dentronix DDUS60 User manual

DDUS60 and DDUS60R

Ultrasonic Cleaning System

Owners Guide

Owners Guide 3

Dentronix®Ultrasonic Cleaner

CAUTION: Federal law restricts this device to sale by or on the

order of a dentist and/or physician.

An essential part of your infection control system

Congratulations on your purchase of a Dentronix Ultrasonic Cleaner.

Developed specifically for the orthodontic industry, Dentronix units

feature unique product design and optimize time and safety in the

office. Dentronix offers a complete line of ultrasonic cleaning sys-

tems and cleaning solutions which provide you with the flexibility to

efficiently clean instruments.

What is ultrasonic cleaning?

Ultrasonic Cleaning is a process created by high frequency sound

waves. The sound waves, enhanced by specially formulated clean-

ing solutions, create high energy cavitation. During cavitation,

millions of tiny bubbles form and then collapse or “implode,”

releasing enormous amounts of energy and shock waves which

scour the surface of instruments, appliances and other apparatus

placed in the cleaning solution. This powerful scouring action

reaches into minute crevices, which manual brushing cannot reach.

The combination of energy and specially formulated solutions make

ultrasonic cleaning the most effective method for removing gross

and microscopic debris.

I. Unpacking

A. Remove your Dentronix unit from the shipping container and

inspect the unit for any possible damage which may have

occurred during shipping.

B. Check the serial number of the unit (found on the back side of

the unit) with the number on the shipping carton. If they are not

the same contact Dentronix.

C. Fill out the warranty card and mail to Dentronix within 10 days

of receipt.

D. Select a location for the cleaner. It should be close to a sink or

to waste lines to facilitate draining. The hose supplied with the

unit will allow you to place the unit on either side of the sink or

connect directly to the waste line. When used in conjunction with

a Dentronix DDS5000 dry heat sterilizer, find the best position for

your ultrasonic unit by calling Dentronix and asking for informa-

tion regarding “Sterilization Perfect Design.”

