DENRYO GD300 User manual

Sine Wave Power Inverter

GD300 Series

User’s Manual

Ver.1.01E

2

Table of Contents

1. Safety Instructions........................................................................3

2. General Information......................................................................4

3. GD300 Inverter Features.............................................................5

3-1 Specification...............................................................................................................5

3-2 De-rating Curve ..........................................................................................................6

3-3 Dimension...................................................................................................................7

3-4 Control Panel..............................................................................................................7

4. Installation and Wiring Connections.......................................8

4-1 Installation Guide .......................................................................................................8

4-2 Wiring Connections....................................................................................................8

4-3 Setting Confirmation................................................................................................10

4-4 How to Start Up ........................................................................................................10

5. Functions........................................................................................ 11

5-1 Change Settings.......................................................................................................11

5-2 The Indicators of setting during operation ............................................................12

5-3 The Protective Function...........................................................................................12

5-4 Remote Connector ...................................................................................................14

5-5 Optional Terminal.....................................................................................................14

6. LED Indicators ..............................................................................15

6-1 The LED Indicator in Normal Status .......................................................................15

6-2 The LED Indicators when Protective Function Activates .....................................16

7. Troubleshooting Guide...............................................................17

Sine Wave Power Inverter GD300 User’s Manual ©2017 DENRYO CO., LTD. All Rights Reserved. No parts

of this document may be reproduced in any form without the prior written approval of DENRYO CO., LTD.

©2017 DENRYO CO., LTD. All Rights Reserved.

3

1. Safety Instructions

This document contains the important safety and operating information for GD300 Inverter. To get most

out of the Pure Sine Wave Inverter, carefully read, follow this guide, and save these instructions. Pay

attention to the Safety Instructions and the CAUTION and WARNING statements found throughout the

manual and on the product.

Precautions During Installation

・To avoid the risk of electric shock and fire, ensure adherence to proper electrical wiring regulations. Do not

disassemble the GD300 Inverter.

・Do not expose the GD300 Inverter to rain, snow, dust or to the places with high humidity.

・Do not install the GD300 Inverter in the environments with high temperature, near a fire, or under sun

exposure directly.

・During the operation of GD300 Inverter, the temperature of the products may become higher. Be

careful while moving or removing the products.

・To avoid covering or obstructing the ventilation openings, do not to place any objects closer than 15

cm near the Inverter.

・To avoid overheating, do not place any stuff on the product.

・To connect with more than one battery, do use the same products of batteries from the same

manufacturer. Connecting different products of batteries at the same time is dangerous.

・Batteries generate explosive gases during normal battery operation. Never smoke or allow a spark or

flame in vicinity of battery.

・This equipment contains components which can produce arcs or sparks. To prevent fire or explosion,

do not install in compartments containing batteries or flammable materials.

CAUTION

Since the battery deteriorates over time, a maintenance on a yearly

basis is recommended. Replace the deteriorated battery to prevent the

hazard of fire.

WARNING

This sign indicates the following contents includes the important

information. The wrong order of handling may lead to the risk of death

or seriously injured.

CAUTION

This sign indicates the following contents includes the important

information. The wrong order of handling may cause damage to the

products and the surrounding stuff.

MEMO

This sign indicates the following contents includes the important

information of the manuals of functions which contains

the safety

instructions or the proper operation of the product.

4

2. General Information

GD300 Inverter is a pure sine wave inverter that converts DC voltage to AC since wave voltage. The output

waveform is as same as the sine wave of commercial power supply, of which the total harmonic distortion

is less than 3%. High efficiency circuit and switching control achieved 90% efficiency at rated load. Without

a built-in fan, the GD300 Inverter cools down by natural convection and has reduced the size of the

products as well as kept quiet during operation. Moreover, the GD300 Inverter is equipped with abundant

protective functions. Even the input polarity is reversed whereas the internal circuit does not be damaged.

With the capability of operating under the wide input voltage range, temperature range and to turn on or

off remotely, the GD300 Inverter could be used in various environments and applications.

Features

・Protecting the input reverse polarity by its internal circuit

・Fan-less quiet operation (natural convection)

・The wide range of operating temperature(-20~60℃)

・Switching output voltage/frequency easily by button

・Pure sine wave output (total harmonic distortion less than 3%)

・Light weight and thin design

・High efficiency (90% efficiency at rated load)

・Built-in remote-control function

・Easy understanding LED indicators

・Abundant protective circuit: Input voltage warning, shut down/Input reverse polarity/

Output voltage/Output short circuit/Overload/Overtemperature

・Buzzer ON/OFF, LED brightness switchable

・Wide input voltage range

・Input system voltage of 12V/24V/48V 3 lineup

・Input terminal cover for dust prevention

・Optional communication function (T. B. D.)

Safety and EMC Certified

Safety standards :EN60950-1:2006/A2:2013

Immunity standards :EN55024:2010

Emission standards :EN55032:2012, FCC class A Part15

FCC Requirements

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interference in which case the user will be required to correct

the interference at his own expense.

