10

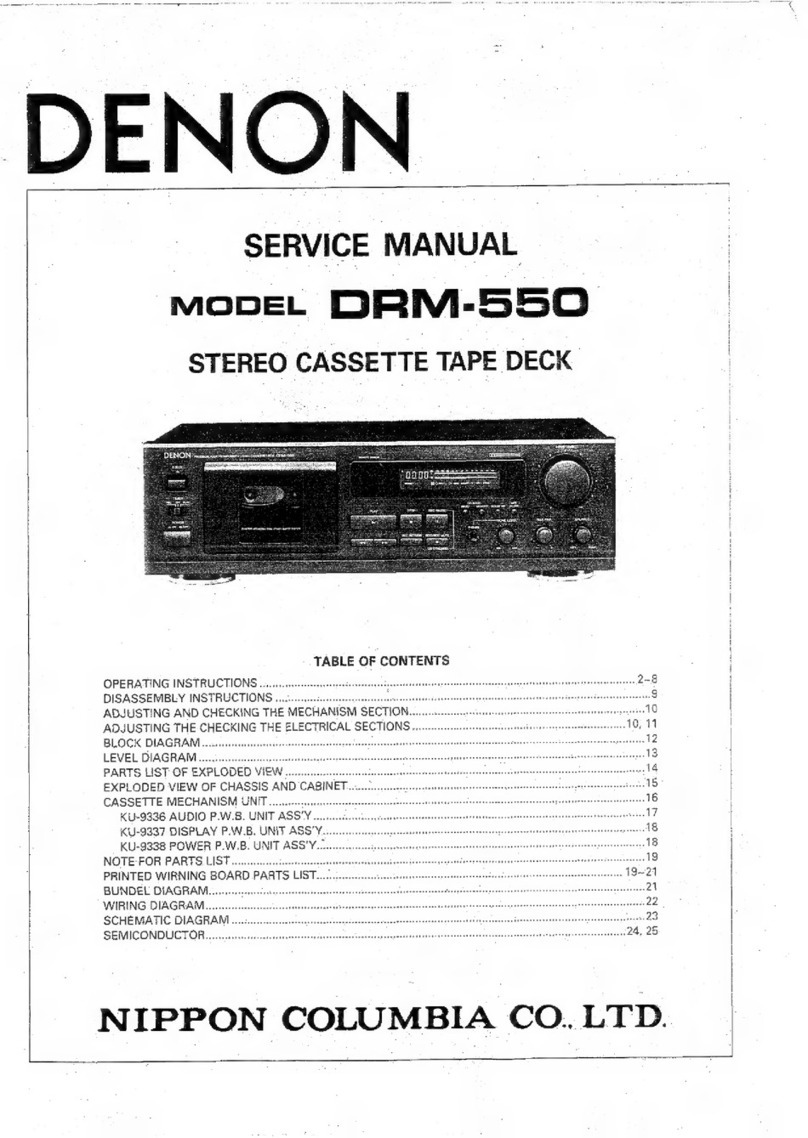

DN-780R

5. Checking the Take-up Torque

Load the cassette type torque meter

FWD side ......... SONY TW2111A

REV side ..........SONY TW2121A

Check to make sure that the average torque meter reading

is within 30 ~ 70g-cm during playback. If it is not within

this range, check the voltage (approx. 4V) of the reel motor.

After the verification, replace the reel motor if there is no

problem with the voltage value.

6. Checking the FF and REW Torques

Load the cassette type torque meter (SONY TW2231).

Check to make sure the torque meter indicates within

90 ~ 180g-cm at the end of FF and REW.

7. Checking the Back Tension Torque During

Record/Playback

Load the cassette type torque meter

FWD side ......... SONY TW2111A

REV side ..........SONY TW2121A

Check to make sure the torque meter reads between

2 ~ 6g-cm during playback and that there is no unevenness.

8. Checking the FF and REW Times

Load a C-60 cassette tape (TDK AC-514); check to make

sure the tape is fast forwarded or rewound within 85 ~

115 seconds. If it is not within this range, check sections 5

and 7.

9. Checking the Operation of the Erase

Prevention, Metal and Chrome Switch

Confirm that the sensor arm properly detecting the tape

type detection holes on the cassette housing.