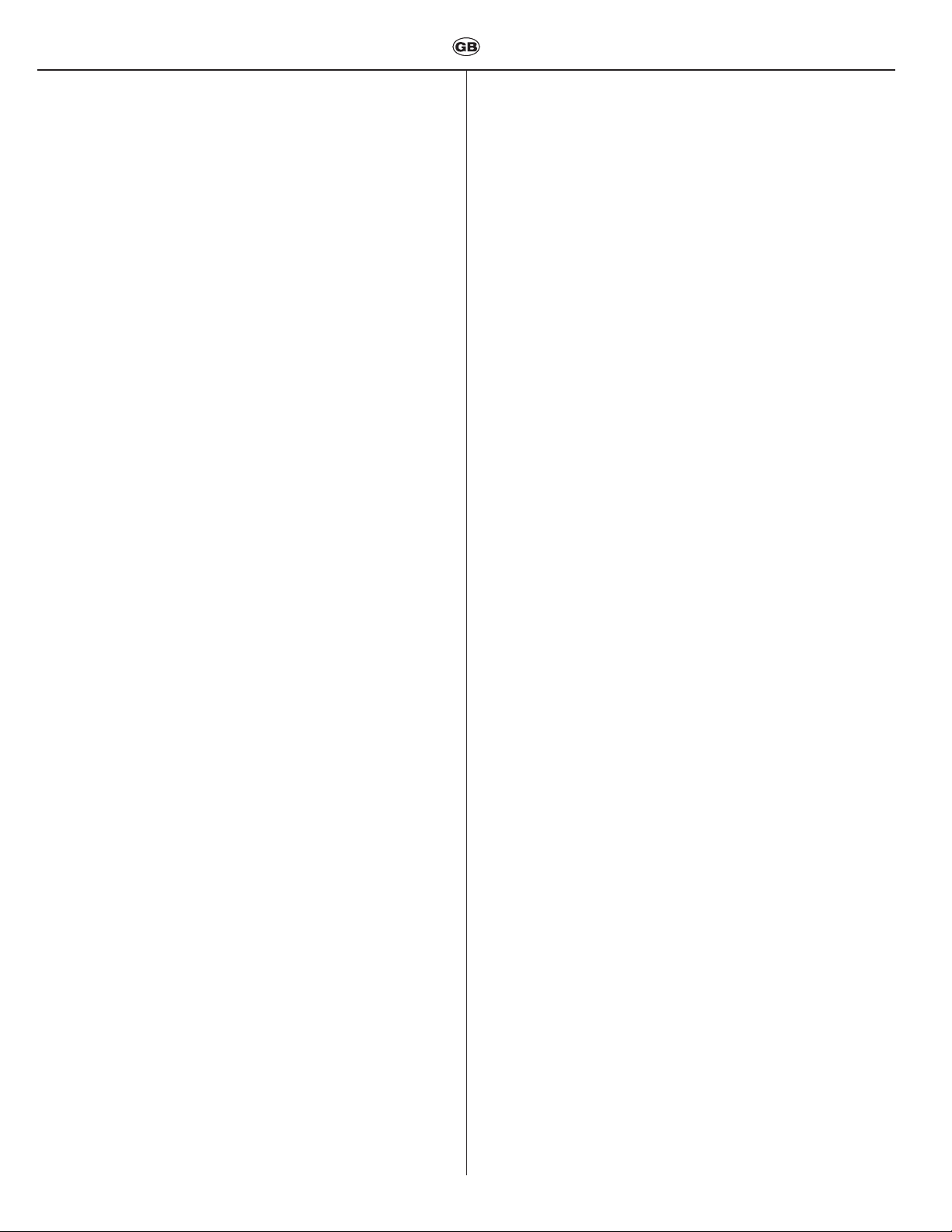

E. Connect one end of the hose to the drain valve (Fig. 1) and

place the other end in the sink. If desired (and recommended for

the DDUS60R), have your plumber connect the hose directly to

the waste system with the appropriate fittings per your local

building code.

II. Installation Instructions for the

DDUS60R Recessed Unit

The Dentronix DDUS60R consists of:

• Tank enclosure

• Electronics enclosure

• Drain tube

• Coaxial cable which is connected between the N female

coaxial connectors on the electronics control housing and the

tank housing

• Four-conductor cable which connects between DIN connec-

tors on the tank enclosure and the electronics enclosure

• Power supply cord

• Four (4) #8 Philips head wood screws

NOTE: Before you begin, please read and understand the safety

instructions provided by the manufacturers of the tools required

for installation.

Tools Required

1 Electric Drill

1 Drill bit to drill a hole large enough to accept a reciprocating

saw blade

1 Reciprocating saw and blade

1 Phillips head screw driver

1 Flat blade screw driver

NOTE: This Ultrasonic Cleaner must be installed by an experi-

enced equipment manager or licensed contractor. Be sure to

follow local building codes.

A. Tank Enclosure

1. Select a location for the cleaner. There must be at least 13"

clear vertical space below the top of the counter to accom-

modate the tank enclosure, and an additional 6" at the loca-

tion of the valve, for a total of 19". The countertop must be flat

and level. Make sure that you are not selecting a location

which will interfere with the drawers or vertical partitions

between cabinets.

2. Tape the enclosed template down to the countertop in the

desired location. Make sure the printed Dentronix logo on the

bezel faces you.

3. Drill four (4) 3/8" diameter holes where indicated on the

template (marked “A”).

4. Drill four (4) holes holes at the four locations marked “B.”

Select your hole size based upon the saw you will use in #5

below.

5. Cut along the “cut line” with a jigsaw or other reciprocating

saw.

6. Clean away dirt or sawdust around the opening, and remove

scrap wood.

7. Place tank enclosure into opening with the printed Dentronix

logo on the bezel facing you.

8. Assemble the bearing plates, lock washers and wing nuts to

the tie-down studs (per Detail A on the template).

9. Tighten all the wing nuts a few turns at a time until the bezel

just contacts the countertop. Once the bezel has contacted

the countertop on four sides, back off each wing nut 1/4 turn.

10. Apply a thin bead of clear RTV silicone sealant between the

bezel and countertop.

B. Electronic Enclosure

1. Select a location for the electronics enclosure which will be

conveniently close to the tank enclosure.

NOTE: Mount control unit so that the fuse drawer is acces-

sible (Section X, sub C). Be sure to leave at least 4" between

the back and sides of the electronic control housing and

cabinet wall. This will allow for adequate ventilation as well as

facilitate the insertion and removal of power/RF cables.

4Dentronix Ultrasonic Cleaner

NOTE: The side of the unit has ventilation louvers. Position

electronics control housing in such a way that liquids cannot

flow into the unit.

