Demon International Tornado P1 Mini Bowser User manual

DEMONTORNADOMINIBOWSERRANGE

TornadoP1MiniBowser

TornadoP2MiniBowser

TornadoP4MiniBowser

TornadoD70MiniBowser

TornadoElectronMiniBowser

Includingelectricstartvariantsandbowserwashers

DeclarationofConformity

(E.H.S.R.)

We,DemonInternationalLimitedofAbbotsClose,LeeMillIndustrialEstate,

Ivybridge,Devon,PL219GA,declarethatthismachinemustbeoperatedin

accordancewiththeoperationandsafetyinstructionsassuppliedwiththis

machine.

Thismachineismanufacturedinaccordancewiththefollowingstandards

andrecommendations.

HSEPVBPM29‐BS5415Part‐BS5415Section2.41986

Thisinstructionmanualisrelevantonlytothefollowingmachineandwillnot

bekeptupdatedunlessspecificallyrequestedbythecustomer.However,

any

changestotheoperatingprocedureorchangeswhichmightaffectthe

safetyofthismachinewillbenotifiedtotheregisteredowner

MachineType

SerialNumber

WorkingPressure

DateofSupply

TornadoP1MiniBowserTornadoP4MiniBowser

Engine HondaGX120 Engine HondaGX34011HP360rpm

PumpRSV3G25D PumpARRK‐15.20H

Pressure 1500PSI Pressure 2900psi/200Bar

Flow 9lpm Flow 15lp,/3.3gpm

HPNozzle 25045 HPNozzle 2505

Gearbox None Gearbox 2:1reduction

Unloader Integrated Unloader Gymatic3BARGM3B250

PumpOil 10W/40 PumpOil 10W/40

GearboxOilN/a GearboxOil EP90

Noise

TornadoP2MiniBowserTornadoD70/ES

Engine HondaGX200 Engine YanmarL70

PumpARXT13‐12 PumpARXT13.12

Pressure 2200PSI Pressure 2900PSI

Flow 13lpm Flow 13lpm/3.3gpm

HPNozzle 25045 HPNozzle 2505

Gearbox 2:1Reduction Gearbox 2:1Reduction

Unloader ARMM4B Unloader ARGM3B250

PumpOil 10W/40 PumpOil 10W/40

GearboxOil EP90 GearboxOilEP90

Noise

TornadoElectron

Motor 24vDC HPNozzle 15045

PumpARXT11‐14 Unloader ARMM4B/C

Pressure 1200PSI

Flow 11lpm PumpOil 10W/40

Battery 2x140amp/hourAGMSealedBatteries

MicroprocessorControlledAutomaticBatteryCharger

24Volt12.5AMP

TechnicalSpecifications

Important—NewP2Machines

EachnewP2machinewillbesetat2000psiasopposedto2200psiuntilthemachinehas

beenrunforapprox2‐3hourscontinuously.

Oncethemachinehasbeenrunthenthepressurecanbeadjustedtoachievethemaximum

2200psibyturningthepressureregulatingvalveuntilitsfullyopen.

