Denlar D1000 Manual

REPORT

#1122

DENLAR Fire Protection LLC

20 Denlar Dr.

Chester, CT. 06412

p:860.526.9846 f:860.526.9585

email: [email protected]

online: www.denlarhoods.com

The D1000

Installation and

Service Manual

Version 2.1

The D1000

Installation and

Service

Version 2.1

1

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PER-

SONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufacturer. If you

have questions, contact the manufacturer at the address or telephone

number listed on the front cover of this manual.

2. Before servicing or cleaning unit, switch power off at service panel and

lock the service disconnecting means to prevent power from being

switched on accidentally. When the service disconnecting means can-not

be locked, securely fasten a prominent warning device, such as a tag, to

the service panel.

3. Installation work and electrical wiring must be done by a qualied per-

son(s) in accordance with all applicable codes and standards, in-cluding

re-rated construction codes and standards.

4. Sufcient air is needed for proper combustion and exhausting of gases

through the ue (chimney) of fuel burning equipment to prevent back-

drafting. Follow the heating equipment manufacturer’s guideline and

safety standards such as those published by the National Fire Protection

Association (NFPA), and the American Society of Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE), and the local code authori-

ties.

5. When cutting or drilling into wall or ceiling, do not damage electrical

wiring and other hidden utilities.

6. To reduce the risk of re or electric shock, do not use this range hood

with an additional speed control device.

7. Ducted fans must always be vented to the outdoors.

8. To reduce the risk of re, use only metal ductwork.

9. Use with approved wiring only.

10. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

1. Never leave surface units unattended at high settings. Boilovers cause

smoking and greasy spillovers that may ignite. Heat oils slowly on low or

medium settings.

2. Always turn hood ON when cooking at high heat or when cooking aming

foods.

3. Clean ventilating fans frequently. Grease should not be allowed to accu-

mulate on fan or lter.

4. Use proper pan size. Always use cookware appropriate for the size of the

surface element.

TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A

RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close-tting lid, cookie sheet, or metal tray,

then turn off the burner. BE CAREFUL TO PREVENT BURNS. If the

ames do not go out immediately, EVACUATE AND CALL THE FIRE

DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN — You may be burned.

3. DO NOT USE WATER, including wet dishcloths or towels - violent steam

explosion will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC extinguisher and you already know

how to operate it.

B. The re is small and contained in the area where it started.

C. The re department is being called.

D. You can ght the re with your back to an exit.

* Based on “Kitchen Fire Safety Tips” published by NFPA.

WARNING

1. For general ventilating use only. Do not use to exhaust hazardous or

explosive materials and vapors.

2. To avoid motor bearing damage and noisy and/or unbalanced impel-

lers, keep drywall spray, construction dust, etc. off power unit.

3. For best capture of cooking impurities and performance of re extin-

guisher, your range hood should be mounted so that the bottom of

the hood is 18-30” above the cooking surface, depending on model.

4. Please read specication sheets for further information and require-

ments.

!

CAUTION

TABLE OF CONTENTS

READ AND SAVE THESE INSTRUCTIONS

1. System Anatomy pg 2

2. Sample Elevations pg 3

3. Preparing thr Install location pg 5

4. Range Element Disconnect install pg 8

5. Installing The D1000 pg 10

6. Fire Alarm System Connections pg 11

7. Manual Pull Station Installation pg 12

8. Test Tank & Demonstration pg 13

9. Electrical Schematic pg 14

10. Accessing The Interals pg 16

11. Maintnence pg 17

12. D1000 Operating System pg 19

13. PLC Schematic pg 22

14. After an Actuation pg 24

15. Ducting and Airow pg 27

16. Spare Parts pg 28

17. Warranty Statement pg 29

18. NFPA101 -F & -R Installation Appendix A

DISCLAIMER: Denlar Fire Protection LLC, shall not be liable for errors contained in this

Manual or for incidental, consequential damages in connection with the furnishing,

performance or use of this information. Denlar Fire Protection makes no warranty

of any kind with regard to this information, including, but not limited to the implied

warranties of merchantability and tness for a particular purpose.

