Den-Mat PSP Pro-Select Platinum Guide

1

Pro-Select Platinum® Operation and Instruction Manual

Operation and instruction manual

easy on you, easy on your patients

Two instruments in one – ultrasonic scaling and heated irrigation

system. PSP® is a superb piezo ultrasonic scaling solution and

the only system that combines scaling with heated subgingival

irrigation. Upgrade your practice today.

1

Pro-Select Platinum® Operation and Instruction Manual

Contents

Page

Product Documentation 2

Overview 3

Accesories 4

Getting Started 6

Operation 10

Operation 11

• Foot pedal

• Scaler mode

• Irrigation mode

Cleaning, Disinfection and Sterilization 13

• Control unit

• Bottles

• Cables

• Handpieces

• Tips

• LED lights

Maintenance and Service 15

• Control unit

• Bottles

• Cables

• Handpieces

• Tips

Warranty 16

Troubleshooting Guide 17

Parts, Accessories and Specifications 18

Disclaimers and Special Conditions 19

Pro-Select Platinum® Operation and Instruction Manual

2

Product Documentation

Date installed: ___/___/_______

Installer:

Control Unit #: Handpiece #: Irrigator #:

Tips:

Tip # Date of first use

Handpiece cable:

Cable # Date started Date finished LED lights

Solution ordered:

NaF CHX Date

3

Pro-Select Platinum® Operation and Instruction Manual

Solution bottles

LED bottle

selection indicators

Power button

Handpiece cable

connector

LCD status display

Brackets

Handpiece holder

Light button

Bottle select button

Flow rate button

Irrigation button

Adjustment buttons

Serial number

Fuse

Power transformer jack

Serial number

bottom module

Foot pedal jack

Control unit

Front view

Back view

Overview

Pro-Select Platinum® Operation and Instruction Manual

4

Item Re-order # Description

Solution bottles S40200 Deliver purified or distilled water

and antimicrobial solutions, such as

chlorhexidine and fluoride

Warning Use distilled or sterile water only in the water bottle. Do not use

tap water. This will void warranty.

Particulate suspensions or viscous fluids should not be used in

PSP® system. This will void warranty.

Scaler handpiece S40801 Connect handpiece to LED cable

and attach tip, see page 8

Irrigator handpiece S40851 Connect handpiece to LED cable

and attach 23g cannula,

see page 8

Foot pedal S40901 Hands-free method for changing

modes and functions,

see page 10

Universal straight tip S30930 Designed to remove calculus and

provide lavage during scaling,

see page 8

23 gauge side 2054 Use for irrigation, see page 9

port cannula

LED cable S40750 Use cable to connect handpieces

to control unit

LED light attachment S40871 Used to illuminate mouth

Accessories

Included with the PSP®

5

Pro-Select Platinum® Operation and Instruction Manual

Item Re-order # Description

Transformer Connect transformer to control

unit then plug into a standard

power outlet

Tip wrench 100773 Tighten and remove tip from

handpiece and measure tip wear

Tip grip 100540 Non-slip rubber makes tip

changing easier

2.0% NaF* 2037MTM • Increased patient comfort because

no trays are required

• In-oce rinse compatible with

composite and porcelain dental

restorations

• Available in both berry or mint

flavors for increased patient

acceptance

0.12% Chlorhexidine* 2193B Antimicrobial rinse

- irrigation solution

*All medicaments packaged separately, not included in Canada.

100200 (US)

S30500 (CAN)

Pro-Select Platinum® Operation and Instruction Manual

6

Getting Started

Note Before use it is recommended that you:

• Lay out all of the components for assembly

• Record date of installation and serial numbers of control unit, scaler handpiece(s),

irrigator handpiece(s) and scaler tip(s)

• Record start use date for handpiece cable(s) and medicament solutions

Warning • To avoid injury, read all operating instructions and safety information before using

PSP®

• Avoid electrical shock, do not plug or unplug transformer with wet hands

• Minimize risk of short circuit and electric shock; prevent water from contacting

control unit

• Do not disassemble or alter handpiece

• Keep away from explosive substances and flammable materials

• Do not use this product in presence of inflammable anesthetics or gases

• Use recommended fuse: 1 Amp / 5x20 Metric / medium time delay

Attention • During vibration, handpiece and cable may aect computer and LAN cables

• Operation near a radio receiver may result in static noise

• Users are responsible for operation control, maintenance and inspection

• Do not subject system to dust, sulfur or salinity

• The handpiece is designed for clinical dental use only

• Always consider patient safety during operation

• Check tip vibration irregularities before use on patient, if found, discontinue use

immediately and contact DenMat Customer Care at 800-433-6628

• Do not force or pull on transformer, handpiece cable or foot pedal

• Do not use tips on metal or ceramic restorations

• Check tip before every use

-

Bent, worn or compromised tips should be replaced

• Contact DenMat at 800-433-6628 for parts and support

!

