Denyo DCA-25USI User manual

INSTRUCTION MANUAL

DENYO

DIESEL GENERATING SETS

Before using, be sure to read this manual for the sake of safety.

Be sure to observe the items under symbol marks "Z[\ WA NING"

and "A CAUTION" for the sake of safety.

Always keep this manual at your machine for the sake of safety.

DCA-2 5 U S I

DCA-25 U S I 2

DCA-45 U S I

DCA-4 5 U S I 2

DCA-60USH

По вопросам продаж и поддержки обращайтесь:

Эл. почта: dne@nt-rt.ru || Сайт: https://denyo.nt-rt.ru/

Архангельск (8182)63-90-72

Астана +7(7172)727-132

Астрахань (8512)99-46-04

Барнаул (3852)73-04-60

Белгород (4722)40-23-64

Брянск (4832)59-03-52

Владивосток (423)249-28-31

Волгоград (844)278-03-48

Вологда (8172)26-41-59

Воронеж (473)204-51-73

Екатеринбург (343)384-55-89

Иваново (4932)77-34-06

Ижевск (3412)26-03-58

Иркутск (395) 279-98-46

Киргизия (996)312-96-26-47

Казань (843)206-01-48

Калининград (4012)72-03-81

Калуга (4842)92-23-67

Кемерово (3842)65-04-62

Киров (8332)68-02-04

Краснодар (861)203-40-90

Красноярск (391)204-63-61

Курск (4712)77-13-04

Липецк (4742)52-20-81

Магнитогорск (3519)55-03-13

Москва (495)268-04-70

Мурманск (8152)59-64-93

Набережные Челны (8552)20-53-41

Нижний Новгород (831)429-08-12

Казахстан (772)734-952-31

Новокузнецк (3843)20-46-81

Новосибирск (383)227-86-73

Омск (3812)21-46-40

Орел (4862)44-53-42

Оренбург (3532)37-68-04

Пенза (8412)22-31-16

Пермь (342)205-81-47

Ростов-на-Дону (863)308-18-15

Рязань (4912)46-61-64

Самара (846)206-03-16

Санкт-Петербург (812)309-46-40

Саратов (845)249-38-78

Севастополь (8692)22-31-93

Симферополь (3652)67-13-56

Таджикистан (992)427-82-92-69

Смоленск (4812)29-41-54

Сочи (862)225-72-31

Ставрополь (8652)20-65-13

Сургут (3462)77-98-35

Тверь (4822)63-31-35

Томск (3822)98-41-53

Тула (4872)74-02-29

Тюмень (3452)66-21-18

Ульяновск (8422)24-23-59

Уфа (347)229-48-12

Хабаровск (4212)92-98-04

Челябинск (351)202-03-61

Череповец (8202)49-02-64

Ярославль (4852)69-52-93

1. Safety Precautions

In order to ensure safe operation, the following symbols are used for explanation of the

machine operation.

The following symbols, found throughout this manual, alert you to potentially dangerous

conditions to the operator, service personnel, or the equipment.

A ARNING: This symbol refers to a hazard or unsafe practice which can result

in severe personal injury or death.

A CAUTION: This symbol refers to a hazard or unsafe practice which can result

in personal injury or product or property damage.

[Note] : This symbols show handling precautions for effective

operation and many years of satisfactory operation.

Some of the items shown by CAUTION" may also cause death or serious injury.

Be sure to observe all the items, as they are important for safe operation.

* If the machine is used by an outsider, you are requested to explain him correct handling

and advise him to read this instruction manual carefully.

* Do not modify the machine at your discretion, as it affects the safety, performance or

the life of the machine.

* If the machine is modified or it is used incorrectly against this manual or unauthorized

parts are used, the warranty of manufacturer will become invalid.

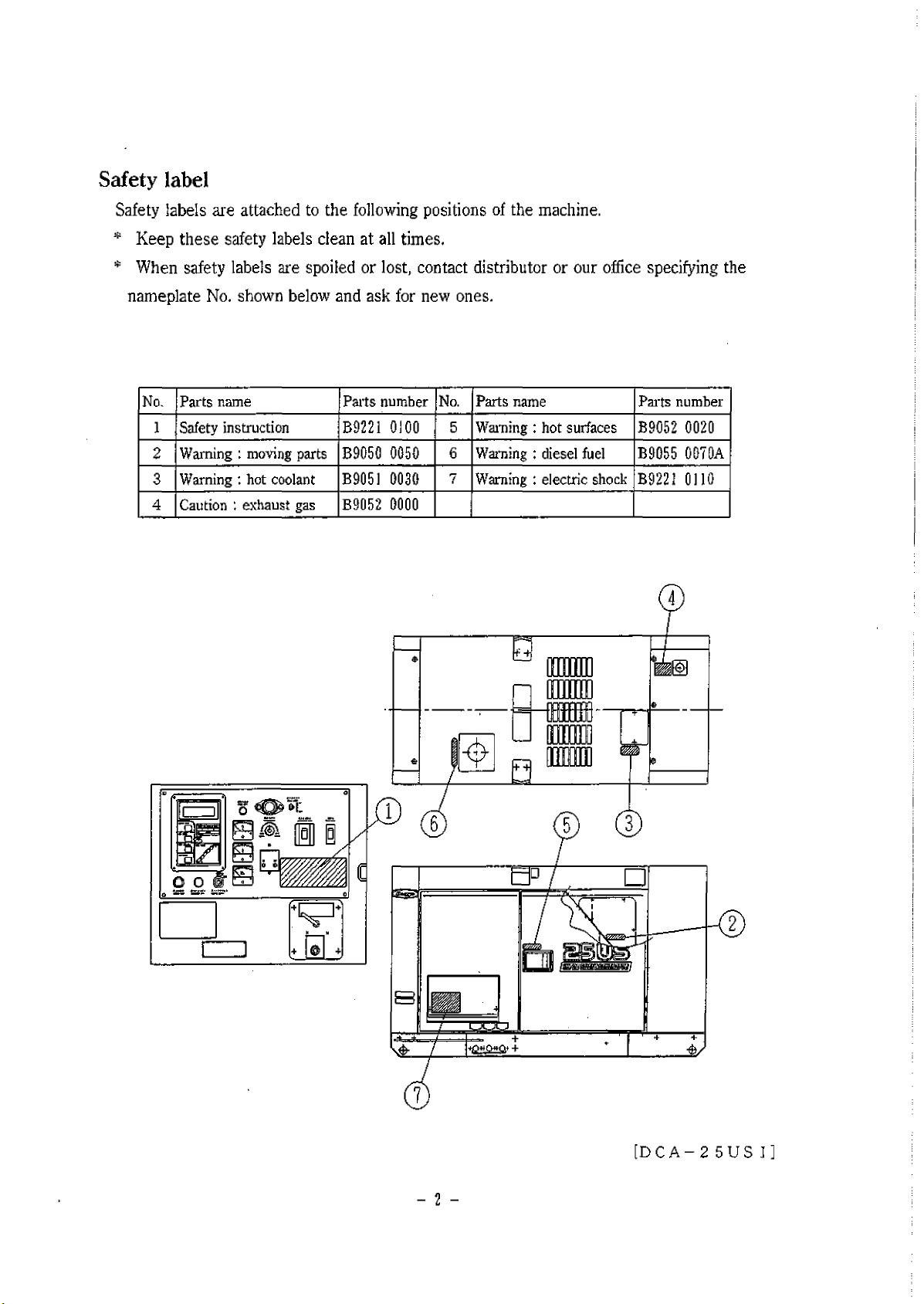

Safety label

Safety labels are attached to the following positions of the machine.

* Keep these safety labels clean at all times.

* hen safety labels are spoiled or lost, contact distributor or our office specifying the

nameplate No. shown below and ask for new ones.

No. Parts name Parts number No. Parts name Parts number

1 Safety instruction B9221 0100 5arning : hot surfaces B9052 0020

2 arning : moving parts Б9050 0050 6arning : diesel fuel B9055 0070A

3arning : hot coolant Б9051 0030 7arning : electric shock B9221 0110

4 Caution ; exhaust gas B9052 0000

-

2

-

A WARNING

ENGINE EXHAUST can kill.

I Insufficient ventilation may lead to death due to

lack of oxygen or poisoning by exhaust gases.

* Do not use the machine in a place of poor ventilation

or in a place where exhaust gases stays.

* Do not use the machine indoors or in storehouse, tunnel,

ship hold, tank, etc. of poor ventilation.

* If it becomes necessary to use the machine in the

above places, the exhaust pipe should be extended

to a well ventilated place. In this case, use a ventilator

to ensure proper ventilation.

* Do not direct the exhaust outlet to nearby pedestrians

and houses.

- 3 -

ELECTRIC SHOCK can kill.

V Do not touch the output terminals during operation

to prevent decease due to electric shock.

* Never touch the output terminals during operation.

If your hands or the machine are wet, it will result

in a death or serious injury.

* hen a wiring work is required, be sure to turn OFF

the circuit breaker and stop the machine.

* Keep the output terminal cover closed and the terminal

bolts tightened while the machine is running.

* A low voltage is generated even when the machine is

in low speed idle operation.

Be sure to stop the machine completely.

■ Do not touch the electrical parts in the machine during operation, as it may

lead to death due to electric shock.

* Always close the control panel and tighten the fixing bolts before operating the machine.

* Always close the side door and lock it before operating the machine.

* hen opening the control panel for voltage selection, etc., turn OFF the circuit breaker

and stop the machine.

A WARNING

- 4 -

A WARNING

ELECTRIC SHOCK by leak can kill

■ Improper grounding may lead to death due

to electric shock.

* Be sure to execute the grounding of the machine and

the load according to the local rule.

A ARNING

MOVING PARTS can cause severe injury.

■ Rotary unit which runs at a high speed is located

in the machine.

(Note that it is very dangerous if you touch it.)

* Be sure to close the door and lock it during operation.

■* hen the door needs to be opened during operation,

do not get your hands and head in the machine to

prevent them from being caught in the machine which

may lead to injury.

* hen making check or maintenance of the machine,

be sure to stop the machine in advance.

* The motor fan for cooling radiator will keep on

running for a while even after engine stops.

Before beginning a repair/maintenance work,

moake sure that the motor fan has stopped

completely.

- 5 -

A WARNING

DIESEL FUEL can cause fire or explosion.

I Fuel and oil are flammable. Incorrect handling

results in danger of ignition or fire.

* hen fuel needs to be supplied to the machine,

be sure to stop the engine. Refrain from smoking.

Keep the machine away from fire.

* Do not leave flammable objects (paper, wood chips,

etc.) and hazardous objects (oil, powder, etc.) near

the machine.

* ipe off spilt fuel and oil.

A ARNING

HOT COOLANT can cause severe scalds.

If the radiator cap is opened while the water

temperature is high, steam or hot water will

spout out.

* During operation or immediately after stopping the

machine, do not open the radiator cap while the

water temperature is high.

* hen cooling water needs to be checked or supplied, ^

wait until the engine is cooled (50 ‘C or less as

measured with the water temperature gauge).

- G -

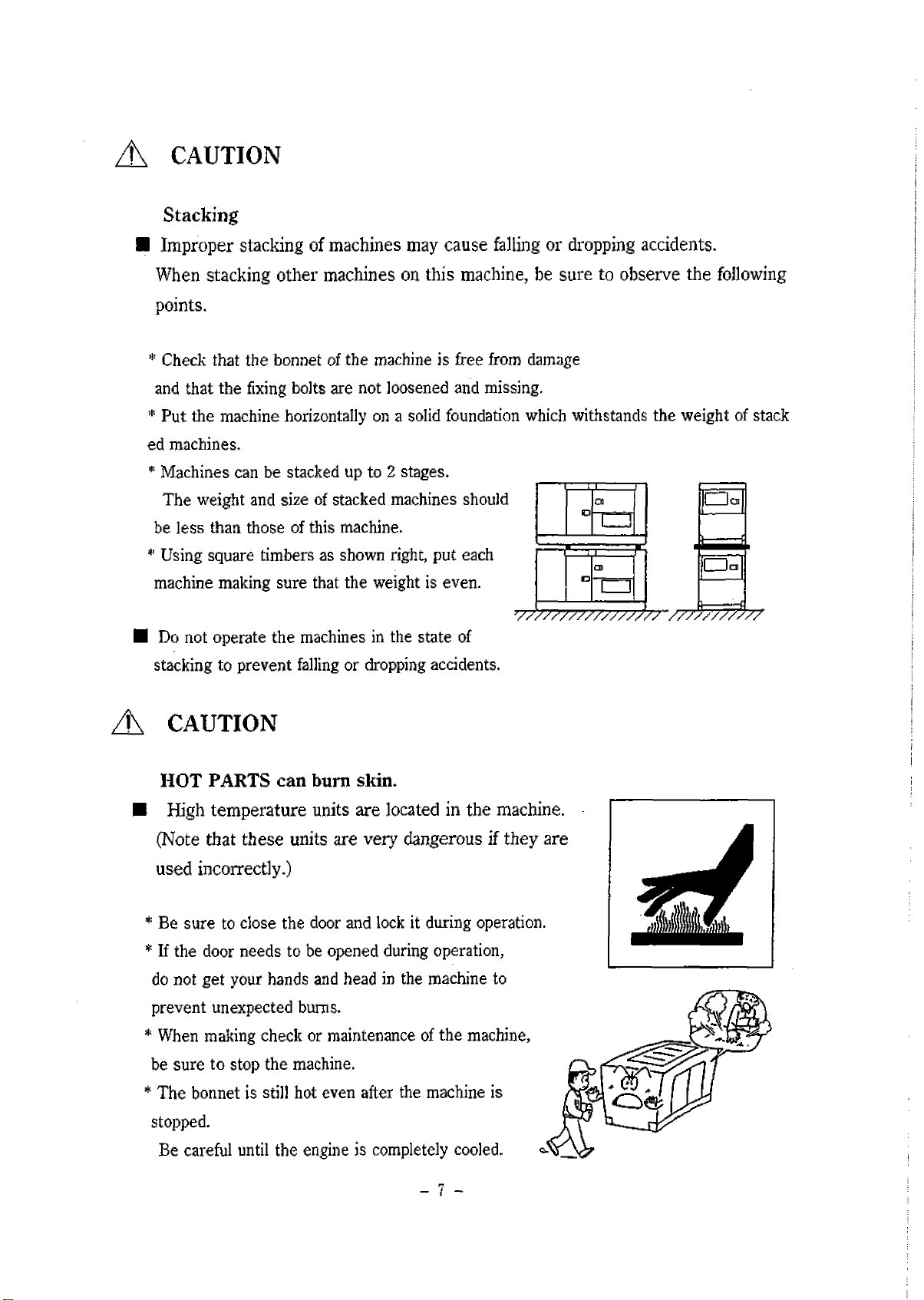

A CAUTION

Stacking

■ Improper stacking of machines may cause falling or dropping accidents.

hen stacking other machines on this machine, be sure to observe the following

points.

* Check that the bonnet of the machine is free from damage

and that the fixing bolts are not loosened and missing,

* Put the machine horizontally on a solid foundation which withstands the weight of stack

ed machines.

* Machines can be stacked up to 2 stages.

The weight and size of stacked machines should

be less than those of this machine.

* Using square timbers as shown right, put each

machine making sure that the weight is even.

1

C l

1

09

1

___

1

.■ ■!

D

1 '

I i □ =

У7777777777777777'/77?7777777

Do not operate the machines in the state of

stacking to prevent falling or dropping accidents.

A CAUTION

HOT PARTS can burn skin.

High temperature units are located in the machine.

(Note that these units are very dangerous if they are

used incorrectly.)

* Be sure to close the door and lock it during operation.

* If the door needs to be opened during operation,

do not get your hands and head in the machine to

prevent unexpected bums.

* hen making check or maintenance of the machine,

be sure to stop the machine.

* The bonnet is still hot even after the machine is

stopped.

Be careful until the engine is completely cooled.

A CAUTION

BATTERY

■ Battery generates flammable gases.

Improper handling may lead to explosion

or serious injury.

* Battery should be charged in a well ventilated

location. Otherwise, flammable gases are

accumulated which may be ignited and exploded,

* hen connecting a booster cable, do not jumper

the terminals (+ and -). Otherwise, the flammable

gases generated from the battery may be ignited

and exploded by sparks.

* For maintenance of the machine, disconnect the

ground cable on the ground side.

HI The battery acid is dilute sulfuric acid. Improper

handling will cause unexpected bums.

* hen the battery acid gets on your clothes or skin, wash it out with a large volume of

water immediately. If it gets in your eyes, wash with a large volume of water

immediately and consult your doctor.

— In the worst case, it will put out your eyes.

-

8

-

A CAUTION

Operator

■ Do not operate the machine, if operator is tired too much or drinks some

alcohol or take some drugs,

* Otherwise, it may cause unexpected accidents or injury.

■ During checking or maintenance, be sure to put on suitable clothes and protectors.

* Do not put on baggy clothes, necklace, etc., because they are easily caught by

projections which may cause injuries.

A CAUTION

Noise

■ This machine generates large noise, if the door is

open. Surrounding to large noise may cause hearing

trouble.

* Close and lock the door during operation.

* If opening the door is necessary during operation,

be sure to put on the ear protector.

A CAUTION

Connection to house wiring

■ Before connecting this machine to any building’s electrical system, a licensed

electrician must install an isolation(transfer) switch.

* Serious injury or death may result without this transfer switch.

-

9

-

Transportation

U Do not lift the machine at the support hook or the ladder

because it is not strong enough for lifting and may cause

a falling accident.

* hen lifting the machine, use the hanger located at the

roof center.

* Keep out under the lifted machine.

■ Do not lift or do not transport the machine during

operation, as it may cause damage to the fan or

serious trouble.

* hen loading the machine on the truck or the like,

fix the machine firmly by support hooks on the both

side.

