FATTENTION DWARNUNG

WAARSCHUWING

AVVERTIMENTO

WARNING

Safety regulations require that the set be restored to its original condition

and that parts which are identical with those specified be used.

Veiligheidsbepalingen vereisen, dat het apparaat in zijn oorspronkelijke

toestand wordt terug gebracht en dat onderdelen, identiek aan de

gespecifieerde worden toegepast.

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten.

Der Originalzustand des Gerats darf nicht verandert werden.

Fur Reparaturen sind Original-Ersatzteile zu verwenden.

Le norme di sicurezza esigono che l’apparecchio venga rimesso nelle

condizioni originali e che siano utilizzati pezzi di ricambiago idetici a quelli

specificati.

Les normes de sécurité exigent que l’appareil soit remis a l’état d’origine et

que soient utilisées les pièces de rechange identiques à celles spécifiées.

“Pour votre sécurité, ces documents

doivent être utilisés par des

spécialistes agrées, seuls habilités à

réparer votre appareil en panne.”

GB NL

I

D

I

F

GB

NL

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce life

drastically.

When repairing, make sure that you are connected

with the same potential as the mass of the set via a

wrist wrap with resistance.

Keep components and tools also at this potential.

Tous les IC et beaucoup d’autres semiconducteurs

sont sensibles aux décharges statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution n’est prise

a leur manipulation.

Lors de réparations, s’assurer de bien être relié au

même potentiel que la masse de l’appareil et enfiler

le bracelet serti d’une résistance de sécurité.

Veiller a ce que les composants ainsi que les outils

que l’on utilise soient également a ce potentiel.

Alle IC und viele andere Halbleiter sind

empfindlich gegen elektrostatische

Entladungen (ESD).

Unsorgfältige Behandlung bei der Reparatur

kann die Lebensdauer drastisch vermindern.

Sorgen sie dafür, das Sie im Reparaturfall

dem Massepotential des Gerätes verbunden

sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls

über ein Pulsarmband mit Widerstand mit auf

diesem Potential.

Alle IC’s en vele andere halfgeleiders zijn gevoelig

voor elektrostatische ontladingen (ESD).

Onzorgvuldig behandelen tijdens reparatie kan de

levensduur drastisch doen verminderen.

Zorg ervoor dat u tijdens reparatie via een polsband

met weerstand verbonden bent met apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

Tutti IC e parecchi semi-conduttori sono sensibili

alle scariche statiche (ESD).

La loro longevita potrebbe essere fortemente ridatta

in caso di non osservazione della piu grande

cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello della

massa dell’apparecchio tramite un braccialetto a

resistenza.

Assicurarsi che i componenti e anche gli utensili

con quali si lavora siano anche a questo potenziale.

LASER SAFETY

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDS

Æ

TTELSE FOR STRÅLING

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL Å PNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATT AESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D'OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE

OF PROCEDURE OTHER THAN THOSE SPECIFIED HEREIN

MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

AVOID DIRECT EXPOSURE TO BEAM

WARNING

The use of optical instruments with this product will

increase eye hazard.

Repair handling should take place as much as possible with

a disc loaded inside the player

WARNING LOCATION: INSIDE ON LASER COVERSHIELD

This unit employs a laser. Only a qualified service person should

remove the cover or attempt to service this device, due to

possible eye injury.

100301DM

WARNING AND LASER SAFETY INSTRUCTIONS

WARNING:

Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended

by the manufacturer.

CAUTION:

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2)

a line to chassis resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from

chassis to either side of the power cord is less than 460 kohms, the set is defective.

WARNING:

DO NOT return the set to the customer unless the problem is identied and remedied.