7

Pro-Select Platinum® Operation and Instruction Manual

Plug in foot control

Warning

PSP® foot pedals are not compatible with any other brand or model.

Interchanging will void warranty.

1. Plug black pedal control connector into black jack on control unit back

2. Push until clicks

3. To remove, depress locking tab and remove connector from jack

Plug in power transformer

1. Plug gray transformer connector into gray jack on control unit back

2. Push until it clicks

3. Control unit will beep

4. To remove, depress locking tab and remove connector from jack

Placing solution bottles

Solution bottles have been designed to slide easily into control unit brackets.

If there is resistance, DO NOT FORCE

1. Fill bottle with appropriate solution. Be sure lid is securely placed on bottle

!

Pro-Select Platinum® Operation and Instruction Manual

8

2. Align bottle with flat sides of lid perpendicular to control unit

3. Grasp bottle by cap

4. Align bottle with control unit bracket. Slide onto bracket until it stops

5. Using cap, rotate bottle right 1/4 turn until it stops

6. Repeat procedure with remaining bottles/brackets

Connect handpiece LED

1. Attach LED on the top of scaler or irrigator handpiece ring, then clip to the bottom

of handpiece

Connect handpiece cable

1. Plug handpiece cable into cable connecter, ensure black ring is seated in opening

2. Plug Scaler handpiece or Irrigator handpiece onto other end of cable

Connect scaler tip

Attention PSP® provides two types of handpieces; one for ultrasonic scaling (threaded);

one for heated subgingival irrigation (non-threaded).