The D1000

Installation and

Service

Version 2.1

2

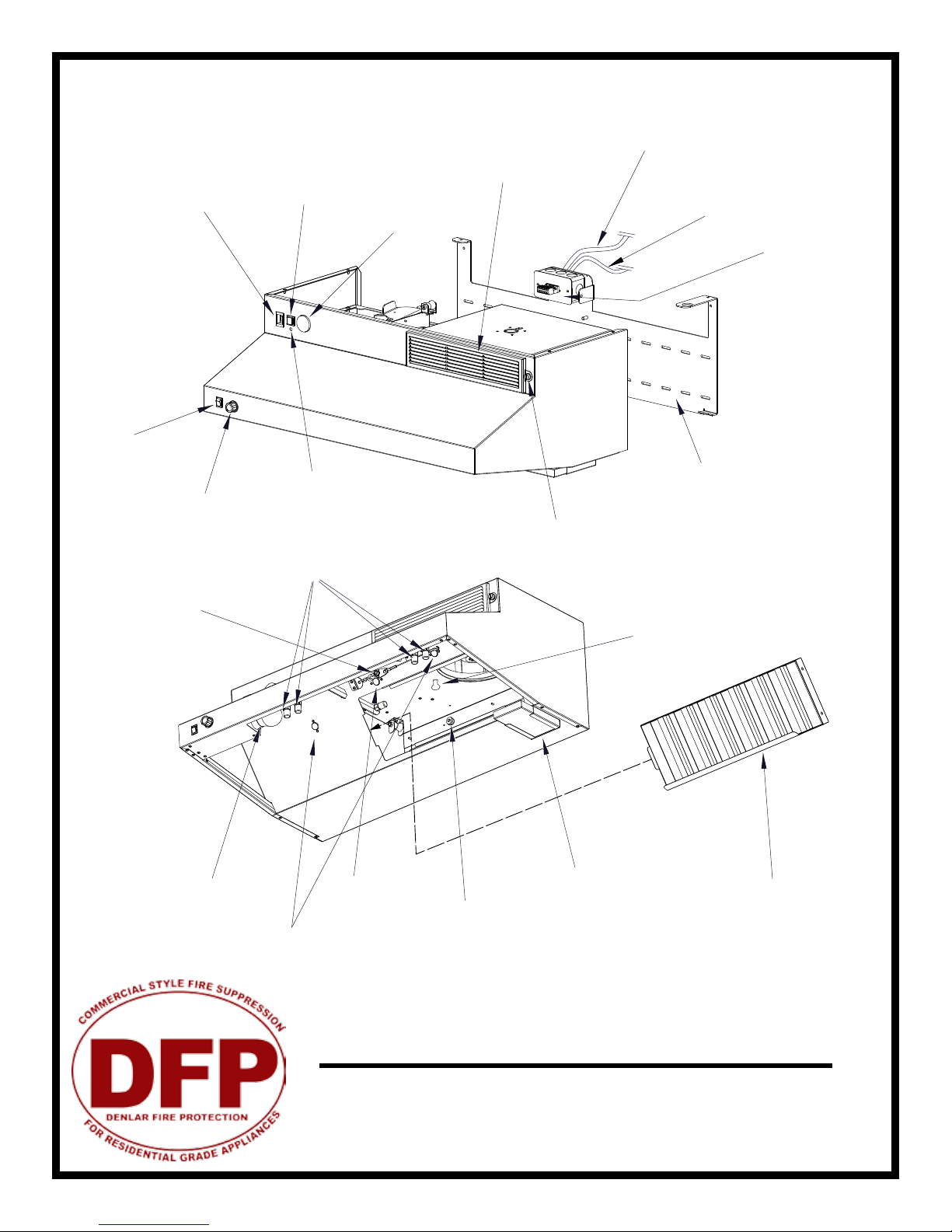

System Anatomy

Recirculating Vent

(recirculating model)

Power Switch Reset Switch

Extinguisher Pressure Gauge

Electrical Disconnect (Black Tape)

110 VAC Power Supply (Red Tape)

Junction Box

Thumbscrew (to remove vent) -on some models

Thumbscrews (2x) (inline models)

Back Support Mounting Bracket

Fan Speed Knob

Light Switch

Discharge Nozzles

(with protective caps)

Fusible Link

Light Bulb

Low Temperature Switches

High Temperature

Switch

Thumb Nut (3x)

Grease Tray Grease Filter

LED Status Light

The D1000

Installation and

Service

Version 2.1

3

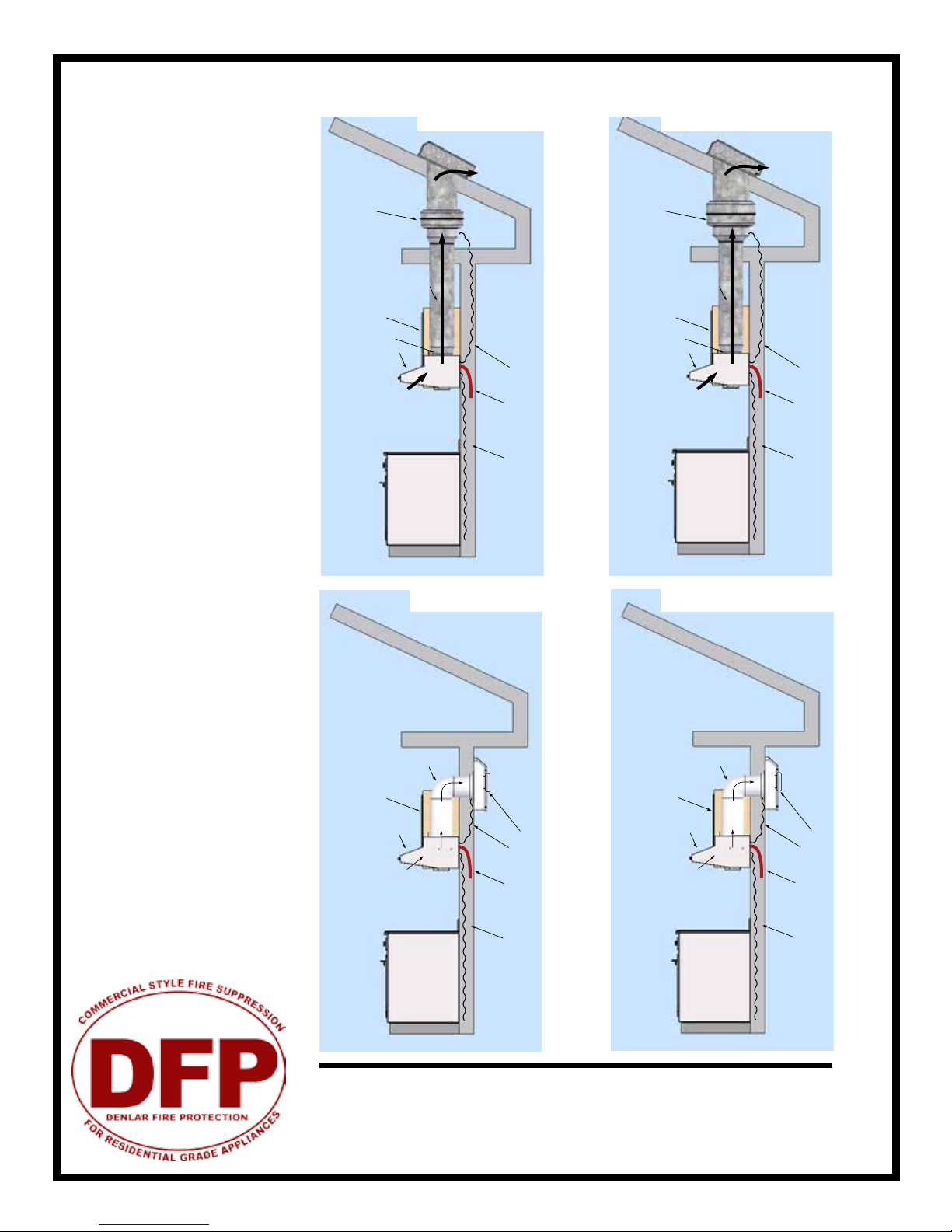

Sample Elevations

Plenum Ready Supply

Cable to Fan

Power Disconnect

Cable

Cabinet

110VAC Supply Cable

Range Hood

7” Ductwork

Fan

Air

Flow

Plenum Ready Supply

Cable to Fan

Power Disconnect

Cable

Cabinet

110VAC Supply Cable

Range Hood

10” Ductwork

Fan

7” to 10” adaptor set

D1000-I_-DF D1000-I_-DF-NFPA101

D1000-I_-WF D1000-I_-WF-NFPA101

Plenum Ready Supply

Cable to Fan

Power Disconnect

Cable

Cabinet

110VAC Supply Cable

Range Hood

12” Ductwork

Fan

Air

Flow

7” to 12” adaptor set

Plenum Ready Supply

Cable to Fan

Power Disconnect

Cable

Cabinet

110VAC Supply Cable

Range Hood

7” Ductwork

Fan

Air

Flow

Air

Flow

The D1000

Installation and

Service

Version 2.1

4

Power Disconnect

Cable

Cabinet

110VAC Supply Cable

Range Hood

Air

Flow

D1000-R_

D1000-F_

D1000-R_-NFPA101

D1000-F_-NFPA101

Power Disconnect

Cable

Cabinet

110VAC Supply Cable

Range Hood Air

Flow Fan Box (NFPA101 rev)

