Denton Vacuum DESK V User manual

Copyright Denton Vacuum, LLC. All Rights Reserved. Version 9142016da 1

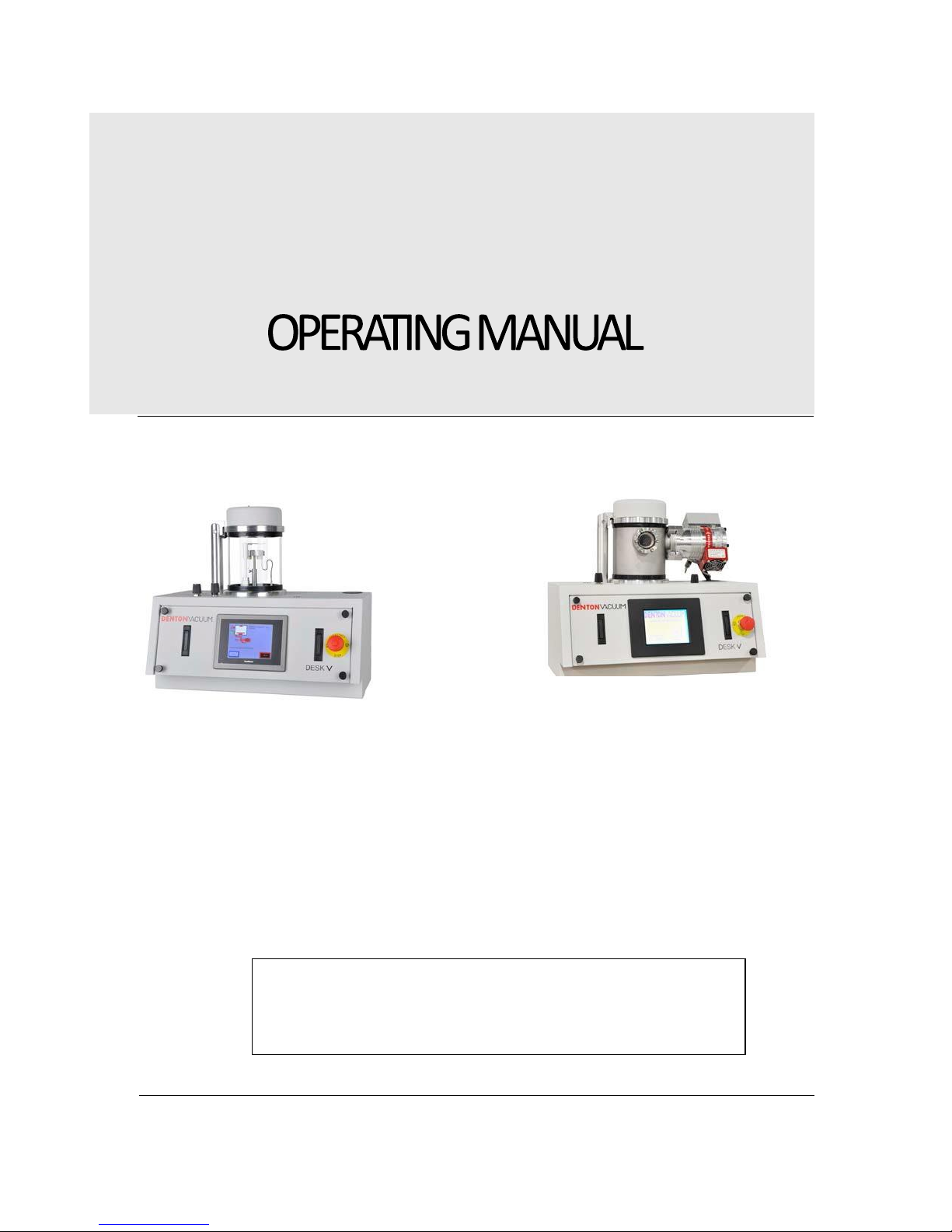

Desk V

DESKV-SPUTTER/ETCHUNITANDACCESSORIES

DENTON VACUUM, LLC

1259 N. CHURCH STREET

MOORESTOWN, NJ 08057

PHONE:856-439-9100

FAX:856-439-9111

WWW.DENTONVACUUM.COM

DENTONVACUUM

DESKV

Desk V

Desk V TSC

Watch the Desk V videos here:

https://www.youtube.com/user/Dentonvacuum

Copyright Denton Vacuum, LLC. All Rights Reserved. Version 9142016da 2

Table of Contents

Contents

INTRODUCTION ...............................................................................................................................................................5