1. Use lint free cloth to wipe all surfaces of threaded scaler handpiece where tip connects

2. Use lint free cloth to wipe threaded end of scaler tip

9

Pro-Select Platinum® Operation and Instruction Manual

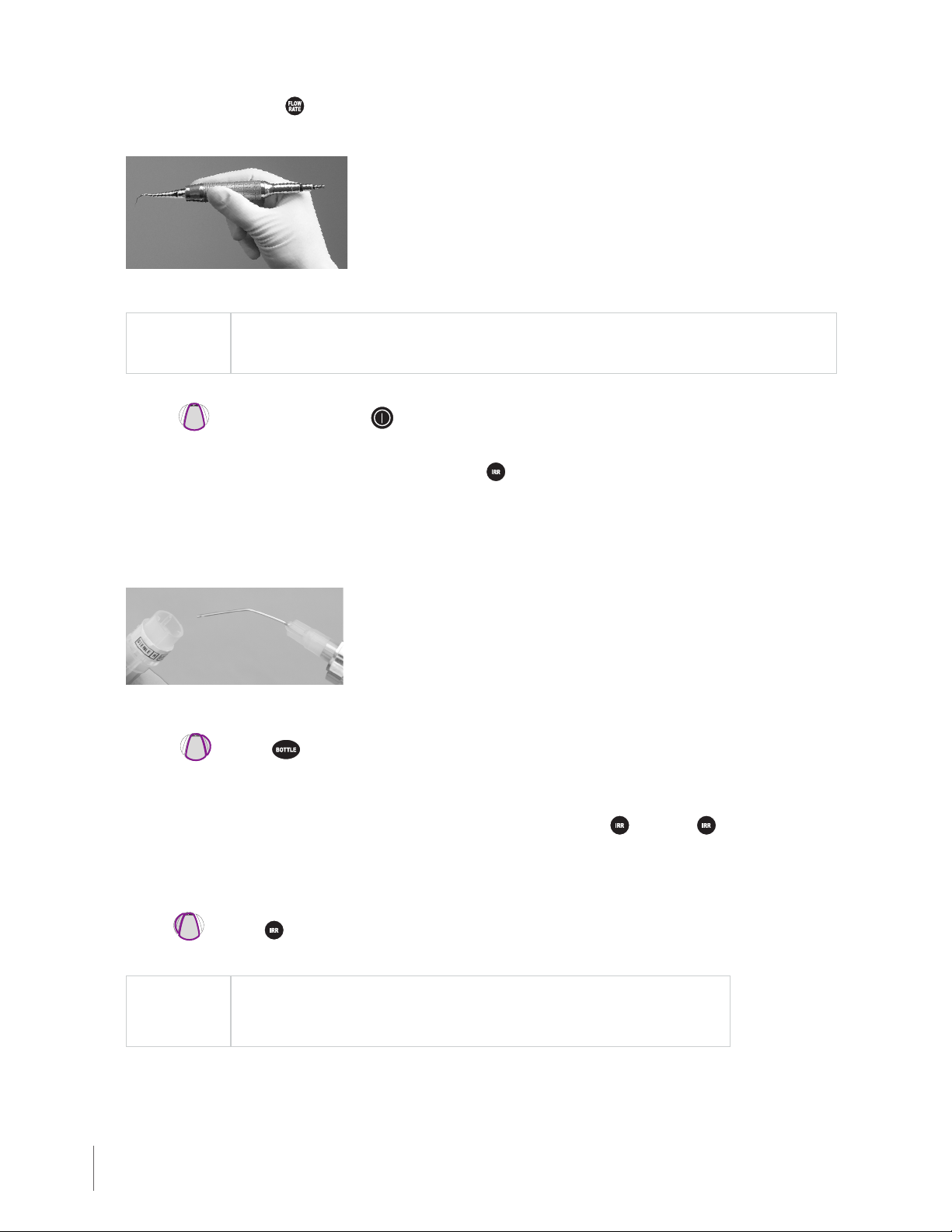

3. To connect scaler tip:

• Place handpiece in center of tip grip

• Using a clockwise rotation, screw tip onto handpiece

• Align tip wrench with flat sides of tip base

• Use tip grip and wrench to tighten until tip is secure

4. To remove the scaler tip:

• Place handpiece in center of tip grip

• Turn wrench counterclockwise to loosen tip and remove tip with fingers

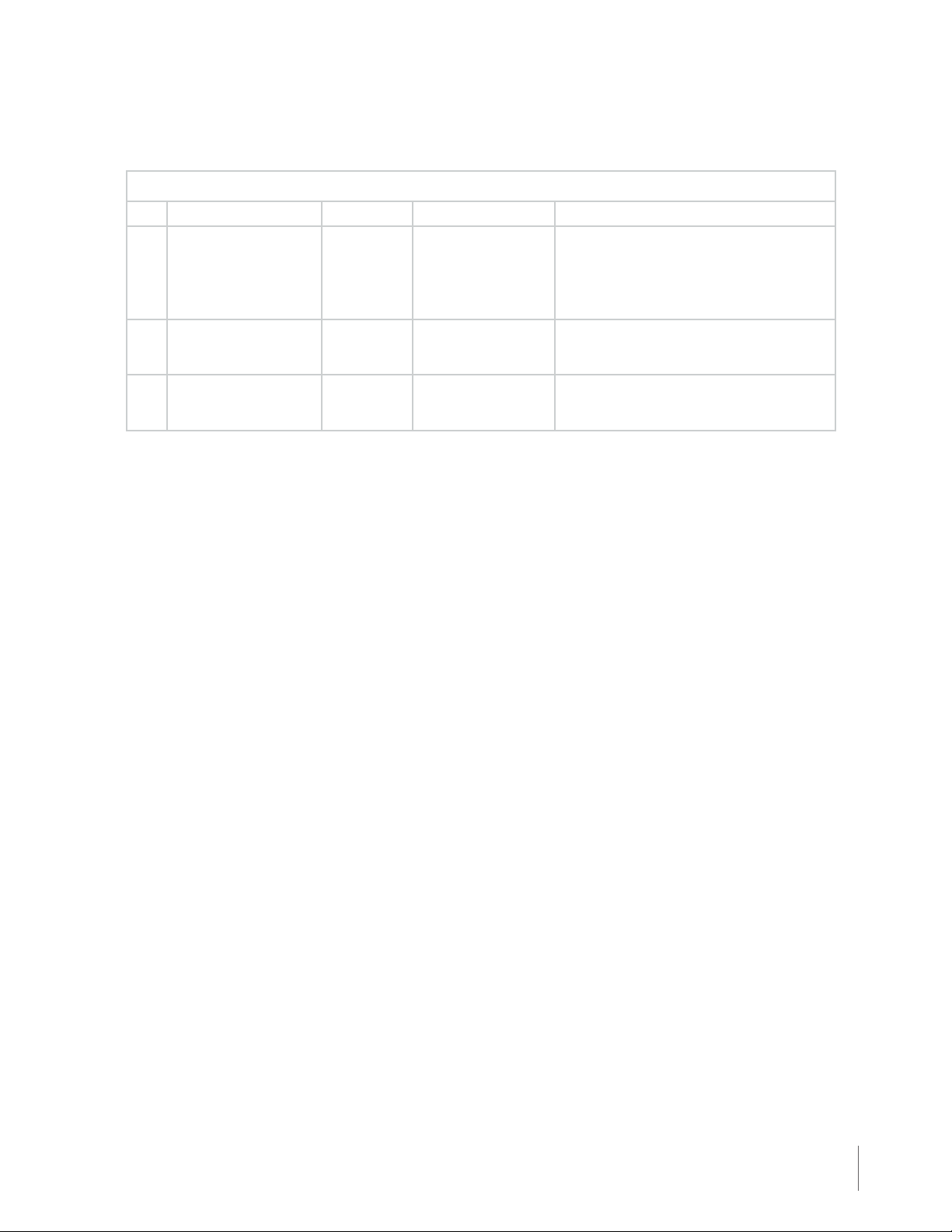

Connect irrigator tip

Warning Irrigation handpiece heater has been designed for use with a 23

gauge side ported cannula. Do not use other gauge cannulas, as

fluid heat variation will result.

1. Slide 23 gauge side ported cannula on irrigation handpiece

2. Using cannula cap, bend cannula for proper adaptation

Attention

An irrigator cannula is a single patient use, disposable item

and should NOT be sterilized.

Connect handpiece to cable

Attention

LED will remain activated for 10 seconds after foot control is released.

1. Plug handpiece into cable

2. Place handpiece in cradle when not in use

!

Pro-Select Platinum® Operation and Instruction Manual

10

Operation

Turn on the PSP®

Press or Press to turn PSP® on or o

Change scaler and irrigation modes

Press and hold down outer pedal, roll foot to center or press to switch from scaler mode to

irrigator mode

Increase power level Decrease power level

Press or press Press or press

Adjust scaler fluid flow rate

Press then use to increase flow and to decrease flow

Select solution bottles

Press and hold down outer pedal, roll foot to center or press to change solution bottles

Using LED handpiece light

Press foot pedal to activate light or press to turn handpiece LED on or o