5

3. GD300 Inverter Features

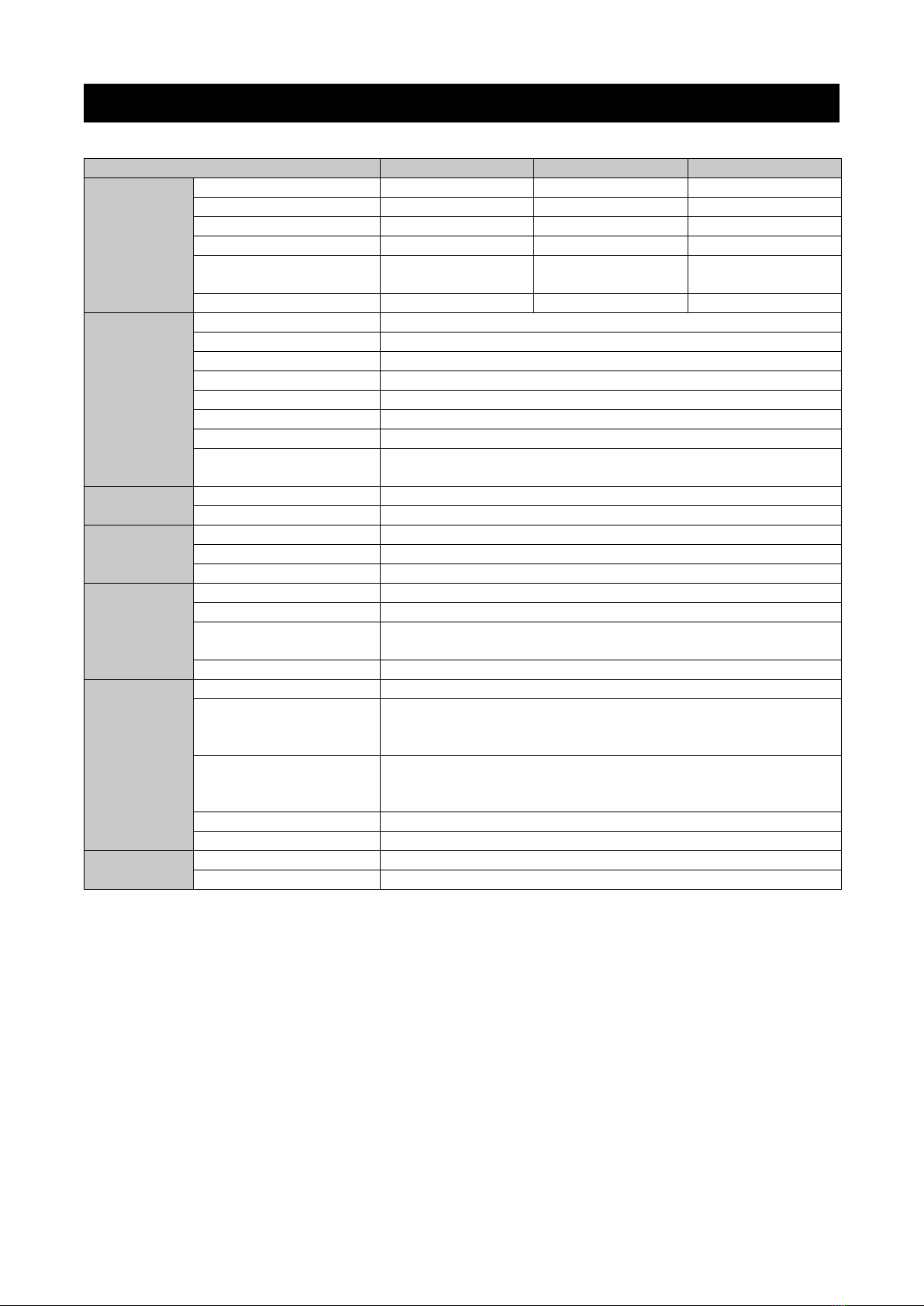

3-1 Specification

MODEL

GD300NA-112

GD300NA-124

GD300NA-148

Input

Battery Voltage

12V

24V

48V

Voltage Range*'

10.5~17Vdc

21~34Vdc

42~68Vdc

Current Range

20~32 A

10~16 A

5~8 A

No-load Current

0.7 A

0.4 A

0.2 A

Standby Mode

Consumption

8mA 7mA 5mA

Efficiency at Rated Load

90%

90%

90%

Output

Rated Power

300VA

Peak Power(3min.)

360VA, refer to 3-2 de-rating curve

Surge Power(3sec.)

420VA

AC Voltage

100 default, 110/115/120Vac, switchable

Frequency

50±0.1Hz default, 50/60Hz, switchable

Waveform

Sine Wave, <3%THD

Voltage Tolerance

±3.0%

LED indicators

Operating status, Battery voltage level, Output power level,

Protection function, Operation setting

Function

Remote-control

Output remote ON/OFF control terminal

Option terminal

six-position four-conductor (6P4C) modular jack

Protection

Input

UVP*², OVP*³, input reverse polarity

Output

OLP*⁴, SCP*⁵, output voltage error

Others

OTP*⁶, detect by internal temperature sensors

Environment

Operating Temperature

-20~+40

℃

at rated load, +60

℃

at 70% load, refer to 3-2 de-rating curve

Operating Humidity

20~90%RH non-condensing

Storage Temperature/

Humidity

-30~+70℃, 10~95%RH

Vibration

10~500Hz, 3G 10min./ 1cycle, 60mins. XYZ axes

Safety &

EMC

Safety Standards

Certified EN60950-1:2006+A11+A1+A12+A2

Withstand Voltage

Battery I/P-AC O/P: 3.0kVac

AC O/P–Ground: 1.5kVac

Battery I/P– Ground:1.5kVac

Isolation Resistance

Battery I/P–AC O/P: >1000MΩ/500Vdc/25

℃

/70% RH

ACO/P –Ground: >1000MΩ/500Vdc/25℃/70% RH

Battery I/P – Ground: >1000MΩ/500Vdc/25

℃

/70% RH

EMC Immunity

EN55024:2010

EMC Emission

EN55032:2012, FCC class A

Others

Dimension

234.0×146.5×44.0mm (L×W×H)

Weight

1.0kg

All parameters NOT specially mentioned are measured at 112:12Vdc, 124:24Vdc, 148:48Vdc input, 300VArated load, power

factor=1.0, 25°C of ambient temperature and under the default setting.

*' Tolerance of voltage: 112±0.5V, 124:±1V and 148:±2V.

*² UVP: Under Voltage Protection.

*³ OVP: Over Voltage Protection.

*⁴ OLP: Over Load Protection.

*⁵ SCP: Short Circuit Protection.

*⁶ OTP: Over Temperature Protection.

6

3-2 De-rating Curve

According to the system and environment that products are used in, the Inverter is still under the protection

of OLP or OTP even in the range of de-rating curve. Since this feature of the Inverter, please design the

system with more allowance. Refer to the graph above, the input voltage will be double under 24V model

and 4 times more under 48V model.

7

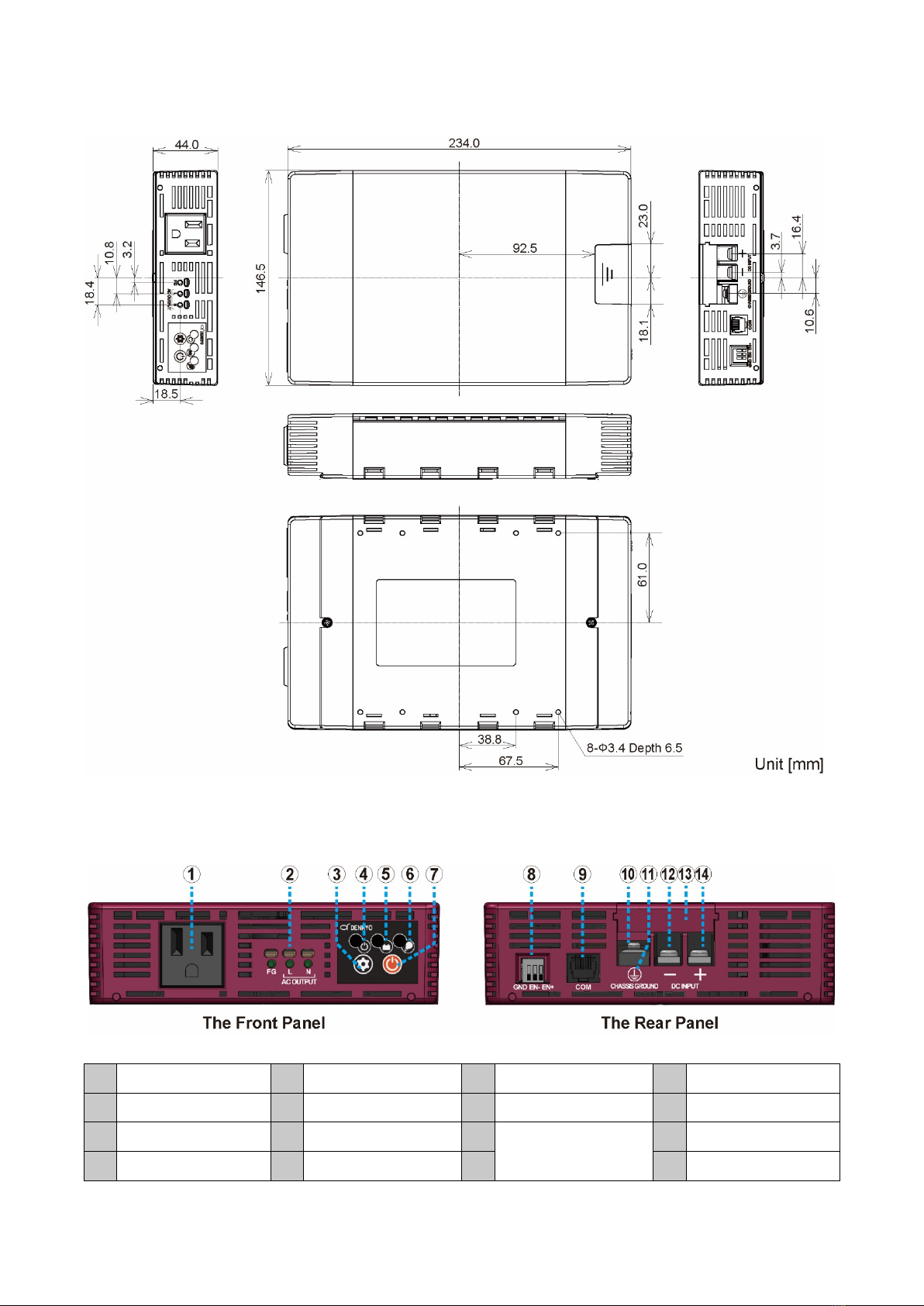

3-3 Dimension

3-4 Control Panel

○

1AC Outlet

○

2AC Output Terminal

○

3Setting Button

○

4Power LED

○

5Battery LED

○

6Load LED

○

7Power Button

○

8Remote Connector

○

9Optional Terminal

○

10 Grounding Terminal

○

11 Reversed Connection

Warning LED

○

12 Battery Input (-)

○

13 Terminal Cover

○

14 Battery Input(+)

8

4. Installation and Wiring Connections

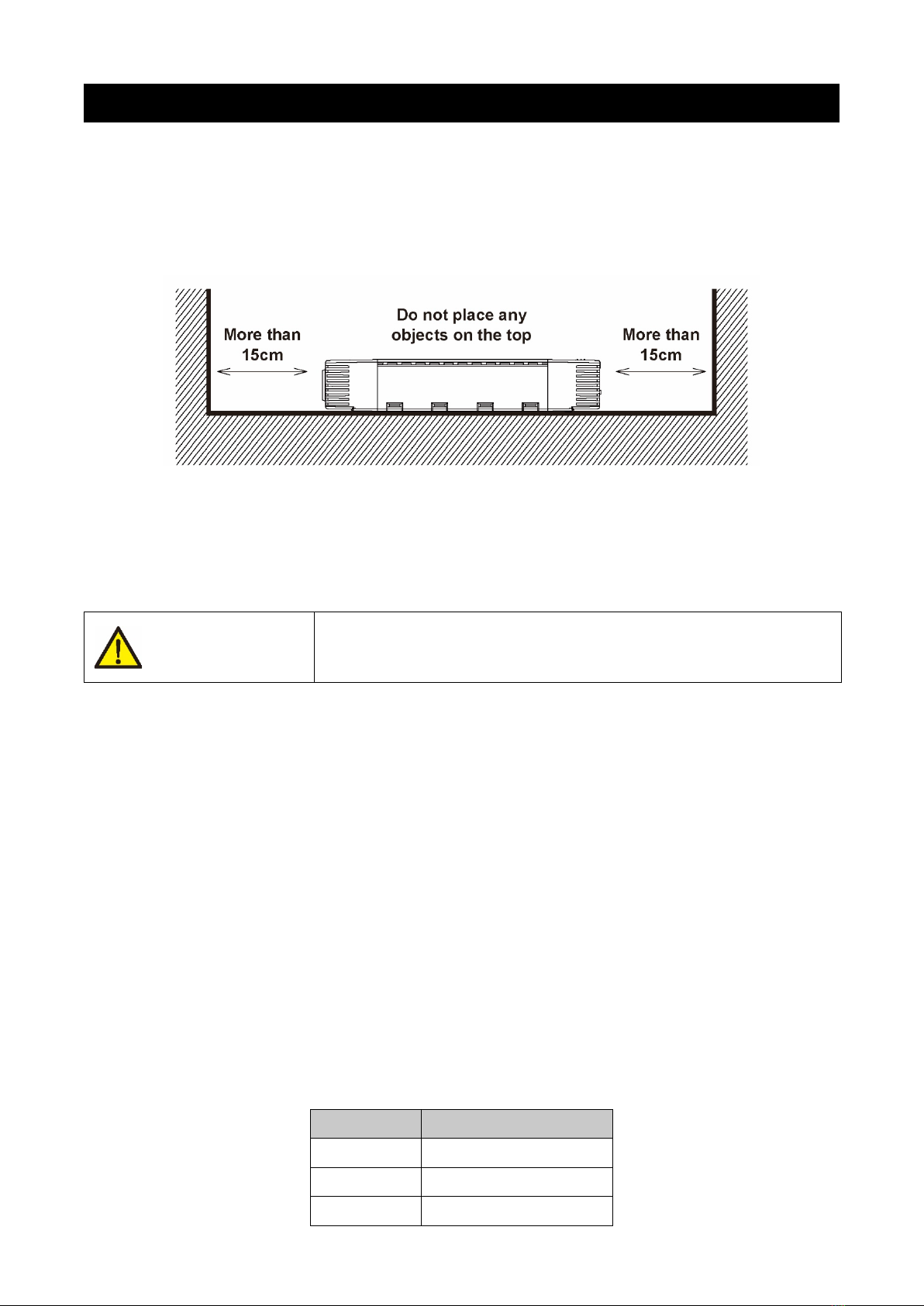

4-1 Installation Guide

Recommended installation location: Locate the GD300 Inverter on a flat place or rack with sufficient

strength. Avoid mounting in a dusty environment or a location with high temperature. Avoid using the