NOTICE:

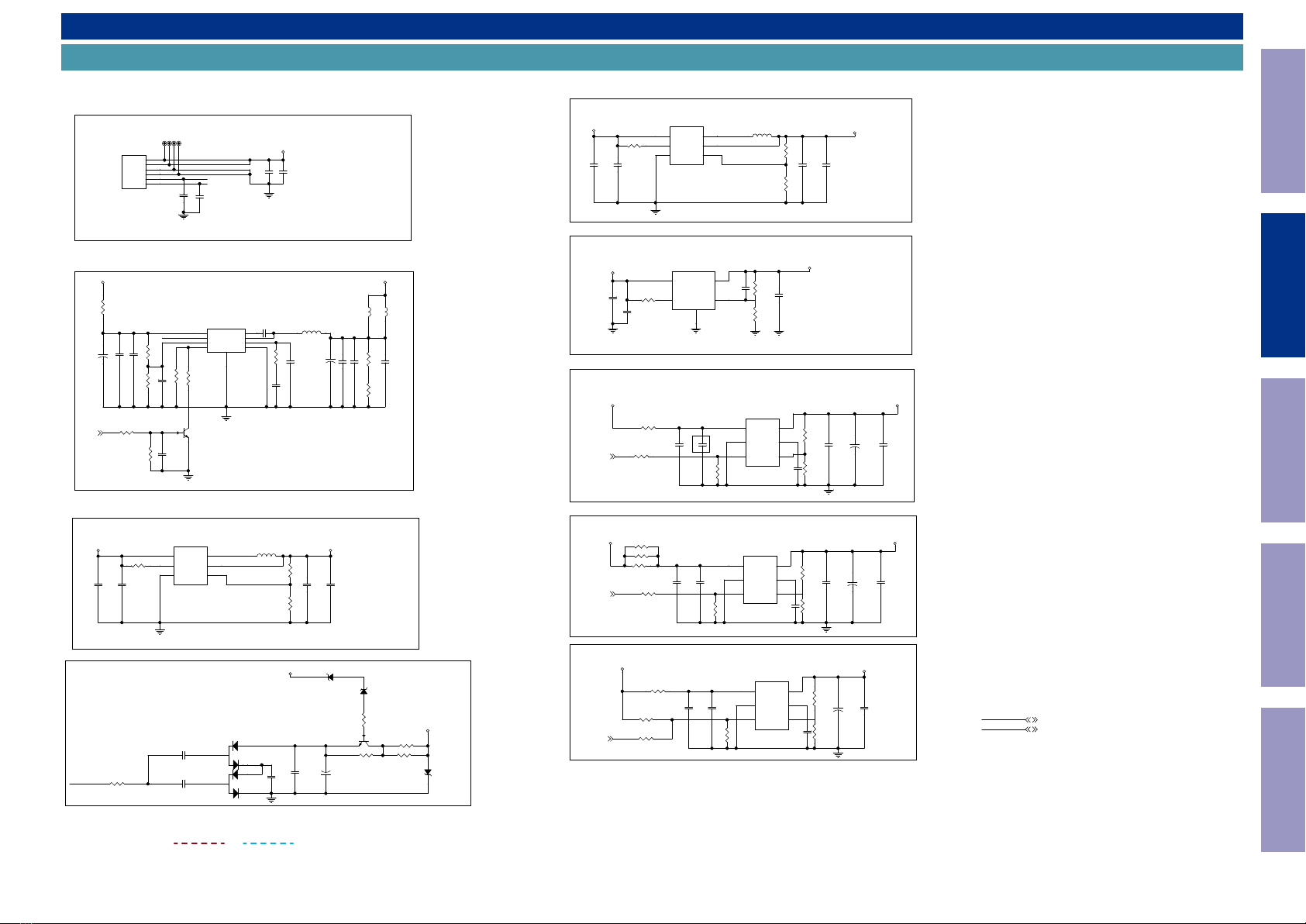

(1) ALL RESISTANCE VALUES IN OHM. k=1,000 OHM / M=1,000,000 OHM

(2) ALL CAPACITANCE VALUES ARE EXPRESSED IN MICRO FARAD, UNLESS OTHERWISE INDICATED. P

INDICATES MICRO-MICRO FARAD. N INDICATES NANO FARAD.

(3) EACH VOLTAGE AND CURRENT ARE MEASURED AT NO SIGNAL INPUT CONDITION.