Monitoring PSP® functions

LCD status display indicates power level, flow rate, current bottle and function mode. LED lights indicate

bottle selection

11

Pro-Select Platinum® Operation and Instruction Manual

Scaler mode

Attention

• Liquid is utilized to flush area and cool frictional heat at tooth surface and scaler tip interface. Liquid flow

should be used at all times during operation.

• Use linear motion similar to hand scaling, move side of tip across tooth surface.

Horizontal orientation Vertical orientation

• Scaler tip length wears with use.

• It is important to regularly measure tip for wear, as shown on page 15.

• Regularly inspect tip for other performance reducing flaws such as a bent tip or tip with flat side(s).

• To flush area for supragingival lavage in scaler mode set power level to “0”, no vibration, and adjust

flow rate as needed.

• Do not place point of scaler tip directly against tooth surface as this could result in tooth damage.

• The last 3 millimeters of scaler tip is the eective working area.

• When scaling, use light, sweeping, eraser-like strokes.

• Do not “tap” tooth or use a start-stop motion.

• For best results, use 3 – 5 grams of lateral pressure.

• The round tip profile allows entire circumference of tip to be used for calculus removal.

1. Press to turn on PSP® or press

2. Select desired fluid bottle

• Press or press on control unit

• A double beep will be heard as you change bottles

• An LED light will illuminate to indicate active bottle and LCD will display which bottle is active

Note

It is common for a clinician to use distilled water, sodium fluoride, or chlorhexidine for periodontal

debridement procedures.

3. Set power level

• Default power level is 3

• Power level has 11 settings shown as 0 - H on LCD

• Use or to change setting

Attention

For a patient with light deposits or for a child, a power setting of “1” or “2” may be adequate.

4. Adjust flow rate

• Default flow rate is 2

• Flow rate has 10 levels; 3 low, 4 medium and 3 high

• Flow rate will be shown on LCD

• Press and then until liquid emits as a fine mist

Pro-Select Platinum® Operation and Instruction Manual

12

5. To reset default press and hold until four beeps are heard

6. A light pen grasp using a stabilizing fulcrum, rather than a power fulcrum, is all that is required using PSP®

Irrigation mode

Attention

• Attach irrigator handpiece while in scaler mode or when power is o.

• Flush distilled water for 30 seconds when finished using medicaments.

1. Place patient in a more upright position

2. Press to turn on PSP® or press

3. Flush irrigator handpiece with water in scaler mode

4. Select irrigator mode by using foot control or pressing on control panel. LCD will show IRR and LCD will

blink while in irrigator mode. Irrigator handpiece will automatically begin a 45 second pre-heat cycle, when pre-

heat cycle is complete a beep will sound

5. Place cannula on irrigator handpiece

6. While waiting for heating cycle activation bend cannula as appropriate for access

7. Select desired fluid bottle

Use or press on control unit. A double beep will be heard as you change bottles. An LED light will

illuminate to indicate active bottle and LCD will show which bottle is active

8. Thorough low volume vacuum is sucient for fluid evacuation from oral cavity

9. Prolonged inactivity will de-activate heater, you must ‘reboot’ by pressing o, then again

to re-activate 45-second pre-heat cycle.

10. Remove and properly discard cannula.

11. Flush irrigator handpiece with distilled water before autoclaving

12. Use or press to switch back to scaler mode. LCD will display scaler mode and current power level.

LCD will stop blinking

Attention

•

Flow rate of liquid from irrigator handpiece is pre-set and not adjustable.

• Studies have shown heated chlorhexidine is more eective than at room

temperature*.

*Data on file

13

Pro-Select Platinum® Operation and Instruction Manual

Cleaning

for Scaler Handpiece, Irrigator Handpiece, and Scaler Tips.

Cleaning protocol (hand piece, irrigator, h/p cable, wrench, tips, tip grip, LEDs)

Step Solution Time (min) Temperature Instructions

1Hospital grade

enzymatic detergent At least 10

Warm, as delivered

from the available

hot water tap

Clean thoroughly - Immerse and soak for

required time, scrub all external surfaces

with a soft bristle brush, or other cleaning

tools as needed. Inspect for visible soil on

exposed surfaces.

2Water At least 1

Warm, as delivered

from the available

hot water tap

Rinse thoroughly immediately after Step 1.

3Air As required Ambient

Allow to air dry in clean area. To speed dry,

place in clean oven at a temperature not to

exceed 40˚ C.

Cleaning for Control Unit

Cover control unit with a disposable barrier or wipe clean with a 70/30 IPA by following disinfectant manufacturer’s

recommendations.

After each patient medicament use and at end of day, each bottle port on control unit, handpiece cable and handpieces

should be flushed with distilled water for 30 seconds. Place distilled water-filled bottles on each of the three brackets

and activate the scaler mode for approximately 30 seconds and repeat process in irrigation mode. It is important no

medicaments are left in control unit lines.

1. Turn o the power switch

2. Remove tip from handpiece using tip wrench and grip

3. Remove handpiece from handpiece cable by grasping the cable connector and pulling straight o connector end of

handpiece, do not pull grasping cable

4. Wipe control unit and foot control with a clean cloth dampened with 70/30 IPA.

5. Do not use an abrasive wipe or cleaning solution, this may damage surface of control unit

6. Safeguards for brushed stainless steel

• Lightly apply high quality stainless steel cleaner on a clean, soft cloth

• Wipe in direction of metal grain. Do not use abrasive cleaning agents or pads which may scratch the finish

• Chlorine compounds can cause stainless steel to discolor if left to stand for more than 5-10 minutes

Pro-Select Platinum® Operation and Instruction Manual

14

Solution bottles

Warning

PSP® bottles are not autoclavable.

Bottles can be wiped clean with a pH neutral surface disinfectant by following

disinfectant manufacturer’s recommendations.

Handpiece cable

After use flush water through cable, wipe cable with a clean cloth dampened

with a surface disinfectant

or

• Roll into autoclave bag for sterilization, avoid crimping

• Follow the autoclave manufacturer’s recommended sterilization procedures

• Cables routinely autoclaved will require more frequent replacement

Handpieces and LED lights

1. Clean outer surface of handpiece and LED light by wiping with a soft cloth

dampened with pH neutral surface disinfection solution

Attention

• Do not use disinfection solution containing phenols.

