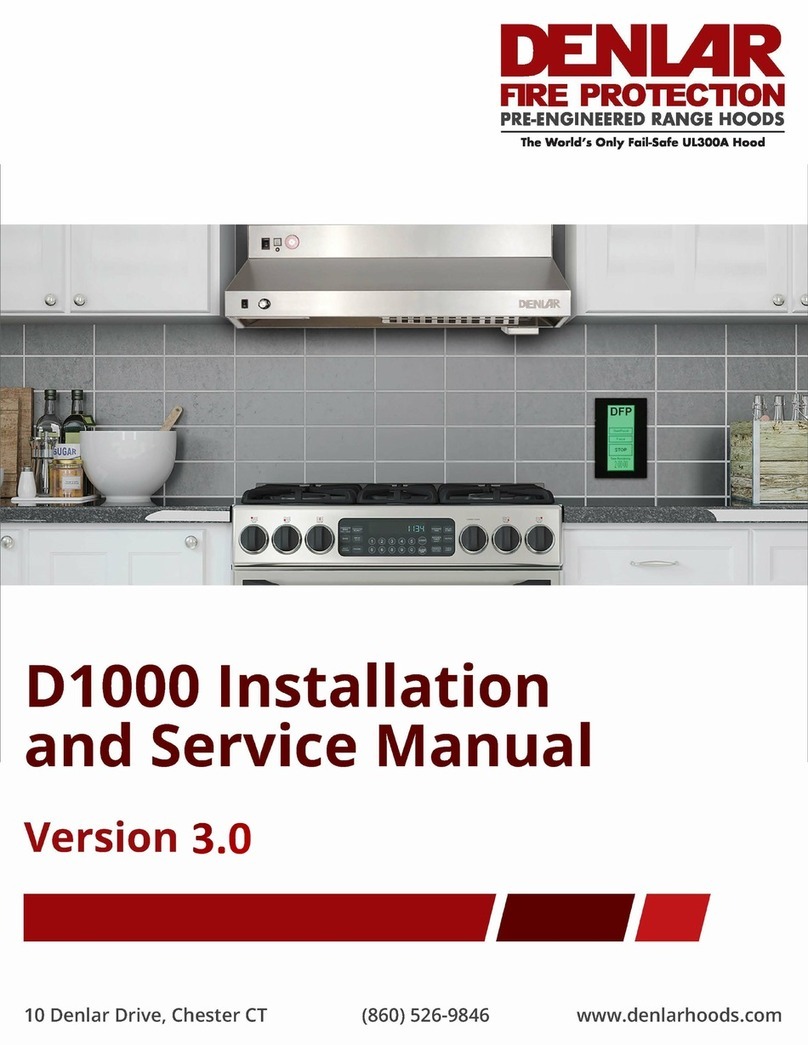

Denlar D1000 Manual

10 Denlar Dr., Chester, CT 06412 LAB-110073 Rev. 2.7 d

D1000 Installation and Service Manual 1

Home LAB-110073 Rev. 2.7

WARNING CAUTION

G

READ AND SAVE THESE INSTRUCTIONS

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the

manufacturer. If you have any questions, contact the

manufacturer at the address or telephone number listed

on the front cover of this manual.

2. Before servicing or cleaning unit, put the unit into

service mode and disconnect power which will prevent

the unit from being powered ON accidentally. When the

service disconnect cannot be locked, securely fasten a

prominent warning device, such as a tag, to the service

panel.

3. Installation work and electrical wiring must be done by a

qualified person(s) in accordance with applicable codes

and standards, including fire-rated construction codes

and standards.

4. Sufficient air is needed for proper combustion and

exhausting of gases through the flue (chimney) of fuel

burning equipment to prevent back drafting. Follow the

HVAC equipment manufacturer’s guidelines and safety

standards such as those published by the National Fire

Protection Association (NFPA) and the American

Society of Heating, Refrigeration and Air Conditioning

Engineers (ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceilings do not

damage electrical wiring and other hidden utilities.

6. To reduce the risk of fire or electric shock, do not use

this range hood with an additional speed control device.

7. Ducted fans must always be vented outdoors.

8. To reduce the risk of fire, use only metal ductwork.

9. Use with approved wiring only.

10. This unit must be grounded.

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

1. Never leave surface units unattended at high settings.

Boil-overs cause smoking and greasy spillovers that

may ignite. Heat oils slowly on low or medium settings.

2. Always turn fan ON when cooking at high heat or when

cooking flaming foods.

3. Clean ventilating fans frequently. Grease should not be

allowed to accumulate on fan or filter.

4. Use proper pan size. Always use cookware appropriate

for the size of the surface element.

TO REDUCE THE RISK OF INJURY TO PERSONS

IN THE EVENT OF RANGE TOP GREASE FIRE

OBSERVE THE FOLLOWING:*

1. SMOTHER FLAMES with a close-fitting lid,

cookie sheet, or metal tray; then turn off the

burner. BE CAREFUL TO PREVENT BURNS.

If the flames do not go out immediately,

EVACUATE AND CALL THE FIRE

DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN –You may

be burned.

3. DO NOT USE WATER, including wet

dishcloths or towels –violent steam explosion

will result.

4. Use an extinguisher ONLY if:

A. You know you have a Class ABC

extinguisher and you already know how to

operate it.

B. The fire is small and contained in the area

where it started.

C. The fire department is being called.

D. You can fight the fire with your back to an

exit.

*Based on “Kitchen Fire Safety Tips published by

NFPA

1. For general ventilating use only. Do not exhaust

hazardous or explosive materials and vapors.

2. To avoid motor bearing damage and noisy and/or

unbalanced impellers, keep drywall debris,

construction dust, etc. way from hood.

3. For best capture of cooking impurities and

performance of fire extinguisher, your range hood

should be mounted so that the bottom of the hood

is 24-36” above the cooking surface, depending

on model.

4. Please read specification sheets for further

information and requirements.

DISCLAIMER

:

DENLAR Fire Protection shall not be liable for errors contained in this Manual or for incidental,

consequential damages in connection with the furnishing, performance or use of this information. DENLAR Fire

Protection makes no warranty of any kind with regard to this information, including, but not limited to the implied

warranties of merchantability and fitness for a particular purpose.

D1000 Installation and Service Manual 2

Home LAB-110073 Rev. 2.7

TABLE OF CONTENTS

INSTALLATION:

1. System Anatomy

2. Sample Elevations

3. Preparing the Installation location

4. NFPA101 - Front/Rear Fan Installation

5. Range Element Disconnect Install

6. Handicap Accessible Controls

7. Installing the D1000

8. Fire Alarm System Connections

9. Manual Pull Station Installation

10. Ducting and Airflow

11. Electrical Schematic

12. Electrical Schematic Table

13. Service Position and Service Mode

14. Tank and Link Replacement

15. Troubleshooting the D1000 System

16. Self-Monitoring System

SERVICE & OPERATIONAL:

17. Maintenance

18. Operating the Hood

19. After an Actuation

20. Common Parts List

Page 3

Page 4

Page 5-7

Page 8-9

Page 10-11

Page 12-13

Page 14

Page 15

Page 16-17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24-25

Page 26-28

Page 29

Page 30-31

Page 32

D1000 Installation and Service Manual 4

Home LAB-110073 Rev. 2.7

SAMPLE ELEVATIONS

D103X-F D103X-D-IF

D103X-R D103X-D-RF D103X-D-WF

Cabinet

120 VAC

Power

Disconnect

Cabinet

Rang

e

Hood

Range Hood

Air

Flow

Sample

Discharge

120VAC

Power Input

120 VAC Power

Disconnect

120VAC

Power Input

Air Flow

Cabinet

Range

Hood

Air Flow

Roof Fan

Cabinet

Range Hood

Air

Flow

Plenum Ready

Supply Cable to

Fan

120VAC Power Input

Cabinet

Wall Mount

Fan

Plug ‘N’ Play

Plenum

Ready Supply

Cable to Fan

Range Hood

7” Duct

Air Flow

Sample

Discharge

Plug ‘N’ Play

Plenum

Ready Supply

Cable to Fan

120 VAC Power

Disconnect

120 VAC Power

Disconnect

120VAC

Power Input

7” Duct

120VAC

Power Input

7” Ductwork

ork

Ca

Range

A

ir

Sam

ple

Plenum

Read y

Supp ly

120 VAC

Power

120 VAC Power

Disconnect

Ducted

Fan

D1000 Installation and Service Manual 5

Home LAB-110073 Rev. 2.7

PREPARING THE INSTALL LOCATION

Note# 1: If cabinets are not present in the space, a Top Cover is required (option D1030 -TC I or F/R or

D1036-TC I or F/R)

Note #2: Center the D1000 over the range. If the range is not in place, the center marking should be relative to its final

Position.

