dentalfarm W.A.FI.S. Manual

DUST FILTERING SYSTEM

W.A.FI.S. Electric Version

MAINTENANCE AND INSTRUCTION MANUAL

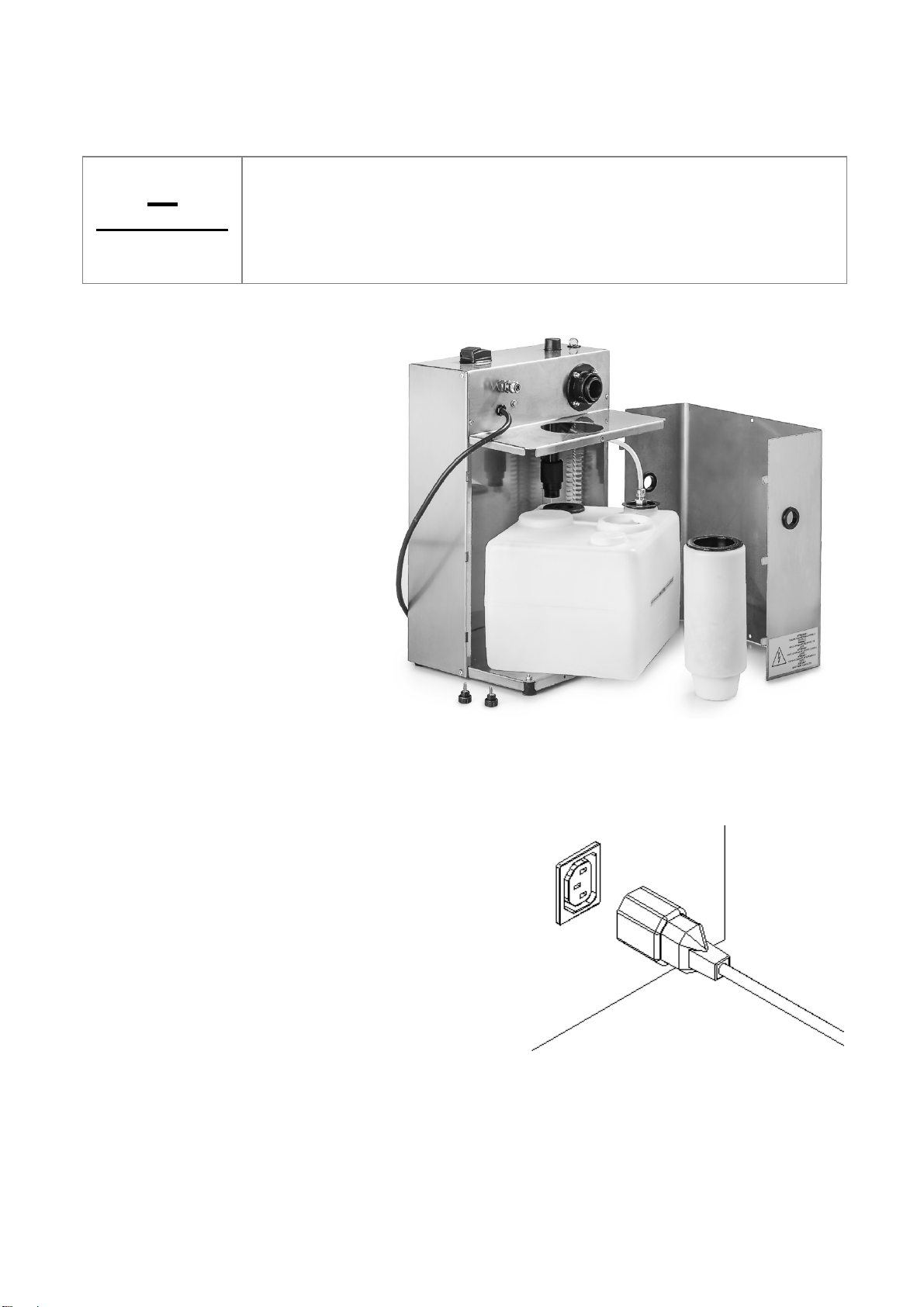

DESCRIPTION

W.A.FI.S. is a dust suction, filtering and elimination system (DENTALFARM exclusive

patent) expressly studied to work in conjunction with the Dentalfarm sandblaster models

which can be easily connected to any blasting chamber.