• Do not spray cleaning solution directly on the handpiece.

2. Remove LED light from handpiece, place handpiece and LED light in a

cassette or sterilization bag and seal

3. Steam sterilize in accordance with autoclave manufacturer’s instructions

Scaler tips

Clean, disinfect, inspect and steam sterilize, per steam autoclave manufacturer’s instructions, before

each use

Tip change kit

1. Tip wrench and tip grip have been designed to be sterilized in a steam autoclave

2. Place tip wrench and tip grip in an autoclave bag and sterilize by following

autoclave manufacturer’s instructions.

Any method of sterilization not specifically recommended in this Operation and Instruction

Manual should be approved by DenMat prior to its use, in order to prevent voiding of warranty

!

15

Pro-Select Platinum® Operation and Instruction Manual

Maintenance

Component Suggested maintenance

Control unit Flush all bottle ports with distilled water at end of every day in both modes

for 30 seconds.

Bottles Clean the filters on the bottom of the stems with soft bristled tooth brush

every 1-2 weeks.

Tip Routinely check tips.

1. Place the tip all the way into the small hole at the end of the tip wrench.

2. If no portion of the tip extends through the hole, then the tip is no longer

functional and needs to be replaced.

3. Regularly inspect for bent tips or wear patterns that result in flattening

of the side(s) of the tip. Tips that exhibit these characteristics need to be

replaced.

4. New tips can be purchased by calling DenMat at 800-433-6628 or at

denmat.com.

Service

To return materials: Please call DenMat Customer Care at 800-433-6628 for an RMA (Return Material

Authorization) number.

Shipping your product in original packaging will oer the best protection against damage during shipping.

All items returned for service must be cleaned, disinfected and sterilized before shipment.

Pro-Select Platinum® Operation and Instruction Manual

16

Limited Hardware Warranty

What does this warranty cover?

Den-Mat Holdings LLC, warrants to the purchaser that the company’s hardware will be free from

defects in workmanship or material under normal use and service for the warranty period as specified

in the warranty schedule below. The warranty period becomes eective on the date of delivery of the

product to the original purchaser. FAILURE ON THE PART OF THE PURCHASER TO USE DISTILLED

WATER OR ANY OTHER NON-APPROVED LIQUID WITH THIS PRODUCT WILL VOID THIS WARRANTY.

What is the Company’s obligation under this warranty?

During the period of this warranty, the company agrees to repair or replace, as its sole option, without

charge to purchaser, any defective hardware (workmanship or material) according to the warranty

schedule below:

WARRANTY SCHEDULE

Item Warranty Period Eligible for Repair

Control Unit 12 months Yes*

Foot Pedal 12 months No, replacement only

Scaler Handpiece 12 months No, replacement only

Irrigator Handpiece 12 months No, replacement only

A/C Adapter 12 months No, replacement only

6’ Autoclave Cable 6 months No, replacement only

Bottles 6 months No, replacement only

Scaler Tips 6 months No, replacement only

LED Light 6 months No, replacement only

Wrench 6 months No, replacement only

Tip Grip 6 months No, replacement only

*If the Control Unit needs to be sent in for repair, all components of the PSP must be included so that DenMat’s

technical support team can repair the unit and test it for functionality prior to returning to the customer.

Hardware may only be returned to the company after a Return Material Authorization (RMA) number

has been obtained. To obtain an RMA number and information on where to deliver the hardware, call

Customer Care at 800-433-6628. Purchaser must return the hardware to the company in an adequate

container for shipping, with freight and insurance prepaid. The RMA number must appear on the outside

of the shipping container. Upon receipt, the company will promptly repair or replace the defective

hardware, and return said hardware to purchaser, freight and insurance prepaid. The company may use

reconditioned or like new parts or systems, at its sole option, when fulfilling its obligations under this

warranty. In any event, the company’s liability for defective hardware is limited to repairing or replacing

the hardware. If hardware is replaced at the option of the company, returned hardware will become the

property of the company.

What does this warranty not cover? This warranty is contingent upon proper use of the hardware.