Note #3: Refer to the model specific engineered submittalsheet for the exact measurements whichare not represented

here (available at denlarhoods.com)

Note #4: Refer to “Installing the D1000” (on page 14) for instructions on attaching the D1000 to the mounting

bracket

Note #5: Refer to option specific schematics for more details on how to connect them to the D1000

Note # 6: As indicated on page 6, allow for 4 5/8” between the top of the mounting bracket and the bottom of the

cabinet above. In order to allow the installation of the NFPA101 compliant version of the D1000-F/R, which uses an

additional Fan Box as shown attach the fan box to the bracket, and then proceed.

NOTE # 5 COMPONENTS

C

D

C

C

E

A

B

F

G

A. DENLAR D1000 (30” or 36”)

B. Range (for reference purposes (gas, electric or dual

element, dual receptacle)

C. Electric Power disconnect (pictured)

D. Gas Power Disconnect (not shown)

E. The CLOCKBOX- range element lockout system (CLBX

option) The Touchscreen is shown, the control module is

not shown.

F. Handicap Accessible Control Box (ADA option)

G. Manual Pull Station (MPK option)

Note: The dual element disconnect (DED option) integrates both the

electric and gas power disconnect options.

View of Mounting Bracket Installed

D1000 Installation and Service Manual 6

Home LAB-110073 Rev. 2.7

Cabinet Bottom

Access Hole for7”

Duct

PREPARING THE INSTALL LOCATION

Min

Max

D1030

24"

30"

D1036

30"

36"

Installation Heights

NFPA101 “F” & “R” Rev

Install

See Pages 8 & 9 for

details

4”

5 7/8”

”

Standard

Bracket

NFPA101

Bracket

Cabinet Front

B

B

A

A

B

C

D

E

F

F

F

F

F

F

F

F

28 5/8”

1/16”

1/16”

10 5/16””

1 5/8”

D1000-D Prep for Ducting

Mounting Bracket for D1000-F/R options

pictured (non-NFPA101)

Note # 6

Mounting Bracket

D1000 MOUNTING BRACKET

A. Center Notches

B. Critical Mounting Points (must be secured to suds or

dry wall hangers)

C. Primary Access Point for Connections to hood

(options/accessories)

a. Supply lines run inside of the wall.

D. Secondary Access Point for connection to hood

(options/accessories)

E. Additional mounting points (secure minimum of 3

screws per row)

7 3/16”

3.5”

4”

D1000 Installation and Service Manual 7

Home LAB-110073 Rev. 2.7

PREPARING THE INSTALL LOCATION

1. Determine the mounting location of the power disconnect (contactor box or gas solenoid valve) and mounting

bracket, if not already done.

2. Run the 14/2 MC wire from the junction box through the wall to the power disconnect location. Run 12/2 MC wire

for the 120VAC input power supply from the junction box to the 120VAC connection. Refer to the wiring diagram

on page 10 for details on how to wire the Power Disconnect Box.

3. If the hood unit is to be linked to a fire alarm system, accommodations for those wires will need to be made at this

time as well. See page 13 for ”Fire Alarm System Connections”

Junction Box with

Connector*

Hood Supply 110-120VAC 15A

(12/2 MC Wire from 110-120 VAC

Supply Line –8 feet long 12/2 MC

Wire –marked with red tape)

Run MC wire from junction box on

mounting bracket to power disconnect

box through wall (14/2 Wire from 110-

120 VAC Supply Line 8 ft. long

marked with black tape)

Supplied with hood

Alarm Wire(s) NO/NC

Local and Remote Alarm

(Not Supplied by DFP)

Electrical disconnect

mounted flush to wall

(50A 250V NEMA 14-

50 receptacle-

supplied by DFP)

Range Supply Line

220-240VAC 50A

max (not supplied

by DFP)

CAUTION: This should be performed by a licensed electrician. Installation

should be completed according to all applicable codes and regulations. Shut

off power at the main breaker to prevent electrical shock. Use Non-Metallic

Tubing clad 12/2 (supplied) or replaced with wire specified by building codes.