A CAUTION

- 10 -

2. Construction

2 -1 Outline and part names

1. control panel

2. output terminal

3. fuel in

A. fuel drain plug

5. oil drain plug

6. hanger rod

7. support hook

8. coolant in

9. exhaust gas outlet

10. coolant drain pulg

-

1 1

-

11. diesel engine

12. AC generator

13. battery

14. radiator

15. electric fan

16. reserve tank

[DCA-4 5 US IJ

17. engine oil in

18. dipstick

19. fuel filter

20. control box

21. air cleaner

22. oil filter

-

12

-

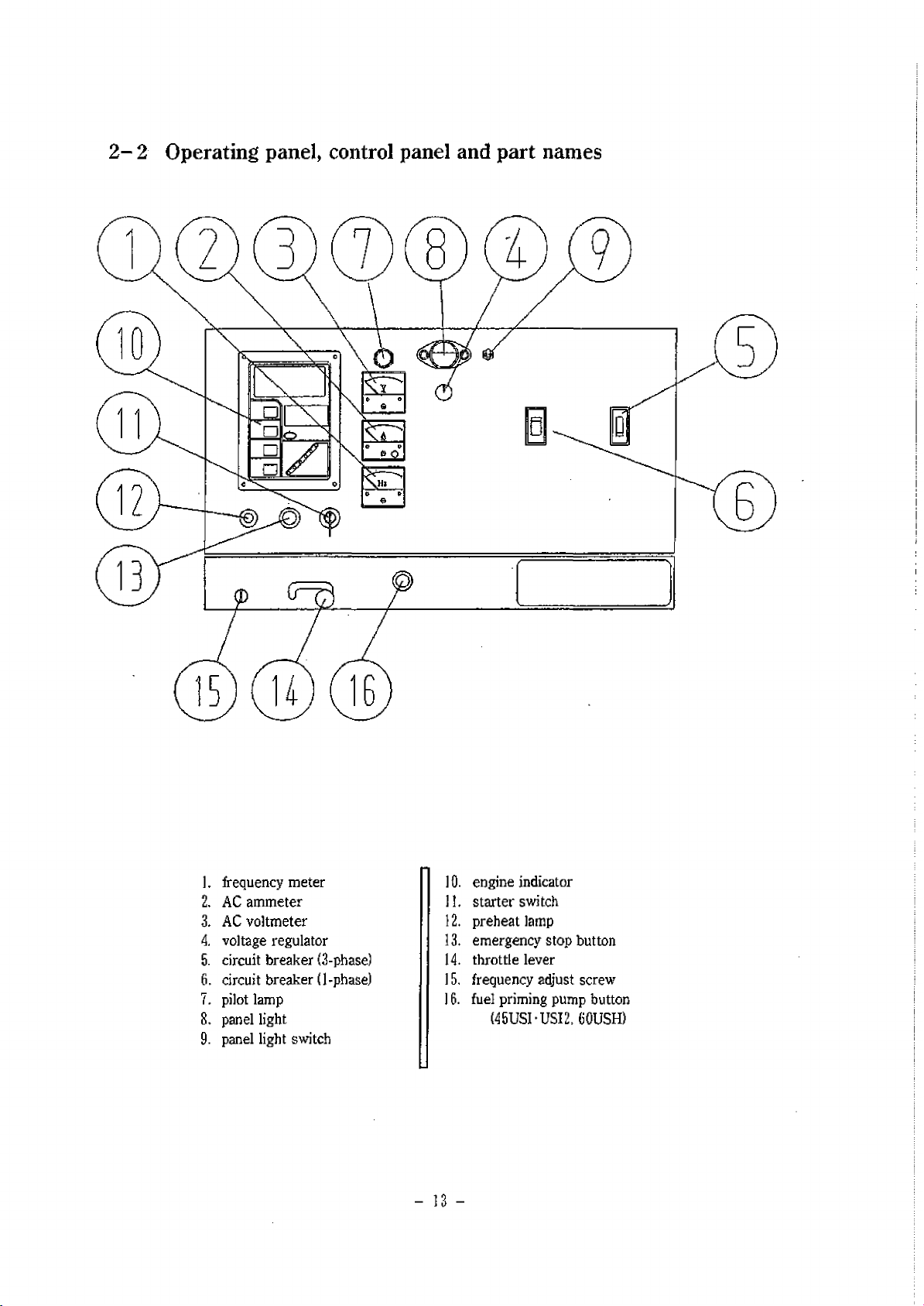

2 - 2 Operating panel, control panel and part names

1. frequency meter

2. AC ammeter

3. AC voltmeter

4. voltage regulator

5. circuit breaker (3-phase)

6. circuit breaker (1-phase)

7. pilot lamp

8. panel light

9. panel light switch

10. engine indicator

11. starter switch

12. preheat lamp

13. emergency stop button

14. throttle lever

15. frequency adjust screw

16. fuel priming pump button

(45USI-USI2, 60USH)

-

13

-

2- 3 Meters

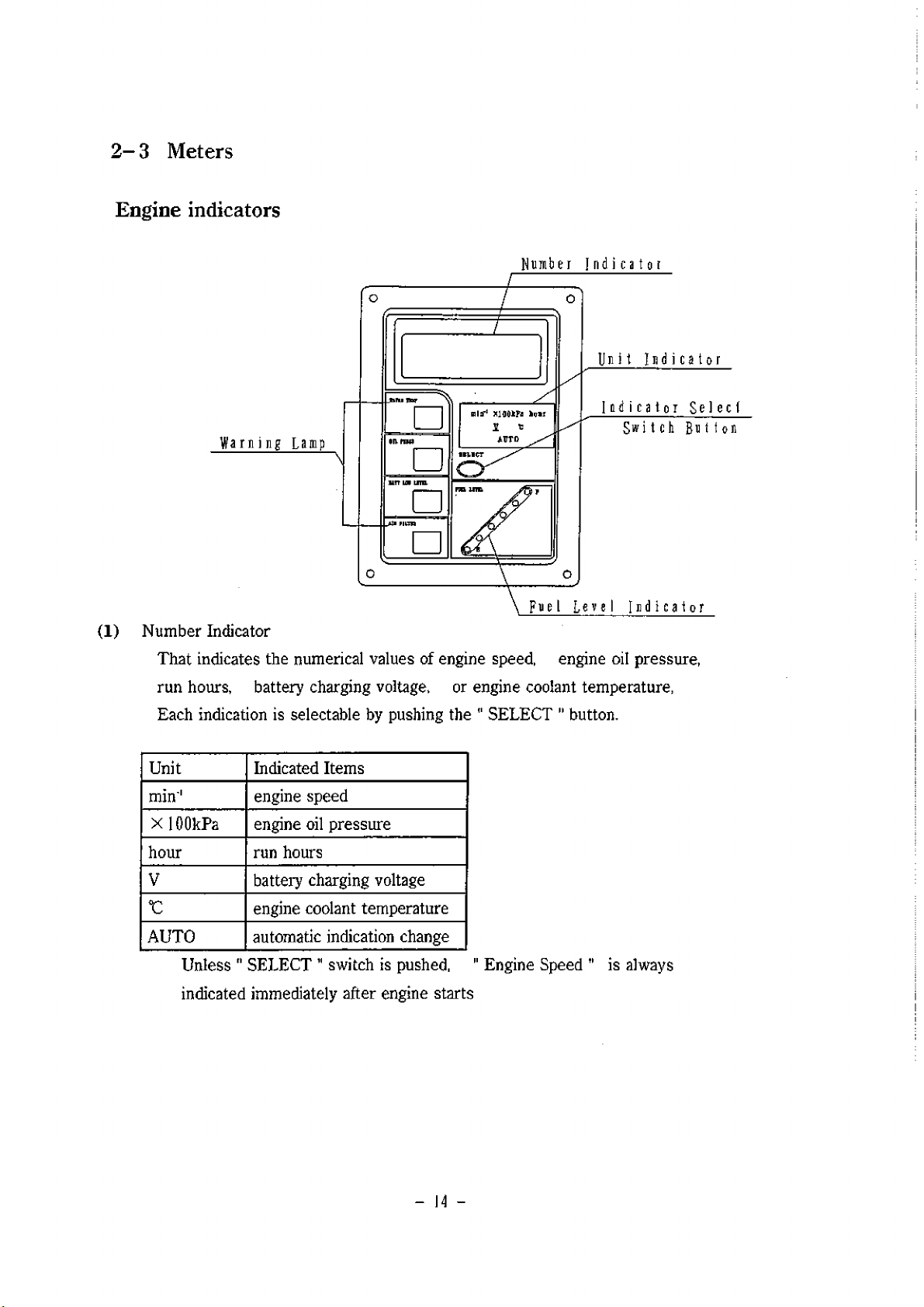

Engine indicators

N u m b er I n d i c a t o r

(1) Number Indicator

That indicates the numerical values of engine speed, engine oil pressure,

run hours, battery charging voltage, or engine coolant temperature,

Each indication is selectable by pushing the " SELECT " button.

Unit Indicated Items

min'1 engine speed

X ЮОкРа engine oil pressure

hour run hours

Vbattery charging voltage

*C engine coolant temperature

AUTO automatic indication change

Unless " SELECT 11 switch is pushed, " Engine Speed " is always

indicated immediately after engine starts

- 14 -

ith " AUTO " selected, indication is automatically changed every

three (3) seconds,

- 1 - Engine Speed

Revolutions per minute is indicated.

1500min ~ 1 is indicated at 50Hz and 1800 m in " 1 is indicated at 60Hz.

- 2 - Engine Oil Pressure

2 to 5 X 100 kPa ( 2 to 5 kg / cm! ) should be indicated at normal

engine operation. Higher value would be indicated in cold condition

immediately after engine starts. Conduct a warming - up operation

until it indicates normal value.

- 3 - Hun Hours

That indicated total running hours.

- 4 - Battery Charging Voltage

That should indicate more than 26V (25USI‘USI2, 45USTUSl2:more than

12. 5V) at engine running.

- 5 - Engine Coolant Temperature

That should indicate a temperature between 75 to 90 tC at engine running.

Note ; If that would indicate higher temperature, disconnect all loads,

decrease the speed for cool - down operation, and wait until the

temperature comes down to normal value.

- 6 - Automatic Indication Change

Each of the above - started indications from the - I - to - 5 - changes by turns

every 3 seconds.

(2) Fuel Level Indicator

That Indicates a fuel level in the fuel tank. Green lamps will turn on with full tank.

As the fuel level drops, the numbers of the turn - on lamps decrease and at the

sametime the color of lamps changes from green to red.

Replenish the tank when there becomes only one lamp turned on.

The table below shows the relation between numbers of turn - on lamps and feul level.

- 15 -

Numbers of

lamps turned - on

Color of lamps

DCA-25USI DCA-25USI2 DCA-45USI

DCA-60USH

DCA-4 5USI2

Fuel level

(L) Fuel level

CL) Fuel level

(L) Fuel level

(L)

6all green 80 to full 70 to full 140 to full 125 to full

5all green 70 to 75 60 to 70 120 to 140 100 to 125

4all green 60 to 70 50 to 60 100 to 120 75 to 100

3red on 1st lamp from

bottomgreen on

2nd & 3rd lamps

45 to 60 35 to 50 75 to 100 45 to 75

2all red 30 to 45 25 to 35 50 to 75 25 to 45

1red 0 to 30 0 to 25 0 to 50 0 to 25

(3) Alarm and Memory at Abnomal Condition

hen any abnormal condition occurs in engine oil pressure, battery charging voltage,

or engine coolant temperature, the indication will change as the followings ;

- 1 - The indication changes to " AUTO " , and the abnormal value and unit will

be indicated lighting on and off.

- 2 - hen the abnormal condition is corrected, the on - and - off indication will

stop.

- 3 - If engine would stop urgently and automatically or stop manuslly with

the abnormal condition, the abnormal value will be memorized, and then

indicated even after engine is started again.

In this case, keep on pushing the button " AUTO " for more than 5 seconds,

and the abnormal indication will be reset to normal.

I

Generator indicators

(1) Frequency meter

This meter indicates frequency of the output

voltage.

Make sure that it indicates 50Hz or 60Hz during

operation.

ф ® S p ф 5s

'X \ ' Л К / A

V7

A-

e ® Ф 0

0 0

... _i

50Hz 60Hz

-

16

-

(2) AC ammeter

This meter indicates AC current flowing into the

connected load. Make sure that it is always

pointing below the rated current.

hen running the three phase and single phase

loads together, this meter indicates total current of

them.

hen running either the three phase or single

phase load, this meter indicates the current flowing

into the load.

The current of each phase can be checked using

the ammeter change over switch.

(Only for 45USI-USI2, 60USH)

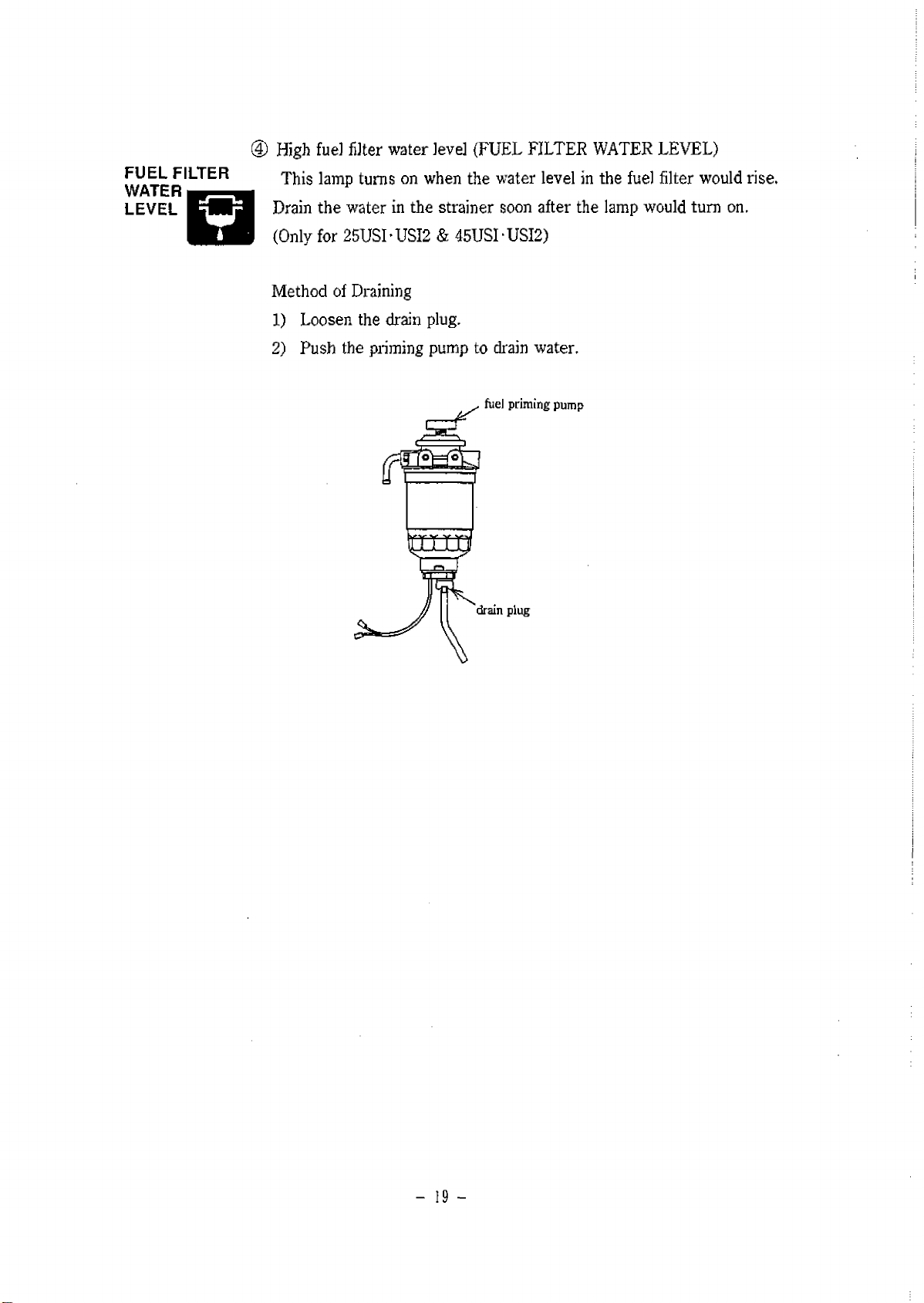

(3) AC voltmeter

50H2 6OH2

\ ij ' л , %x>

Ф &

00

This meter indicates AC output voltage. Make

sure that it indicates rated voltage.

-

17

-

Indication/alarm lamp

(1) Preheat lamp

hen the starter switch is set in the preheat position,

this lamp becomes red heated in about 30 seconds,

indicating that the machine has been preheated to be ready

for startup.

In the case of 25USI-USI2 and 45USI-USI2 it will

automatically preheating device.If turn the.starter switch to "R

un" position, it will according to cooling water (coolant)

temperature with the preheat lamp goes on. hen the prehe

at lamp goes off, it indicates that preheating is completed.

(2) arning Lamps

This monitor indicates the following failures, if any one of them occurs.

ф High jacket water temperature ( ATER TEMP)

WATER TEMP lamP Soes on when the water temperature rises abnormally. If

the lamp goes on during operation, the emergency stop

device immediately operates to shut down the engine automatically.

© Oil pressure failure (OIL PRESS)

OIL PRESS ^ this lamp goes on during operation, the emergency stop device

immediately operates to shutdown the engine automatically.

® Air filter blinding (AIR FILTER)

AIR FILTER hen the air element is blinded, this lamp goes on. Indicating that

the element should be immediately cleaned or replaced.

- 18 -

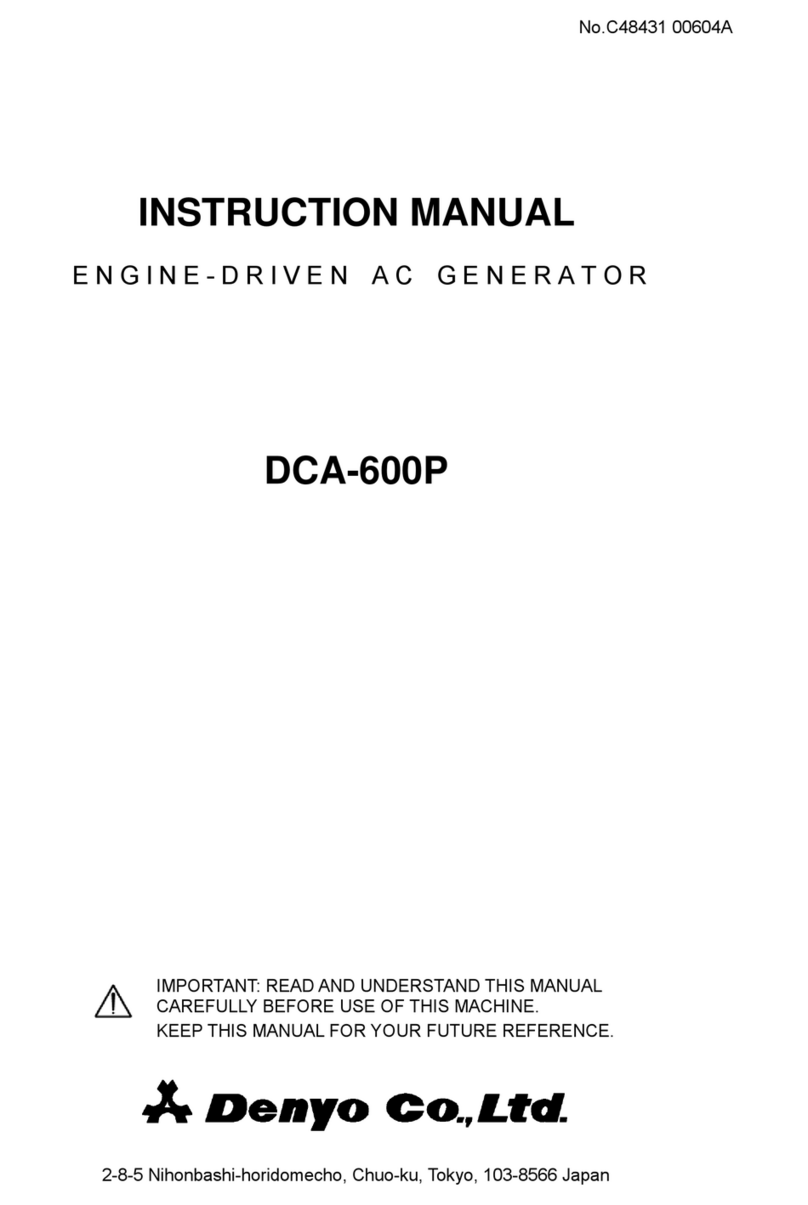

<D High fuel filter water level {FUEL FILTER ATER LEVEL)

FUEL FILTER This lamp turns on when the water level in the fuel filter would rise.

WATER м

LEVEL Е Я З Drain the water in the strainer soon after the lamp would turn on.

(Only for 25USI-USI2 & 45USLUSI2)

Method of Draining

1) Loosen the drain plug.

2) Push the priming pump to drain water.

- 19 -

This manual suits for next models

4

Table of contents

Other Denyo Portable Generator manuals

Denyo

Denyo DCA-150LSKE User manual

Denyo

Denyo DCA-6LSX User manual

Denyo

Denyo DCA-150ESK User manual

Denyo

Denyo DCA-60ESI2 User manual

Denyo

Denyo DCA-600P User manual

Denyo

Denyo DCA-13ESK User manual

Denyo

Denyo DCA Series User manual

Denyo

Denyo DCA-13LSK User manual

Denyo

Denyo DCA-SP Series User manual

Denyo

Denyo DCA-600SPK User manual

Popular Portable Generator manuals by other brands

Generac Power Systems

Generac Power Systems QT018 Specifications

BluWater Technology

BluWater Technology Genesis Blu Fusion user manual

Powermate

Powermate PMD5000s owner's manual

DUROMAX

DUROMAX XP12000HX user manual

MULTIQUIP

MULTIQUIP GA36HR operating manual

VICI DBS

VICI DBS MISTRAL EVOLUTION 10 user manual