Normal wear to scaler tips, cables and bottles are not covered. The warranty does not cover damage

due to accident, unusual physical, electrical or electromechanical stress, neglect, misuse, unauthorized

sterilization procedures, improper installation, failure of electric power, air conditioning, humidity

control, transportation, or tampering with or altering the hardware. The company assumes no

responsibility or obligation to purchaser resulting from future hardware changes made by the company

or its component suppliers, after purchase of the hardware.

17

Pro-Select Platinum® Operation and Instruction Manual

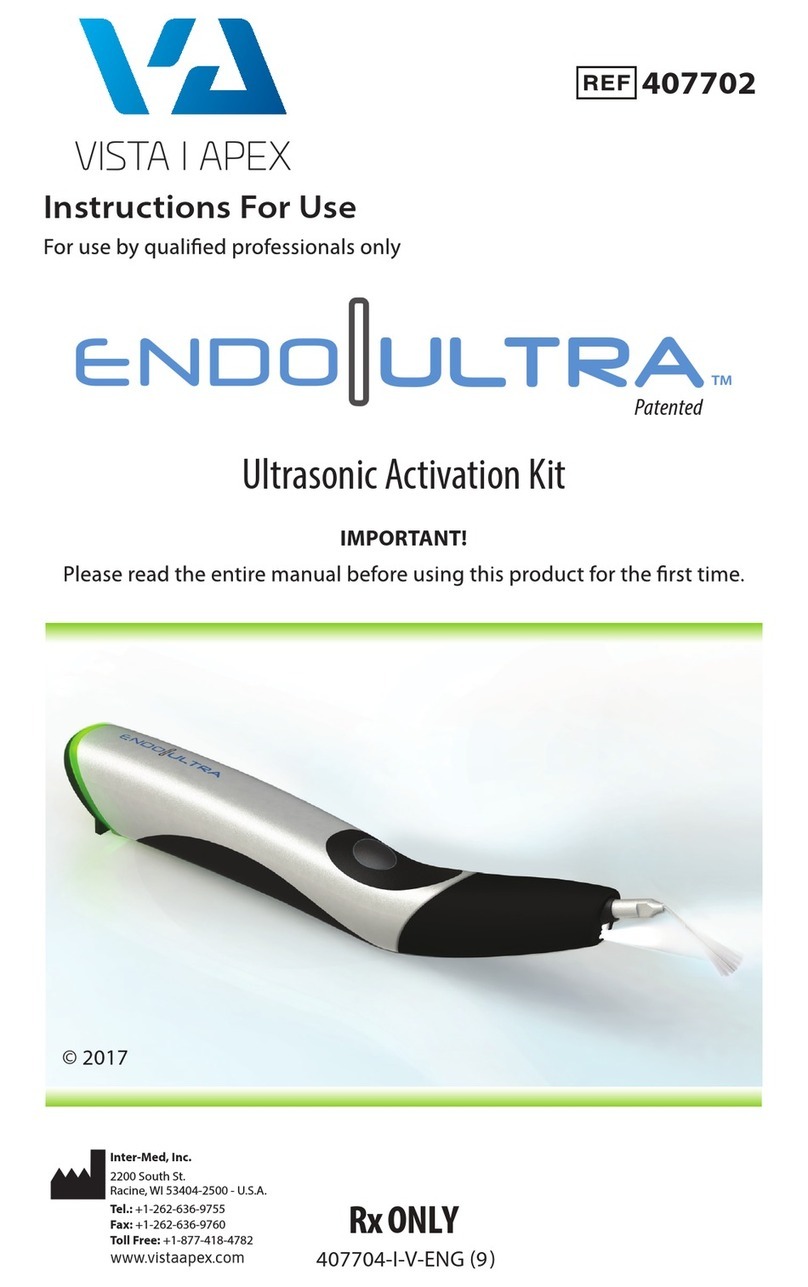

Troubleshooting Guide

Problem Solution

System produces water,

but has no tip vibration or

has pulsing tip vibration

• Make sure cable is firmly attached to handpiece and control unit

• Measure tip

• Make sure tip is cleaned and tightened with tip wrench and tip grip

• Try second cable

• Try second handpiece

• Try second tip

• If problem persists, contact DenMat Customer Care at 800-433-6628

No water flow in scaler or

irrigator mode

• Check to ensure that the flow rate is set on Low, Med, or Hi on the LCD display