Power Disconnect

Cable

Cabinet

110VAC Supply Cable

Range Hood Air

Flow

Power Disconnect

Cable

Cabinet

110VAC Supply Cable

Range Hood

Air

Flow

Fan Box (NFPA101 rev)

The D1000

Installation and

Service

Version 2.1

5

Preparing the Install Location

A

F

E

DC

B

G

Installation Elevation: KEY

A. DENLAR D1000 (30” or 36”)

B. Stove (For Reference Purposes)

C. Electric Range Element Disconnect

D. Gas Range Element Disconnect (not shown)

E. e CLOCKBOX - Range Element Time-Out System (CLBX option)

F. Handicapped Accessible Control Box (ADA option)

G. Manual Pull Station (MPK option)

Note #1: If cabinettes are not present in the space, a Top Cover is recommended (option D1000-TC)

Note #2: Center the D1000 over the range. If the range is not inplace, the center marking should be relative to it’s nal position

Note #3: Refer to the model specic engineered submittal sheet for exact measurements not represented here (www.denlarhoods.com)

Note #4: Refer to “Installing e D1000” for instructions re: attaching the D1000 to the mounting bracket

Note #5: Refer to option specic installation instructions for more specic details on how to connect them to e D1000

Note #6: (Next Page) Allow for 4.535” between the top of the mounting bracket and the bottom of the cabinette above. e NFPA101

compliant version of the D1000-F/R uses an additional Fan Box as shown. Attach the fan box to the bracket, then proceed.

Note #5

Contact a DENLAR Distributor to discuss lead-ship delivery of the D1000’s

installation components. is may allow you to complete installation

connections, prior to delivery of the unit

The D1000

Installation and

Service

Version 2.1

6

0”

0”

8 1/2”

6 1/2”

2 1/2”

4 1/2”

11”

1 5/8”

28 5/8”

10 5/16” 1/16” 1/16”

5 7/8”

4”

.A

A.

B.

B.

B.

C

DE

F

FF

F

F F F

F

Min Max

D1030 18” 26”

D1036 24” 30”

Installation Heights center

line

D1000 Mounting Bracket: KEY

A. Center Notches

B. Critical Mounting Points (must be secured to studs or d/w hangers)

C. Rear Access to Junction Box (not shown)

D. Primary Access Point for connections to Junction Box (recommended)

E. Secondary Access Point for connections to hood (options/accessories)

F. Additional Mounting Points (secure minimum of 3 screws per row)

C

L

Cabinet Front

Cabinet Bottom

Access Hole - Fan Wire

Access Hole for 7” Duct

713/16”

5 15/16”

Note #6

NFPA101 -F & -R Rev Install

See Appendix A for details

D1000-I: Prep for Ducting

Standard

Bracket

NFPA101

Bracket

The D1000

Installation and

Service

Version 2.1

7

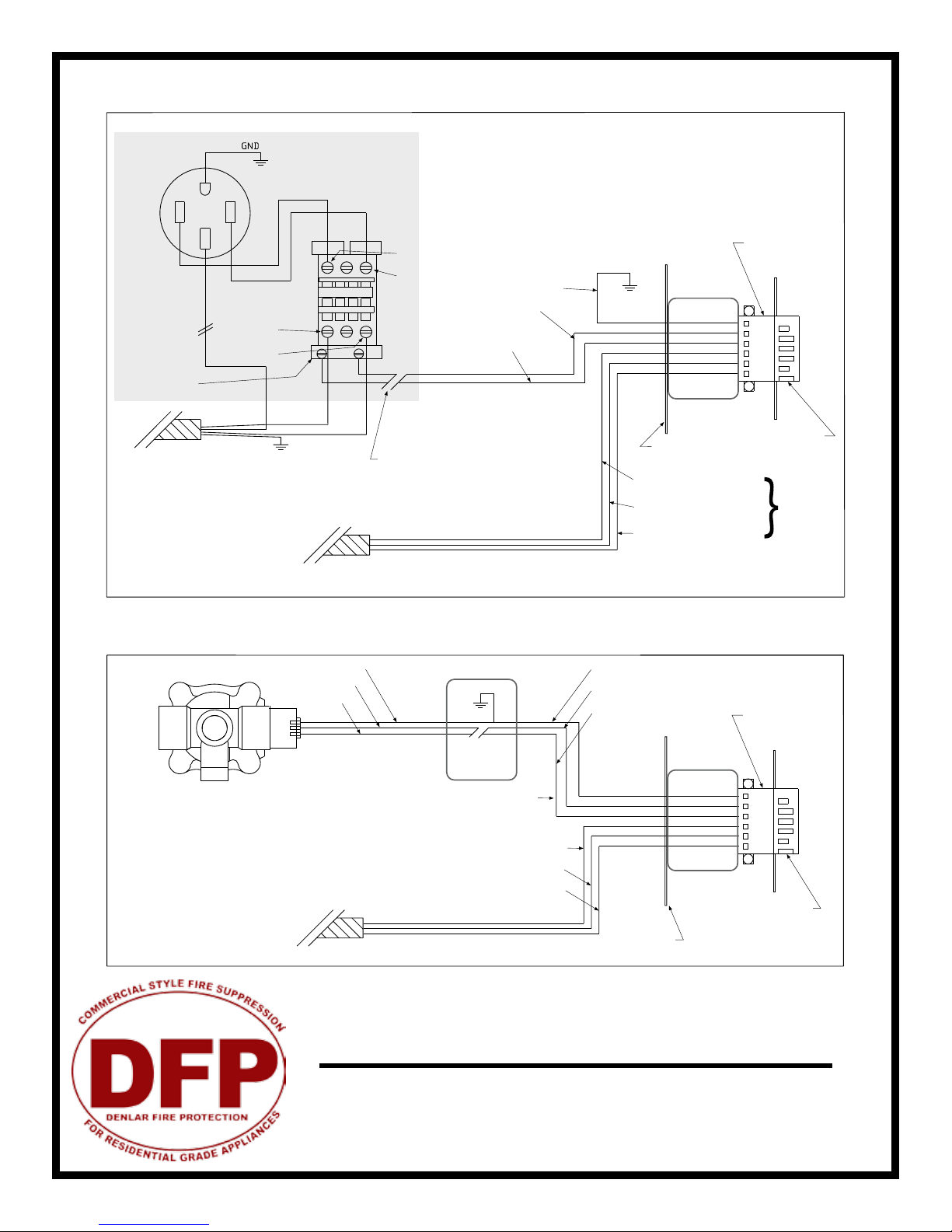

1. Determine mounting location of the power disconnect (contactor box or gas valve) and mounting bracket, if not already

done.