*Plug ‘N’ Play Connector

D1000 Installation and Service Manual 8

Home LAB-110073 Rev. 2.7

NFPA101 FRONT/REAR (F/R) DISCHARGE INSTALLATION

The NFPA101 compliant calibration of the DENLAR

D1000 was engineered to comply with the

requirements of the NFPA Life Safety Code, related

to residential cooking appliances used in non-

production cooking environments. Due to the

specific performance requirements in the code, the

NFPA101 version of the D1000 differs slightly from

the standard calibration. Refer to this section for

NFPA101 front/rear version-specific information.

Fan Box (NFPA

101)

Duct Access (Remove plate for

rear exhaust configuration)

MPK

Min

Max

D1030

24"

30"

D1036

30"

36"

Installation Heights

Mounting Bracket

Duct Collar

Front Grille (-F configuration)

Safety Key

MPK

Extinguisher Tank

D1000 Hood

Stainless Steel Grease Filter

Stainless Steel Grease Tray

The NFPA101 versions of

the D1000-F and D1000-

R are identical barring the

rear’s (R) need for

ducting to pass through

the exterior wall. Where

the “R” expels vapor

through the rear of the

hood, this version does

not include a front grille.

This model, the fascia of

the fan box is a

continuous stainless steel

surface.

NOTE: The NFPA101

versions of the D1000-D

does not change the hood

as the fans are installed

remotely.

NOTE: The NFPA101 recirculating option is not approved for use in installations in

Group I-1 and I-2 occupancies per section 505.3 of the 2018 version of the International

Mechanical Code.

Input/output supply

Wires running

inside of wall.

D1000 Installation and Service Manual 9

Home LAB-110073 Rev. 2.7

If installing under cabinets, keeping the fan

box flush to the underside will guarantee

correct spacing. Otherwise, center and

mark the installation area according to the

mounting bracket prior to hanging.

1. Insert/attach the top portion of the

MPK conduit through the fan box.

2. Attach the fan box to the mounting

bracket with included 8/32 nuts,

then complete the installation on

the MPK conduit and top/bottom

unions.

The fan box is 4.5” tall. If prepping a space

for install, 4.5” must be left between the

top of the mounting bracket and the

bottom of the cabinet.

The additional height of the unit should not

result in reduced range clearance.

Cabinets should be installed approximately

5” higher to accommodate the additional

size of the NFPA101 fan box assembly.

NFPA101 FRONT/REAR DISCHARGE INSTALLATION

NOTE: The NFPA LSC (101) requires

500CFM of airflow in a 300A hood and

suppression system. This amount of

airflow, through a recirculating hood, will

create inefficiencies within the system

resulting in additional noise production.

Fan Box

Conduit

Coupler

Fitting

MPK

Conduit

4 ½”

Fan Box

8-32 Nuts

Mounting Bracket

D1000 Installation and Service Manual 10

Home LAB-110073 Rev. 2.7

RANGE ELEMENT DISCONNECT INSTALLATION

¾” NPT

110-120VAC Power

Disconnect Output from

Hood- Electrical Connection

GAS POWER DISCONNECT

SOLENOID VALVE-GD

The gas solenoid has two female ¾” NPT pipe

threads. Be sure to note the arrow indicating the

direction of the flow marked on the body of the

valve.

NOTE: The coil voltage cannot be used to power any of the

electrical components on the range, including the ignitors.

If the electricity needs to be disconnected as well as the

gas you will need the Dual Element Disconnect (DED).

The DED integrates both the electric and gas options.

¾” NPT

208-240VAC Power

Disconnect output

110-120 VAC (from

hood-black tape)

Face Plate

ELECTRICAL POWER DISCONNECT BOX - ED

1. Cut a hole in the drywall for the electric disconnect; refer to the

specification sheets for the dimensions. Be sure to note the 1 ¼”

overhang on both sides of the face plate. The hole should be about 8

3/8”. The power disconnect has been designed to fit a standard 2” x

4” framed wall.

2. Run 110-120VAC output supply wiring from the junction box location

found on the hood’s mounting bracket, to the power disconnect

location. Using a box connector install the wire through one of the

knockouts.