GENERALDESCRIPTION............................................................................................................................................5

SYSTEMVIEWS.......................................................................................................................................................6

FRONTVIEW OF UNIT...............................................................................................................................................6

REAR VIEW OF UNIT.................................................................................................................................................7

ELECTRICALREQUIREMENTS.....................................................................................................................................8

DESK V HP & DESK V TSC ..........................................................................................................................................8

CARBON ROD ACCESSORY AND CARBONYARN ACCESSORY .......................................................................................9

ENVIRONMENTALCONDITIONS ................................................................................................................................9

OPTIONS ........................................................................................................................................................... 10

ROTATION .............................................................................................................................................................10

THICKNESS MONITOR.............................................................................................................................................10

CARBON ROD EVAPORATION..................................................................................................................................10

CARBON YARN EVAPORATION ................................................................................................................................10

SAFETYWARNINGS ......................................................................................................................................................... 10

SAFETYSYMBOLS.................................................................................................................................................. 13

UNPACKING&SETUP ....................................................................................................................................................... 13

SYSTEM .............................................................................................................................................................. 13

Emergency Stop Button........................................................................................................................................14

INSTALLATIONINSTRUCTIONS...............................................................................................................................................15

VOLTAGE SELECTION ......................................................................................................................................... 15

........... 15

CHAMBER PREPARATIONS......................................................................................................................................18

MECHANICAL PUMP INSTALLATION ......................................................................................................................... 19

The mechanical pump installed ............................................................................................................................... 19

TARGET INSTALLATION & REPLACEMENT .................................................................................................................... 21

INITIAL START-UP .................................................................................................................................................... 22

INSPECTION......................................................................................................................................................... 22

START-UPPROCEDURE .............................................................................................................................................. 23

OPENINGTHECHAMBER........................................................................................................................................ 24

DESCRIPTIONOFCONTROLS ............................................................................................................................................... 25

SYSTEMSTARTSCREEN...........................................................................................................................................25

SCREENS ...............................................................................................................................................................26

Verifythattheincomingpowerconnectionissetforthepropervoltage!

Copyright Denton Vacuum, LLC. All Rights Reserved. Version 9142016da 3

.................................................................................................26

MANUAL SPUTTER ............................................................................................................................................ 27

St an d ar d Desk V HP ...........................................................................................................................................27

.....................................................................................27

MANUAL SPUTTER DESK V TSC.......................................................................................................................... 29

TIMED SPUTTER.....................................................................................................................................................31

Desk V TSC .............................................................................................................................................................. 32

Desk V Timed Recipe Programming......................................................................................................................34

How to Use Timed Recipe Programming..............................................................................................................35

MANUAL ETCH .....................................................................................................................................................37

DESK V HP................................................................................................................................................................ 37

TIMED ETCH...........................................................................................................................................................40

OVERVIEW.............................................................................................................................................................42

OPERATION...................................................................................................................................................................44

ETCH ................................................................................................................................................................. 45

SPUTTER............................................................................................................................................................. 47

TIMEDETCHOPERATION ........................................................................................................................................ 49

TIMEDSPUTTEROPERATION................................................................................................................................... 50

SHUT-DOWNPROCEDURE...................................................................................................................................... 52

OPTIONS ............................................................................................................................................................ 52

QUARTZ CRYSTALMONITOR...................................................................................................................................52

DESK V TSC ............................................................................................................................................................53

CARBON ROD ACCESSORY ......................................................................................................................................54

Copyright Denton Vacuum, LLC. All Rights Reserved. Version 9142016da 4

CARBON YARN ACCESSORY .......................................................................................................................................57

Loa d i ng the Carb on Yarn ............................................................................................................................ 58

MAINTENANCE ............................................................................................................................................................. 59

GENERALMAINTENANCE....................................................................................................................................... 59

MECHANICALPUMP ..............................................................................................................................................59

MECHANICAL PUMP –OIL CHANGE ........................................................................................................................60

SPUTTERTARGET....................................................................................................................................................60

TROUBLESHOOTING ................................................................................................................................................62

VACUUMPERFORMANCEDATASHEET .................................................................................................................................... 64

USEDTARGET ................................................................................................................................................................ 65

TYPICALPERFORMANCEDATA ............................................................................................................................................. 66

PUMPDOWN ...................................................................................................................................................... 66

DEPOSITIONRATE................................................................................................................................................. 69

PACKINGDESKVFORRETURN.............................................................................................................................................72

PACKINGPHOTOS ................................................................................................................................................. 73

SUGGESTEDSPARES ......................................................................................................................................................... 74

CONSUMABLESFORDESKVANDTSC....................................................................................................................... 74

FUSES.................................................................................................................................................................75

CONSUMABLESFORCARBONRODACCESSORY.......................................................................................................... 76

CONSUMABLESFORCARBONYARNACCESSORY ........................................................................................................ 77

TARGETSFORDESKVANDTSC ................................................................................................................................ 78

AdjustingtheVacuumSafetyBellowsSwitch........................................................................................... 79

Emergency Stop Button........................................................................................................................................80

Battery Advisory: ..................................................................................................................................................80

Copyright Denton Vacuum, LLC. All Rights Reserved. Version 9142016da 5

INTRODUCTION

GENERALDESCRIPTION

The Denton Vacuum DESK V Cold Sputter/Etch Unit is designed to deposit a conductive coating on an

SEM sample and to provide some limited surface cleaning in some models.

A standard 6”diameter Glass Cylinder with top and bottom seals sits on the aluminum Baseplate.

Metal chamber is optional with Turbo Pump option (TSC).

A two-stage, direct-drive Mechanical Pump, is located outside of the system cabinet,

evacuates the cylinder. Turbo molecular pump is optional (TSC).

An automatic Vent Valve is slaved to the mechanical pump. It will automatically open when the

Mechanical Pump is turned OFF to vent the chamber to atmosphere. It will automatically close when

the Mechanical pump is turned on.

An insulated Specimen Table with provisions for height adjustment is mounted within the Pyrex

cylinder. Rotation is optional.

The Sputter Cathode is clamped to an insulated aluminum plate in the chamber cover.

A manual Shutter is provided to shield the Sputter Cathode from contamination during the Etch

cleaning cycle. The shutter control knob is left of the chamber. Clockwise rotation of the knob will

open the shutter and counterclockwise rotation will close it.

A manual Gas Control is provided to control pressure in the cylinder. The Gas Control knob is to the

left of the chamber.

For servicing and inspection convenience, all Fuses are mounted externally on the rear panel and the

rear panel is hinged to provide access to internal components.

There are six main operations for the system: Vacuum, Etch Enable (if equipped), Rotation (if

equipped), Sputter Enable, Timed Etch (if equipped) and Timed Sputter.

A Programmable Logic Controller (PLC) controls the system. A Touch Screen is used to interface with

the PLC. Operator interface is through a graphics program that is running on the Touch Screen. This

control system will be described in detail in the Operation section of this manual.

NOTE:Thesystemoffersyouarangeofthinfilmprocessoptions.

However,it is importantto notethatwithallof thissystem’s potential,thereexistsafety

considerations.Individualswhoare to operate,service,or maintainthissystemshould

familiarizethemselveswiththismanual.

This manual suits for next models

1

Table of contents

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual