurred.Itdoesnotcoverthecostoftransportorcarriage.Itistheowners

responsibilitytoreturnthemachinetoaservicedepotorpaythetravelling

expensesofaserviceengineertoattend.DemonInternational’sdecisionin

warrantymattersisfinalandbinding.

DemonInternationalLtdundertaketorepairorreplace,anycomponentwhichmayfailduetoa

manufacturingfaultwithinaperiodof12monthsfromthedateofpurchase,providedthatanyfault

ordamagewasnotsustainedby;

A.Lackofregularandpropermaintenance,usernegligence,misuse,ordamagecausedbyiceand

frost.

B.Theeffectsofcontaminatedfuelorwater,theuseofnon‐approvedchemicalsoraninsufficient

orunsuitableelectricalsupply.

C.Theeffectsofun‐authorisedmodificationanduse.

D.Compressiondamagetohighpressurehose.(HOSESWARRANTEDFOR1MONTHONLY)

E.Wornoutitemsconsideredfairwearandtear.

Partswhichmayormaynotwearoutduringthefirstyearandwhichareconsidered

serviceitemswhichwillneedreplacingfromtimetotime:Highpressurenozzle,lance,trigger,hoses,

fuelnozzle,fuelfilter,pistonseals,valves,unloaderseatsandseals,waterfilter,non‐returnvalve,

chemicalbarbs,chemicalpipesandpumpoilseals.

ItistheownersresponsibilitytoensurethePressureWasheriskeptinasafeandsuitableenviron‐

mentandanyfaultsreportedbyoperativestoberectifiedattheearliestpossibledate.

ItistheoperatorsresponsibilitytocheckthePressureWasherforanyfaultsandreportthemimme‐

diately.ThePressureWashermustbeusedinaccordancewiththemanufacturersspecificationsand

guidelines.

DemonInternationalLtdundertaketousethehighestqualitycomponentsavailableduringmanufac‐

ture,butcannotbeheldresponsibleforanyundueconsequencearisingfromtheuseoftherePres‐

sureWasher.

Thiswarrantyisgiventotheoriginalpurchaseronlyandisnottransferablewithoutthefully

authorisedandwrittenconsentofDemonInternationalLtd.

DemonStormManual—Issue10/07 Page14

WarrantyProcedure

EndUsers

Ifyourmachinedevelopsaproblem:

1. PhoneDemonforadvicewiththemodelandserialnumbertohand.

2. Describefullytheproblemasbestyoucan.

3. Iftheproblemcannotberesolvedoverthephonethenthemachinecanbebookedinforrepai

r

andifthefaultsarecoveredbythewarrantytherepairwillbecarriedoutfreeofcharge.

4. Ifyoucannotbringthemachineinforrepairthenwewilldespatchanengineer.Ifthefaulti

s

coveredbythewarrantythenwewillnotchargeforlabourorsparesused,howeverthetranspor

t

chargewillbepayableweatherornottherepairiswarranty.

HireCentresandDealers

Ifyourmachinedevelopsaproblem:

1. PhoneDemonforadvicewiththemodelandserialnumbertohand.

2. Describefullytheproblem.

3. Wewilladviseyouonthebestcourseofaction,howeverifpartsarerequiredyoumustraise

a

purchaseordernumbertocovertheparts.Whenthepartsarefittedtheymustbereturnedfo

r

examinationbeforeacreditnoteisissued.

4. Ifyouareunabletorepairthemachinethenwewilldespatchanengineertocarryouttherepair

.

Wewillneedapurchaseordertocoverthecostoftransporttoandfromthesiteandforpartsan

d

labouriftherepairisnotcoveredunderthewarranty.

5. IfrequiredDemonwillarrangeforacarriertocollectadamagedmachine,ifthewarrantyclaimi

s

validwewillpaythiscost,ifnotitwillbechargedtothecustomer.

6. ForpartswarrantyringDemonandrequestawarrantyclaimformfaxedtoyou.Thisformmus

t

accompanyanyreturnedparts.

Notes:

Youwillnotinvalidatethewarrantybyinvestigatingfaultsandrepairingthemyourselfprovidingyo

u

followouradvice.HireCentresandDealersareexpectedtocarryoutallrepairsthemselveswithDemo

n

creditingfaultypartsuponreceiptandinspection.

Sparepartsfittedtomachinesareguaranteedfor1monthonlyortheremainderofthewarrantyperio

d

whicheverislonger.

DemonStormManual—Issue10/07 Page15

DemonStormManual—Issue10/07 Page16

DemonStormManual—Issue10/07 Page17

DemonStormManual—Issue10/07 Page18

This manual suits for next models

6

Table of contents

Other Demon International Pressure Washer manuals