3. Run 208-240VAC input supply line from the site to the contactor. This

will provide 208-240VAC power to the receptacle. See page 11

“Electric Power Disconnect” for details.

4. Secure the wire connections then secure the face plate to the power

disconnect.

D1000 Installation and Service Manual 12

Home LAB-110073 Rev. 2.7

HANDICAP ACCESSIBLE CONTROLS (ADA)

COMPONENTS

•ADA Wire Harness Assembly

o(1) Metal 2-Gang Enclosure

o(2) Toggle Switches (white)

o(15’) Three Conductor Cable inside of a Non-Metallic Tubing

with a Ground

o(1) Gray or Green Eight Position Male Connector (Plug-N-Play)

o(1) 2-Gang White Switch Cover

o(2) Mounting Brackets

o(1) Junction Box with four wire multi-conductor

o(1) Four wire harness with Gray or Green Eight Position

Female Connector

PREPERATION

Turn OFF the main 110-120 VAC power (at the panel) to the Hood or unplug the Gray or Green 6 position connector at

the Handy Box (Hood). Remove the ADA Wire Harness Assembly from the packing.

INSTALLATION

1. Unscrew the two switches from the Metal 2-Gang Enclosure.

2. Mount the Metal 2-Gang Enclosure to the desired wall using the mounting

brackets in accordance with local building codes and electrical codes.

3. Screw the two switches back to the Metal 2-Gang Enclosure.

4. Install the 2-Gang White Switch Plate on the Metal 2-Gang Enclosure.

5. Run and secure the Three Conductor Cable inside of a Non-Metallic

Tubing with a Ground .

6. Secure the Junction Box (Non-Metallic Tubing Clad wire to four wire multi-

conductor transition box) to the wall. Ensure the Gray or Green Eight

Position Male Connector can reach the top center of the Hood.

7. Plug the Eight Position male and female connectors together

8. Ensure electrical connections are tight.

9. Turn the power on for the Hood.

10. The switch on the left of the Metal 2-Gang Enclosure with the Red and

White wires connected to it is for the fan function. Turning on this switch

enables the fan to run at High Speed only. There is no speed control with

this switch.

Note: In order to turn the fan OFF, both the ADA toggle switch and the speed

control at the hood need to be OFF.

11. The switch on the right of the Metal 2-Gang Enclosure with Black and

White wires connected to it is for the light function.

Note: In order to the tur the light OFF, both the ADA toggle switch and the light

switch at the hood need to be OFF.

Eight Position Gray or Green

Connector Male & Female

Handicap Accessible

Controls

D1000 Installation and Service Manual 14

Home LAB-110073 Rev. 2.7

INSTALLING THE D1000

1. Line unit up to the secured D1000 mounting

bracket and seat lower tabs into slots in the back of

the hood.

3. Connect the power to the junction box.

2. On the tank, remove the safety pin-identified

with the yellow flag “caution” from the trigger

on top of the extinguisher bottle.

Safety Pin

5. Remove the safety key from the actuator arm by

rotating and lifting the key straight upwards.

THE SYSTEM WILL NOT ACTUATE

WITHOUT COMPLETING STEPS 4 & 5.

Safety Pin

NOTE: The system is

armed after steps 4

& 5 are completed.

NOTE: Install the MPK prior to arming the system.

6. Tilt the D1000 hood towards wall and thread

the three thumb nuts to the bolts in the back

support mounting bracket. See page 21 for

location of thumb nuts.

2. While holding the unit up, hook cable to the

chain link on the mounting bracket and screw

the nut to close the link. The hood is now in

service position.

Yellow Caution Flag

Safety Key

D1000 Installation and Service Manual 15

Home LAB-110073 Rev. 2.7

FIRE ALARM CONNECTIONS

The D1000 has three fire alarm connections (discrete switches), each independent from each other. Two are controlled by

the PLC and one is mechanical.

•A connection is made to one output (Y#) and one common (C#) at the PLC. The output labeled YO is triggered by

a fault from HiTemp, 190F, pressure switch or hose switch. A buzzer in the unit will sound and the power

disconnect will turn off.

•Output, Y1, is triggered by a high temperature switch, 190F, and a low pressure fault in the extinguisher tank

(the fire suppressant has discharged). When there is a fault, a buzzer in the unit will sound and the power

disconnect will turn off.

PLC CONTROLLED ALARMS-REQUIRE POWER TO THE HOOD

•Local Alarm Connection: Connect to output Y0 and common C0

•Remote Alarm Connection: Connect to output Y1 and common C1

To connect to the alarms, it is recommended that you use a 3.22mm spade fork connector (not supplied), however a

stripped wire is acceptable.

Either one of the connections may be used depending on the needs of the job site.

Connecting the alarm system in configurations described above results in a normally open connection.

Common

Normally Open

Normally Closed

Fire Alarm Switch

Figure 14.2

MECHANICAL SWITCH –NOT POWERED

This connection does not require power to be supplied to the hood in order to function. The alarm switch is located above

the actuator arm, next to the PLC assembly. The alarm switch is tripped when the actuator arm is released.

•Wire the alarm to the common connector and normally open, or normally closed connection as shown, depending

on what the on-site alarm requires.

Actuator Arm

PLC Assembly

Y0

C0

C1

Y1

D1000 Installation and Service Manual 16

Home LAB-110073 Rev. 2.7

MANUAL PULL STATION (MPK) INSTALLATION

STEP 1: INSTALLING CONDUIT

Mount the pull box in an appropriate location according to local building codes. The MPK suplied with

twenty-five feet of wire rope cable and three elbow pulleys as our listing requires.

•Install ½” conduit (not provided) between the unit and the pull box, using the pulleys as

needed.

•Pull the wire rope cable through the conduit, and allow 8-12” of slack to be left at the hood unit

end.

Be sure to abide by all local building and fire codes when installing the conduit.

STEP 2: PLACE UNIT IN SERVICE MODE (TO HELP PREVENT ACCIDENTAL DISCHARGE)

•Ensure that the unit is in service mode (see Page 20).

CHECK THE FOLLOWING:

•The safety pin is in its slot at the top of the extinguisher tank. See figure 14.3 Tank Safety

Pin

•The safety key is in its slot in the actuator arm.

STEP 3: INSTALL ACTUATION CABLE AND PIN TO HOOD

•Thread the actuation cable through the conduit, with the pin reaching the unit.

•Remove the grease baffle.

•In the upper corner locate the two pulleys see Figure 14.4 Pulley-Unit)

•Hold the rear-most pulley in place.

•From the top of the unit, replace its pin with the one on the actuator cable.

•Push the pin through the pulley until it clicks in place.

•Re-attach the actuation cable onto the actuator arm.

STEP 4: INSTALL WIRE ROPE CABLE TO PULL FACE

•While the unit is still in service position, attach the wire rope cable to the pull face by

crimping a loop in the wire rope cable through the back side of the handle.

•Ensure the wire rope cable is securely crimped to withstand at least 40 lbs. of pull

force.

•Leave no more than 12” of slack in the line on the pull face end, but maintain 8-12” of

slack.

•Remove the handle by loosening the set screw in one of the studs, and sliding the

red plastic rod out.

•Attach the pull face to the pull box that is already mounted to the wall, collecting any

slack into the pull box.

•Do not allow slack wire rope cable to collect above the hood. (See Figure 14.5 MPK

Front Plate)

Pull Box (X1)

Pull Face (X1)

Elbow Pulley (X3)

Wire Rope Cable

and Pin (25ft)

Figure 14.3

Tank Safety Pin

NOTE: The D1000 hood systems only ship with 25’ of cable; longer sections are not sold;

DFP recommends following installation requirements found in NFPA96 Section 10.5

WARNING: You must allow for 8-12” of slack in the

wire rope cable to sit at the pull face. Failure to do so

will cause the unit to discharge the next time the unit is

lowered into its service position.

Conduit Attachment

mounting bracket

Figure 14.4

Pulley-Unit

Figure 14.5

MPK Front

Plate

Red Plastic

Break Rod

Set Screw

Crimp

D1000 Installation and Service Manual 17

Home LAB-110073 Rev. 2.7

MANUAL PULL STATION (MPK) INSTALLATION

CABLE TRAVELING/DISCHARGE MECHANICS

Positioning the Hood

•Lowering the hood form Normal Operating Position (NOP) to 45⁰Service Position (SP)

▪The stainless-steel rope travels 3.5 inches when lowering the hood from NOP to 45⁰SP

•In order to ease the force required to manually activate the MPK, a momentum of force is suggested

when pulling the cable at the MPK station.

Manual Activation

•Per NFPA 96 Code:

oForce

▪Shall not require more than 178N (40lbs.) of force to activate

•Our system is tested at 15.6 lbs.

oTravel Distance

▪Movement not to exceed 356 MM (14 inches)

▪Since the minimum traveling distance of the SS cable is 3.5 inches and the maximum per code is

14 inches, we recommend 7-10 inches of extra cable slack

oCable Slack Location

▪The extra cable needs to be located at the MPK Station coiled inside of the junction box.

NFPA 96 SECTION 10.5

-

NFPA® 96

Standard for

Ventilation Control and

Fire Protection of

Commercial Cooking

Operations

10.5 Manual Activation

10.5.1 A readily accessible means for manual activation shall be located between 1067 mm. and 1219

mm (42 in. and 48 in.) above the floor, be accessible in the event of a fire, be located in a path of

egress, and clearly identify the hazard protected.

10.5.1.1 At least one manual actuation device shall be located a minimum of 3m (10ft.) and a

maximum of 6 m (20 ft.) from the protected hood exhaust system(s) within a path of egress or at an

alternative location acceptable to the AHJ.

10.5.1.2 Manual activation using a cable-operating pull station shall not require more than 178 N (40

lb.) of force, with a pull movement not to exceed 356 mm. (14 in.) to activate the automatic fire-

extinguishing equipment.

10.5.2 The automatic and manual means of system activation external to the control head or releasing

device shall be separate and independent of each other so that failure of one will not impair the

operation of the other except as permitted by 10.5.3.

D1000 Installation and Service Manual 18

Home LAB-110073 Rev. 2.7

DUCTING AND AIRFLOW

The ductwork and fittings used for outside venting must be carefully selected to ensure that the static pressure is in line

with the fan parameters. The ducting is provided by other and should be specified by the HVAC contractor on the job as

each local requirement may differ.

Please see table below for maximum duct length. The recommended duct length for all “I” models, allows for up to three

90angles.

STATIC PRESSURE TESTING

The magnehelic gauge test port opening is located beneath the grease tray. The static pressure needs to be measured to

ensure air flows meet design criteria. The airflow is measured by attaching the gauge tubing to the magnehelic gauge

inlet, and the hood fitting is attached to the grease drain hole beneath the grease tray.

Refer to chart above to meet design standards. This reading will correspond to the static pressures of the ductwork, hood

and fan combination.

Low High Without With Without With

Standard 62 70 -0.01 -0.09 -0.02 -0.18 174 276

NFPA 60 84 -0.04 -0.26 -0.23 -1.38 216 514

Standard 62 70 -0.01 -0.09 -0.01 -0.17 139 279

NFPA 60 80 -0.03 -0.25 -0.17 -1.35 174 519

Standard 57 69 -0.03 -0.23 -0.11 -0.61 283 474

NFPA 60 70 -0.05 -0.29 -0.20 -0.89 297 545

Standard 56 60 -0.02 -0.14 -0.05 -0.28 208 281

NFPA 60 75 -0.01 -0.10 -0.11 -0.66 172 522

Standard 61 73 -0.07 -0.40 -0.14 -0.84 357 499

NFPA 63 75 -0.08 -0.39 -0.22 -1.09 326 548

CFM

(+ - 2.5%)

Low

High

Fan Speed

Grease Filter

Front

Rear

In-line

Wall Mount

Roof Mount

dB's

PRESSURE (InWater)

Fan Speed

Low

High

Figure 14.12 Magnehelic

Gauge Test Port

WARNING: The static pressure must be

maintained in order for the hood to perform

properly. The grease filter must be in place

when performing the reading.

WARNING: The amount of fittings and ductwork directly a

ff

ects the resistance or static pressure placed on the system. If

the system is not within the proper static pressure range, the heat sensors and controls will be adversely a

ff

ected and will

impact the proper functioning of the safety controls. Therefore it is required that air flow testing be recorded along with

install documentation. The air testing area is accessed by the removal of the grease tray and measured with an air flow

pressure gauge.

Other manuals for D1000

1

This manual suits for next models

5

Table of contents

Other Denlar Ventilation Hood manuals