Inverter in a high temperature environment. For ventilation, do not mount any objects within 15 cm around

the inverter.

Figure 4.1 The example of installation

Recommended installation Regulation: Refer to 3-3 Dimension, there are 8 holes, Φ3.4mm, and depth

6.5mm, in the bottom of the Inverter, which could be utilized when installing the Inverter. It is recommended

to install the Inverter horizontally with the ground.

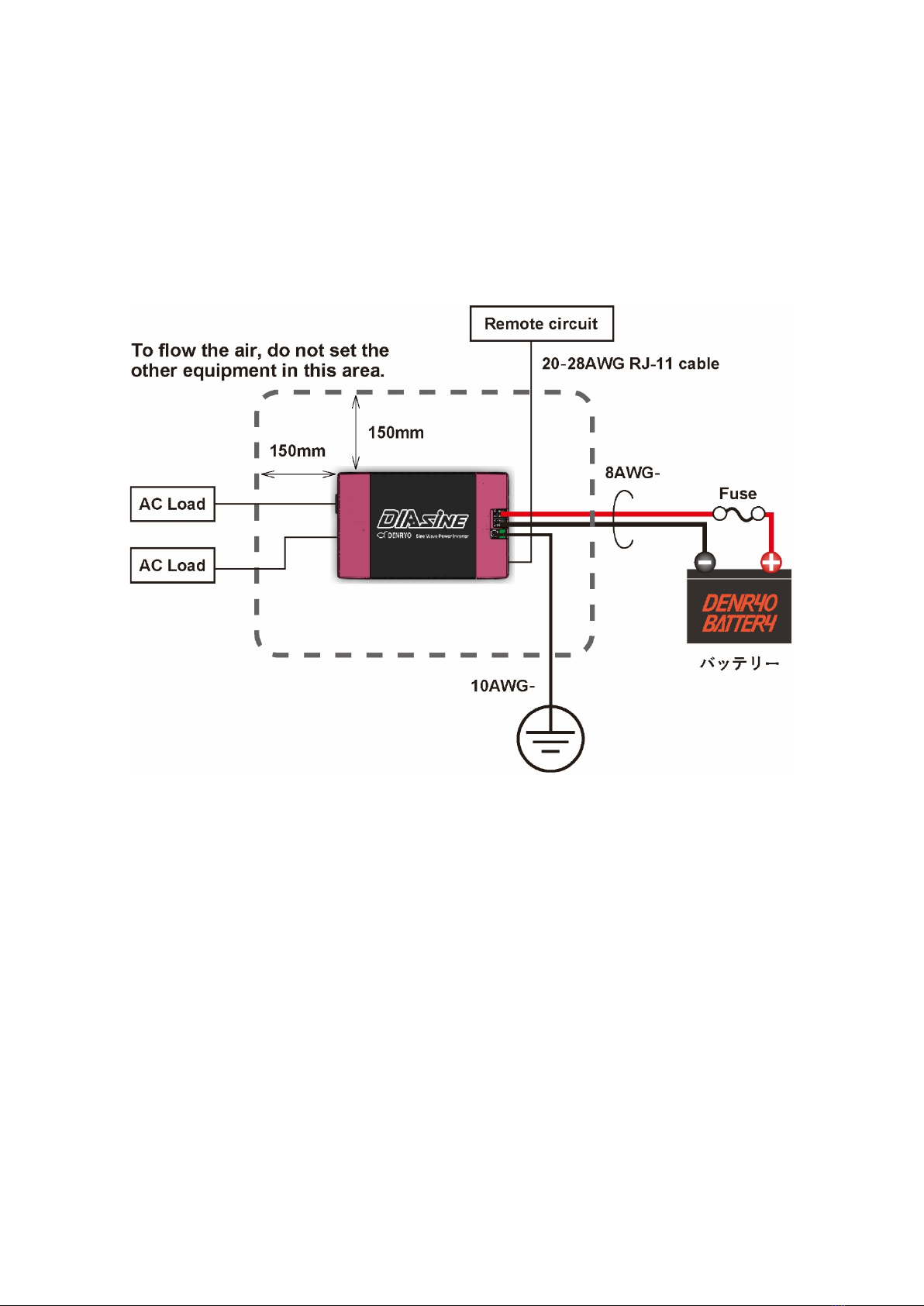

4-2 Wiring Connections

To make Battery wiring connections:

Remove the cover of the terminal on the rear side of GD300 Inverter, and wire it to the battery input terminal.

When removing the cover, slide while pushing the terminal cover toward the bottom. Mount a fuse in the

plus side wiring. Please refer to Table 4.1. to select the fuses based on the system. Please use suitable

wiring cable for power supply terminal. The screw size of battery input terminal is M4; the width of the

terminal is 9 mm. The cable size recommended to be used at rated load is 8 AWG; the torque

recommended for installation is 1.5 N · m. Using too thin cable may lead to overheating or ignition of cable.

The length of Battery wiring connection should be as short as possible that within 1.5 m is recommended.

Before continuing Battery wiring connection, check the power LED in front of GD300 is lighting orange.

Check the voltage of Battery if not lighting. Further, if the polarity of Battery is reversed, the reverse

connection warning LED near the grounding terminal in the rear of the GD300 Inverter lights red. Please

correct the polarity and check if the reverse connection warning LED is off.

Table 4.1 Fuse recommended

Model Current

112 Under 40A

124 Under 20A

148 Under 10A

CAUTION

Burns Hazard.

During operation, the temperature of GD300 Inverter will get higher. Be

careful not to touch it.

9

To make the grounding wire connection:

Connect from the grounding terminal in the rear of GD300 Inverter to the system is being used. The screw

size of the grounding terminal is M5; the width is 14mm. Please use solderless terminals, like R5.5-5S,

and fasten it with a screw. The cable size of 10AWG and torque 2.0 N・m is recommended.

To make load wire connection:

Connect the load from the AC outlet in the front of the GD300 Inverter or the AC output terminal. Choose

to use the cable with proper withstand voltage of AC output terminal when connecting the AC output

terminal. The VVF1.6 cable is recommended to be used here. It is connected by inserting the cable, which

is peeled off the cover, into the hole which is marked as AC OUTPUT on the front panel. The length to peel

off is around 15-20 mm and make the part which the cover has been peeled off could not be seen from

outside. Make sure that the wire connected to line (L) and neutral (N) is not short-circuited after connection.

When removing the cable, insert a flathead screwdriver in the oval hole above the cable insertion hole,

and pull the cable while pressing the flathead screwdriver to remove it.

DO NOT short the line and the neutral. Make sure the connection of the line and the neutral is correct in

your system when using both the outlet and the terminal of the Inverter.

Precautions about load:

Inverter is able to operate at most of loads under AC environment. However, even continuously suppling

300VA, there is a possibility that Inverter may not operate properly at some loads.

(1) An extremely large current, around 6~10 times more than at rated load, is required for Inverter

to startup at inductive load or the motor. The Inverter may not be able to startup normally in the

case. Please check the amount of peak current at load before choose Inverter.

(2) To ensure the complete startup of the Inverter, when connecting with a capacitive load or a

rectifier such as switching power supply, do not activate the load while the Inverter startup.

Alternatively, start up the Inverter with a smaller load and increase load afterward. If connecting

with more than two loads, please activate one load at once after the Inverter started up.

WARNING

Explosion Hazard

The short of Battery is very dangerous. Make the wire connection of

input terminal of GD300 Inverter before connecting the Battery.

CAUTION

Terminal damage.

Pressing the flathead screwdriver obliquely and strongly, the terminal

may be damaged.

WARNING

Shock Hazard

Make sure the core wire does not expose to the outside. Moreover,

when connecting the AC terminal, be sure to connect it without output

voltage.

10

To make Remote Connecter wire connection:

By the function of remote connecter in the rear of GD300 Inverter, it is able to turn the output ON/OFF

without pressing power button. Please refer to 5-4 Remote Terminal. The recommended size of cable for

remote connecter is 20~28AWG.

To make Optional Terminal wire connection:

The optional terminals in the rear of GD 300 Inverter uses a six-position four-conductor (6P4C) modular

jack to adapt to various application. Check DENRYO Official Website for more details.

Figure 4.2 System Wiring Diagram

4-3 Setting Confirmation

The default setting is output voltage 100Vac, output frequency 50Hz, buzzer ON, and normal mode of the

LED brightness. Pressing the setting button on the front panel to change the settings, refer to Chapter 5-

1 Change Settings. Settings remain even the Battery went out its power.

4-4 How to Start Up

Keep pressing the power button on the front side of the Inverter for around 1 second. Make sure the

Inverter is not under the protection mode by checking the LED indicators and turn on the load. The

introduction of LED indicators during operation please refer to Chapter 6 LED Indicators.

11

5. Functions

5-1 Change Settings

1. Connect with battery and set the GD300 Inverter to the standby status the power LED is lighting

in orange and other LEDs are off. Do not connect anything to AC outlet and AC output terminal.

2. Pressing the setting button in the standby status, the current setting will display around three

seconds. To change the setting, press and hold the setting button. Hold down the button for

about two seconds, and a buzzer sound* comes from the Inverter while only the power LED

indicator lights. Release the setting button and proceed to the next step.

*The Inverter does not sound once the buzzer is setting OFF.

3. Check the output frequency setting refer to Table 5.1. Press the setting button to select the color

of power LED until it matches the color of output frequency you choose. Hold the setting button.

4. Check the battery LED in the center of the Inverter is lighting. Refer to Table 5.1, press the setting

button to select the color of battery LED until it matches the color of output voltage you choose.

Hold the setting button.

5. Check only the load LED on the right side of the Inverter is lighting. Refer to Table 5.1, press the

setting button to select the color of load LED until it matches the buzzer setting ON/OFF and the

LED brightness you choose. Press and hold the power button for more than 2 seconds to

complete the settings and back to the standby status. If pressing and holding the setting button

before holding down the power button, the setting mode begins again from the output frequency.

6. Press the setting button. Check the Inverter is the same as the setting you chose.

Figure 5.1 The LED and settings button

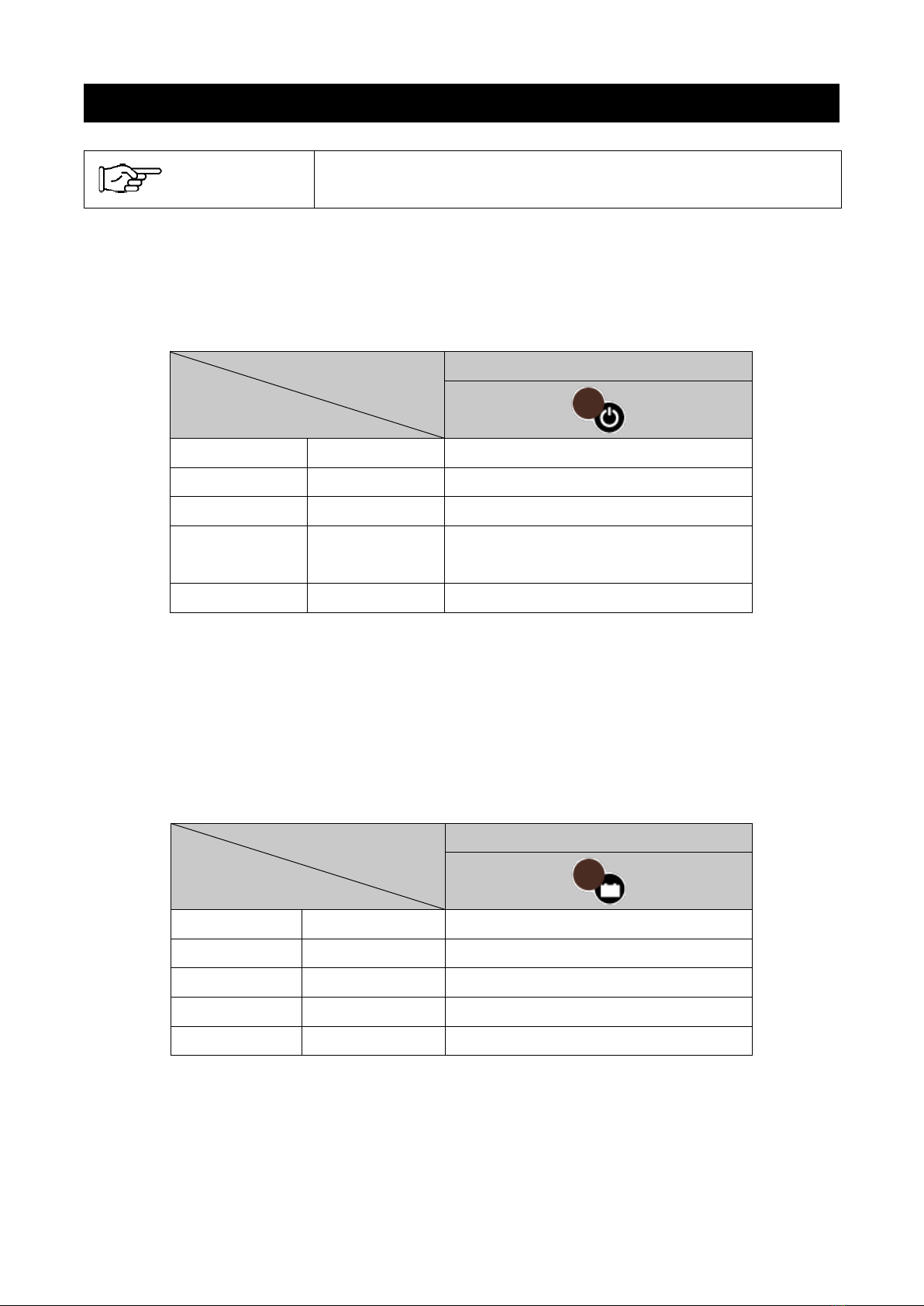

Table 5.1 The LED color of settings

LED

LED Color

Power LED Battery LED Load LED

Green

●

50Hz 100Vac Buzzer ON, bright LED

Yellow

●

60Hz 110Vac Buzzer ON, dark LED

Blue

●

- 115Vac Buzzer OFF, bright LED

Purple

●

- 120Vac Buzzer ON, dark LED

12

5-2 The Indicators of setting during operation

It is possible to check the current settings during operation by pressing the setting button, refer to Table

5.1. Settings are not able to be changed during operation.

5-3 The Protective Function

To prevent error operation, GD300 Inverter is equipped with the following functions.

A. Reversed battery polarity protection: The reverse warning LED near the grounding terminal in the

rear of GD300 Inverter lights red when the battery polarity is reversed. Please unconnected the

wire and connect with the correct polarity.

B. Battery low voltage protection: When the battery voltage falls below the value of low voltage

warning, the buzzer sounds three times consecutively around every 5 seconds. When the battery

voltage falls below the shut off value of low voltage, the Inverter automatically shuts off the output,

the buzzer sounds five times consecutively around every 5 seconds, and battery LED blinks red.

When the battery voltage reaches or exceeds the low voltage recovery value, it automatically

resumes output. The buzzer does not sound when the buzzer is setting OFF.

C. Battery overvoltage protection: If the battery voltage is higher than the overvoltage warning value,

the buzzer sounds three times consecutively around every 5 seconds. When the battery voltage is

higher than the shut off value of overvoltage, the inverter automatically shuts off the output, the

buzzer sounds five times consecutively around every 5 seconds, and the battery LED lights red.

When the battery voltage falls below the overvoltage recovery value, it automatically resumes

output. The buzzer does not sound when the buzzer is setting OFF.

D. Overtemperature protection: When the internal temperature of the Inverter becomes higher than

the overtemperature warning value, the buzzer sounds three times consecutively around every 5

seconds. When the internal temperature rises further, the overtemperature protection works and

automatically shuts off the output, the buzzer sounds five times consecutively around every 5

seconds, and the power LED lights red. When the internal temperature falls below the value, the

Inverter automatically resumes output.

CAUTION

Damage Hazard

Please use a battery matching the input voltage range with the Inverter.