2. Run wire from junction box through the wall to the power disconnect location. Run MC wire for the 110VAC supply from

the junction box to the 110VAC connection. Refer to the wiring diagram on the following page for details on how to wire

the Power Disconnect Box.

3. If the hood unit is to be linked to a re alarm system, accomodations for those wires will need to be made at this time as

well. See re alarm appendix.

Power disconnect

moutned ush to

wall (50A 250V

NEMA 14-50

receptacle -

supplied by DFP)

Range Supply Line

208-220VAC 50A max

(not supplied by DFP)

Hood Supply 110-120VAC 15A

(Metal Clad Wire from 110-120

VAC Supply Line -12/2 8ft Length

-marked with red tape)

Junction Box with

Connector

Run MC wire from junction box

on mounting plate to power

disconnect box through wall

(Metal Clad Wire from 110-

120 VAC Supply Line -14/2 8ft

length -marked with black tape)

Alarm Wire(s)

NO/NC Local and

Remote Alarm

(Not Supplied by DFP)

Supplied by DFP

CAUTION: This should be performed by a licensed electrician. Installation

should be performed according to all applicable codes and regulations.

Shut o power at the main breaker to prevent electrical shock. Use metal

clad 12/2 (supplied) or replaced with wire specied by local building codes.

110VAC Supply from Hood

-Electrical Connection

3/4” NPT

Gas Flow

3/4” NPT

Face Plate

The D1000

Installation and

Service

Version 2.1

8

1. Cut a hole in the drywall for the relay box; refer to the

specication sheets for dimensions. Be sure to note the

1 1/4” overhang on each side of the face plate. Given this

the hole should be about 6 3/8” by 8 3/4”. The relay box

has been designed to t in a standard 2x4 studded wall.

2. If you havent already done so, run wiring from the

junction box location (on the unit mounting plate) to

the power disconnect box location and string through

one of the knockouts in the box.

3. Make all wiring connections and secure face plate to

box in wall.

The gas solenoid is designed for use

with 3/4” NPT pipe. Be sure to note

the “IN” and “OUT” ends of the sole-

noid body (as marked on the body).

This determines direction of gas ow.

Refer to wiring diagram for details on

electrical connection.

Range Element Disconnect Installation

Gas Disconnect Valve - G

Electrical Disconnect Box - E

208-220VAC (supply to stove)

120VAC (from hood - black tape)

The D1000

Installation and

Service

Version 2.1

9

50AMP 250V

NEMA 14-50

L1 208-220 VAC Black Hot

L3 208-220 VAC Red Hot

T1 208-220 VAC Black Hot

T3 208-220 VAC Red Hot

}

}

Not Supplied by DFP

Supplied by DFP

T1

L1

T3

L3

50 AMP 208-240 VAC Single Phase

Supply Line (not supplied by DFP)

110 VAC Coil

Wire Nut

Neutral

Lines

6 Position

Orange

Connector

6 Position

Orange

Connector

6 Position

Grey

Connector

6 Position

Grey

Connector

15 AMP 110-120 VAC

Supply Line

(not supplied by DFP)

15 AMP 110-120 VAC

Supply Line

(not supplied by DFP)

Metal Clad to 110-120 VAC

Power Disconnect (Supplied

by DFP) Black Tape - 14/2

Metal Clad Wire from 110-120 VAC

Supply Line (Red tape)

Metal Clad Wire from 110-120 VAC

Supply Line (Red tape)

Multiconductor

(4 Conductor)

110-120 VAC Gas Solenoid

Green Ground

Wire nut inside power

disconnect box

Green

Green Ground

Green Ground

Green Ground

Black Hot

110-120 VAC 14/2

Black

Hood

Hood

White Neutral

White Neutral

White Neutral

Black Hot 110-120 VAC

Black Hot 110-120 VAC

Black Hot 110-120 VAC

Junction

Box

Junction

Box

Junction Box

Wire Nut

White Neutral

White

Contactor 50A

Supplied

by DFP

Power Disconnect Box

8” x 6” x 4”

Back Support

Mounting Bracket

Back Plate

GND

NEUT

HOT

GND

NEUT

HOT

GND

NEUT

HOT

GND

NEUT

HOT

H

N

H

HH

Metal Clad to 110-120 VAC

Power Disconnect (Sup-

plied by DFP) (Black Tape)