• Make sure the bottles are locked in and there is liquid in the bottles

• Check flow rate directly from control unit

• Select a dierent bottle, replace bottle

• Check flow rate from the cable, try a second cable

• Check flow rate from the handpiece, try a second handpiece

• Check flow rate from the tip or cannula, try a second tip or cannula

• If problem persists, contact DenMat Customer Care at 800-433-6628

LED light not working

• To activate handpiece LED light press center foot pad or on the keypad

• Make sure the metal connection at the top of the LED light is secured to the handpiece ring

• Make sure cable is firmly attached to handpiece and control unit

• Try a second LED light

• Try a second cable

• If problem persists, contact DenMat Customer Care at 800-433-6628

Irrigator not working

• Make sure irrigator assembly/set up has been precisely followed

• Make sure system is in irrigator mode

• Make sure irrigator handpiece is being used

• Make sure cable is firmly attached to handpiece and control unit

• Try a second cable

• Try a second irrigator handpiece

• If problem persists, contact DenMat Customer Care at 800-433-6628

Too much water

• Lower the flow rate (see page 8) in scaler mode only

• Make sure to use the proper cannula in irrigator mode only

• If problem persists, contact DenMat Customer Care at 800-433-6628

Will not change to irrigation

mode with foot pedal

• Check foot pedal (up/down) to verify foot pedal

• Manually change to irrigator mode with keypad

• If problem persists, contact DenMat Customer Care at 800-433-6628

To contact DenMat Customer Care, call 800-433-6628

What are the limits on the company’s liability? In any case, the company shall not be liable for the loss of

profits, lost savings, special, incidental, consequential, indirect or other similar damages arising from the

breach of contract, negligence, or other legal theory even if the company or its agent has been advised of the

possibility of such damages, or for any claim by any other party.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER REPRESENTATIONS AND WARRANTIES,

EXPRESS OR IMPLIED; AND SELLER EXPRESSLY DISCLAIMS AND EXCLUDES ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE. SELLER SHALL NOT BE LIABLE FOR ANY

INCIDENTAL OR CONSEQUENTIAL DAMAGES FOR BREACH OF ANY EXPRESS OR IMPLIED WARRANTY ON

THIS PRODUCT.

Pro-Select Platinum® Operation and Instruction Manual

18

Parts, Accessories and Specifications

Replacement part numbers

When inquiring about new or replacement parts for your PSP®

system, please refer to the following part numbers

2037MTM 2.0% Neutral NaF irrigation solution (64oz)

2054 Irrigator cannulas (100/Box)

2193B 0.12% Chlorhexidine irrigation solution (16 oz.)

100351 Autoclave cassette

100540 Tip grip

100773 Tip gauge/wrench

100200* Power transformer

S30500* Power transformer

S30550 6 ft. Autoclavable cable (non-LED)

S30920 Set of three tips (left, right, straight)

S30930 Universal straight tip

S30940 Set of three left curve tips

S30950 Set of three right curve tips

S30960 Set of three universal straight tips

S40200 Solution bottle with lid assembly

S40750 LED handpiece cable

S40871 LED light

S40801 Scaler handpiece

S40851 Irrigator handpiece

S40901 Multi-function foot pedal

*Refer to label on back of control box

Specifications

Device classification: Class II equipment

Type bf applied part

Dimensions

Control unit

Length 11.25 In (28.6Cm) depth 6.2 In (15.75Cm)

Height 8.6 In (21.9Cm)

Handpiece w/tip Length 6.5 In (16.5Cm)

Weight

Control unit 114 oz (3228 grams)

Handpiece 1.8 oz (52 grams)

Voltage, frequency 120v, 50/60 hz

Transducer piezoelectric

Transformer 24vac, 50/60 hz /model #S30500

Fuse 1 amp / 5x20 metric / medium time delay

Power consumption 35 watts max.

Tip design Universal straight tip, similar to periodontal probe

Tip operating frequency Approx. 45,000 Hz (vibrations per second)

Operating temperature 15°c to 35°c

Table of contents

Other Den-Mat Dental Equipment manuals

Popular Dental Equipment manuals by other brands

Zubler

Zubler VARIOstar Series instructions

W&H

W&H Endea Endo Cursor EB-62 Instructions for use

Aseptico

Aseptico ADU-40CF Command Air OPERATION, MAINTENANCE & SERVICE MANUAL

Blancone

Blancone ARCUS+ Instructions for use

Dekema

Dekema AUSTROMAT 624i operating instructions

Vista Apex

Vista Apex EndoUltra Instructions for use