(4) CIRCUIT AND PARTS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE.

Electrostatic breakdown of the semi-conductors or optical pickup may occur due to a potential differ-

ence caused by electrostatic charge during unpacking or repair work.

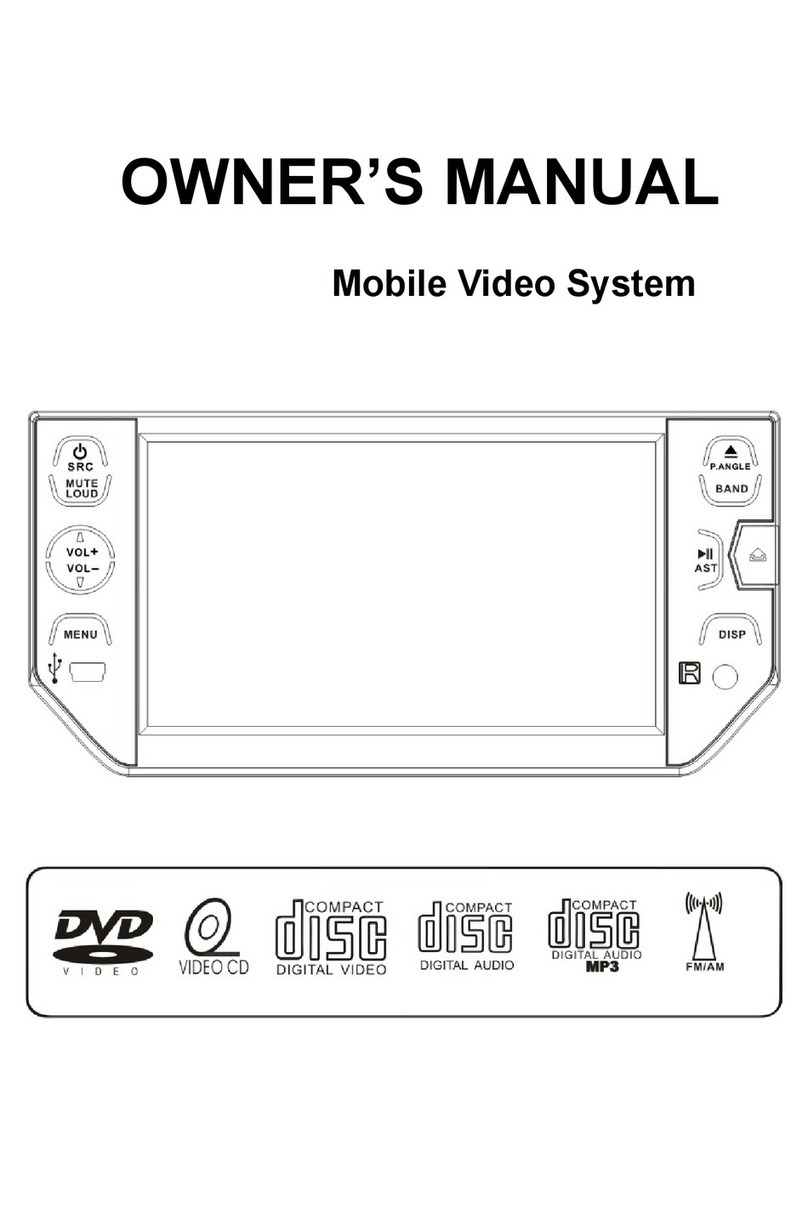

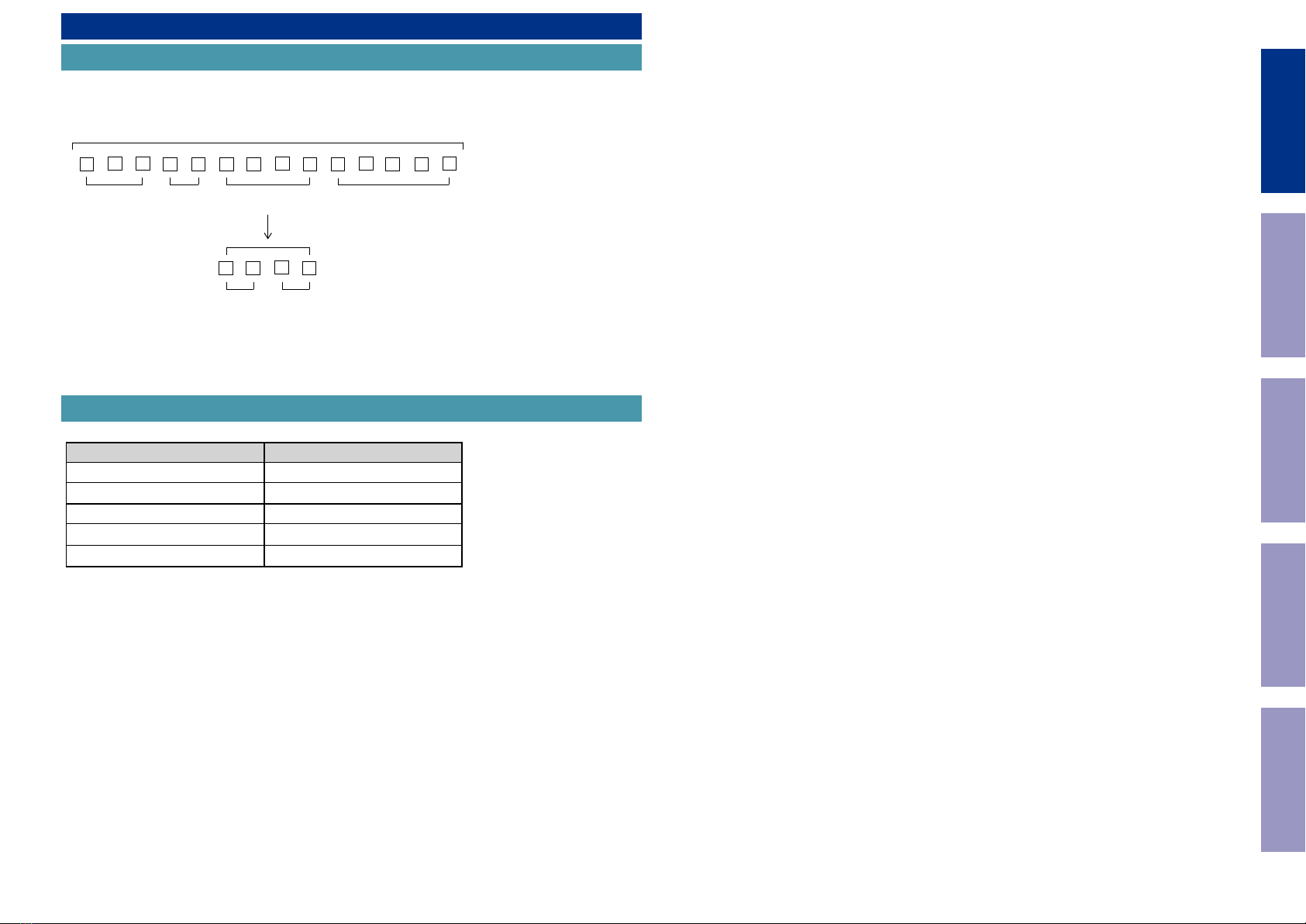

1. Ground for Human Body

Be sure to wear a grounding band (1 M ohm) that is properly grounded to remove any static electricity

that may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate with proper grounding (1 M ohm) on the work-

bench or other surface, where the semi-conductors are to be placed. Because the static electricity

charge on clothing will not escape through the body grounding band, be careful to avoid contacting

semi-conductors with your clothing

<Incorrect>

CBA

Grounding Band

Conductive Sheet or

Copper Plate

1MΩ

1MΩ

<Correct>

CBA

NOTE FOR SCHEMATIC DIAGRAM

HANDLING THE SEMICONDUCTOR AND OPTICS

Before Servicing

This Unit Electrical Mechanical Repair Information Updating

4