Gas Solenoid

Electric Contactor

The D1000

Installation and

Service

Version 2.1

1 0

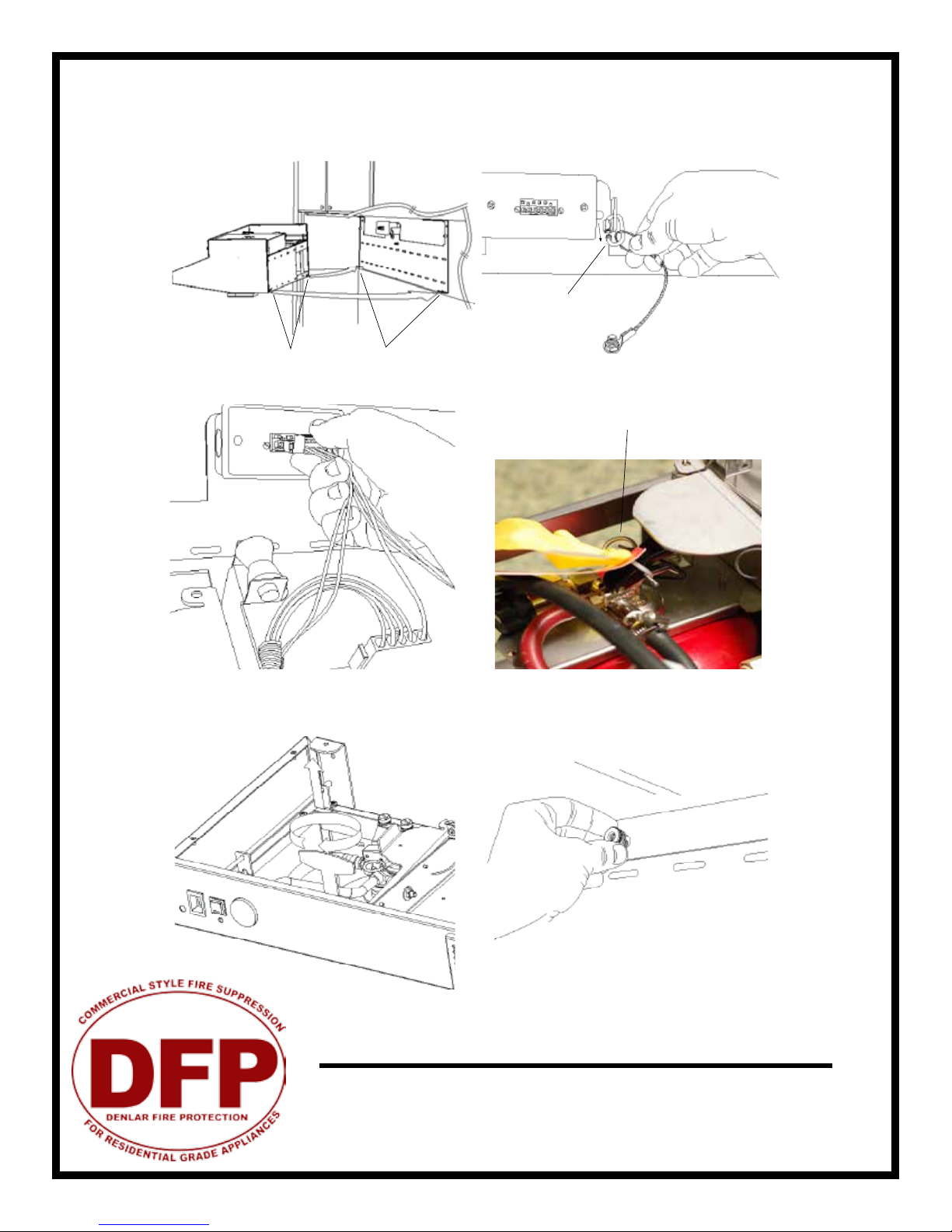

1. Lift unit to mounting bracket and seat lower tabs into

slots in back of hood.

2. While holding the unit up, hook cable to chain link on

mounting bracket and screw nut to close the link. The

hood is now in the service position.

3. Connect power to junction box. 4. Remove the safety pin -identied with the yellow

ag “caution”- from the trigger on top of the extin-

guisher bottle.

Slots Lower Tabs

Chain Link

Safety Pin

5. Remove the safety key from the actuator arm by rotat-

ing and lifting straight upwards. Note that the system will

not actuate without completing steps 4 and 5.

6. Lift unit to wall and thread the three thumb nuts to the

bolts in the back support mounting plate. Check page 16

for location of thumb nuts.

Installing The D1000

The D1000

Installation and

Service

Version 2.1

1 1

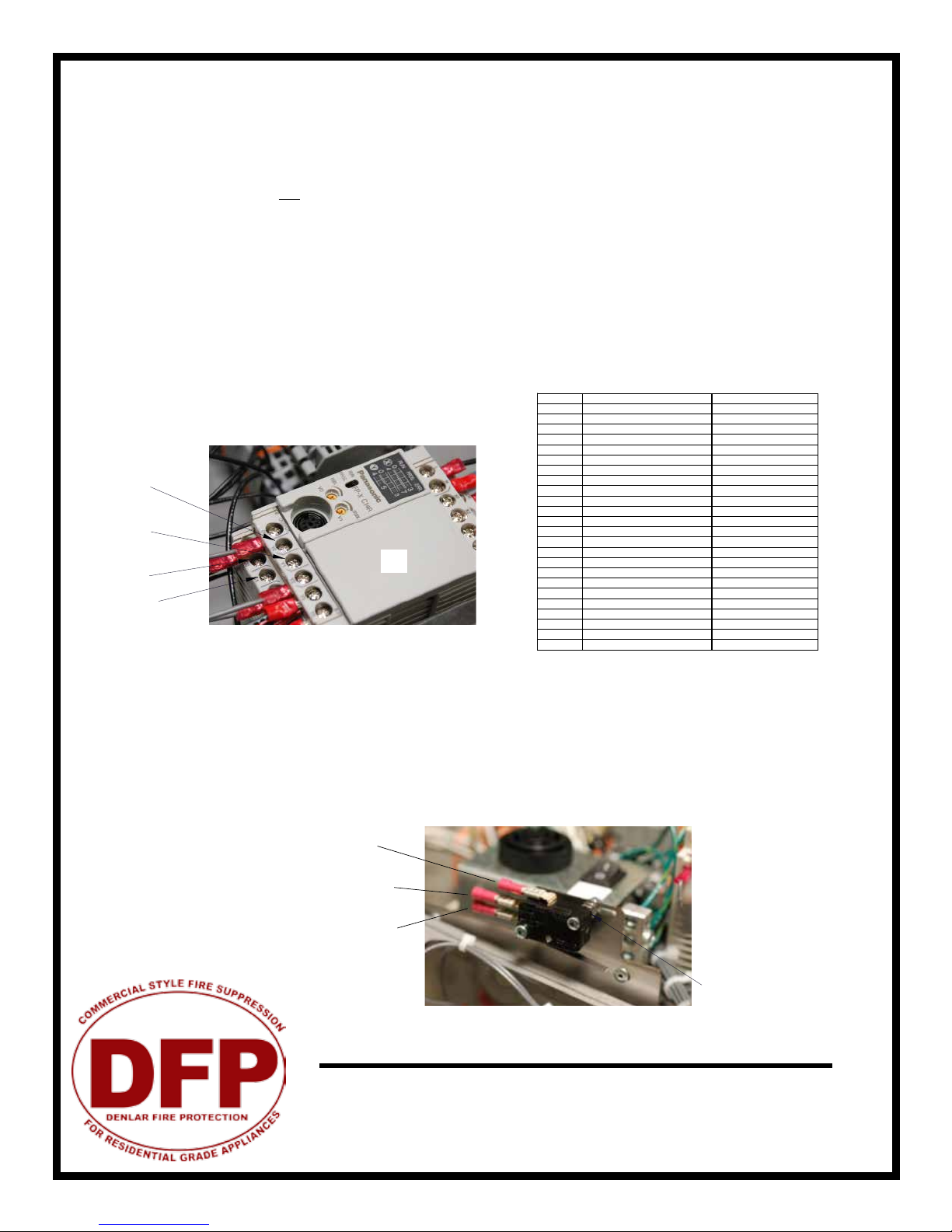

The hood unit has two re alarm connections (discrete switches), each with its own trigger. A connection is

made to one output (Y#) and one common (C#) at the PLC. The output labeled Y0 is triggered by a fault from

the low temperature switch (150 F), pressure switch, or hose switch. Output Y1 is triggered by a high tempera-

ture switch (190 F) and a low pressure fault in the extinguisher tank (the re suppressant has discharged). You

may use either one connection or both, depending on your situation. When there is a fault, a buzzer in the unit

will sound and the power disconnect will turn o.