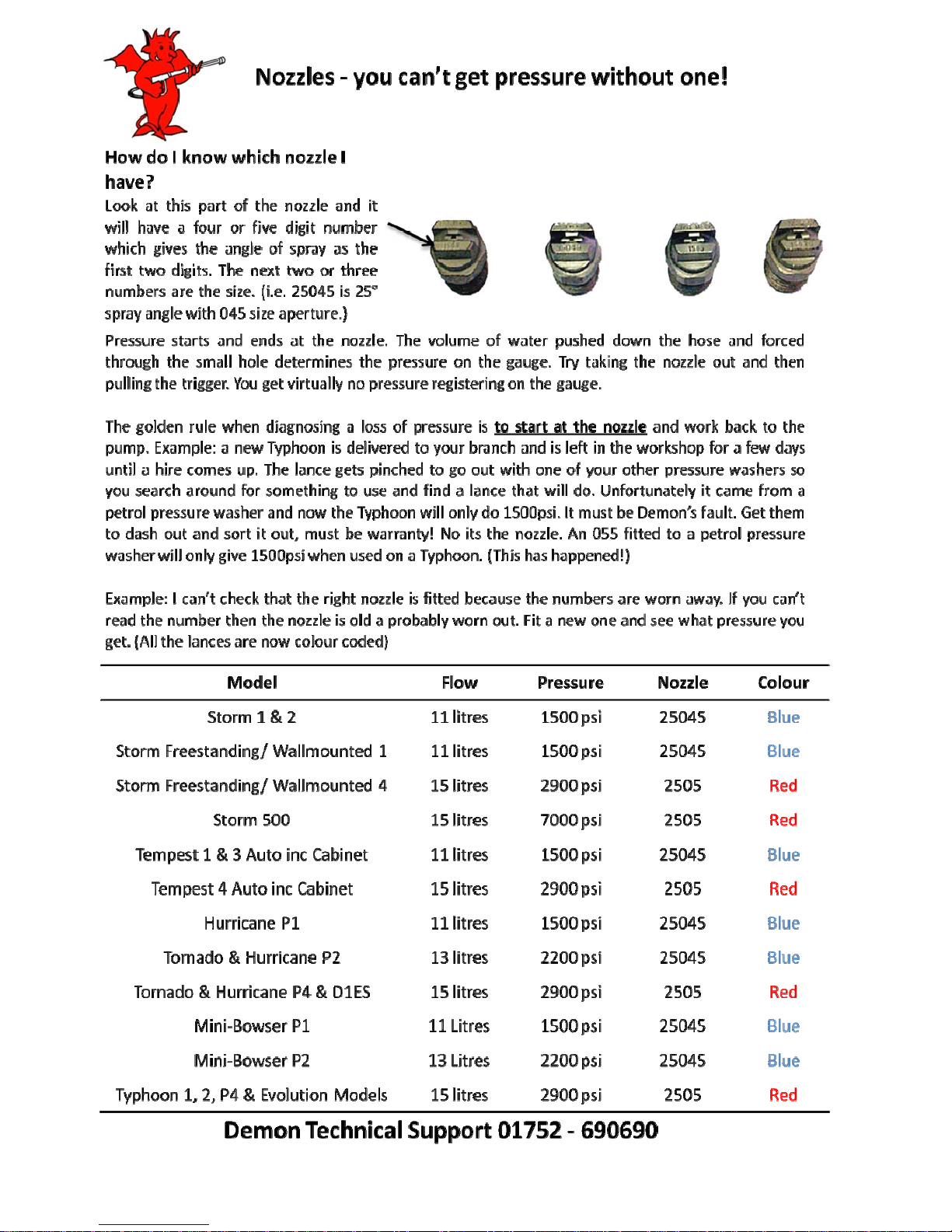

Machine P1 P2 P4 Tornado D70 Tornado Electron

Valve Kit 2186 1864 1828 1864 1864

Seal Kit 2189 1874 1857 1874 1874

Piston Kit 2629 2757 2629 2629

Oil Kit 2188 1872 1855 1872 1872

Support Ring Kit 1829

O Rings 2190

Kits for the Tornado Mini Bowser

FAULTFINDER

FAULT

CAUSE

REMEDY

Machinestopssuddenly

Orwillnotstart.

Lowoil

FlatBattery

(Electron)

• checkandtopupoil

Re‐charge

Suddenpressureloss.Watersupplyfailed.

Nochemical

Checkwatersupply.

Checkchemicaldrum,closevalve

LowpressureHPnozzlewornor

unloaderset

Incorrectly.

ReplaceHPnozzle.Setunloader

tocorrectsetting.

Lowpressurewithnoiseand

vibration.

Valveswornor

blocked.Pistonseals

worn.

Pumpsuckingair.

Clean/replaceasrequired.

Replace.

Checkwatersupplypipeand

unions.

Pumpwillnotby‐pass.Nonreturnvalve

dirtyorjammed.

Cleanorreplace.

Waterdripsfrompumpbox.Pumpsealsworn.Replace.

Oildripsfrompumpbottom.Oilsealworn.Replace.

Oilismilkyincolour.Wateringress

throughoilfilterplug.

Rinsepumpoutandreplaceoil.

IFINDOUBTASK—OURADVICEISFREEANDCANSAVEYOUMONEY

DAILYCHECKTHEFOLLOWING

a.Oillevel‐topupasrequired.

b.Fueltank‐topupasrequired.

c.Allhoseunionsforleaks‐replaceOringsifleaking.

d.Hosecondition‐cutsetc.

EVERY500HOURSORSIXMONTHS(WHICHEVERCOMESFIRST)

a.Drainandreplacepumpoil.

b.Drainandrefillfueltank.

c.Replacefuelfilter.

d.Cleanwaterfilter.

e.Replacehighpressurenozzle.

EVERY1000HOURSOR12MONTHS(WHICHEVERCOMESFIRST)

a.Complete500hourservice.

b.Replacepumpseals.

c.Replaceoilseals.

d.Checkunloadingpressureandsafetyvalvepressureandadjust.