If using a 12V battery with a 24V model that the voltage of the battery is

lower than the input voltage range, the Inverter will not operate.

Conversely, if using a 48V battery with a 24V model that the voltage of

the battery is higher than the input voltage range, the Inverter may be

damaged.

13

E. Output voltage error protection: When the AC output voltage is too high or too low, the inverter

shuts off the output, the buzzer sounds five times consecutively around every 5 seconds, and the

load LED lights red. To cancel the protected status, please restart the Inverter.

F. Output short circuit protection: When the output terminal of the Inverter is short-circuited or the

load suddenly increases, the Inverter cuts off the output, the buzzer sounds five times continuously

every 5 seconds, and the load LED lights red. To cancel the protected status, please restart the

Inverter.

G. Overload protection: When the output is within the range of 300 to 360 VA, continues for about 3

minutes or more, and the output continues for about 3 seconds at 360 VA or more, the overload

protection is activated to cut off the output and the buzzer. The buzzer sounds five times

consecutively every 5 seconds, and the load LED lights red. To cancel the overload protected

status, please restart the Inverter.

Refer to Table 5.2 for the input voltage setting value of protective function in each model activates and

resumes. Also, refer to 6-2 LED indicator of protective function status for LED indicators during protective

function activates.

Table 5.2 The input voltage setting value of protective function

Low voltage Overvoltage

Model Warning Shut off Resume Warning Shut off Resume

112 11.5Vdc 10.5Vdc 12.5Vdc 16.5Vdc 17.0Vdc 16.5Vdc

124 23.0Vdc 21.0Vdc 25.0Vdc 33.0Vdc 34.0Vdc 33.0Vdc

148 46.0Vdc 42.0Vdc 50.0Vdc 66.0Vdc 68.0Vdc 66.0Vdc

When the warning and protective function activated, the buzzer could be set OFF by pressing the setting

button. If the buzzer has been set OFF by the setting button, the buzzer will sound again once other

warning or protective function activated again. Moreover, even the warning status is cancelled, the buzzer

will sound again once the Inverter activated the warning status again.

Example 1. The low voltage warning activated and the buzzer was beeping. The buzzer has been set

OFF by setting button. The buzzer beeps again when the Inverter shuts off because of low

voltage protection.

Example 2. The overtemperature warning activated and the buzzer was beeping. The buzzer has been

set OFF by setting button. After the temperature dropped and the warning was released,

the buzzer beeps again once the temperature warning activates again.

If you want to set OFF the buzzer anytime, please change the settings to stop the buzzer, refer to Chapter

5-1.

MEMO The protected status can be canceled by turning the output ON/OFF by

remote connector. Please cancel the protected status after checking the

cause of protected status has been removed.

14

5-4 Remote Connector

As the figure 5.4 method 1, inverter output can be turned ON by inputting the battery voltage to the

ENABLE+ (EN+) terminal of the remote connector. The Inverter activates the standby status when input

disappears. As the figure 5.4 method 2, inverter output can be turned on by connecting the ENABLE-

(EN-) terminal and the GND terminal. When the EN- terminal and GND terminal are disconnected, the

Inverter activates the standby status. The power LED lights blue when the Inverter output is turned on by

the remote connector. The Inverter can be controlled either by method 1 or method 2.

When the Inverter was turned on by EN+ terminal or EN- terminal input, pressing the power button will

turn the Inverter into standby status. Even if pressing the power button in this state, output cannot be

turned on unless the EN + terminal or EN - terminal input disappears once.

Figure 5.4 The wiring of remote connector

5-5 Optional Terminal

The GD300 Inverter is able to achieve various application by using the optional terminals on the rear of

the Inverter. Check DENRYO Official Website for more details.

15

6. LED Indicators

6-1 The LED Indicator in Normal Status

Power LED: Power LED indicates the ON/OFF status of output or the overtemperature warning status.

Refer to Table 6.1 for the indicators of LED colors and the status.

Table 6.1 Power LED Indicators

LED

LED Colors

Power LED

Orange

●

Standby

Blinking orange

●●●●●

Standby (*)

Green

●

Power ON

Blue ●Power ON

Remote is operating

Blinking yellow

●●●●●

Overtemperature warning

*When the inverter was turned on by remote connector, and is turned off by the power button, the Power

LED blinks orange. In the case, the inverter cannot be turned on again unless the remote connector is

once removed.

Battery LED: Battery LED indicates the voltage value of battery during operation. Refer to Table 6.2 for the

indicators of LED colors and voltage value of battery. The voltage value of 124 and 148 models is double

and 4times more than the value listing below.

Table 6.2 Battery LED Indicators

LED

LED Colors

Battery LED

Blinking yellow

●●●●●

Input voltage 10.5-11.5Vdc

Yellow

●

Input voltage 11.5-12.0Vdc

Green

●

Input voltage 12.0-14.0Vdc

Blue

●

Input voltage 14.0-16.5Vdc

Purple

●

Input voltage 16.5-17.0Vdc

Load LED: Load LED indicates the percentage of output power during operation. Refer to Table 6.3 for the

indicators of LED colors and the percentage of output power.

Table 6.3 Load LED Indicators

MEMO The blinking frequency of each LED indicator is once in two seconds,

repeat lighting and off.

16

LED

LED Colors

Load LED

Blue

●

0-40% output power

Green

●

40-70% output power

Yellow

●

70-100% output power

Blinking yellow

●●●●●

Over than100% output power

6-2 The LED Indicators when Protective Function Activates

When the GD300 Inverter activates the protective function, LED indicates the status of the protective

function and cut off outputting. Refer to Table 6.4 for the LED indicators and the status of protective

functions.

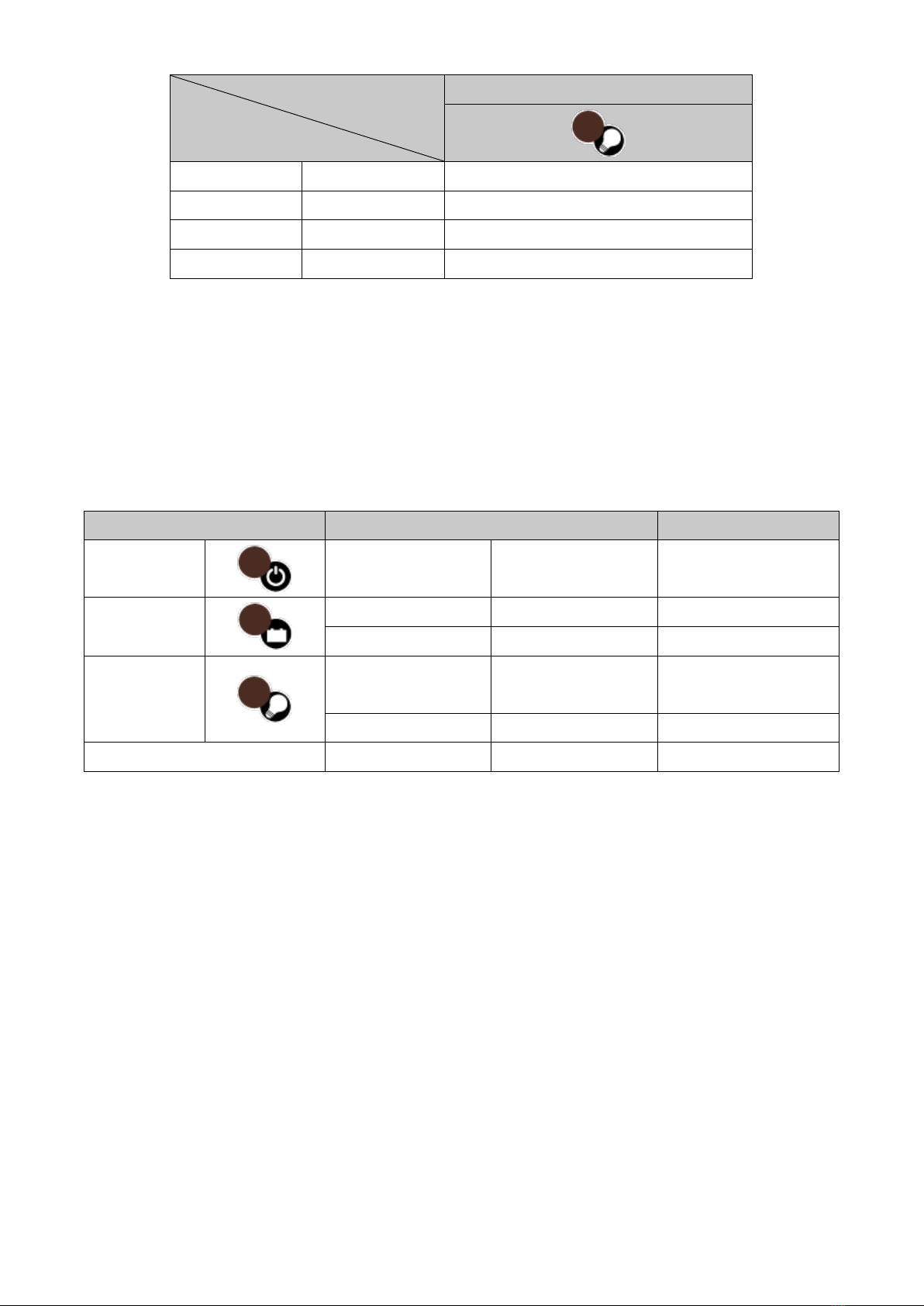

Table 6.4 The Indicators of protective functions

Lighting LED Indicators Protective Function

Power LED

Red

●

Overtemperature

Battery LED

Red

●

Input overvoltage

Blinking red

●●●●●

Input low voltage

Load LED

Red ●Overload/Load

terminal short-circuited

Blinking red

●●●●●

AC output error

All LEDs Red/ Blinking red

●/●●●●●

Internal error*

* Please consult with the dealer if an internal error occurs.

17

7. Troubleshooting Guide

Fault Condition

Possible Cause

Solution

No AC output

voltage

Input voltage error

Battery LED lights red/ blinks red

Check the value of DC input voltage

and adjust the range of input voltage.

Overtemperature protection

Power LED lights red

Check the status of the ventilation is

blocked or the air temperature is too

high. Please reduce the load capacity or

lower the outside air temperature.

Overload protection

Load LED lights red

Check the status of the load capacity,

including the instantaneous value,

exceeds the rated value of load or not.

Short-circuit protection

Load LED lights red

Check the status of the load wiring

connection is short-circuited or not.

AC output terminal wiring problem Check the status of the wiring to the AC

output terminal is appropriate or broken.

Internal error

All LEDs light red/blink red

It is possible that internal parts of the

Inverter may be damaged. Please

consult with the dealer.

Short operation

time of the

Inverter

Battery problem

Please change the battery.

Lack of battery capacity Please check the battery specifications

and increase the battery capacity.

Output voltage,

frequency error

Wrong setting Refer to Chapter 5-1 Change Settings,

and change the settings.

Power LED does

not light up even

connecting with

battery

Reversed connection of battery

polarity

Reverse connection warning LED

lights red

Correct the connection to the correct

polarity

The internal fuse cuts off Parts of the internal Inverter may be

damaged. Please consult with the

dealer.

Remote

connector does

not work

Wiring problem Check if the status of wire connection of

the remote connector is correct.

If the fault condition cannot be solved, please consult with the dealer.

DENRYO CO., LTD.

28

-5, Nishinippori 2Chome, Arakawa-ku

,

Tokyo 116

-0013, Japan

Phone :

+81-3-3802-3671

FAX : +81

-3-3802-2974

Email:

info-[email protected]

www.denryo.com/en

DM-5004

Table of contents

Popular Inverter manuals by other brands

BARRON

BARRON EXITRONIX Tucson Micro Series installation instructions

Baumer

Baumer HUBNER TDP 0,2 Series Mounting and operating instructions

electroil

electroil ITTPD11W-RS-BC Operation and Maintenance Handbook

Silicon Solar

Silicon Solar TPS555-1230 instruction manual

Mission Critical

Mission Critical Xantrex Freedom SW-RVC owner's guide

HP

HP 3312A Operating and service manual