Local Alarm Connection: Connect to output Y0 and common C0

Remote Alarm Connection: Connect to output Y1 and common C1

To connect to the alarms, it is preferred that you use a spade terminal connector (supplied), but a stripped wire

is acceptable.

Connecting the alarm system in the conguration described above results in a normally open connection.

In addition to the PLC connections above, a second connection may be made to the re alarm switch installed in the unit. Unlike the

connection above, this switch does not require power to be fed to the hood in order to function. The re alarm switch is located above the

actuactor arm, beside the PLC assembly. The re alarm switch is activated when the actuator arm trips.

To connect the re alarm switch, wire the re alarm to the common connector and normally open or normally closed connection as shown.

Fig: 14.1

C0

C1

Y0

Y1

PLC

Fire Alarm Switch

Common

Normally Open

Normally Closed

Fire Alarm System Connections

DESCRIPTION VALUE

CB CLOCK BOX 2 HR

F1 PLC FUSE 1 AMP FAST BLOW

F2 FAN FUSE 2 AMP SLOW BLOW

F3 DUAL DISCONNECT 1 AMP SLOW BLOW

F3 DISCONNECT FUSE 0.5 AMP SLOW BLOW

F4 MAIN FUSE 8 AMP SLOW BLOW

F5 CLOCK BOX FUSE 8 AMP SLOW BLOW

MP1 MAIN POWER CONNECTOR

FP2 FAN CONNECTOR

SW1 MAIN POWER SWITCH

SW2 LIGHT SWITCH

SW3 SERVICE SWITCH

SW4 RESET SWITCH

SW5 OPTIONAL ADA LIGHT

SW6 OPTIONAL ADA FAN

HSW1 HOSE SWITCH

HITH1 HIGH TEMP THERMOSTAT 190°

LOTH1,2 LOW TEMP THERMOSTAT 150°

FSP1 FAN SPEED CONTROLLER 4.0 FLA

FAN INLINE OR RECIRC FAN

CAP1 FOR RECIRC FAN 10 UF

M1 STOVE DISCONNECT 40 FLA 50 A RES

LIGHT HOOD LIGHT 60 WATT

PLC COMPUTER DRIVING HOOD

HORN ALARM IN HOOD 90DB

The D1000

Installation and

Service

Version 2.1

1 2

Parts Included:

Step 1: Installing Conduit

Mount the pull box in an appropriate location according to local building

codes. Keep in mind you are supplied with 25 feet of cable and 3 elbow

pulleys. Install 1/2” conduit (not included) between the unit and the pull

box, using the pulleys as needed. Pull cable through the conduit, and

allow 8-12“ of slack to be left at the hood unit end. Be sure to abide by all

local building codes when installing conduit.

Step 2: Replace Safety Pin and Key (to prevent accidental discharge)

With the unit lowered into its service position, put the safety pin in

its slot at the top of the extinguisher tank. Also replace the safety

key in its slot in the actuator arm. Then remove the cable from the

actuator arm.

Pull Box (x1) Pull Face (x1) Elbow Pulley (x3) Cable and Pin (25 ft)

Conduit attachment to backplate

Safety Pin

Actuator Arm

Safety Key

Cable

Crimp

Step 3: Install Cable and Pin to hood

Thread the cable through the conduit, with the pin reaching the unit. Remove the

grease lter. In the upper right corner, nd the two pulleys as illustrated to the right.

Hold the rear-most pulley in place. From the top of the unit, replace its pin with the one

on the cable. Push the pin through the pulley until you hear it click in place. Go back to

the actuator arm and rehook cable onto the arm.

WARNING: You must allow for 8-12”of slack in the cable to sit at the pull face. Failure to do so will cause

the unit to discharge the next time the unit is lowered into its service position.

CAUTION: Make sure the cable does not become caught on any part of the hood or conduit, or the cable

will not be able to be pulled, and the unit will not discharge.

Step 4: Install Cable to Pull Face

With the unit in its lowered position, attach the cable to the pull face by crimping a loop

in the cable through the hole on the back side of the handle. Be sure cable is securely

crimped to withstand at least 50 lbs of pull force. Leave no more than 12”of slack in the

line on the pull face end, but maintain 8-12”. To make this easier, the handle may be

removed by loosening the set screw in one of the studs, and sliding the red plastic rod

out. Attach the pull face to the pull box already mounted on the wall, collecting any slack

into the pull box. Do not allow slack cable to collect above the hood.

Manual Pull Station Installation - MPK

The D1000

Installation and

Service

Version 2.2

1 3

Once the hood has been installed, it may be necessary or desired to test the unit with a test tank. This is a tank lled only

with pressurized nitrogen (Need to order separately).

1. Following the “Removing the Extinguisher Tank” instructions in the service manual, remove the extinguisher tank and

replace it with a test tank.

2. The unit can be actuated one of two ways:

A. Cut Test Links: Replace the actuator arm’s safety key. Loosen the turnbuckle in the fusible link cable assembly (underside

of hood). Replace one of the fusible links with a test link. Re-tighten the turnbuckle to the proper tension. Remove the safety

key and raise the unit to its operational position. To test, cut the test link with wire cutters or similar.

B. Manual pull kit (if installed): Raise the unit to its operational position after the test tank has been installed. Remove the

plastic break rod from the pull face with an allen wrench (refer to manual pull station appendix for more detailed infomation

on this). Pull the handle to actuate the unit. Refer to the manual pull kit appendix on how to return the pull station to an

operational state.

Safety Pin

Turnbuckle Fusible Link

WARNING: The safety pin must be in place in the extinguisher tank until the unit is ready to

be returned to service or to be tested. Always wear safety glasses during this procedure.

3. Nitrogen should be released from each nozzle simultaneously.

4. Replace the test tank with the extinguisher tank, the test link with a fusible link, and replace the unit to its operational

position. The unit is now ready to be put into service.

WARNING: Be careful of the protective caps on the nozzles. These

will y o the nozzles when the unit is actuated. Always wear safety

glasses during this procedure.

Test Tank & Demonstration - TKD

Safety Key

The D1000

Installation and

Service

Version 2.2

1 4

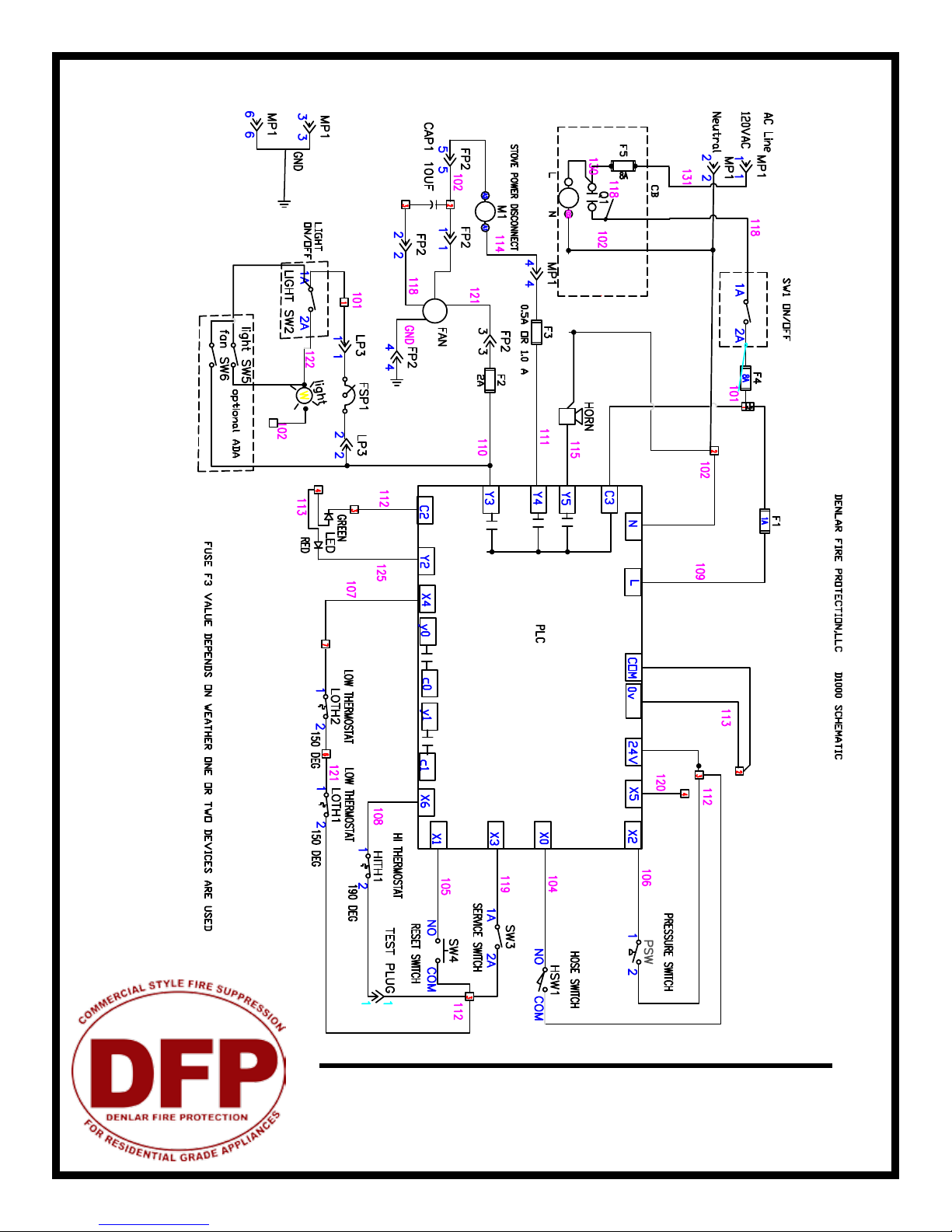

Electrical Schematic - Complete

The D1000

Installation and

Service

Version 2.1

1 5

The D1000 is the rst range hood with an integrated re suppression system. It functions as a standard ventilation

range hood with the added capability to suppress stove top res.

Designed for use over a standard 30” and 36” residential range, it uses a mechanical, commercial style automatic re

suppression system.

Refer to the illustration below to familiarize yourself with the following functions.

• A PLC provides an internal alarm plus connections for up to two external alarms that may go to a local alarm panel

and/or remote location, i.e. the local re department.

• The unit is powered from standard 115 VAC / 60Hz / single phase. A main Power Switch is located at the upper left

of the front surface.

• For normal daily use, the unit provides a fan speed control knob and a light switch for the light.

• A Reset Button (white) is provided to energize the PLC and the main power disconnect contactor (electric range)

or valve (gas stove). Upon initial power up, the control system is not enabled and this reset button needs to be

pressed. In doing so the Status LED below the reset switch will turn from red to green.

Recommended Maintenance Schedule

Monthly Annually Every 10 years

Cleaning

Suppression Nozzles Inspect Inspect

Fusible Links Inspect Replace

Extinguisher Tank Inspect Recertify Replace

Service & Operational Manual

How it works

WARNING: Safety glasses must be worn whenever service operations are performed

Service & Recertication Schedule

The D1000

Installation and

Service

Version 2.1

1 6

Moving the unit between‘operating’ and ‘service’ positions

All D1000 models have been congured as a standalone unit mounted to a wall plate. As such, the unit may

easily be tilted down into a service position, giving you access to the electronics and extinguisher tank, or be re-

moved completely for maintenance and cleaning. Provisions have been made to facilitate easy removal includ-

ing a minimal amount of fasteners and modular electrical connections.

To place the unit in the service position, a few simple steps are required. Be sure to wear safety glasses at all

times during this process:

1. Shut the unit o with the power switch on the front of the hood;

2. Remove the grease tray then the grease entrapment lter;

3. Loosen and remove the brass knurled service nuts that are on the rear inside wall of fan housing compart-

ment. On units with a ducted fan, remove the two thumbscrews located at the top inside near the fan intake

(refer to illustration below). Slowly lower the unit;

4. The unit will now freely pivot downward to a stop position. A safety cable is provided to prevent the unit

from falling or lowering too far.

5. Place safety pin in the tank valve to avoid accidental discharge.

With the unit in this position, basic servicing and cleaning may be performed, including servicing the extin-

guisher tank assembly.

To move the unit back to the operating position, simply reverse the process as outlined above.

WARNING: An electrical shock hazard is present at the electrical compart-

ment whenever there is power to the hood. Use caution when working

around this device while the unit has power.

WARNING: Be careful while working with the unit in the service position.