Theaboveserviceschedulesareintendedasaguideonly,actualservicetimes

andreplacementspartsrequiredwillvaryaccordingtotheareaandtheusage

ofthemachine.

MINIMUMSERVICESCHEDULES

OPERATINGINSTRUCTIONS

SAFETY

IWaterathighpressureisdangerousandcancauseseriousinjury.Thismachineistobe

usedwithgreatcaution.

IIPetrolisextremelyflammableandexplosiveundercertainconditions.

EXHAUSTFUMESCONTAINCARBONMONOXIDE–InhalationofsuchfumescanKILL.

IIIDieselisflammableandharmfulifswallowed.

AAlwaysrefuelinanareawhichisadequatelyventilated.

BDONOTsmokewhenrefueling.

CAvoidoverfilling.

DShouldfuelbespilt,wipeoffanyfuelspiltonmachineorengine.

EMovetheequipmentawayfromtheareawherefuelhasbeenspilt.

FDONOTrefuelwhentheengineisrunning.

GDONOTruntheengineinanareawhichhasahazardousorexplosiveatmosphere.

HAlwaysensurethatthefuelcapissecureafterrefueling.

IKeeptheengineatleast3metresormoreawayfromanyotherequipmentor

Building.

JTakecarenottogetfuelonyourclothing.Ifthishappens–CHANGEyourclothing

IMMEDIATELY.

DONOTstartanenginewhenclothinghasbeencontaminatedwithfuel.

KUseonlyapprovedtypecontainersforfuel.DONOTstandthemoutinstrongsunlight,

keepthemintheshade.

LAlwaysensurethatthereisasuitabletypefireextinguisheravailableandiswithin easy

access.

MDONOTleaveanenginerunningunattended,ALWAYSSTOPitbeforeleavingthearea.

NNEVERpointthehighpressuresprayjetatanyperson,animal,glassorother

Materialwhichmayshatter.

O PREVENTanyoversprayfrominjuringotherpeopleordamagingproperty.

PDONOTeventrytouseapressurewasheronmachineryorelectricalequipmentthatis

connectedinanywaytothemainssupply(ALLswitchesintheOFFposition,pulloutplugs,

ifpossibleremovefuses).Coverorsealelectricmotorsandfittingstoprevententryof

water.Beforereconnectingelectricmainssupplycheckforwaterpenetration.

QDOALLyoucantokeepplugsandsocketsinadryplaceorcoveredtoprevententryof

water.

RALWAYSwhenusingthismachine:‐

• wearsafetygogglesandhelmetorhelmetwithavisor.

•Wearwaterproofclothingandgloves.

• Takepaticularcarewithdetergentsandchemicals.

SNEVERattempttodisconnectanyhosewithpressureinitorallowthehosetobeflattened

orkinked.

TDONOTuseahighpressurehosefromaladder.Useaplatformtowerorproper

scaffolding.

UShouldtheequipmentfailtooperate,DONOTattempttorectifyorrepair,butcontactthe

nearestServiceCentreforadvice.

VAlwaysrinseyourpumpoutafterusingseawater.

PREPARATION

WaterSupply:

AEnsurethereisanadequatewatersupplyeitherfromthemainsorareservoir.

BAttachwatersupplyhosestosuitabletaporimmersethesuctionhosewithapprovedsuc‐

tionfilterintothereservoir.

NOTE:ONLYCLEANWATERSHOULDBEUSED.THEPUMPMAYBEDAMAGEDIFDIRTYOR

CONTAMINATEDWATERISALLOWEDTOPASSTHROUGHTHEPUMP.

Hoses:Lowpressureinlet.

Formodelsupto13litresperminuteuse½“boresuctionhoseorfeedpipe.

Formodelsfrom13litresto24litresperminuteuse¾”boresuctionhoseorfeedpipe.

Hoses:Highpressureoutlet.

Forallmodelsuse3/8”RITor3/8”R2Thoses.

AChecktheconditionofthe“O”ringsintheendsofthehose.

BAttachthehighpressurehosetothepumpconnection.

CAttachthesprayguntooppositeendsofthehighpressurehose.

OPERATION

ATurnonthewatersupply.

BStarttheengine

CDirectlanceontosurfacetobecleaned.Pressthelancetrigger.

ELECTRON

D Fullychargebattery6‐8hoursorovernight.

ETostartDCMotorturnkeyandpullswitchup.

DAdjustpressureregulatorasrequiredtoobtainworkingpressureifrequired.