2. Four (4) #8 Phillips head wood screws have been included if

you wish to mount the electronics enclosure to one of the inte-

rior cabinet walls. Four adhesive-backed rubber feet have

been applied to the underside of the electronic control unit.

3. Connect the two cables between the electronics control box and

the tank enclosure. The cables are configured such that they

cannot be inserted into the wrong receptacle. If you have diffi-

culty plugging in a cable, check that it matches the receptacle.

4. Plug the power cord into the electronics control box, then into

a power outlet.

WARNING: Power should not be supplied to the unit until all

interconnections between the electronics enclosure, tank

enclosure and any accessories are securely connected.

WARNING: This unit must be properly grounded. Failure to

properly ground unit may result in serious injury.

5. The hose supplied with the DDUS60R allows waste disposal

in accordance with your local, state and/or federal regulations.

III. Operating Instructions

A. General Cleaning

1. Fill the tank with water to the fill line indicator (Fig. 2).

2. Pour the required amount of Dentronix DMP-US+Ultrasonic

Cleaning Solution or other Dentronix ultrasonic cleaning solu-

tion into the tank.

NOTE: Never operate the unit without solution. Operating a dry

tank may result in permanent damage to the unit and void the

warranty. Do not place objects directly on bottom of tank. Use

accessory baskets, cassette racks or beaker positioning cover.

3. Plug the line cord into a grounded AC outlet (or per local

regulations).

4. To activate the unit, turn the timer knob to the desired cleaning

time. The pilot light will glow when the unit is in operation. The

unit will automatically shut off at the end of the cycle.

5. Change the solution in the tank daily, or sooner if it appears

soiled or discolored. When beakers are used, change the

solution in the beaker after each use.

6. Drain unit by opening the valve and allow solution to empty

into sink or waste system. Rinse tank and close valve.

B. Degassing

Degassing the ultrasonic solution is an important step. Degassing

is the removal of large air bubbles found in all fresh solution, which

act as a barrier to efficient cleaning. Degassing is necessary

every time new solution is added. Degas the solution by activating

the unit for 15 minutes before you add any items to be cleaned.

C. Cover

The Dentronix Ultrasonic Cleaner should always be covered when

operating to trap aerosols in the unit. The Dentronix DDUS60

and DDUS60R are equipped with a “hinged” cover for easy,

one-hand opening. The cover conveniently lifts off for cleaning

and may also be used as a carrying tray for accessories.

D. Instrument Draining

The DDUS60 and DDUS60R are equipped with a bezel

surrounding the tank. The bezel drains condensation back into

the tank, keeping the work area around the unit dry. The bezel

also acts as a draining stand for the large basket or cassette

racks. Simply position the corner of the basket or rack on two of

the draining tabs at opposite corners of the tank (Fig. 3, 4) and

allow the solution to drain off instruments.

IV. Cleaning Methods

A. InTank

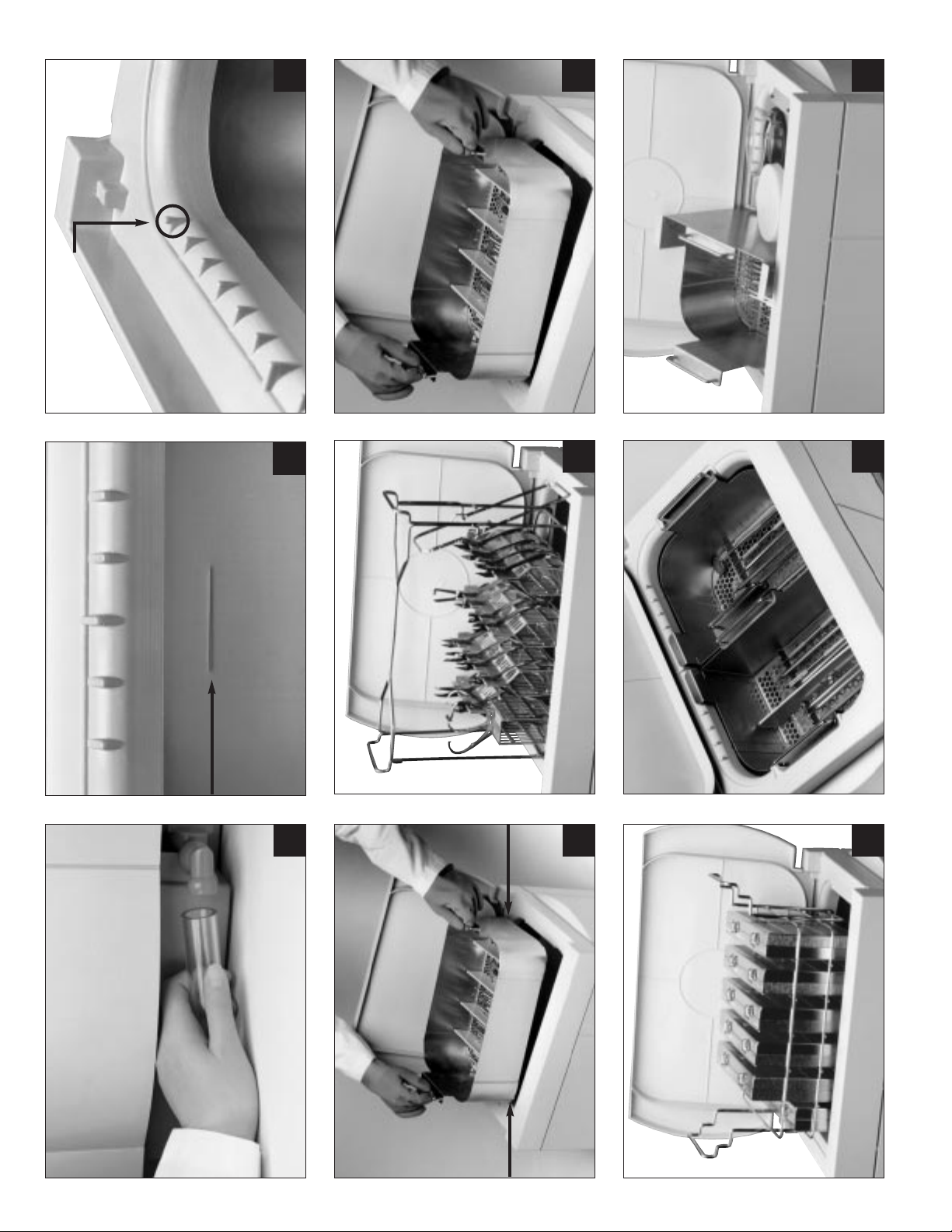

1. The DDUS60P for use with Dentronix Vertical Plier Stands.

Slide up to four (4) large or up to eight (8) small Dentronix

Vertical Plier Stands into the “rails” on the bottom of the rack

(Fig. 5). The Plier Stands will be held in place during handling,

even when held at an angle. The handle on top of the rack

facilitates lowering and raising the rack into and out of the

tank, and is also equipped with a “kick stand” for draining on

the bezel of the unit.

2. The DDUS60K and DDUS60W for use with Instrument Basket

Cleaning:

Place parts to be cleaned into the basket. Then place the

basket directly into the main tank containing ultrasonic solution.

NOTE: Baskets are furnished with adjustable Section Inserts

(DDUS60I) to keep instrument set-ups separated by user or

procedure, eliminating sorting and speeding instrument

processing

(Fig. 6). Baskets are not recommended for the

cleaning of cutting instruments, and baskets are not

designed for use in the DDS5000 dry heat sterilizer. For more

information, contact Dentronix.

3. The DDUS60S for use with Instrument Cassette Cleaning:

Place loaded rack into tank containing ultrasonic cleaning

solution

(Fig. 7)

B. In Beaker (for specialized item cleaning):

Place item into a beaker (DDUS60B), add desired cleaning

solution (e.g. Dentronix DCR-2 Cement Remover) according to

the manufacturer’s directions. Place the beaker band around

the beaker so that the bottom 1/3 will be suspended in the main

bath. Suspend the beaker in the tank by using the beaker posi-

tioning cover (DDUS60C).

V. Accessory Use Directions

A. DDUS60P – DentronixVertical Plier Stand Rack

Slide up to four (4) large or up to eight (8) small Dentronix

Vertical Plier Stands into the “rails” on the bottom of the rack.

The Plier Stands will be held in place during handling, even

when held at an angle. The handle on top of the rack facilitates

lowering and raising the rack into and out of the tank, and is also

equipped with a “kick stand” for draining on the bezel of the unit.

B. DDUS60K –

Large hands-free FingerGuard™ Instrument Basket

Dentronix Large FingerGuard Instrument Basket cleans large

volumes of instruments and increases instrument processing

efficiency. The Large FingerGuard Instrument Basket comes with

five (5) adjustable Basket Section inserts, which help stabilize

Vertical Plier racks or sort scalers and such by set-up or type.

