dentalfarm MICRA Evoluzione Operating instructions

MICROBLASTER

MICRA Evoluzione

USER AND MAINTENANCE MANUAL

1. DESCRIPTION

MICRA Evoluzione is a sandblasting unit designed for microblasting operations in the

Dental and Jewellery field.

The main features of the machine are: the ergonomic layout of the working chamber, the

safety of use, and the trouble-free structure of the mechanical installation. MICRA

Evoluzione is equipped with useful accessories and ensures a fast, practical and accurate

work. The unit consists of 2 EASY tanks, featuring a pressure release system and an

instant stop of the blasting jet. The unit can thus operate with two different abrasive

media.

The sandblasting process originates toxic dust which must not be inhaled; for this reason,

it is absolutely forbidden to operate the machine if a proper suction system has not

been previously connected to the sandblaster.

DENTALFARM has developed the so-called W.A.FI.S. (WATER AIR FILTERING

SYSTEM), a patented solution which eliminates airborne dust thanks to the combined

action of water and air pressure, in compliance with hygiene and safety regulations. The

WAFIS system can be easily connected on the top left side of the machine and starts

automatically when the sandblaster is switched on.

DENTALFARM ranges also include PRO-3 and PRO-3 Shake suction units, which can be

easily connected to any sandblasting machine.

2. TECHNICAL REFERENCE REGULATIONS AND TEST PROCEDURES

The appliance is mass-manufactured by DENTALFARM in compliance with technical and

safety rules in force, as provided for by the Machinery Directive 2006/42 EEC.

Careful inspection and full routine testing is carried out singularly on each machine which

is furtherly processed by an automatic testing installation assuring compliance with the

fixed limits

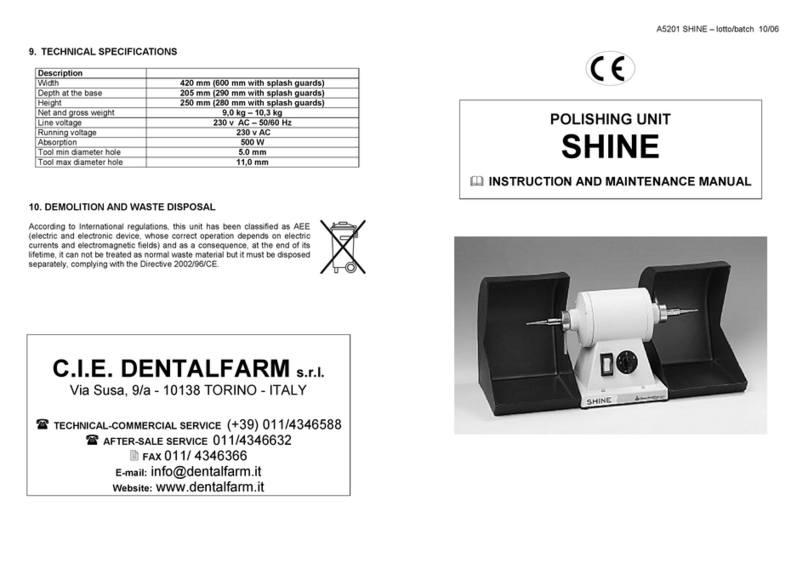

DEMOLITION AND WASTE DISPOSAL

According to International regulations, this unit has been classified as AEE

(electric and electronic device, whose correct operation depends on electric

currents and electromagnetic fields) and as a consequence, at the end of its

lifetime, it can not be treated as normal waste material but it must be

disposed separately, complying with Directive 2002/96/EEC.

3. INSTALLATION INSTRUCTIONS

/!\

ATTENTION

Installation of this machine is quite easy but must be carried out paying

utmost attention in order to avoid any mistake which may originate

problems, inconveniences and even damages during operation.

1. Place the machine on a proper workbench, which must be stable and strong enough to

hold the machine safely. Keep a sufficient distance (10/15 cm) on the right side of the

machine for the pipes and the feeding cables, as well as in order to have access to the

shutter and the filter. If a built-in WAFIS system is present, preferably choose a

workbench and a position (for instance on the bench edge) allowing the exhaust pipe to

fall perpendicularly into the collection tank.

2. Insert the quick clutch fitting on the male intake (A) located on the right side of the unit

and connect the pneumatic feeding pipe (polyethylene or rilsan, with diameter ∅8x6)

to the pipe-fitting. It is also possible to use a ∅12x6 elastic feeding pipe, by using the

fitting supplied with the unit.

3. Connect the electric feeding cable to the pre-fitted electric socket on the unit (B) and

plug into an approved 220v AC - 50Hz network socket with ground connection.

4. Install the preferred suction system; WAFIS, PRO-3 or any other.

The built-in WAFIS should be installed on the top left side of the

unit: unscrew the 4 screws fixing the black collection intake and

mount the WAFIS, unscrew the cap (C) and replace it by the pipe-

fitting delivered in the package, put together with the other portion

of pipe and plug the feeding cable into the electric socket (D).

PRO-3 suction units can be connected in two different ways: on

the top left to extract dust

particles only; in this case,

insert the piping into the black

collection intake; alternatively,

on the rear bottom of

the working chamber:

in this case, all the

exhausted abrasive will

be extracted. In both

cases, remove the protection caps from their holes.

Any other suction system can be connected to the black

collection intake by means of flexible piping; the inside

manifold fits a ∅30mm pipe, the outside manifold fits a

∅40mm pipe.

5. Adjust the air flow to avoid the machine being under pressure. Slightly turn the mobile

section of the adjusting valve when the suction system is on and stop when you notice

that the gloves are still slightly inflated.

6. Microblasting tanks (EASY tanks) are identical in layout, but can feature different

components (calibrated metering system) and external nozzles which vary

according to the abrasive mixture they can supply; it is therefore necessary to

observe the indications written on the identifying labels. Should you need to use an

abrasive compound of different grainsize (not listed below), it is possible to request the

assembly components and to replace them.

The unit can thus operate with three different abrasive media. It is also possible to

upgrade the unit to 3 or 4 microblasting tanks, thus offering the possibility to work with 4

different abrasive media.

To pour abrasive media into the tank, unscrew the tank cap and fill in the tank till

approximately 2/3 of its capacity (respect the maximum level marked on the label); then

close the tank.

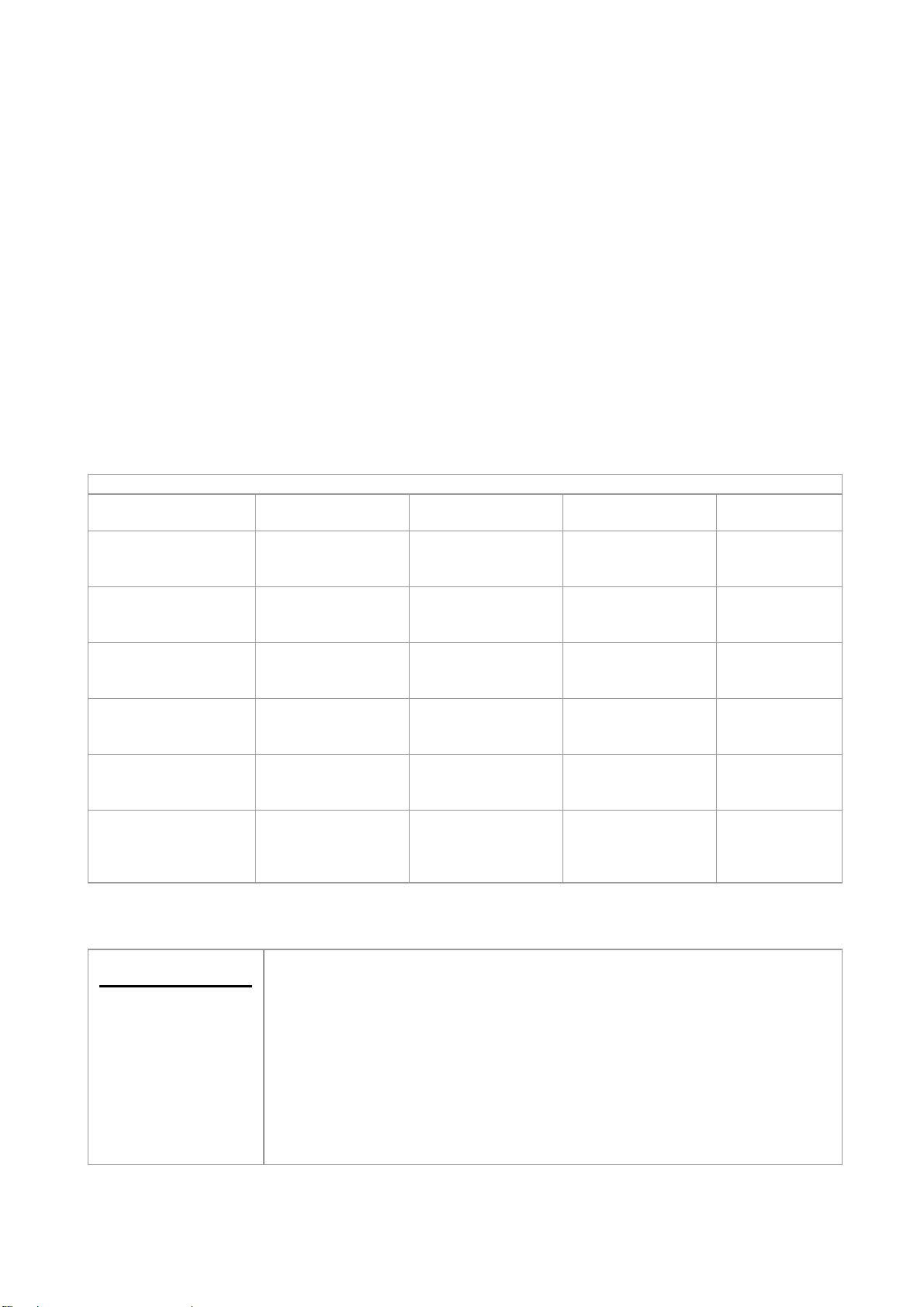

Strictly observe the following parameters, based on the abrasive grainsize.

TREATMENT TANK

(dosing system) RECOMMENDED

ABRASIVE NOZZLE

DIAMETER PRESSURE

Surface roughness on

metals for composites A1072G

(coarse)

AP-060

Orange label

(AL2O3 60 - 250µ)

2,0 mm

(RMN046)

4 BAR

Surface roughness on

metals for composites A1072M

(medium)

AP-120

Pink label

(AL2O3120 - 105µ)

1,2 mm

(RMN043)

3/4 BAR

Surface roughness on

metals for ceramic or

resin

A1072M

(medium)

AP-150

Green label

(AL2O3150 - 95µ)

0,8 mm

(RMN044)

3/5 BAR

Surface roughness on

metals for ceramic A1072M

(medium)

AP-180

Red label

(AL2O3180 - 80µ)

0,8 mm

(RMN044)

3/5 BAR

Sculpture on ceramic A1072S

(fine)

AP-270

Yellow label

(AL2O3270 - 50µ)

0,5 mm

(RMN045)

3/5 BAR

Satin-finishing on any

type of metal A1072M

(medium)

AP-090

MICROBLAST

White label

Higher precision

0,8mm

Higher speed

1,2 mm

3/4 BAR

4/5 BAR

A longer nozzle with ∅0,8 mm size (RMN044L) is available on request to carry out

cleaning operations on ceramic prosthesis without metal support.

/!\ WARNING: Very fine abrasives are highly sensitive to moisture and must be

stored in a dry place, after the can has been accurately sealed and

the dessiccant packet has been duly introduced into the can (if

needed, replace them periodically).

When filling the abrasive tanks, check the condition of the abrasive

product; if the moisture content is too high (bad flowability and

presence of clots) it is recommended to heat the abrasive in order to

allow it to dry up completely. It is also of utmost importance to check

the condition of the compressed air which in no way must contain

evidence of moisture or of any polluting agents (oil, grease or rust).

4. INSTRUCTIONS FOR USE

• Press the switch to illuminate the working chamber and feed the operating controls.

/!\

ATTENTION:

May we remind that the sandblasting process will start only provided

the suction system is operating – as a consequence, the filtering

system MUST always be installed and OPERATED BEFORE you

start to work.

• Lift the window to introduce the pieces to be treated into the working chamber.

• Turn the selector switch knob to choose the type of blasting procedure you prefer –

references marked on the label are herewith specified.

POSITION OF THE

POINTER

SELECTED FUNCTION

GREEN MICROBLASTING FROM THE GREEN TANK

BLUE MICROBLASTING FROM THE BLUE TANK (if any)

RED MICROBLASTING FROM THE RED TANK (if any)

WHITE MICROBLASTING FROM THE WHITE TANK

• Press the foot control: air enters the selected tank putting it under pressure, it gets

mixed with abrasive micrograins and will then be propelled by the spraying nozzle.

• Adjust the working pressure by means of the pressure adjusting device located next to

the pressure gauge: lift the knob and turn it rightwards (to increase) or leftwards (to

decrease). To lock the knob, push the knob back down.

The microprojectors are ideally positioned in the centre of the working chamber to facilitate

use with both hands. We recommend to put back them in place on their support at the end

of the work.

The window is made of anti-scratch polycarbonate material, resisting to the rebounding

abrasive grains. We recommend to use a soft cloth to clean it and to remove the dust from

inside and the use of ptotection screens (code 1000533).

Table of contents

Other dentalfarm Dental Equipment manuals