ENOTE;:Thehighpressurewaterwillcausethegunto“kick”.Makesureyouhaveafirmgrip

ofgunandlance.

FOncompletionofoperationstoptheengine.

g.Operatelancetrigger

h.Turn“OFF”watersupply

i.Releaseresidualpressureingunandlancebyoperatingtrigger.

WhenusingCleaningAgents:

A.Setmachineupasforwater.

B.Connectdetergenthosetomachineandplacefilterendintodetergent.

C.Oncompletionofwork,flushthroughhoseandgunwithcleanwatertoremoveanyresid‐

ualdetergent.

NOTE:CHEMICALPICKUPONLYOPERATESATPRESSURESBELOW250PSI.

OPENLANCEVALVEFULLYTOOBTAINTHISPRESSUR

Electron

TheElectronisfittedwithabatterymonitorwhichwillindicatetheconditionofthebatteries.

Theindicatorisfittedwithanaudiblealarmwhichwillsoundwhenthebatterychargeissuch

astorequirere‐charging.Thebatteryindicatorwillshowthecurrentconditionofthebattery

bywayofagaugeandpercentagelevel.Failuretore‐chargethebatterieswhenthealarm

indicatesmayleadtodamageandlifeexpectancyofthebatteries.Batteriesmustbe

re‐chargedfullyusingthesuppliedintelligent240vchargerbeforeusingtheElectron,after

theindicatoralarmhasbeenactivated.

Electronscanbefittedwithamotor/batteryprogrammablecontroller.

IfyourElectronhasthisfacilityitwillmonitorthebatterydischargeandissettooperatewhen

thevoltagefallsbelowapreprogrammedsetting.

Whenthecontrolleractivatesthemotorwillslowitsrevolutionsandthepressurewilldrop.

AtthistimeitisrequiredthattheElectronbere‐charged.

Thecontrollerisdesignedtopreventlowvoltagedamagetothebatteryplates.

Thecontrollerisnottobere‐setotherthanbyaqualifiedDemonelectronicsengineer.

TornadoMini‐Bowser‐GeneralArrangement

TankLidTOR0116

LidSealsTOR01115

BrakedCasterWheel

Wheel500

Wheel

Wheel400

15MtrHose

HH00050MVGHR

Hosereel

MTM20021

Engine

P1HondaGX120

P2HondaGX200

UnloaderValve

ChemicalPick‐UpPipe

DEM10115

PressureGuage

DEM20620

FastDrain

BV12169

Pump

PumptoHose

ReelHose

HH00188

TornadoElectron‐GeneralArrangement

Lockable Emergency

Stop DEM 100751

Battery Controller

BAT013

Relay BAT015

Dual Voltage Charger

BAT010

-

24v

-

+

+

-

E/Stop

BDI

24v

Motor

24V

CONTROLLER RELAY

Dual Voltage

Charger

-

+

++

+

+

+ + - -

+

++

+85 86-

-

Electron Mini Bowser

240V/110V

Batteries

DEM100751

BAT010

MTR00302

BAT016

BAT009

BAT013 BAT015

UK/USACompliant

TSS

L L

BB

L = Load

B = Battery

30 87

WARRANTY

Thiswarrantycoversthecostofallreplacementpartsandlabourchargesincurred,butdoesnot

coverthecostoftransportorcarriage.Itistheownersresponsibilitytoreturnthemachinetoa

servicedepotorpaythetravellingexpensesofaengineertoattend.DemonInternationals

decisioninwarrantymattersisfinalandbinding.

DemonInternationalLtd,undertaketorepairorreplaceattheirdiscretion,anycomponentwhich

mayfailduetoamanufacturingfaultwithinaperiodof12monthsfromthedateofpurchase,

providedthatanyfaultordamagewasnotsustainedby;

ALackofregularandpropermaintenance,usernegligence,misuse,ordamagecausedby

iceorfrost.

BTheeffectsofcontaminatedfuelorwater,theuseofnon‐approvedchemicals,oranin

sufficientorunsuitableelectricalsupply.

CTheeffectsofun‐authorisedmodificationanduse.

DCompressiondamagetohighpressurehose.(Hosesarewarrantedforonemonthonly)

EWornoutitemsconsideredwearandtear.

Partswhichmayormaynotwearoutduringthefirstyearandwhichareconsideredservice

itemswhichwillneedreplacingfromtimetotime:Highpressurenozzle,lance,trigger,hoses,

fuelnozzle,fuelfilter,pistonseals,valves,unloaderseatsandseals,waterfilter,non‐return

valve,chemicalbarbs,chemicalpipes,andpumpoilseals.

Itistheownersresponsibilitytoensurethepressurewasheriskeptinasafeandsuitableenvi‐

ronmentandanyfaultsreportedbyoperativestoberectifiedattheearliestpossibledate.

Itistheoperatorsresponsibilitytocheckthepressurewasherforanyfaultsandreportthemim‐

mediately,andtousethepressurewasherinaccordancewiththemanufacturersspecifications

andguidelines.

DemonInternationalLtd,undertaketousethehighestqualitycomponentsavailableduring

manufacture,butcannotbeheldresponsibleforanyundueconsequencearisingfromtheuseof

theirpressurewashers.

Thiswarrantyisgiventheoriginalpurchaseronlyandisnottransferablewithoutthefullyauthor‐

izedandwrittenconsentofDemonInternationalLtd.

The3YearStructuralWarrantyreferstoallDemonfabricatedstructuralparts,butthisdoes

excludetheBoilercoil.

WarrantyProcedure

EndUsers

Ifyourmachinedevelopsaproblem:

1.PhoneDemonforadvicewiththemodelandserialnumbertohand.

2.Describefullytheproblemasbestyoucan.

3.Iftheproblemcannotberesolvedoverthephonethenthemachinecanbebookedinfor

repairandifthefaultsarecoveredbythewarrantytherepairwillbecarriedoutfreeofcharge.

4.Ifyoucannotbringthemachineinforrepairthenwewilldespatchanengineer.Ifthefault

iscoveredbythewarrantythenwewillnotchargeforlabourorsparesused,howeverthe

transportchargewillbepayableweatherornottherepairiswarranty.

HireCentresandDealers

Ifyourmachinedevelopsaproblem:

1.PhoneDemonforadvicewiththemodelandserialnumbertohand.

2.Describefullytheproblem.

3.Wewilladviseyouonthebestcourseofaction,howeverifpartsarerequiredyoumustraise

apurchaseordernumbertocovertheparts.Whenthepartsarefittedtheymustbereturned

forexaminationbeforeacreditnoteisissued.

4.Ifyouareunabletorepairthemachinethenwewilldespatchanengineertocarryoutthe

repair.Wewillneedapurchaseordertocoverthecostoftransporttoandfromthesiteandfor

partsandlabouriftherepairisnotcoveredunderthewarranty.

5.IfrequiredDemonwillarrangeforacarriertocollectadamagedmachine,ifthewarranty

claimisvalidwewillpaythiscost,ifnotitwillbechargedtothecustomer.

ForpartswarrantyringDemonandrequestawarrantyclaimformfaxedtoyou.Thisformmust

accompanyanyreturnedparts.

Notes:

Youwillnotinvalidatethewarrantybyinvestigatingfaultsandrepairingthemyourselfproviding

youfollowouradvice.HireCentresandDealersareexpectedtocarryoutallrepairsthemselves

withDemoncreditingfaultypartsuponreceiptandinspection.

Sparepartsfittedtomachinesareguaranteedfor1monthonlyortheremainderofthewar‐

rantyperiodwhicheverislonger.

LanceandMachineColourCodes

Part

Number Description Storm Wall

Mounted Hurricane Tempest

Inc Cabinet Typhoon Evolution Tornado &

Mini-Bowser

DEM10031B Cold Water Lance

045 Blue

Storm

1 & 2,

FS1 WM1 P1 & P2 N/A N/A N/A P1 & P2

DEM10031R Cold Water Lance

05 Red FS4 WM4 P4 & D1 N/A N/A N/A P4 & D1

DEM10032B Hot Water Lance

045 Blue N/A N/A N/A Tempest

1, 3 &

4 (13.17 pump) N/A N/A N/A

DEM10032R Hot Water Lance

05 Red N/A N/A N/A Tempest 4

(15.20 Pump) Typhoon

1, 2 & P4 Evo1 &

Evo 2 N/A

Company/marketing/lancechartissue306/10

PosPartNoDescriptionQty

1N26001/1504NozzleP11

1N26001/15045NozzleP21

1N26001/1505NozzleP4&D1ES1

2MTM90040AdjustableNozzle1

3DEM10031BQRLamceP21

3DEM10031YQRLanceP11

3DEM10031RQRLanceP4&D1ES1

4DEM10030QRTrigger1

5MTM70012MVGCoupling1

COLDWATERLANCES

This manual suits for next models

4

Table of contents

Other Demon International Pressure Washer manuals