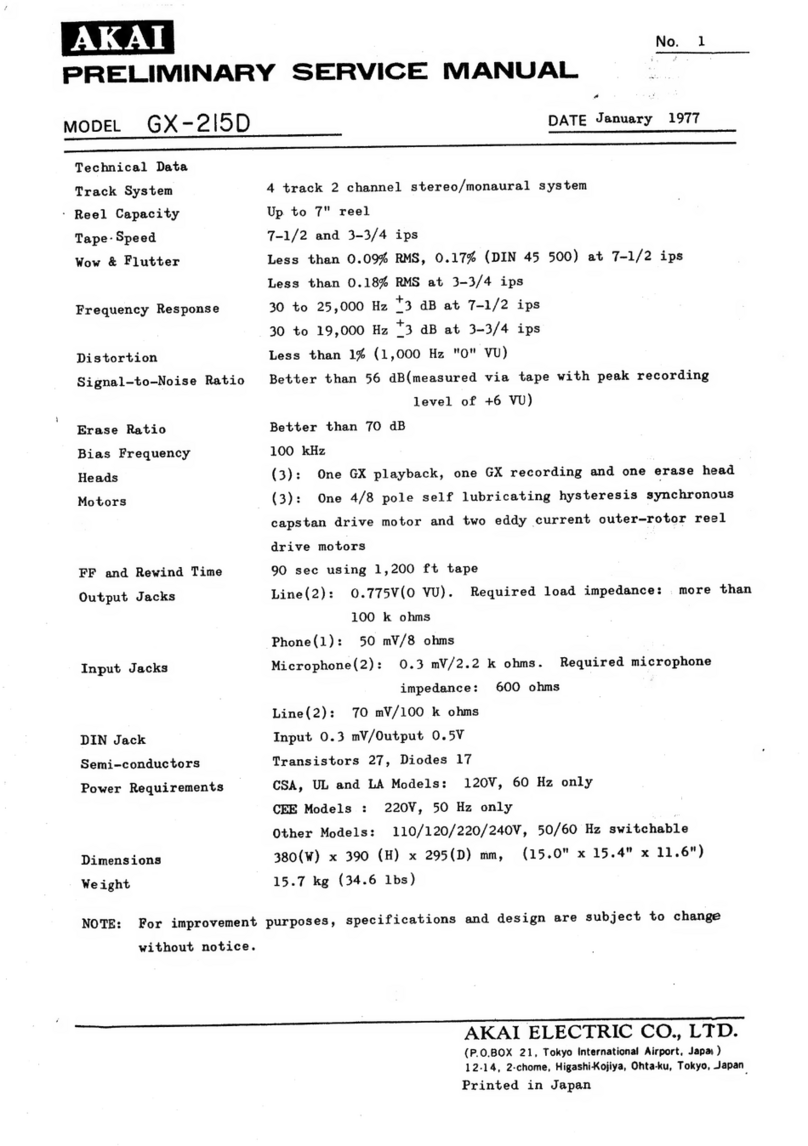

ADJUSTING THE ELECTRICAL SECTIONS

Measuring instruments necessary for

adjustments

(1) Audio signal generator

(2) Variable resistance attenuator

(3) Electronic voltmeter

(4) Oscilloscope

(5) Frequency counter

(6) Adjustment screwdriver.

(7) Trap coil adjustment square stick

(8) Test tapes (SONY TY-224)

(A-BEX TCC-130, TCC-153, TCC-262B/162B)

(TDK AC-514)

(9) Transport Check cassette tape (A-BEX TCC-902)

Caution on adjusting

(1) Before adjusting, clean the head surface, capstan and

the pinch roller with a gauze or cotton swab moistened

with alcohol.

(2) Demagnetize the R/P HEAD and the E HEAD with a

head eraser.

(3) Completely demagnetize the adjustment screwdriver.

(4) Unless instructed otherwise, set the various controls

as follows:

INPUT volume ....................... maximum

DOLBY NR button ................. OFF

TAPE SPEED-A (-B) ............. Center click position

PHONES SELECT ................ MIX

INPUT SELECT .................... LINE B

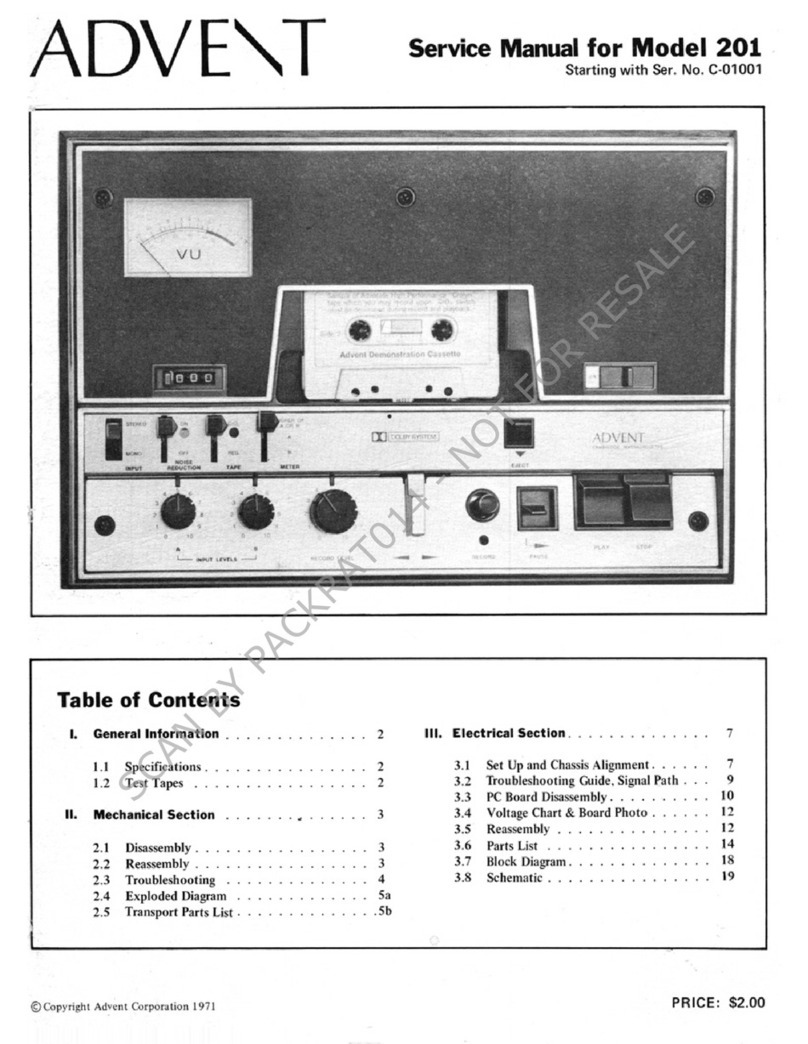

1. Tape Transport Check

Load the transport check cassette. In the operational mode,

illuminate the fixing guides of the R/P HEAD with a lamp

and check to make sure the tape edge does not come in

contact with the tape guide section.

The tape transport is the most important element in

determining the performance of a cassette deck.

Avoid moving the various adjustment screws, nuts, etc.,

as much as possible. Refer to the pages on "Adjusting

and Cheking the Mechanism Section" when replacing or

adjusting the R/P HEAD.

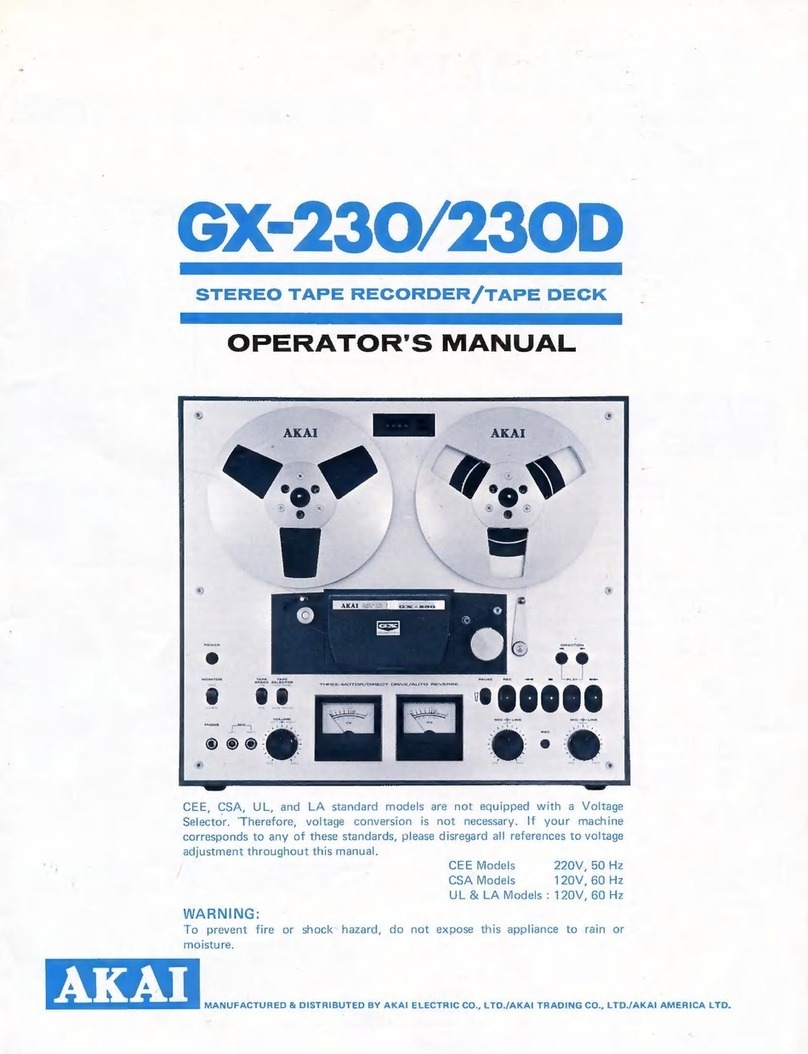

2. Adjusting the Azimuth

(1) After completing the tape transport check, load the

test tape (A-BEX TCC-153).

(2) Playback (both FWD side and REV side) the test tape;

adjust the azimuth screw so that section A of the

Lissajous waveform is maximum and section B is

minimum.

L

R

PB Amp

A-BEX TCC-153

LINE OUT

V

H

A

B

FWD REV

R/P Head