The system fully complies with international existing rules referred to environmental

hygiene.

The WAFIS system definitevely solves the problems related to the toxic dust originated

during any sandblasting process by the impact of the abrasive grains on both investment

and casting oxidations. The level of dust elimination attained, certified by an official

institute, covers 99.8% of the total dust developed.

The size and the power are compared to the requirements of the Dental Laboratories.

Maintenance and consumption are very restricted thanks to the high reliability of this

entirely pneumatic machine.

POSSIBILITIES OF CONNECTION FOR THE WAFIS

Connection of the WAFIS to a blasting machine is very simple

but two different procedures have to be followed according to:

A) if the WAFIS has to be connected to Dentalfarm already

pre-arranged blasters:

1) release the connection flange to the working chamber;

2) push and turn clockwise to connect the hose (24) of

WAFI.S. on the same flange;

3) place your WAFIS on the floor and connect the other

end of the pipe to the upper manifold (30), adjusting its

length in order to avoid any siphons or very tight

curves;

B) if the WAFIS has to be connected to other machines not

pre-arranged, and even not manufactured by DENTALFARM,

you should:

1) remove the dry filtering bag wherever it is located;

2) stop up definitively the free hole;

3) find a suitable location to connect the dust suction

system; we recommend to install it on the back panel of the working chamber, not

too low in order to avoid abrasive from being sucked, too but also distant from the

area under the blasting jet in order to avoid the pipe from being struck.

4) utilize the flange supplied as drilling jig to carry out the four

fixing holes (∅4,5 mm) and fix in place with the screws;

5) drill additional holes in the middle, having the correct diameter

sufficient to ensure the dust particles to blow quickly away;

6) turn clockwise to fit the WAFIS flexible hose onto the flange;

7) place your WAFIS on the floor and connect the other end of

the pipe to the upper manifold, adjusting its length in order not

to make siphons or very tight curves.

INSTALLATION INSTRUCTIONS

/!\

ATTENTION:

The WAFIS must be positioned on the floor, under or near the

bench where the sandblaster has been placed. The connection

pipe must fall perpendicularly avoiding any pockets and/or

siphons which may collect sediment inevitably causing am loss in

the intake power (eventually cut the pipe).

To arrange the machine, follow these instructions:

A)fill the internal tank

• loosen the pressure knobs

to remove the panel (23)

• remove the air outlet pipe

from the water tank (12)

• pull to disassemble the

water injector (10) from the

depressor body (29)

• lift the connection sleeve

(29) making it slide on the

smooth side of the

depressor (29)

• pull out the tank (14) and

fill in with water up to the

maximum limit (WATER

LEVEL)

• re-assemble every

component paying attention to the watertight seals.

B)connect pneumatically the machine to proper pipe-fitting (9) (rilsan or polyethylene 8x6

pipe) a special pipe-fitting for the rubber pipe is also supplied, eventually replace.

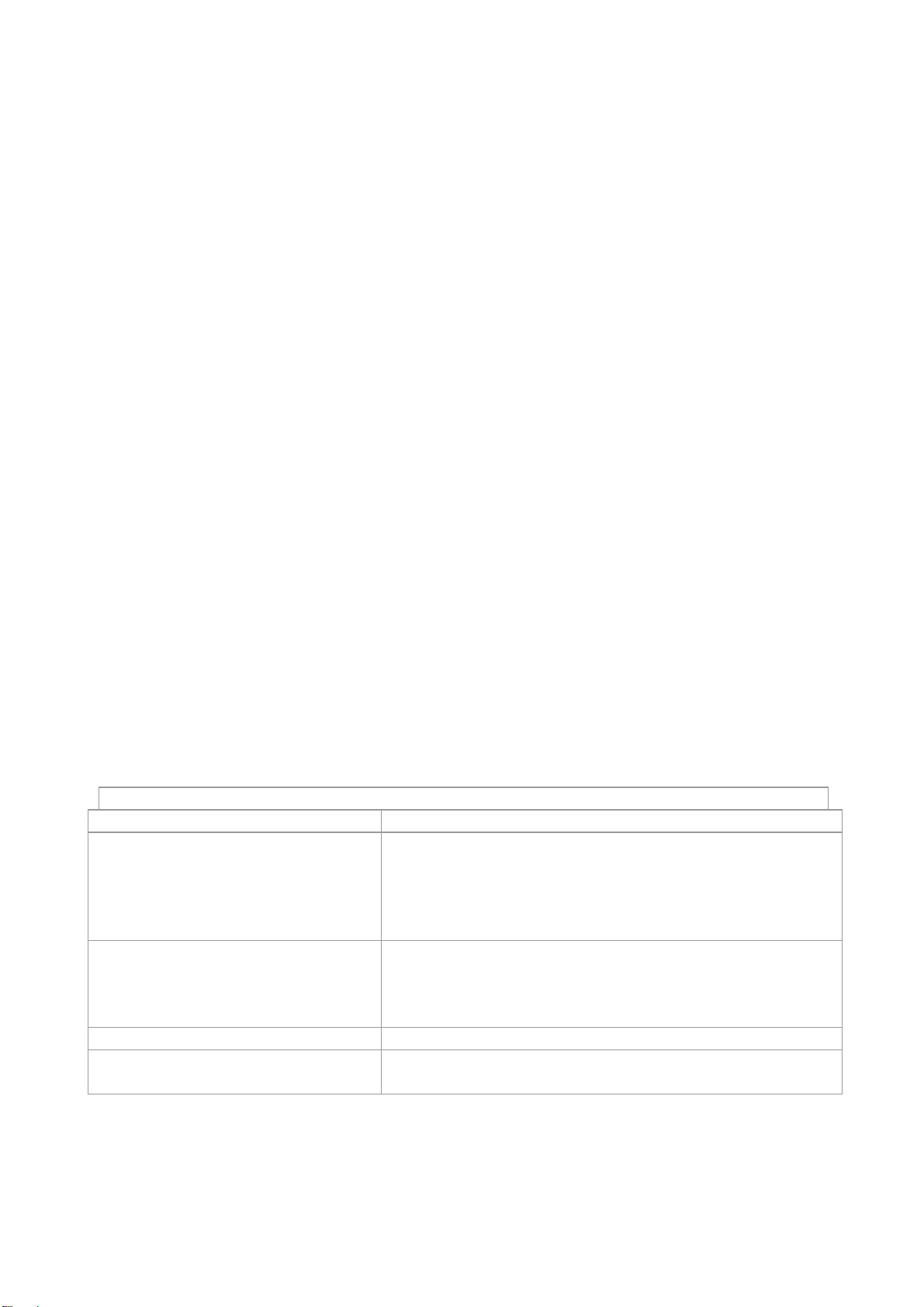

C) Connect the feeding cable (7) to the proper

plug located at the base of the machine (if any)

or use the supplied cable (8) to tie into a

standard 230V AC outlet with ground.

INSTRUCTIONS FOR USE

To operate the WAFIS system connected to a pre-arranged DENTALFARM sandblaster, it

is sufficient to leave the switch (pos. 1) on and turn the light on.

On the other hand, in case the WAFIS is connected to the power outlet, you must turn on

acting on its own switch.

The operating principle is very simple: the electric impulse opens the solenoid valve: the

air flow will pass from the spraying nozzle, enter the depressor body where, by expanding,

it creates vacuum and causes the dust particles to be sucked. The filtering system is

originated in the upper portion of the pipe where the air mixed up with dust particles is

sprinkled by a fine jet of atomized water; the dust particles become heavier and are then

separated from air which can not be moistened and will accumulate on the bottom of the

collection tank.

MAINTENANCE INSTRUCTIONS

The only maintenance operations required are:

• the regular cleaning of the depressor (30): remove the cap (3) and introduce the

cleaning swab (1) provided for that specific purpose - Frequency: once a day.

• the water replacement in the internal tank: operate as for the first installation but

taking care to clean carefully all the components - Frequency: once every 15/20

days.

GUIDE TO SOLVE THE PROBLEMS

Problem: DUST IS COMING OUT FROM THE BLASTING CHAMBER

Possible cause Remedy

The depressor is clogged

Activate the depression system, remove the cap or the

suction pipe, introduce the cleaning swab and let it

slide repeteadly to eliminate any residuals. It could

also be necessary to clean the connection area

between the working chamber and the pipe itself.

The depressor nozzles are dirty

or clogged Pull out the water feeding injector and clean it with a

proper tool. Repeat the same operation with the air

injector and introduce it in its seat checking that the

side opening corresponds to the water inlet.

The water filter is clogged Replace it.

The exhaust pipe is clogged

Disconnect from the tank, clean the metallic straw

(wash and blow), ev. replace.

PNEUMATIC CIRCUIT

No.

1

2

3

4

5

DESCRIPTION

SOLENOID VALVE

DEPRESSOR

SEDIMENT COLLECTION TANK

EXHAUST PIPE

SUCTION PIPE

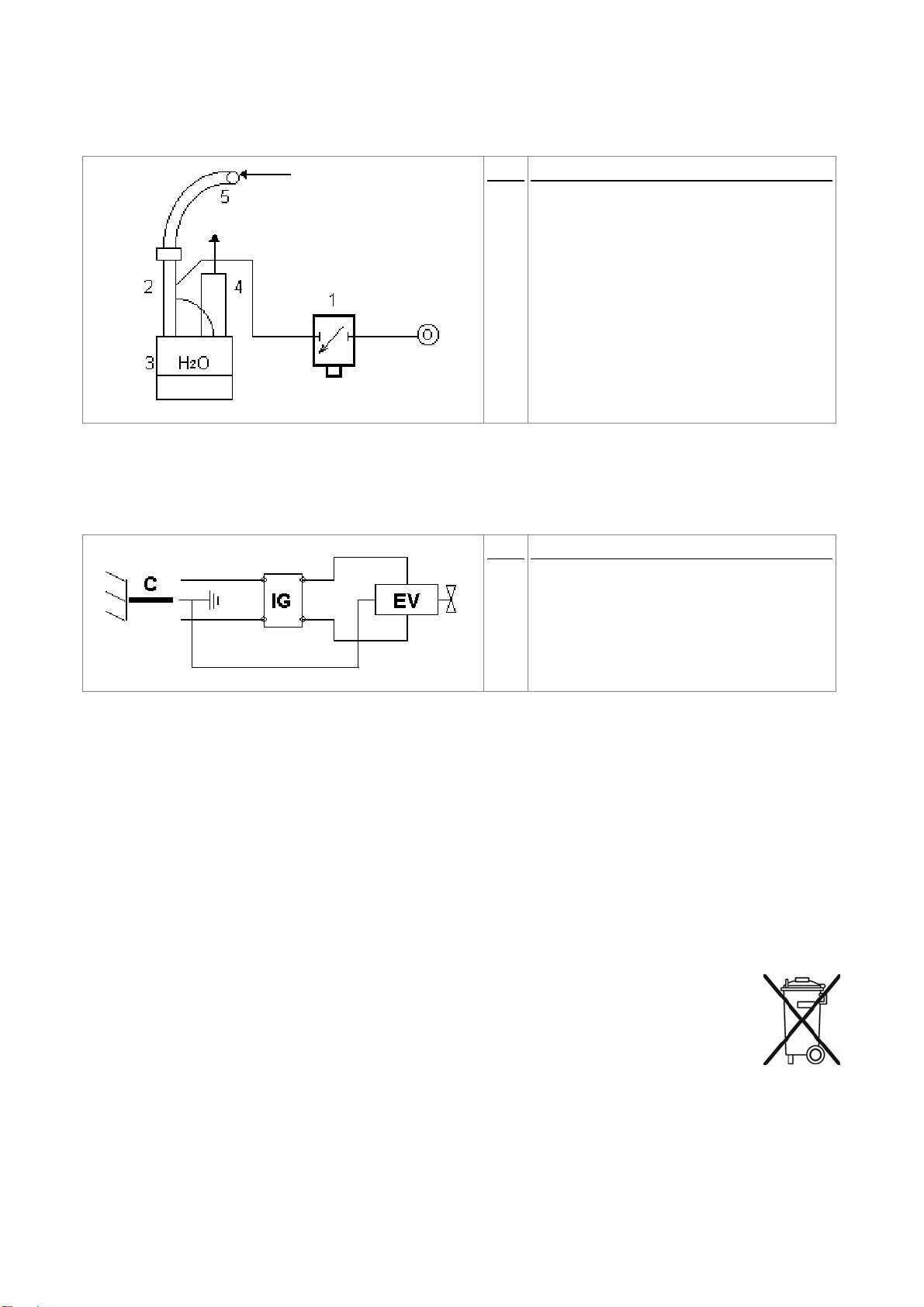

WIRING DIAGRAM

No.

