Denville Scientific XL3000I XL8-10 User manual

XLM/11/2002 ANG OK 1/7/03 8:20 PM Page 1

XLM/11/2002 ANG OK 1/7/03 8:20 PM Page 2

6

XLM/11/2002 ANG OK 1/7/03 8:20 PM Page 4

CONTENTS

1 - INTRODUCTION

2 - VOLUME SETTING

3 - METHOD OF PIPETTING

4 - RECOMMENDATIONS

5 - RECALIBRATION

6 - MAINTENANCE

7 - PIPETTE KIT AND ACCESSORIES

8 - SPARE PARTS

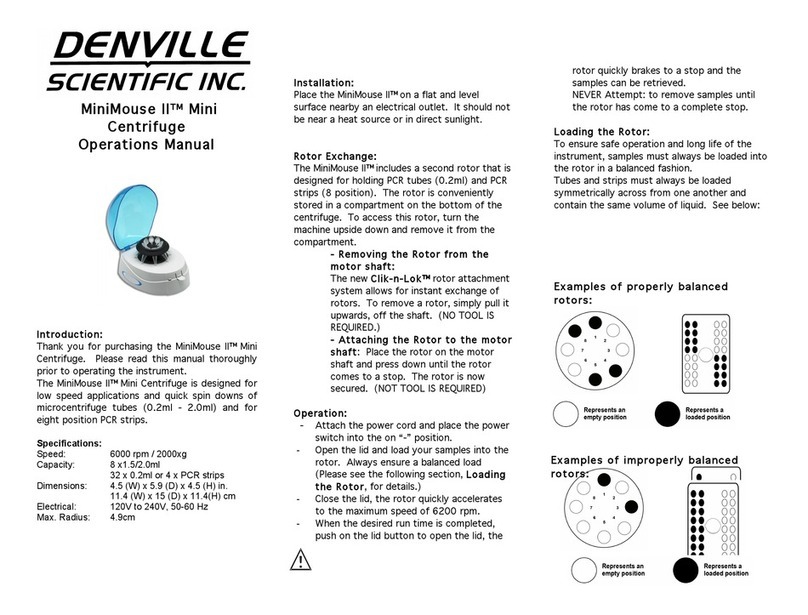

1 - INTRODUCTION

Multichannel p pettes have been

des gned for use w th m croplates. The p pettes

enable prec se

and s multaneous del very of 8

or 12 preset-volumes of l qu d.

Multichannel

p pettes are produced n four

ranges of volumes: 1-10 µl, 5-50 µl, 20-200 µl,

50-300 µl.

Multichannel p pettes

are

equ pped w th a d g tal readout counter, bu lt nto

the p pette’s handle,

for measur ng volumes,

(F g. 1F). Volume sett ngs are cont nuously

adjustable and are controlled by rotat ng the

cal brat on knob, (F g 1B). The volume range of

the

p pette

s nd cated on the p pett ng push-

button, (F g. 1A).

Multichannel p pettes

should be

used w th polypropylene d sposable t ps, to

ensure safety and accuracy, (F g. 1C). The

shafts ensure the compat b l ty of the

p pettes

w th a broad assortment of t ps, and the spec al

ejector shape reduces the force requ red for

the r eject on. In order to protect the user aga nst

nadvertent contact w th used t ps, the

p pettes

are equ pped w th t p ejectors, (F g. 1D). By

turn ng the mult channel module clockw se n

1 2

relat on to the handle, (F g. 2), t s poss ble to

d sable the ejector’s operat on n order to avo d

acc dental use, or to change ts pos t on n such

a way as to make f ll ng of m croplates more

conven ent.

The spec f cat ons for accuracy and prec s on

g ven n the follow ng table are obta ned us ng

t ps. These f gures are only

guaranteed when t ps are used.

8

channel

12

channel

The spec f cat ons for the volumetr c perfor-

mance are der ved from extens ve grav metr c

tests as prescr bed by the Deutsches Inst tut für

Normung e.V. To ver fy the performance of your

p pette

request document DIN 12650.

Cond t on of measurments: d st lled water at tem

-

perature 20±1°C.

The

p pette

des gn enables the user to perform

the recal brat on process accord ng to the

gu del nes presented n sect on 5.

XL8-10 Min 1 ±8.0 ≤ 8.0

Max 10 ±2.0 ≤ 2.0

XL8-50 Min 5 ±4.0 ≤ 3.0

Max 50 ±1.6 ≤ 1.0

XL8-200 Min 20 ±2.0 ≤ 1.5

Max 200 ±1.0 ≤ 0.8

XL8-300 Min 50 ±1.6 ≤ 1.5

Max 300 ±1.0 ≤ 0.8

Model No. Volume Inaccuracy Im recision

[µl] [%] [%]

Model No. Volume Inaccuracy Im recision

[µl] [%] [%]

SPECIFICATIONS

XL12-50 Min 5 ±4.0 ≤ 3.0

Max 50 ±1.6 ≤ 1.0

XL12-200 Min 20 ±2.0 ≤ 1.5

Max 200 ±1.0 ≤ 0.8

XL12-300 Min 50 ±1.6 ≤ 1.5

Max 300 ±1.0 ≤ 0.8

SPECIFICATIONS

XLM/11/2002 ANG OK 1/7/03 8:20 PM Page 6

2 - SETTING THE VOLUME

In order to set the volume of the sample to be

del vered, the cal brat on knob w th d splay s

used.

The volume shown by the d splay s repre-

sented

by three d g ts, wh ch should be read

from

top to bottom. Typ cal meter read ngs are

shown

n the follow ng table:

To ach eve accurate del very of the requ red

volume, the operator should turn the cal brat on

knob n the d rect on d m n sh ng d splay rea-

d ngs. If the volume be ng currently set s h gher

than the prev ous one, the operator should turn

the cal brat on knob 1/3 of a turn beyond the

requ red value, and then slowly rotate t back-

wards, observ ng d m n sh ng read ngs, unt l the

requ red value s ach eved.

3 - METHOD OF PIPETTING

F t the t ps onto the cones of the mult channel

module. When you put the t ps on the shafts the

p pette

should be pressed aga nst the t ps n the

box. The l qu d asp rated nto the t ps should

not flow out by grav ty from properly f xed t ps.

Wh le hold ng the

p pette

n a vert cal pos t on,

t ps should be mmersed n the l qu d to a depth

of 2-4 mm, and flushed once by draw ng a volume

of l qu d and d spens ng t out w th slow and

steady movement.

Model No.

Counter

readings

Set

volume

Basic

increment

0

3

5

2

5

0

0

8

5

0

6

5

XL8-10

XL8-50

XL12-50

XL8-200

XL12-200

XL8-300

XL12-300

3.5 µl

6.5 µl

85.0 µl

250.0 µl

0.02 µl

0.10 µl

0.20 µl

1.0 µl

3 4

Next, st ll hold ng the

p pette

vert cally, the ope-

rator should press the p pett ng button unt l the

f rst res stance po nt s felt, and mmerse the t ps

n the l qu d to the depth of 2-4 mm, (F g. 3B).

Releas ng the p pett ng button w th a slow and

un form movement dur ng 2-3 seconds, the l qu d

should be drawn nto the t ps, (F g. 3B) wh ch

should then be l fted above the l qu d’s surface.

The

p pette

should next be pos t oned at an

angle of 10-45 degrees n relat on to nner walls

of the dest nat on vessels and t ps should be

empt ed by press ng the p pett ng button

slowly unt l the f rst res stance po nt s felt,

(F g. 3C). After wa t ng one second, the p pett ng

button should be pressed to the second res s-

tance po nt n order to d spense rema n ng l qu d,

(F g. 3D). Then t ps should be l fted out from the

vessels wh le ma nta n ng contact between

the ends of the t ps and the nner walls of the

vessel unt l the p pett ng button has been

released, (F g. 3E). F nally, press ng the ejector

button, the operator should separate the t ps

from the mult channel module’s cones, (F g. 3F).

- RECOMMENDATIONS

To ach eve max mum safety, prec s on and re-

l ab l ty, the follow ng pr nc ples should be ob-

served:

• do not draw l qu ds w thout t ps f tted on the

p pette

cones,

• do not lay the

p pette

flat w th t ps f lled,

• do not draw volumes of l qu d exceed ng the

p pette

’s range,

• check f the t ps are f tted properly,

•dur ng operat on, the

p pette

must be held

vert cally, t ps should be mmersed n l qu d

to the depth of 2 to 4 m ll meters and the p pet-

t ng button should be depressed and released

slowly and evenly,

• new t ps must be re-wetted pr or to p pett ng,

by draw ng and expell ng the l qu d to be me-

asured. Th s s espec ally mportant when wor-

k ng w th l qu ds of v scos t es and dens t es

d fferent from that of water and n temperatu-

res other than amb ent temperature,

XLM/11/2002 ANG OK 1/7/03 8:20 PM Page 8

6

The recalibration can be performed within one

full turn of the key to the right or to the left only.

Recalibration conditions:

• Amb ent temperature and the temperature of

the p pette, t ps and l qu d should be w th n

the range 20-25°C and stab l zed dur ng we gh-

ng

w th n ±0.5

°

C

•Measurements should be conducted us ng

d st lled water

• Balance sens t v ty should be su table for the

volume to be controlled

Recalibration procedure:

• Set the volume depend ng on the p pette volu-

me accord ng to the follow ng table:

•Perform three asp rat on ser es (each ser es

should nclude the asp rat ons from all chan-

nels), we gh each t me and calculate the aver-

age value of the asp rat ons.

• Calculate average asp rated volume n µl mul-

t ply ng the average asp rat on amount [mg]

by the d st lled water dens ty coeff c ent

[µl/mg], wh ch depends on temperature and

pressure accord ng to the follow ng table:

5

• when p pet ng l qu ds wh ch tend to wet walls

of t ps, such as serums, prote ns, organ c sol-

vents, measur ng must be performed much

slower than w th other l qu ds,

•

t ps must be replaced w th new ones, when

chang ng from one l qu d to another, or f drops

of l qu d rema n ns de the t ps,

• after use, the p pette should be stored vert cal-

ly n a holder w th t ps removed.

5 - RECALIBRATION

Multichannel p pettes are cal brated

by grav metr c method, us ng d st lled water, at

the temperature 20±1°C, accord ng to DIN

12650.

If dur ng p pette operat on you f nd that the

accuracy error (the d fference between the real

asp rated volume and the preset volume)

exceeds the perm ss ble value g ven n the table

n sect on 1, the p pette recal brat on procedure

should be carr ed out.

Before start ng the recal brat on t s necessary

to check whether the follow ng requ rements

have been fulf lled dur ng error determ nat on:

• the amb ent temperature, and the temperature

of the p pette, t ps and water was dent cal

• the dens ty of the l qu d used s close to that

of d st lled water

•the balance w th appropr ate sens t v ty has

been used

• mg/µl convers on factor has been taken nto

account

•the requ rements g ven n sect ons 3 and 4

have been fulf lled

If the above cond t ons are sat sf ed and the accu-

racy error for selected volume g ven n sect on 1

exceeds the perm ss ble value, the p pette

recal brat on procedure should be carr ed out.

Volume checked

[µl]

0.1 - 10

10 - 100

> 100

Balance sensitivity

[mg]

≤ 0.001

≤ 0.01

≤ 0.1

Temperature [°C] Pressure [hPa]

960 1013 1067

20 1.0028 1.0029 1.0029

21 1.0031 1.0032 1.0032

22 1.0032 1.0033 1.0033

23 1.0035 1.0035 1.0036

24 1.0037 1.0038 1.0038

25 1.0039 1.0040 1.0041

1 - 10

5 - 50

20 - 200

50 - 300

1

5

20

50

0.92 - 1.08

4.8 - 5.2

19.6 - 20.4

49.2 - 50.8

0.33

1.67

6.30

10.00

Range

of the i ette

volumes [µl]

Preset

volume

[µl]

Permissible

volumes

[µl]

Volume change ∆V for

full turn of the calibra-

tion key [µl]

(24 increments)

XLM/11/2002 ANG OK 1/7/03 8:20 PM Page 10

If the average asp rated volume exceeds the

perm ss ble value, the follow ng should be done:

• Remove the p pett ng pushbutton, (F g. 4A)

•Hold ng the volume sett ng knob to protect

t aga nst rotat on, nsert the cal brat on key

nto the cuts of the cal brat on screw, (F g. 4B)

• Turn the key clockw se to reduce the asp rat-

ed volume, or counter-clockw se to ncrease

the volume, (F g. 4C). One full turn of the cal bra-

t on key changes the p pette asp rat on volume

by the amount g ven n the table

•Take out the key and replace the p pett ng

pushbutton, (F g. 4D).

Determ ne the average asp rated volume. The

average volume should be w th n the perm ss -

ble range g ven n the table. If the volume

exceeds the values stated, the recal brat on pro-

cedure should be repeated.

6 - MAINTENANCE

Cones should be kept clean us ng ethyl alcohol.

7 - PIPETTE KIT

AND ACCESSORIES (OPTIONAL)

Pipette kit

The p pettes are del vered n the k ts nclud ng:

• P pette

• Instruct on manual

• Cal brat on key

• Ident f cat on labels

Accessories (Opt onal)

Pipette Tip Choices

10 µl, 10 racks of 96 (960 ti s er ackage)

XL8-10

200 µl, 10 racks of 96 (960 ti s er ackage)

XL8-50

XL8-200

XL12-50

XL12-200

300 µl, 10 racks of 96 (960 ti s er ackage)

XL8-300

XL12-300

Pipette Stand Choices

Stand for eight channel i ette

XL8

Stand for twelve channel i ette

XL12

7 8

8 - SPARE PARTS

The spare parts for mult channel, (F g. 1, F g. 4):

1. Pushbutton

2. Ejector pushbutton

3. Calibration knob

4. Ejector

5. Piston assembly

6. Calibration key

can be ordered from Denville (type of the p pette

and name of the part for th s p pette should be

spec f ed).

Before return ng a p pette to Denville please

ensure that the p pette s completely free of any

contam nat on (chem cal, m crob al or rad o-

act ve).

Warning: The replacement of the plunger

requires conducting of calibration proce-

dure according to section 5.

XLM/11/2002

XLM/11/2002 ANG OK 1/7/03 8:20 PM Page 12

XLM/11/2002 ANG OK 1/7/03 8:20 PM Page 14

This manual suits for next models

6

Table of contents

Other Denville Scientific Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual