Dentsply Maillefer CALAMUS DUAL Manual

A1300

Directions For Use

Instructions d'utilisation

Distributed by

F1902103.X / 03 / 2008 – updated 01/2014 GB-FR 3 / 38

Directions For Use

Table of Contents

1) INDICATIONS FOR USE......................................................................4

2) CONTRAINDICATIONS........................................................................4

3) WARNINGS .............................................................................................4

4) PRECAUTIONS ......................................................................................4

5) ADVERSE REACTIONS........................................................................5

6) STEP-BY-STEP INSTRUCTIONS.......................................................6

6.1) PACKAGE CONTENTS .............................................................................6

6.2) SETTING UP THE UNIT ............................................................................6

6.3) OPERATION ..............................................................................................7

6.4) STERILISATION, DESINFECTION & MAINTENANCE ...........................10

6.5) CLINICAL TECHNIQUE 12

6.6) TROUBLESHOOTING .............................................................................14

6.7) FREQUENTLY ASKED QUESTIONS......................................................14

6.8) WARRANTY & SERVICE.........................................................................15

6.9) SPECIFICATIONS ...................................................................................15

6.10) CERTIFICATION......................................................................................16

6.11) STANDARD SYMBOLS ...........................................................................16

7) DISINFECTION, CLEANING AND STERILISATION .................17

F1902103.X / 03 / 2008 – updated 01/2014 GB-FR 4 / 38

For dental use only

1) INDICATIONS FOR USE

Calamus Dual is an integrated obturation device with hand pieces that are used for Downpack (Pack)

and Backfill (Flow) of root canals.

The Pack hand piece is intended to heat pluggers for warming and softening gutta-percha master

cones and searing off gutta-percha cones.

This hand piece is also intended to heat accessory thermal response tips that subject a tooth to heat

in order to determine pulp vitality.

The Flow hand piece is intended for heating and placement of gutta-percha into the root canal.

The single-use cartridges are destined for placement of the heated gutta-percha into the cleaned and

shaped canal.

2) CONTRAINDICATIONS

Do not use on patients with a known sensitivity to natural rubber latex, silver or copper.

3) WARNINGS

Equipment is not suitable for use in the presence of a flammable mixture.

The gutta-percha cartridges contain natural rubber latex which may cause an allergic reaction.

When replacing a cartridge during a procedure, the hand piece cartridge nut and expended

cartridge may be hot to the touch. CAUTION: Do not remove a hot cartridge!

Risk of fire: Do not contact the heated tip or hand piece with flammable gases or liquids.

Do not immerse in water. Dropping the unit into water may cause electric shock.

This equipment provides ordinary protection against harmful ingress of liquids. Do not submerge

the hand piece or cartridges in any liquid or spray any fluid directly onto the hand piece.

Plugger tips become hot during use. Turn off unit and allow to cool before exchanging tips.

Do not clean unit with a flammable cleaning solution.

4) PRECAUTIONS

A rubber dam should be used with any dental procedure.

Always unplug the unit before changing fuses or adjusting the voltage selector.

Applying too much pressure with the Flow hand piece may result in a broken cannula.

Place the cannula gently into the canal. Too much pressure will stop the motor from turning.

Take care when replacing a cartridge during a procedure, the cartridge nut and the expended

capsule may be hot to the touch.

The forward portion of the Flow hand piece becomes warm during use. The heat shield (included

with the system) may be used optionally to reduce the hand piece surface temperature. If the heat

shield is not utilized, avoid contact with the forward portion of the Flow hand piece.

When replacing tips during a procedure, the plugger tips may be hot to the touch.

The Calamus device may be used only with original Calamus tips and cartridges!

This product must only be used in hospital environments, clinics or dental offices by qualified

dental personnel.

F1902103.X / 03 / 2008 – updated 01/2014 GB-FR 5 / 38

Three digit LED

display

Chemclaving is not recommended for sterilization and maintenance of the tips as this would

cause corrosion.

Do not stay in the root canal with a heated tip for more than 4 seconds for safety!

Place gutta-percha on the tip of the thermal response tip before applying the tip to the patient’s

tooth! Do not place the tip directly on the tooth!

5) ADVERSE REACTIONS

Use in patients with a known sensitivity to latex, silver or copper may cause an allergic reaction. Such

an allergic reaction to latex may result in swollen eyes, lips or face. It may also cause difficulty in

breathing. The patient should be advised to notify you immediately if any of these symptoms occur.

OPERATIONAL CONTROLS & COMPONENT IDENTIFICATION

Figure 1 – Component & Control Identification

Figure 2 - Back of device

Decrease / Increase

Buttons

Voltage selecto

r

Programming Port

For Service / Production Use

Only

AC Power Cord Receptacle

Fuse Compartment

Pack hand piece Flow hand piece

Pack temperature key

Preset keys

–

User Definable

Activation cuff

Pack activation indicato

r

Blue LED indicates

Pack side in use

Pack tone volume key

Thermal response key

Hand piece cartridge nut

Blue LED indicates

Flow side in use

Activation cuff

Gutta-Percha level indicato

r

Flow Temperature key

Flow rate key

Flow hand piece connecto

r

Power On/Off switch

Pack hand piece connector

Flow Cartridge Plunger

Retract Key

F1902103.X / 03 / 2008 – updated 01/2014 GB-FR 6 / 38

6) STEP-BY-STEP INSTRUCTIONS

6.1) PACKAGE CONTENTS

Calamus Dual obturation device with hand pieces for Downpack (Pack) and Backfill (Flow)

Remote power cord

Cartridge needle bending tool

Flow hand piece cleaning brush

Replacement cartridge nut

Flow hand piece heat shield

Directions for use

Additional products to be used with the device:

Pluggers:

Small Black ISO 40/.03

Medium Yellow ISO 50/.05

Large Blue ISO 60/.06

Thermal Response Tip

Package of 10 gutta percha cartridges, size 20G (0.8 mm / 90µl/ 0,25g)

Package of 10 gutta percha cartridges, size 23G (0.6 mm / 90µl/ 0,25g)

6.2) SETTING UP THE UNIT

1. Unpack the console and check that the Voltage Selector is set to the proper voltage. Use the

115V position for 110-120V 60Hz voltages, and the 230V position for 220-250V 50Hz voltages.

Always unplug the unit before changing fuses or adjusting the voltage selector. To change

voltage, use a flat head screwdriver to turn the Voltage Selector on the back of the console to the

proper voltage setting. To change voltage, replace the fuse to match voltage (see Specifications).

Replace with 0,3 A, 230/250V slow blow fuse (0,6 A for 115V). For replacement, press on the

black plastic clip of the fuse, pull out and replace with the correct fuse. See Fig. 2

2. Remove packaging from hand pieces. Clean the exterior of the hand pieces with a soft cloth

moistened with mild non-chlorinated detergent or disinfecting solution. Do not use disinfecting

solutions which contain phenol, anticorrosives, very acidic or very alkaline solutions - do not

submerge hand pieces.

Place the hand pieces into their respective holders - Pack on the left side and Flow on the

right side.

The forward portion of the Flow hand piece becomes warm during use. The heat shield (included

with the system) may be used optionally to reduce the Flow hand piece surface temperature. If

the heat shield is not utilized, avoid contact with the forward portion of the hand piece. Sterilize

the heat shield before first use and between each patient use. See Sterilization, Disinfection &

Maintenance.

3. Connect hand piece cables to console: The hand piece cables are color-coded and keyed to only

fit the proper receptacle on the console. With the arrow on the connector facing up, gently push

the connector into the console receptacle.

4. Attach the power cord to the back of the console and plug into a grounded electrical outlet.

5. Sterilize Pluggers and Thermal Response Tip: Steam autoclave for 18 minutes at 134°C.

6. Pack: Install plugger into Pack hand piece: Push plugger into hand piece tip and slowly rotate it

until it keys in with hand piece tip. Push plugger in fully.

F1902103.X / 03 / 2008 – updated 01/2014 GB-FR 7 / 38

7. Flow: Remove a cartridge from blister pack and install cartridge into Flow hand piece: Unscrew

and remove the cartridge nut from the hand piece. Insert a cartridge into the hand piece, needle

facing outward. Slip cartridge nut over needle and screw cap on clockwise lightly - do not tighten.

NOTE: Take care when replacing a cartridge during a procedure, the hand piece cartridge nut

and the expended cartridge may be hot to the touch.

Note: Allow cartridge to cool before removing. If the cartridge doesn’t fit completely into the

hand piece, press the Power switch on the front of the console to the ‘ON’ position and press the

Return button on the console.

The plunger must be in its retracted position to accept the cartridge.

8. Turn the unit to the ‘OFF’ position before replacing a cartridge.

9. Gently place the heat shield over the cannula and hand piece as necessary. Then turn the heat

shield to make the flow indicator visible.

Figure 3 – Flow hand piece with heat shield

10. Use the cannula bending tool to place a smooth radius curve on the cannula so the cannula can

extend to within 5 mm of the working length of the canal.

11. Place the cannula between the two raised bending posts. Gently bend the cannula to the desired

angle.

12. The device is now ready for operation.

WARNING: Do not touch hot pluggers or hot cartridges.

6.3) OPERATION

After the unit has been set up, you are ready for operation as follows:

1. Turning the device on

Press the Power On/Off switch located on the front panel. Power is applied and removed to the device

by alternately pressing and releasing this switch.

Buttons on the left side of the keypad are destined for Downpack, buttons on the right are for

Backfill. To change settings use up and down buttons.

2. Pack or Flow side activation

To activate either side of the device, do one of the following: Press the hand piece cuff or any

button for the Pack or Flow side. The blue LED indicator at the top of the device will light

indicating which side is active. (At initial power on, the Pack side of the device is turned on by

default, regardless of which side of the device was last used.) The last used settings are

retained in memory.

F1902103.X / 03 / 2008 – updated 01/2014 GB-FR 8 / 38

3. PACK Side - Program new temperature and volume settings

a. Press the Pack Temperature button on the left side of the keypad and then use the up/down buttons

to set the desired temperature. Press either button repeatedly to increase/decrease the temperature in

10°C increments, or hold down the button to rapidly scroll through the temperature range (100°C

minimum to 400°C maximum). The temperature settings are displayed on the numerical LED Window

and the yellow Pack Temperature LED illuminates, indicating that the temperature setting mode has

been enabled. NOTE: The thermal response mode temperature is preset to 90°C and is not

adjustable.

b. Press the Volume button and then use the up/down buttons to set the desired audible tone volume.

Press either button repeatedly to increase/decrease the volume level in 20% increments, or hold down

a button to rapidly scroll through the volume range (0% minimum to 100% maximum). The volume

settings are displayed on the numerical LED Window and the yellow Volume LED illuminates,

indicating that the volume setting mode has been enabled. NOTE: The numerical LED Window

automatically defaults to displaying the selected temperature setting. If the Volume button is pressed,

the numerical LED Window will display the volume for 5 seconds and then revert to the selected

temperature setting.

4. Flow Side - Program new temperature and flow rate settings

a. Press the Flow Temperature button on the right side of the keypad and then use the up/down

buttons to set the desired temperature. The LED diode next to the button will flash, indicating that the

hand piece is heating up.

b. Press the Flow Rate Button and use the up/down buttons to set the desired flow rate.

5. Store your custom settings

To store your new settings for later recall, press either of the two Preset keys and hold for

approximately two seconds. The specific Preset key’s LED will illuminate when the settings have been

successfully stored. Settings for both the Pack side and Flow side are now stored in memory.

6. Preset Use

The two Preset buttons store all of the settings for both the Pack and Flow sides of the device. The

factory default settings are: 200°C temperature and 40% tone volume for the Pack side and 170°C

temperature and 60% flow rate for the Flow side. The Thermal Response key is set at 90°C and is

fixed at that setting for the Pack side. The presets can be manually programmed to store your

personal settings by pressing and holding either Preset button for at least two seconds. The Preset

button’s LED will illuminate indicating that it is active.

7. Operation - PACK

Press the circumferential cuff on the hand piece to begin heating its tip to the selected temperature

setting. If the Temperature LED is illuminated, the selected temperature will display on the numerical

LED window. As the tip’s temperature rises, one tone frequency (approximately 2500 Hz) is heard.

Once the tip is within 20°C of the selected temperature setting, the tone will change to a lower

frequency (approximately 2000 Hz) and remain at this tone until the hand piece cuff-switch is

released. When pressing the cuff, the tip will heat for a maximum time of 15 seconds if the selected

temperature setting is 200°C or lower. For temperature settings above 200°C, the tip will heat for no

more than 10 seconds before timing out and turning off. When in the thermal response mode, the tip

will heat for up to one minute while the cuff switch is depressed. To restart heating after a timeout has

been reached, release the hand piece cuff and then press it again.

NOTE: The temperature setting on the console has been optimized based on clinical review.

Therefore, the setting does not directly correlate to the absolute temperature of the heated plugger.

CAUTION: Do not stay in the root canal with a heated tip for more than 4 seconds for safety!

CAUTION: Place gutta-percha on the tip of the thermal response tip before applying the tip to

the patient’s tooth! Do not place the tip directly on the tooth!

CAUTION: Always press the thermal response key to set the temperature to 90°C before

starting the pulp sensitivity test!

F1902103.X / 03 / 2008 – updated 01/2014 GB-FR 9 / 38

8. Operation - Flow

Dispense gutta-percha: Press the activation cuff to start the flow of filling material. You will notice a

short delay as the plunger engages and pushes gutta-percha to the tip of the needle. Extrude a small

amount of gutta-percha from the needle. Wipe the excess gutta-percha from the tip before inserting

the needle into the canal. Engage the needle within the root canal in accordance with your preferred

technique. Hold the hand piece lightly when placing material to allow the device to readily back out of

the canal. As the material is expressed, the indicator will help you estimate how much material

remains in the cartridge.

Note: Applying excessive downward pressure or not allowing the cannula to back-out of the

canal may result in a broken cannula.

9. Standby Mode Flow

After 20 minutes of inactivity, the Flow heater will turn off and slowly cool to room temperature. The

Temperature LED will also go out. Press any button on the Flow side of the console to reactivate the

Flow heater.

10. Replacing a cartridge

NOTE: When replacing a cartridge during a procedure, the hand piece cartridge nut and

expended cartridge are hot to the touch.

1. Select a 20 or 23 gauge cartridge.

2. Retract the delivery plunger by pressing the Return button.

3. Turn the unit off.

4. Allow the hand piece to cool.

5. CAUTION: Allow cartridge to cool before removing.

6. Unscrew and remove the Flow hand piece cartridge nut.

7. Using the hole in the included bending tool, remove the cartridge from the hand piece.

8. Dispose of used cartridge in an appropriate biohazard container.

9. Insert a new cartridge, cannula out, into the hand piece end.

10. Slip cartridge nut over cannula and screw on clockwise lightly - do not tighten.

11. Cool hand piece cartridge nut before removing any excess gutta-percha.

11. Replacing the fuses

NOTE: The Calamus Dual is manufactured with 250V 300mA rated fuses installed for a 230VAC

power source. If power source is 115 VAC, ensure that 250V 600mA rated fuses are installed.

WARNING: Turn the power off and unplug the unit before following the steps below.

1. Remove the fuseholder from the power inlet connector.

2. Replace the fuses in the fuseholder.

Replacement Fuses:

230V: 300 mA, 250V rated slow-blow type (Fuse size: 5 x 20mm)

115V: 600 mA, 250V rated slow-blow type (Fuse size: 5 x 20mm)

3. Replace the Fuseholder.

Figure 4 – Fuse Holder

AC Power INLET

connecto

r

Fuse Holder

F1902103.X / 03 / 2008 – updated 01/2014 GB-FR 10 / 38

Figure 5 - FLOW HAND PIECE COMPONENTS

Figure 6 - PACK HAND PIECE COMPONENTS

6.4) STERILISATION, DESINFECTION & MAINTENANCE

Control Console – Clean the exterior of the console by wiping with a soft cloth moistened with mild

non-chlorinated detergent or disinfecting solution. Do not use disinfecting solutions which contain

phenol, anticorrosive or very acidic or very alkaline solutions.

CAUTION: DO NOT SUBMERGE the device in any fluid.

NOTE: When wiping down the hand piece cable, gently wipe from the middle of the cable out to the

hand piece and console. Avoid gripping the cable tightly.

Hand pieces – Clean the exterior of the hand piece with a soft cloth moistened with mild non-

chlorinated detergent or disinfecting solution. Do not use disinfecting solutions which contain phenol,

anticorrosive, very acidic or very alkaline solutions.

CAUTION: DO NOT SUBMERGE the hand pieces in any fluid or spray any fluid directly onto the hand

pieces.

Hand piece Cartridge Nut

Ventilation Gap

Gutta-Percha Level indicator

Hand Piece Activation Cuff

Electrically Heated Plugger

Activation Cuff

Blue Activation Indicator

F1902103.X / 03 / 2008 – updated 01/2014 GB-FR 11 / 38

PACK:

Pluggers and Thermal Response Tip

Keep the connector portion of the plugger clean. Oxidation from repeated autoclaving should be gently

removed. This maintenance will insure proper electrical connection to the hand piece.

Pluggers and tips must be cleaned, disinfected and sterilized before every use:

1. Gently use a brush for removal of debris. Clean the disinfected pluggers and tips under running

water for a minimum of 1 minute. Clean with water and mild, non-abrasive, detergent or disinfection

solution. Do not use disinfecting solutions which contain phenol, anticorrosive, very acidic or very

alkaline solutions. Clean the disinfected pluggers and tips under running water for a minimum of 1

minute to remove all chemicals. Dry thoroughly.

2. Steam autoclave plugger tips for 18 minutes at 134°C before initial use and between each patient

use.

3. Observe that the pluggers and thermal response tip you are using are not damaged. A deformed or

oxidized tip should be replaced. All tips will gradually lose their heating efficiency over a period of time.

4. The tips can be re-used, if they are treated with care, are not damaged or contaminated. Any further

use of damaged or contaminated tips is at the user’s own risk. All risk and liability is excluded in this

case.

NOTE: Observe the concentration of the cleaning or disinfecting solution stated by the manufacturer!

WARNING: Do not touch hot pluggers!

FLOW:

Hand Piece Cartridge Heater - If gutta-percha gets into the cartridge heater section of the hand

piece, turn on the unit and press the Return button on the console to fully retract the plunger. Allow the

heater section to reach operation temperature (180°C). Turn off unit. Insert the included hand piece

cleaning brush into the heating chamber. Rotate the brush several times to remove the gutta-percha

from the chamber.

Hand Piece Delivery Plunger – Annually: Without a cartridge inserted, press the activation cuff

until the gutta-percha indicator moves all the way forward. Then, push the Return button and allow the

indicator to completely retract.

Hand Piece Cartridge Nut - Allow the Flow hand piece cartridge nut to cool before removing any

excess gutta-percha. The cartridge nut may be steam autoclaved for 18 min at 134°C.

Cartridges – Cartridges are intended for single patient use. Prior to using the device on a patient,

wipe the cannula with alcohol or a disinfectant. (Make sure that the device has been switched off and

cooled down.) Store cartridges at room temperature. Do not immerse the cartridges into any liquid.

Dispose of cartridge in a biohazard container. The cartridges must not be used after the expiration date!

Heat Shield – Steam autoclave for 18 minutes at 134°C.

NOTE: All liability is disclaimed for failure to follow these instructions or use of non-validated

methods for the re-use of instruments!

F1902103.X / 03 / 2008 – updated 01/2014 GB-FR 12 / 38

6.5) CLINICAL TECHNIQUE

Only use filling materials compatible with this filling technique such as Gutta-percha (for consistency)

or root canal sealer.

The actual temperature in the root canal largely depends on the amount of filling material used.

Although the device is able to precisely control the heat transmission to the tip, it is unable to prevent

undesired heating up of the root. We recommend testing on extracted teeth.

ATTENTION: Do not penetrate the root canal with a heated tip for more than 4 seconds for

safety!

ATTENTION: Recommended temperature setting is 200˚C for all downpack techniques!

NOTE: Do not touch the lips, the gums or the oral mucosa with the plugger, the cannula or the

hand piece cartridge nut, as they may get hot to the touch after longer exposure.

INSTRUCTIONS FOR USE

6.5.1) Cone Fit & Plugger Selection

1. Prepare the canal optimally recognizing shaping facilitates 3-D cleaning and filling.

2. Select a larger size manual plugger that will work passively and effectively over a range of a

few millimeters in the coronal one-third of the canal.

3. Select a medium size manual plugger that will work passively and effectively over a range of a

few millimeters in the middle one-third of the canal.

4. Select a smaller size manual plugger that will work passively, effectively and deeper in the

straightaway portion of the canal and to within 4-5 mm of the canal terminus.

5. Select an electric heated plugger that will passively fit through the straightaway portion of the

canal and optimally to within 5 mm from the working length. Set the silicone stop at this depth

to promote safety and accuracy.

6. In a fluid-filled canal, fit a non-standardized, fully tapered gutta-percha master cone that

visually goes to the working length, exhibits apical tugback and is confirmed radiographically.

7. Dry the canal with appropriately sized paper points to determine final working length.

8. Trim the master cone back to the canal terminus based on the paper point drying technique.

9. Lubricate the master cone lightly with sealer and gently insert it to length.

6.5.2) Downpack: Continuous Wave Technique

1. Activate the electric heat plugger and sear off the master cone at the level of the orifice.

2. Select the larger manual plugger and step its working end around the circumference of the

canal using short, firm strokes to move gutta-percha apically, clean the canal walls and flatten

the material.

3. Use this larger manual plugger and press for five seconds to compact warm gutta-percha

vertically and laterally into this region of the root canal system (first wave of condensation).

F1902103.X / 03 / 2008 – updated 01/2014 GB-FR 13 / 38

4. Activate the electric heated plugger and, in one deliberate and continuous motion, press the

heated plugger through the thermosoftened gutta-percha until the silicone stop is 2 mm from

the reference point. This procedure must be limited to two to four seconds to prevent thermal

injury.

5. Deactivate the plugger and continue to maintain firm apical pressure on the cooling instrument

until the silicone stop reaches the reference point.

6. Maintain firm apical pressure for ten seconds to compact the mass of warm gutta-percha into

the apical one-third of the root canal system and to offset shrinkage during the cooling phase.

7. Activate the electric heated plugger for one second, then deactivate and remove the plugger

from the root canal using a back and forth motion. This procedure separates and removes

gutta-percha from the coronal two-thirds of the canal without disturbing the gutta-percha in the

apical one-third.

8. Select the small manual plugger and step its working end around the circumference of the

canal using short, firm strokes to clean the canal walls and re-condense the most coronal

aspect of the gutta-percha within the apical one-third.

9. Use Flow hand piece to optimally fill the rest of the canal.

6.5.3) Backfill

1. Position the tip of the warm cannula against the previously packed filling material for 5

seconds.

2. Press the activation cuff on the Flow hand piece and dispense a small (a few millimeters)

segment of warm gutta-percha into this region of the canal. Hold the hand piece lightly so it will

back out of the canal during use.

3. Select the smaller manual plugger and step its working end circumferentially around the canal

using short, firm strokes to clean the canal walls and flatten the dispensed warm gutta-percha.

4. Use the same small manual plugger and press for five seconds to three-dimensionally compact

warm gutta-percha into this region of the canal and to offset shrinkage during the cooling

phase.

5. Position the tip of the warm cannula against the previously packed filling material for five

seconds.

6. Press the activation cuff on the Flow hand piece and dispense a few more millimeters of warm

gutta-percha into this region of the canal.

7. Select the medium size manual plugger and step its working end circumferentially around the

canal using short, firm strokes to clean the canal walls and flatten the dispensed warm gutta-

percha.

8. Use the same medium size manual plugger and press for five seconds to three-dimensionally

compact warm gutta-percha into this region of the canal and to offset shrinkage during the

cooling phase.

9. Continue the backfilling technique, in the manner described, until the canal is completely filled

or stop at any point to accommodate a post to facilitate the restorative needs.

F1902103.X / 03 / 2008 – updated 01/2014 GB-FR 14 / 38

6.6) TROUBLESHOOTING

1. Device does not turn on:

a) Verify that the power cord is plugged into the device and into wall outlet.

b) Unplug device and check fuse. If fuse is blown, replace it. See Operation, Replacing the fuses.

2. Flow: Cannot remove hand piece cartridge nut:

a) Press Return button and allow drive mechanism to back out in order to relieve pressure on cartridge

nut.

3. Flow: Gutta-percha does not flow through cannula:

a) Verify that the cannula is not kinked - avoid over bending of cannula.

b) Verify that the device has reached operational temperature for gutta-percha to flow.

c) Increase temperature if needed.

4. Pack: Hand piece does not work:

a) Make sure the tip is sitting in the hand piece correctly.

b) Replace tip.

5. Pack: The tip does not get warm:

a) Check temperature settings.

b) Replace tip with a new one.

6. Flow: Delivery plunger does not retract:

a) If, after pushing the Return button, the gutta-percha indicator does not fully retract to the end of the

indicator window, push the Return button again.

7. Flow: Motor stops turning:

a) If the motor stops turning, the cannula may have been placed too firmly in the canal. Reduce the

pressure applied to the cannula and the motor may begin turning again.

6.7) FREQUENTLY ASKED QUESTIONS

What size is the smallest tip?

The smallest is the small black plugger with ISO 40 Taper 03. The material of the outer surface is

made out of stainless steel.

How hot can a tip get?

At maximum power, a tip can reach 400°C. You can adjust the heat down to 100°C by using the

lowest power setting. The recommended working temperature for downpack is 200°C.

Isn’t this high temperature dangerous?

Like other dental equipment, the unit should only be used by a trained professional. You can use the

high heat setting to sear off gutta-percha in the lateral condensation technique where a cluster of

cones are cut through. If you want to remove gutta-percha, with continuous wave technique you

should use a lower heat setting of 200°C.

What is the normal power setting?

The maximum heat setting should be used only when searing off gutta-percha. For the vertical

condensation technique and continuous wave technique, we recommend a power setting of 200°C.

How long will the tip last?

It depends on how well you take care of the tip. The life of a tip will be reduced by:

a. running it too hot for long periods of time

b. working with high temperatures

c. bending or putting to much mechanical force on it.

F1902103.X / 03 / 2008 – updated 01/2014 GB-FR 15 / 38

The tips should be used only to transfer heat – not to exert manual force! Our recommendation

is that you use a cold manual plugger for that purpose. All tips will gradually lose their heating

efficiency over time. This is strongly depending on the user.

6.8) WARRANTY & SERVICE

Manufacturer warrants this product against defects in material or workmanship for a period of one

year, from date of original invoice.

Manufacturer’s sole obligation under product warranty is (at its sole option and discretion) to repair or

replace any defective component or product in part or whole. Manufacturer shall be the sole arbiter of

such action.

In the event of alleged defect under warranty, the purchaser is to notify the distributor promptly. The

distributor will provide instructions, usually directing that the product be returned for service. Shipment

to the manufacturer and the cost thereof is always the responsibility of the purchaser.

Accidental misuse, inappropriate installation, or failure to perform directed maintenance voids the

warranty.

Manufacturer does not assume, under this warranty, any risks or liabilities arising from the clinical use

of its products, whether or not such use involves coincidental utilization of products manufactured by

others.

Manufacturer makes no warranty other than that stated above, express or implied.

6.9) SPECIFICATIONS

Console dimensions: 11,2 cm x 15,0 cm x 15,2 cm (4.4” x 5.9” x 6.0”)

Weight: 1,6 kg (3.6 lbs)

Power source: 115V/60Hz, 230V/50Hz

Current rating: 115V/0,6A, 230V/0,3A

Fuses: 115V: 0,6A/250V Slo-Blo® fuse

230V: 0,3A/250V Slo-Blo® fuse

Plugger: Stainless Steel

Cartridge contents: Gutta Percha

Cartridge: Aluminium

Cannula: Silver

Environmental Conditions:

Operating Temperature : 10° to 28°C (50° to 82.4°F)

Storage Temperature : -20° to 60°C (-4° to 140°F)

Relative Humidity : 5 to 95% non-condensing

Altitude : 0 to 3048 meters (0 to 10,000 feet)

Pack Duty Cycle: 25%

Temperature range Pack : 100° – 400°C

Volume range Pack : 0 - 100%

Temperature range Flow : 160° – 200°C

Flow rate : 20% - 100%

Pack hand piece maximum continuous heating time:

10 seconds for temperatures above 200°C.

15 seconds for temperatures at or below 200°C.

One minute in thermal response mode.

F1902103.X / 03 / 2008 – updated 01/2014 GB-FR 16 / 38

Caution: This device has been tested and found to comply with the emissions requirements of IEC

60601-1-2:2001-09. These requirements provide reasonable protection against harmful

electromagnetic interference in a typical medical installation. However, high levels of radio-frequency

emissions from electrical devices, such as cellular phones, may disrupt the performance of this device.

To mitigate disruptive electromagnetic interference, position this device away from radio frequency

transmitters and other sources of electromagnetic energy.

6.10) CERTIFICATION

This product is classified as a Class IIa product and bears the CE marking (CE 0459). The

product complies with standards; Europe: IEC 60601-1, Canada: CAN/CSA-C22.2 No. 601.1 and

USA: UL 60601-1, First Edition (2003).

M

anufactured by: Aseptico, Inc., Woodinville, WA 98072, USA

Advena Ltd., Pure Offices, Plato Close, Warwick CV34 6WE UK

Distributed by:

Maillefer Instruments Holding Sarl,

CH-1338 Ballaigues, Switzerland

6.11) STANDARD SYMBOLS

Class II equipment

Type BF Applied part

Dangerous voltage

Alternating current

Hot surface

See directions for use

Green dot

Opened packages are not

replaced

Do not throw away. This product

and all its components must

absolutely be recycled through

your supplier.

Expiration date

Cartridge: aluminium

Cannula: silver

Cartridge contains gutta-percha

LATEX !

Caution, this product contains natural

rubber latex which may cause allergic

reactions

Keep away from sunlight and heat

Do not re-use

Fuse ratings

115V: 0.6A

230V: 0.3A

250V SLO-BLO

Pluggers are autoclavable

1 Package content

EU Authorised Representation

F1902103.X / 03 / 2008 – updated 01/2014 GB-FR 17 / 38

7) DISINFECTION, CLEANING AND STERILISATION

Reprocessing procedure for dental instruments and implantable radicular devices.

Foreword

For hygiene and sanitary safety purposes, all instruments not marked “sterile” must be cleaned, disinfected and

sterilized before each usage to prevent any contamination. This concerns the first use as well as the subsequent

ones.

Area of application

Disinfection and sterilisation before first usage and reprocessing procedures concerning:

A1. Instruments:

Cutting instruments, (hand and engine driven) such as:

Endodontic instruments (files, broaches, reamers, enlargers, endodontic burs, ultrasonic inserts);

Rotary cutting instruments (Diamond burs, tungsten carbide burs, stainless steel drills, carbon steel burs).

Root canal filling instruments (Pluggers, spreaders, compactors);

Supports, kits and instrument organisers

Hand instruments and clamps.

A2. Implantable devices:

Dentinal and radicular posts made of steel, titanium and glass fibers.

Supports, kits and organiser systems for posts.

A3. Contra angle

B. Filling material: Only chemical disinfection (no sterilisation)

Gutta percha, Thermafil obturation devices.

Exclusion

- Equipment such as Motors, Apex locators and other devices with reprocessing procedures included in the

individual Direction for Use.

- MTA, Glyde, TopSeal.

General recommendation

1 - Use only a disinfecting solution which is approved for its efficacy (VAH/DGHM-listing, CE marking, FDA

approval) and in accordance with the DFU of the disinfecting solution manufacturer. For all metal instruments, it is

recommended to use anticorrosion disinfecting and cleaning agents

2 - For your own safety, please wear personal protective equipment (gloves, glasses, mask).

3 - The user is responsible for the sterility of the product for the first cycle and each further usage as well as for

the usage of damaged or dirty instruments where applicable after sterility.

4 - Limitations and restrictions on reprocessing :

The individual DFU indicates if the useful life of a device might be reduced by the number of reprocessing

cycles.

Furthermore, the appearance of defects such as cracks, deformations (bent, twisted), corrosion, loss of colour

coding or marking, are indications that the devices are not able to fulfil the intended use with the required safety

level.

5 - Single use marked instruments are not approved for re-use.

6- The water quality has to be convenient to the local regulations especially for the last rinsing step or with a

washer-disinfector.

7 - Tungsten carbide burs, plastic supports, hand instruments and NiTi instruments are degraded by Hydrogen

Peroxide (H2O2) solution.

8 - NiTi Instruments are degraded if immerged more than 5 minutes in a solution of NaOCl at more than 5%.

9 - Instruments made of aluminium are degraded in presence of caustic soda solutions with mercury salt. Do not

use acid (pH < 6) or alkaline (pH > 8) solutions.

10- The washer-disinfector is not recommended for instruments made of aluminium, tungsten carbide or carbon

steel.

F1902103.X / 03 / 2008 – updated 01/2014 GB-FR 18 / 38

Step-by-step procedure

A. Devices

A

3. Contra Angle

A

2. Implantable devices

A

1. Instruments Following uses

First use

Operation Operating mode Warning

1. Disassembling - Disassemble the device,

if required

Silicone stops have to be removed. X

2. Pre-Disinfection

- Soak all instruments

immediately after use in a

detergent and disinfecting

solution combined with

proteolytic enzyme if

possible.

- Follow instructions and observe concentrations and

immersion times given by the manufacturer (an excessive

concentration may cause corrosion or others defects on

instruments).

- The disinfecting solution should be aldehyde free (to

avoid blood impurities fixation) and without di- or

triethanolamines as corrosion inhibitor.

- Do not use disinfecting solutions containing Phenol or

any products which are not compatible with the

instruments (See general recommendations).

- For visible impurities observed on instruments a pre-

cleaning is recommended by brushing them manually with

soft material.

X

3. Rinsing - Abundant rinsing (at least

1 min)

- Use quality water in accordance with local regulations.

- If a pre-disinfectant solution contains a corrosion

inhibitor, it is recommended to rinse the instruments just

before the cleaning.

X

4a. Automated

Cleaning

with washer-

disinfector

- Place the devices in a kit,

support or container to

avoid any contact between

instruments or posts.

- Put them in the washer-

disinfector

(Ao value > 3000 or, at

least 5 min at 90 °C).

- Discard any instruments with large obvious defects

(broken, bent).

- Avoid any contact between instruments or posts when

placing in the washer-disinfector use kits, supports or

container.

- Follow instructions and observe concentrations given by

the manufacturer (see also general recommendations).

- Use only approved washer-disinfector according to EN

ISO 15883, maintain and calibrate it regularly.

XXXX

OR

4b Manual Cleaning

or assisted by an

ultrasonic device

- Place the devices in a kit,

support or container to

avoid any contact between

instruments.

- Immerse in the disinfecting

solution with cleaning

properties, assisted by an

ultrasonic device if suitable.

- No visible impurities should be observed on the

instruments.

- Discard any instruments with large obvious defects

(broken, bent, and twisted).

- Follow instructions and observe concentrations and time

given by the manufacturer (see also general

recommendations).

- The disinfecting solution should be aldehyde free and

without di- or triethanolamines as corrosion inhibitor.

XXX

5. Rinsing - Abundant rinsing (at least

1 min)

- Use quality water in accordance with local regulations.

- If a disinfecting solution contains a corrosion inhibitor, it

is recommended to rinse the instruments just before the

autoclaving.

- Dry on a single use non-weaved cloth, or with a drying

machine or filtered compressed air.

XXX

6. Inspection - Inspect devices and sort

out those with defects.

- Assemble the devices

(stops)

- Dirty instruments must be cleaned and disinfected again.

- Discard instruments which show any deformations (bent,

twisted), damages (broken, corroded) or defects (loss of

colour coding or marking) affecting the resistance, the

safety or the performance of the instrument or posts.

- Protect carbon steel bur with corrosion inhibitor before

packaging.

- For Contra Angle : lubricate the device with an adequate

spray before packaging

XXXX

F1902103.X / 03 / 2008 – updated 01/2014 GB-FR 19 / 38

A

3. Contra Angle

A

2. Implantable devices

A

1. Instruments Following uses

First use

Operation Operating mode Warning

7. Packaging - Place the devices in a kit,

support or container to

avoid any contact between

instruments or posts and

pack the devices in

“Sterilisation pouches”.

- Avoid any contact between instruments or posts during

sterilization. Use kits, supports or containers.

- Check the validity period of the pouch given by the

manufacturer to determine the shelf life.

- Use packaging which are resistant up to a temperature of

141°C (286°F) and in accordance with EN ISO 11607.

XXXX

8. Sterilization - Steam sterilisation at:

134 °C / 273°F during 18

min.

- The instruments, posts and the plastic supports must be

sterilized according to the packaging labelling.

- Use only autoclaves that are matching the requirements

of EN 13060, EN 285.

- Use a validated sterilisation procedure according ISO

17665

- Respect the maintenance procedure of the autoclave

device given by the manufacturer.

- Use only this recommended sterilization procedure.

- Control the efficiency (packaging integrity, no humidity,

colour change of sterilisation indicators, physico-chemical

integrators,

digital records of cycles parameters).

- Traceability of procedure records

XXXX

9. Storage - Keep devices in sterilization

packaging in a dry and clean

environment

- Sterility cannot be guaranteed if packaging is open,

damaged or wet.

- Check the packaging and the medical devices before

using them (packaging integrity, no humidity and validity

period).

XXXX

B. Filling material

Operation Operating mode Warning

1. Disinfection - Immerse the obturation

devices in NaOCl (2,5 % at

least) during 5 mn at

ambient temperature.

- Do not use disinfecting solutions containing Phenol or any products

which are not compatible with the treated filling material

(See general recommendation).

Maillefer Ref. ZF1902103.FE / 03 / 2007 – updated 01/2014

Aseptico / PN 420567 / Rev-D / ECO 13254 – 01/2014

Maillefer Instruments Holding Sarl

Chemin du Verger 3

CH – 1338 Ballaigues

Switzerland

Manufactured by :

Aseptico, Inc.

P.O. Box 1548 - 8333 216th Street SE

Woodinville

,

WA 98072 - US

A

Distributed b

y

:

Advena Ltd.

Pure Offices, Plato Close, Warwick CV34 6WE UK

This manual suits for next models

1

Table of contents

Other Dentsply Maillefer Dental Equipment manuals

Dentsply Maillefer

Dentsply Maillefer X-SMART PLUS NE274 User manual

Dentsply Maillefer

Dentsply Maillefer THERMAPREP PLUS Manual

Dentsply Maillefer

Dentsply Maillefer START-X A0660 Manual

Dentsply Maillefer

Dentsply Maillefer X-SMART User manual

Dentsply Maillefer

Dentsply Maillefer ProTaper Series Manual

Dentsply Maillefer

Dentsply Maillefer ProTaper Universal Treatment Manual

Dentsply Maillefer

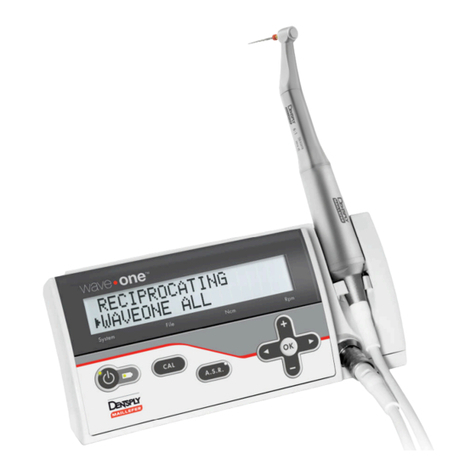

Dentsply Maillefer WaveOne endo motor User manual

Dentsply Maillefer

Dentsply Maillefer GUTTA CORE A Series Manual

Dentsply Maillefer

Dentsply Maillefer X-SMART Plus User manual

Dentsply Maillefer

Dentsply Maillefer X-SMART EASY User manual