3. Warnings

These polishing unit exhaust hoods models A110, A110C,

A110S, A110CS have been designed and manufactured for

use by gold-smiths, dental technicians or in similar

laboratories and cannot be used in any other

environments.

The unit shall be used by quali sta only and

exclusively for the suction of dust produced when polishing

manufactured products. It is necessary to remember that

the exhaust hoods receive a 220 V power supply and all

the necessary precautions.

Make sure that the existing electric system is in conformity

with current standards.

Disconnect power supply every time it is necessary to opera-

te on the interior of the unit.

Do not use the hood for other purposes than those

described in the instructions for use and in the brochure.

Non-conformity with the provisions contained herein will

cause the immediate forfeiture of any guarantee rights.

4. Information and useful tips

The polishing unit exhaust hood is delivered already

inclusive of all components. Use special trolleys for

transport and do not overturn the carton.

Remove the exhaust hood from the carton and dispose of

packaging according to current regulations.

Note: Dentalfarm shall not be held responsible for packa-

ging left in inappropriate places.

Once the packaging has been removed from the exhaust

hood, check that all parts are intact; in case of broken or

damaged parts attributable to the carrier, advise the latter

immediately and notify by registered letter with return

receipt both, DENTALFARM and the forwarding agency.

Make sure that all components and complementary

accessories are included as listed is the delivery note.

In case of requests, remember to state the purchase date,

model and serial number shown on the data plate. DEN-

TALFARM shall be free from any liability whatsoever regar-

ding third parties if the data plate should be removed

from the appliance.

5. Materials

Hood structure made from electrogalvanized plate, 10/10

mm thick, with epoxy powder coating, oven-dried at

210°C.

The exhaust motor installed is manufactured by EBM-PAPST

- GERMANY. This model is equipped with

containers and bags in which dust is collected.

Dust elimination is ensured by 2 (one on each

exhaust outlet) in conformity with standard B.I.A. ZH1/487

6. Equipment

The polishing unit exhaust hood comes equipped with the

following:

•exhaust motor with speed regulator

•2 B.I.A. ZH1/487

•LED lighting

•polishing connection socket (A110 / A110C)

•recessed polishing lathe (A110S / A110CS)

•adjustable protective screen

•2 ribber trays

•working surface covered with stainless steel

•stand with drawer and inner basin on model A110C

•instructions manual (that shall always be provided with

the appliance, even in case of second-hand sale)

•guarantee (applicable as from the date of

purchase)

•conformity declaration

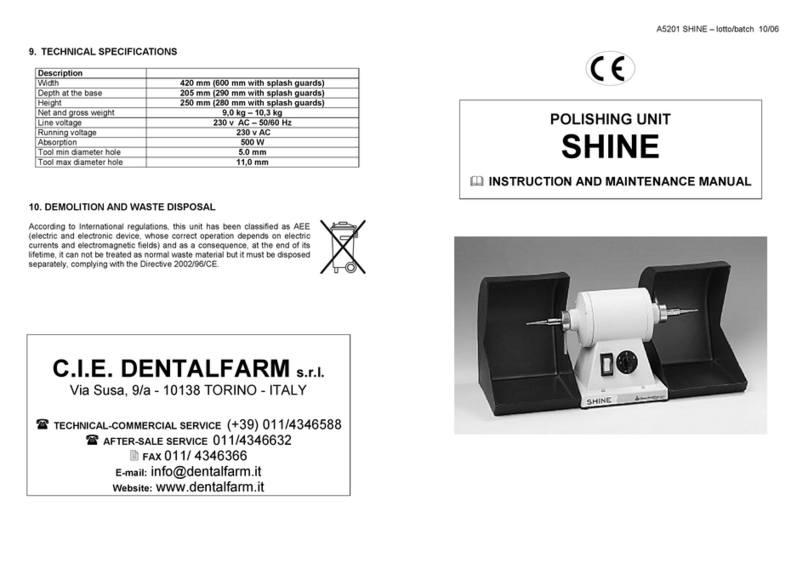

7. Technical features

Power rating........................................................................230 V

Frequency ...................................................................... 50/60 Hz

Max. absorbed power (A110 / A110C)........................200 W

Max. absorbed power (A110S/ A110CS) ...................600 W

Fuse ..........................................................................16 A - 250 V

Power cord ..............................................................3 x1,5 mm²

Max. load of socket for connection

of polishing late ......................................................................1500 W

Maximum size in mm :

models A110 / A110S .................W. 730 x D. 550 x H. 460

models A110C / A110CS ............W. 730 x D. 550 x H 580

No part of this manual may be reproduced without the prior permission in writing of DENTALFARM Srl MI 18 A110 R00 4