Release of the cable system or applying force to the tank valve assembly may

cause discharge of the tank. The high pressure discharge has the potential to

cause skin or eye damage and injury!

(3x)

Thumbscrew locations (for ducted fan only)

Accessing the Internal Components

The D1000

Installation and

Service

Version 2.1

1 7

Cleaning the Hood

To remove built up grease and cooking debris, clean the unit thoroughly with mild detergent and water. Be

careful when using abrasive cleaning pads as they may scratch or mar the stainless steel surfaces. The grease

entrapment lter, front discharge grille and grease tray are dishwasher safe. The carbon lter cannot be washed,

and should be replaced periodically as needed.

Inspect the nozzle caps

The nozzle caps should be inspected and cleaned. All 5 nozzles should have protective caps installed. If neces-

sary, remove the caps and check for build up of debris or any signs of clogging of the nozzle orice. If clogging

is suspected, remove the nozzle with a 7/16” wrench, and ush with hot water until it ows freely through the

nozzle. Replace the nozzle and protective cap.

Replacement caps and nozzle O-rings are available from DFP or your distributor.

Inspect Fusible Link System*

Periodic inspection of the fusible link system ensures the unit is ready to work in the case of a re.

1. Place safety pin in tank valve.

2. Remove tank from hood.

3. Remove tension from cable system by loosening the turnbuckle.

4. If the fusible links need to be replaced, you may order some by calling your local distributor.

5. Inspect pulleys and cable. Pulleys should rotate freely and cable should be exible. Everything should be free

of grease build-up.

6. Tighten the turnbuckle, reapplying tension to the stainless steel rope, making sure the cable is running

through the pulleys properly and there are no kinks or knots.

WARNING: The protective caps stay on the nozzles at all times. In the event

of a discharge, the caps will blow o on their own.

Actuator arm under tension

in ready position

7. Reposition the tank.

8. Remove safety pin from tank valve.

*Each fusible link is date-stamped and must be replaced if expired or after 12 months of use.

Maintaining the System

Inspection Procedure

The D1000

Installation and

Service

Version 2.1

1 8

10 Year Maintenance

Hydrostatic testing and new liquid agent, or tank replacement is recommended at ten-year intervals. The man-

ufacture date is stamped on the top of the tank. This should be performed by an authorized technician or at the

manufacturer’s facilities. Material safety data sheets are available from DFP.

Lighting

Illumination is provided by a 60 Watt medium-base shatterproof incandescent light bulb. To replace, make sure

the light switch is in the “o” position, and then gently unscrew the bulb. (Bulb: 60A15/TF)

WARNING: Rubber gloves and safety glasses should be worn during ser-

vice or inspection of the tank. If contact with skin or eyes occurs, ush

immediatly with water for 15 minutes. If irritation persists, contact a physi-

cian. If taken internally, do not induce vomiting. Dilute with water or milk

and contact a physician.

WARNING: If grease build up on the cable is not kept to a minimum, the ca-

ble could become sti and will not discharge the suppressant in the event

of a re.

Removing the Extinguisher Tank

1. Lower the hood to its service position

2. Insert the safety pin in the valve head so that accidental release of the suppressant does not occur.

3. Unlpug the pressure switch wire and move it out of the way for now.

4. Disconnect the discharge hose from its tting located inside the unit closest to the user.

5. Unscrew the two wingnuts holding the bracket for the tank.

6. Lift the tank out of the hood.

7. To replace the tank, simply reverse these steps.

Safety Pin

Discharge Hose

Pressure Gauge

Tank Valve

Pressure Switch

Mounting Bracket

The D1000

Installation and

Service

Version 2.1

1 9

Programmable Logic Controller (PLC)

LED Indications

The PLC operating system is designed to enhance the functionality of the unit and the safety of the cooking

environment.

The system relies on input from a set of thermostats to control the fan and shuto power to the stove when the

temperature reaches preset points.

As the temperature rises, the PLC monitors the environment with the 3 thermostats. The board is programmed

to respond to 2 temperature thresholds: the rst at 150 deg F and the second at 190 deg F.

At the rst temperature threshold the ventilation fan will turn on, REGARDLESS OF THE FRONT PANEL SWITCH

SETTING.

At the second temperature threshold, several events happen:

1) The power disconnect to the stove (valve or contactor) is de-energized, shutting o power to the stove;

2) The “local” alarm output is tripped, indicating a trouble condition with the unit. This output is from

contacts C0 and Y0 on the PLC.

3) The on-board audible alarm sounds (high pitched tone).

DESCRIPTION VALUE

CB CLOCK BOX 2 HR

F1 PLC FUSE 1 AMP FAST BLOW

F2 FAN FUSE 2 AMP SLOW BLOW

F3 DUAL DISCONNECT 1 AMP SLOW BLOW

F3 DISCONNECT FUSE 0.5 AMP SLOW BLOW

F4 MAIN FUSE 8 AMP SLOW BLOW

F5 CLOCK BOX FUSE 8 AMP SLOW BLOW

MP1 MAIN POWER CONNECTOR

FP2 FAN CONNECTOR

SW1 MAIN POWER SWITCH

SW2 LIGHT SWITCH

SW3 SERVICE SWITCH

SW4 RESET SWITCH

SW5 OPTIONAL ADA LIGHT

SW6 OPTIONAL ADA FAN

HSW1 HOSE SWITCH

HITH1 HIGH TEMP THERMOSTAT 190°

LOTH1,2 LOW TEMP THERMOSTAT 150°

FSP1 FAN SPEED CONTROLLER 4.0 FLA

FAN INLINE OR RECIRC FAN

CAP1 FOR RECIRC FAN 10 UF

M1 STOVE DISCONNECT 40 FLA 50 A RES

LIGHT HOOD LIGHT 60 WATT

PLC COMPUTER DRIVING HOOD

HORN ALARM IN HOOD 90DB

D1000 Operating System - PLC Drive Functions

Environmental Monitoring / Pre-Suppression Functions

110 - 120 VAC

Other manuals for D1000

1

This manual suits for next models

8

Table of contents

Other Denlar Ventilation Hood manuals

Popular Ventilation Hood manuals by other brands

Bosch

Bosch DWW063462 OPERATING AND INSTALLATION Manual

FALMEC

FALMEC Gruppo incasso Touch Vision 70 Instruction booklet

ROBLIN

ROBLIN BALTIC 900 instruction manual

Miele

Miele DA 6881 Operating and installation instructions

IKEA

IKEA FOLJANDE manual

ROBINHOOD

ROBINHOOD RHCI9SS - IMPRESA installation instructions