C. DDUS60W –

Twin hands-free FingerGuard™ Instrument Basket

The Twin FingerGuard Basket provides you with the versatility of

cleaning two basket loads of instruments or basket and beaker

cleaning simultaneously. Place Twin FingerGuard Baskets side by

side, or use one basket with beaker positioning cover (DDUS60C)

(Fig. 8, 9). Twin FingerGuard Baskets may be used with or without

Owners Guide 5

Basket Section Inserts. Place instruments across ridges in bottom

of basket. Place basket in tank and clean for desired time.

D. DDUS60I – Basket Section Inserts

Place the “H” shaped Section Supports into the holes of the

raised ridge on the bottom of the basket. The tapered end

should be pointing up. Insert the flat Basket Section inserts into

the slots of the “H” shaped supports. For optimum stability, place

the supports at equal distance from the basket walls.

E. DDUS60C – Beaker Positioning Cover

Place the Beaker Positioning Cover on bezel. Place rubber ring

around the beaker so that at least 1/3 of the beaker is suspended

in the main bath. Clean for desired time. To reduce aerosols, place

white plastic beaker cover over the beaker during operation.

F. DDUS60S –

Hu-Friedy IMS(1) /Thompson(2) Instrument Cassette Racks

This rack will hold three (3) large or six (6) small cassettes. Up

to three (3) large cassettes may be placed horizontally in each

of the three tiers of the rack. Up to six (6) small cassettes can be

placed either horizontally or vertically in the rack. Place filled

rack in tank containing Dentronix solution. Once cassette

contents or instruments are cleaned, remove rack from tank and

tilt back over tank to drain (rack has stops on the back to prevent

the cassettes from sliding out (Fig. 7). Rinse rack and cassettes

on all sides thoroughly under running tap water. Place rack on

draining tabs of unit bezel to dry. (See Instrument Draining

section (III-D) for more details.)

(1) a registered trademark of Hu-Friedy Inc.

(2) a registered trademark of Thompson Inc.

VI. Environmental Conditions

• Intended for indoor use.

• Maximum altitude 2000m.

• Temperature range 5°C to 40°C.

• Maximum relative humidity 80% for temperatures up to 31°C,

decreasing linearly to 50% relative humidity at 40°C.

• Mains supply voltage fluctuations not to exceed 10% of the

nominal voltage.

• Transient over voltages category II.

• Pollution degree 2.

• Class I equipment.

VII. Warnings

• Do not operate the unit without sufficient solution in the tank.

• Do not use water alone as the carrier bath. Water is not a

satisfactory coupling agent unless a wetting agent is used.

For best results, use Dentronix DMP-US+Cleaner solutions.

• Do not place objects directly on bottom of the tank. They may

block cavitation, cause heat buildup in the transducer and

premature failure. Use accessory baskets, cassette racks or

beaker positioning cover to hold items.

• Do not use flammable liquids with Dentronix units.

• Do not restrict air flow. Provide adequate ventilation.

• Do not use acids in the stainless steel tank.

• Do not subject unit to shock or impact.

• Do not immerse the unit in water.

• Keep unit covered to reduce aerosols.

• Unspecified or improper use of this product may impair

safety protection.

• This equipment generates, uses, and can radiate radio

frequency energy and if not installed and used in accordance

with the instruction manual, may cause interference to radio

communications. It has been tested and found to comply with

the limits for an ultrasonic cleaner pursuant to Subpart C of

Part 18 of FCC Rules, which are designed to provide reason-

able protection against such interference when operated in

accordance with these instructions. Operation of this equip-

ment in a manner inconsistent with this manual is likely to

cause interference in which case the user, at his own expense,

will be required to take whatever measures may be required

to correct the interference.

VIII. Order Information

A. Units

Cat. No. Description Contents

DDUS60-115 Unit (115V, 50/60Hz) 1

DDUS60-230CE Unit (230V, 50/60Hz) 1

DDUS60R-115 Unit (115V, 50/60Hz) 1

DDUS60R-230CE Unit (230V, 50/60Hz) 1

B. Accessories:

DDUS60K Large hands-free FingerGuard

Instrument Basket 1

DDUS60W Twin hands-free FingerGuard

Instrument Basket 1

DDUS60P Dentronix Plier Stand Rack 1

DDUS60S Cassette Rack for Hu-Friedy IMS/

Thompson cassettes 1

DDUS60C Two-Beaker Positioning Cover 1

DDUS60I Basket Section Inserts 2

DDUS60F Replacement Drain Filters 3

DDUS60H Drain Hose 1

DDUS60B 600ml Borosilicate Beaker with

Cover and Rubber Ring 1

C. Ultrasonic Cleaning Solutions:

DMP-US+Super Concentrate General Purpose Ultrasonic

Cleaning Solution Concentrate in 8oz. (236ml)

Meter Dose Dispensing Bottle

D-CR2 Ultrasonic Cement Remover Concentrate in 8oz.

(236ml) Meter Dose Dispensing Bottle

IX. Unit Specifications

DDUS60 Countertop model

Tank capacity 4.8 gallons (18.3 liters)

Use capacity 4.0 gallons (15.2 liters)

Power 400 watts max

Operating frequency 40 kHz

100-115V Fuse T8A/250V, 5x20mm

230-240V Fuse T4A/250V, 5x20mm

Tank dimensions 14.0" x 9.0" x 8.75"

(35.6 x 22.9 x 22.2cm)

Overall dimensions 19.0" x 12.25" x 14.0"

(31.1 x 48.3 x 35.6cm)

6Dentronix Ultrasonic Cleaner

DDUS60R Recessed model

Tank capacity 4.8 gallons (18.3 liters)

Use capacity 4.0 gallons (15.2 liters)

Power 400 watts max

Operating frequency 40 kHz

100-115V Fuse T8A/250V, 5x20mm

230-240V Fuse T4A/250V, 5x20mm

Tank dimensions 14.0" x 9.0" x 8.75"

(35.6 x 22.9 x 22.2cm)

Above countertop 17.125" x 12.125" x 2.25"

(43.5 x 30.8 x 5.7cm)

Below countertop 17.125" x 13.0" x 14.0"

(43.5 x 33.0 x 35.6cm)

Electronic enclosure 17.0" x 7.5" x 4.5"

(43.2 x 19.0 x 11.4cm)

Complies with the MDD93/42/EEC

ISO 3864, No. B.3.1

Caution (refer to accompanying documents)

ISO 3864, No. B.3.6

Caution, risk of electric shock

C-UL-US listing is for the following catalog number

items only: DDUS60-115, DDUS60R-115

417-IEC-5016-a

Fuse location

X. Maintenance and Service

A. Cleaning

All components should be cleaned each day by wiping with a

soft cloth moistened with a commercially available mineral

deposit remover. Follow by cleaning with isopropyl alcohol or a

mild disinfectant. The stainless steel surfaces of the enclosures

should be cleaned with a stainless steel cleaner or isopropyl

alcohol when needed. Do not use phenolic based cleaners on

the electronics enclosure (DDUS60R only).

CAUTION: Do not use petroleum based solvents, iodophors or

phenolic based products. (Iodophors and phenolics can stain

the surface of the unit.) Clean up all liquid spills immediately.

B Inspecting the Power Cord

Periodically check the power cord for damage and see that the

connectors at both ends of the cord are fully seated.

C. Changing the Fuse

1. Turn the main power switch to the “off” position.

2. Remove the power cord from the wall outlet first and then

from the power cord receptacle on the rear of the unit.

!

3. The fuse is held by a fuse drawer which is inserted into the

fuse holder. The fuse holder remains fixed to the

DDUS60/DDUS60R housing. The fuse drawer encircles the

fuse and allows the fuse to be removed from the fuse holder.

These parts are located directly next to the power cord

receptacle. To access the fuse in the 115V unit, insert a small,

flat blade screwdriver in the slot on the fuse drawer and pry

the drawer open. To access the fuse on the 230V unit,

depress the center tab on the fuse drawer and pull the

drawer open.

4. Remove the fuse from the fuse drawer.

5. Examine the fuse. If it is blown, replace with a fuse which

matches the fuse type listed under the unit specifications

section of this manual. If fuse appears to be in good condi-

tion and power is not activated when the main power on/off

switch is turned “on,” return the unit to Dentronix.

6. Slide the fuse back into the holder. To secure the fuse drawer,

simply push the drawer closed.

7. Make sure the main power switch is “off.” Plug the power cord

into the power cord receptacle on the rear of the unit. Then

plug the power cord into the wall receptacle.

D. Service

This unit must be serviced by an authorized Dentronix Service

Center and should always be shipped complete with tank

assembly and electrical control unit.

XI. Limited Warranty

This product has been carefully manufactured and has met strin-

gent quality assurance requirements. If, in normal use, it is found

defective in material or workmanship within a period of one year

from date of purchase, it will be repaired or at Dentronix’s option,

replaced. Tampering with any of the components, misuse, negli-

gence, alteration, water damage, accident, or lack of reasonable

or proper maintenance and care, will void this warranty.

THE FOREGOING IS IN LIEU OF ANY EXPRESSED OR

IMPLIED WARRANTIES, INCLUDING WITHOUT LIMITATION,

ANY WARRANTIES OR MERCHANTABILITY OR FITNESS

FOR USE.

DENTRONIX ASSUMES NO RESPONSIBILITY FOR ANY

INCONVENIENCE,LOSS,INJURY,OR DIRECT,INDIRECT,OR

CONSEQUENTIAL DAMAGE ARISING FROM THE POSSES-

SION OR USE OFTHE PRODUCT.

Any claim for damage or breakage in transit should be made at

once against the carrier. If factory service is required, be certain

to properly pack your equipment and return prepaid and insured

to the factory.

Dentronix is a division of Coltène/Whaledent Inc.

46

7 8 9

Draining

Tab Draining

Tab

5

12

Fill Line

3

Draining Tab

P/N 86674B

MANUFACTURER

Coltène/Whaledent Inc.

750 Corporate Drive

Mahwah, NJ 07430

Tel. 201-512-8000

Fax 201-529-2103

SOLD BY

Dentronix Inc.

101 Steamwhistle Drive

Ivyland, PA 18974

Tel. 215-322-4220

Fax 215-364-8607

AUTHORIZED

EU REPRESENTATIVE

Coltène Whaledent

Dentalvertriebs GmbH

Fischenzstraße 39

D-78462 Konstanz / Germany

Tel. +49-7531-1208-0

Fax +49-7531-27069

This product complies with

MDD/93/42/EEC

This manual suits for next models

1

Popular Other manuals by other brands

PTP Turbo Blankets

PTP Turbo Blankets Turbo Blanket Installation instructions manual

Aqua Medic

Aqua Medic Cubicus CF Operation manual

NEC

NEC NEC020513 Applications

Eneo

Eneo PLS-5308 Full manual

Kalamazoo

Kalamazoo KAL-OL-MB180 brochure

Painless Performance Products

Painless Performance Products 20110 installation instructions

Phoenix Gold

Phoenix Gold MS-250 user guide

Aston Global

Aston Global Langham SDR978 Installation and owner's manual

Aquadistri

Aquadistri SuperFish Aqua 20 Warranty and manual

Robinson

Robinson R-66 Series Lithium-Ion installation instructions

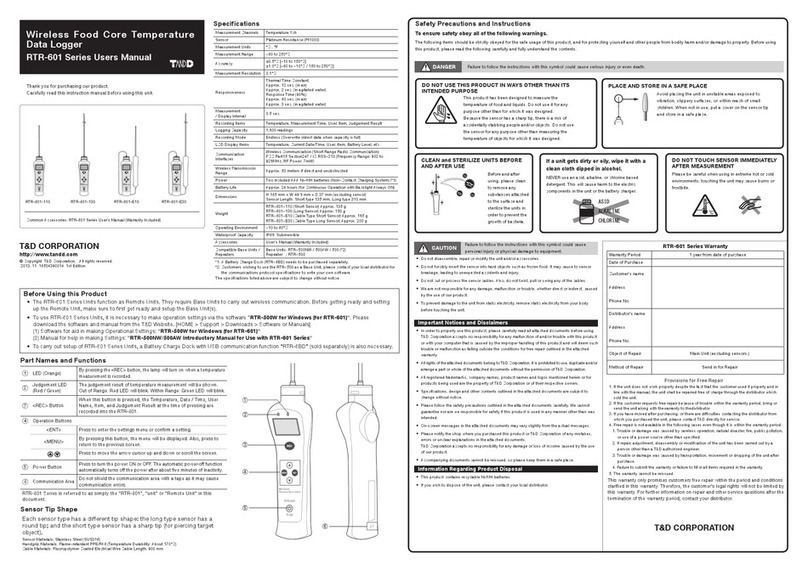

T&D

T&D RTR-601-130 user manual

aquaHabitats

aquaHabitats MicroHabitat 30 Instructions for use