IG

EV

C

DESCRIPTION

MAIN SWITCH (4)

SOLENOID VALVE (6)

FEEDING CABLE (7-8)

TECHNICAL REFERENCE REGULATIONS AND TEST PROCEDURES

Every unit is mass-manufactured by DENTALFARM in compliance with technical and

safety rules in force, as provided for by the 2006/42 EEC Community Directive on

Machinery. Careful inspection and full routine testing are carried out singularly on each

filtration system.

DEMOLITION AND WASTE DISPOSAL

According to International regulations, this unit has been classified as AEE

(electric and electronic device, whose correct operation depends on electric

currents and electromagnetic fields) and as a consequence, at the end of its

lifetime, it can not be treated as normal waste material but it must be disposed

separately, complying with the Directive 2002/96/CE.

EXPLODED DRAWING AND SPARE-PART LIST

No CODE DESCRIPTION

1 RCS044 DEPRESSOR CLEANING SWAB

2 NEA111 PLASTIC FERRULE D.=16

3 RCB030 DEPRESSOR INSPECTION CAP

4 NEC016 MAIN SWITCH

5 1201021 STAINLESS STEEL HOUSING

6 NES029 WAFIS SOLENOID VALVE + CONNECTOR

7 NEV014 ELECTRIC CABLE 3X1 WITH IEC320 PLUG

8 NEV013 FEEDING CABLE

9 NPR119 8x6 1/8” MALE STRAIGHT PIPE-FITTING

-- NPR220 7 1/8” PIPE-FITTING

10 RCB034 DEPRESSOR WATER INJECTOR

11 NVP040 6x4 PIPE FOR PNEUMATIC CONNECTIONS

12 RCB514N EXHAUST PIPE COMPLETE

13 NEA113 JOINT FOR WATER TANK

14 1201023 FILTERING TANK COMPLETE

15 NVI010 WATER FILTER

16 NVP060 8x6 PIPE FOR PNEUMATIC CONNECTIONS

17 NPR104 8x6 1/8” FEMALE STRAIGHT PIPE-FITTING

18 RCB080 FILTER FITTING CAP

19 NPR111 6x4 1/8” MALE STRAIGHT PIPE-FITTING

20 NVG049 RUBBER FEET

21 NEA101 FAIR-LEAD

22 1201022 MOBILE PANEL

23 NVT151 M 4 KNOB

24 NEV060 30x36 FLEXIBLE CONNECTION HOSE

25 RWA007 SUCTION PIPE FIXING FLANGE

26 RWA006 FLANGE JOINT

27 RCB070 DEPRESSOR MANIFOLD

28 NPOR128 OR128 JOINT ON MANIFOLD

29 1039029 DEPRESSOR PIPING

30 1039028 DEPRESSOR MANIFOLD

-- RCB501 DEPRESSOR COMPLETE

31 RCB033 DEPRESSOR AIR INJECTOR

TECHNICAL DATA

Height 410 mm

Width 275 mm

Depth 220 mm

Net Weight 5.7 Kg

Gross Weight 7.2 Kg

Minimum working pressure 2 BAR

Maximum working pressure 6 BAR

Air consumption 28 l/min at 2 BAR - 63 l/min at 5 BAR

Number of machines which can be connected 2

Maximum distance allowed between devices 1.5 meters

Percentage of eliminated dust 99,8%

Power tension 230v - 50Hz

DENTALFARM s.r.l.

Via Susa, 9/a - 10138 TORINO - ITALY

COMMERCIAL SERVICE - (+39) 011/4346588

AFTER SALE SERVICE – (+39) 011/4346632

FAX – (+39) 011/ 4346366

E-MAIL - [email protected]

WEBSITE: www.dentalfarm.it

Table of contents

Popular Water Filtration System manuals by other brands

3P Technik

3P Technik VF1 Installation and maintenance instruction

Concoa

Concoa 580 6001 Assembly, installation and operation instructions

Sven

Sven Platinum Pro Operation manual

Pentair

Pentair Cristal-Flo Installation and user guide

BWT

BWT MINISTIL 1iD Installation and operating manual

3M

3M Aqua-Pure AP801 Housing Installation and operating instruction manual