DER EE DE-33 User manual

HCA003300-00020R

ELECTRICAL INSTRUMENT CO., LTD.

7F-2, NO.351, SEC.2, CHUNG SHAN ROAD.,

CHUNG HO CITY, TAIPEI HSIEN, TAIWAN

TEL : 886-2-2226-6789(REP.) FAX : 886-2-2226-7979

E-mail: deree@ms21.hinet.net

http://www.deree.com.tw

Thanks for purchasing K-type Wireless Thermometer DE-33.

Please read the operation manual carefully before using and

keep it properly for contingent use and reference. Thanks!

Model No. DE-33

Instruction Manual

K-Type Wireless Thermometer

...........................................01~02

..........03~07

.............03

.................................04

..... ...05~07

..... ..... ...... . .... . . .... . . .... . 08~13

..............................08~11

......................09~11

.............................12~13

.........................14~25

..................14~15

......................16

.........................17~19

..........................20

.................21

.............................22

...23

......................24

.......................................25

..........26~28

Catalogue

Ⅰ. Features

Ⅱ. Introduction of main unit and sensor unit

(A). Main unit – appearance and functions

(B). Main unit – display

(C). Sensor unit – appearance and placing

Ⅲ. Power on process

(A). Battery installation

(B). Set up I.D. (identity code)

(C). Set up time (clock)

Ⅳ. Application of thermometer

(A). Function and operation of key

(B). Measurement of temperature

(C). Set up alarm function

(D). Read temperature record

(E). Search temperature of sensor unit

(F). Max / Min temperature

(G). Low battery symbol of main unit and sensor unit

(H). Trouble shooting of main unit

(I). Function table

Ⅴ. Specification of main unit and sensor unit

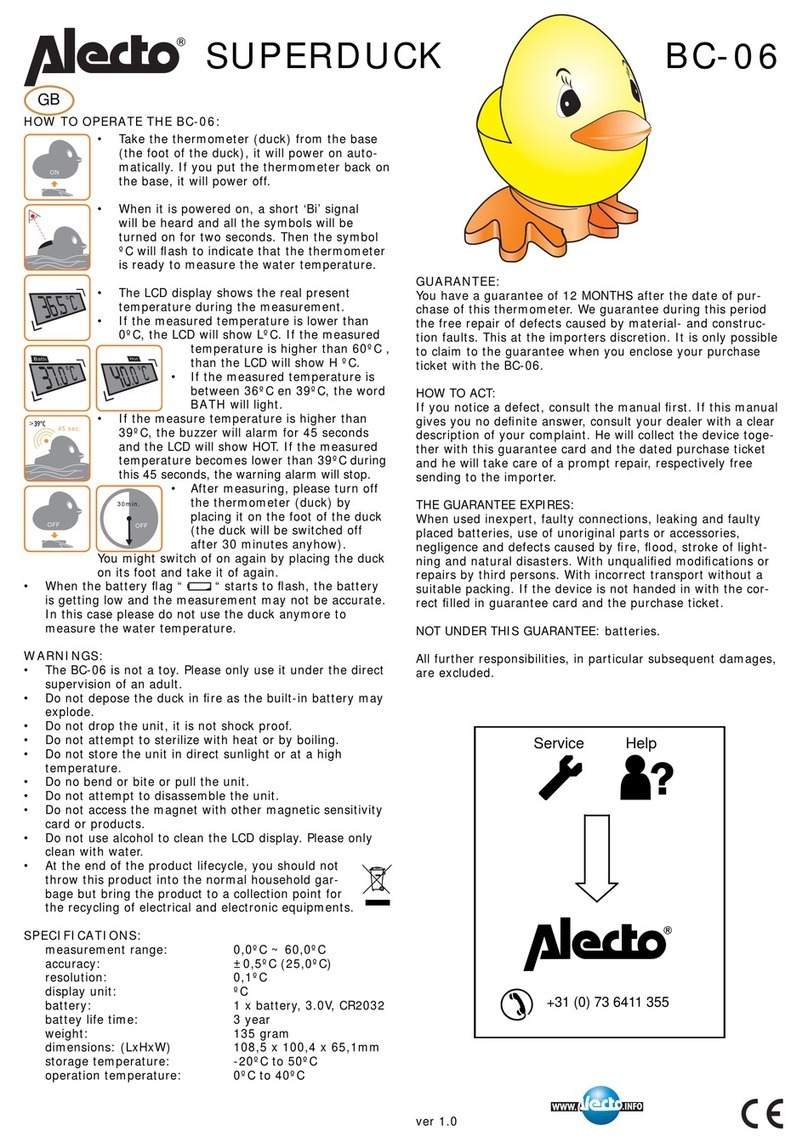

● Main unit with big LCD display and easy for read.

● Simultaneous display 2 sets of temperature measured

through sensor unit.

● Temperature data detected by sensor unit transmits to main

unit placed at remote position from sensor unit (maximum

distance is around 100M in open space). The thermometer is

suitable to apply indoor or outdoor use by user’s need.

● 24 hours clock.

● Auto data logging for 12 hours with 24 sets data.

Temperature and clock time are recorded every 30 minutes

on the hour.

● Main unit automatically records and refreshes MAX

(maximum) and MIN (minimum) temperatures with real time

detected by sensor unit.

K-Type WIREL ESS THER MOMETER

DE-3 3R

MODE

OC LGR CALL

SEARCH MAX / MI N

RESET PUSH 2sec

DE -3 3T

K-Type

WIRELESS

THERMOMETER

TRANSMITTER

-01- -02-

Ⅰ. Features ● Sensor unit is equipped with 2 thermocouples to detecting the

temperature change of environment, water or soil at the same

time.

● Temperature alarm function to alert the temperature is

beyond the range set by the user.

● K-type temperature range: - 200°C ~ +1370°C

● Main unit and sensor unit each has 8 identity codes (1 ~ 8

and I.D. for short). The I.D. provides the protection from

interference of transmission where have two sets or more

thermometer using at the same time in the same radius area.

● Audible alarm of main unit alerts 4 possible status –

1.Battery power is low at main unit or sensor unit.

2.Temperature is over the range set by the user.

3.Transmission is disconnected.

4.In measuring mode but main unit displays “no”.

CH1 temperature

(CH1 = A plug of

sensor unit)

CH2 temperature

(CH2 = B plug of

sensor unit)

K-type thermocouple

Clock

main unit

sensor unit

K-Type WIREL ESS THER MOMETER

DE-3 3R

MODE

OC LGR CALL

SEARCH MAX / MI N

RESET PUSH 2sec

① ② ③ ④

②

③

①OC

MODE

LGR CALL

SEARCH

-03-

MAX / MIN

RESET

PUSH 2sec

⑤

⑥

⑦

⑧

⑨

⑩

⑪

⑫

⑬

⑭

⑮

⑯

CH1

⑤

⑥

⑦

⑧

⑨

⑩

⑪

⑫

⑬

⑭

⑮

⑯

⑰

⑱

⑳

⑱

⑲

⑭

⑮

Ⅱ. Introduction of main unit and sensor unit

(A) Main unit – appearance and functions

(B) Main unit – display

MODE key: (function change key)

a. CH1 & CH2 in measuring mode.

b. Alarm set for CH1 & CH2 (initial set is 180°C at manufactory)

c. Call out temperature data from memory.

d. Clock setting.

◎ Refer to page 14 ◎

SEARCH key:

a. Search the transmission signal from sensor unit and display

data at main unit.

b. Push SEARH key to search the signal from sensor unit if no

signal or interruption. Each search is lasting 5 minutes.

◎ Refer to page 21 ◎

MAX/MIN key: (maximum / minimum temperature recording)

a. Simultaneously record maximum (MAX) & minimum (MIN)

temperature from CH1 & CH2.

b. Each memory comes with real time.

c. Shift reading MAX and MIN value at CH1 & CH2

◎ Refer to page 22 ◎

RS-232 socket

(equipped PC use

RS-232 adaptor

socket) – optional

a. Connect RS-232 cable to link with PC and recording

the temperature change and form in graphic.

b. Refer to Help in PC software operation for relevant

operation.

④

● Main unit – key function

hanger hole beeper hole

battery door

stand rack

Attention: do not attempt to

loose those 4 screws. ● Description of symbol on display:

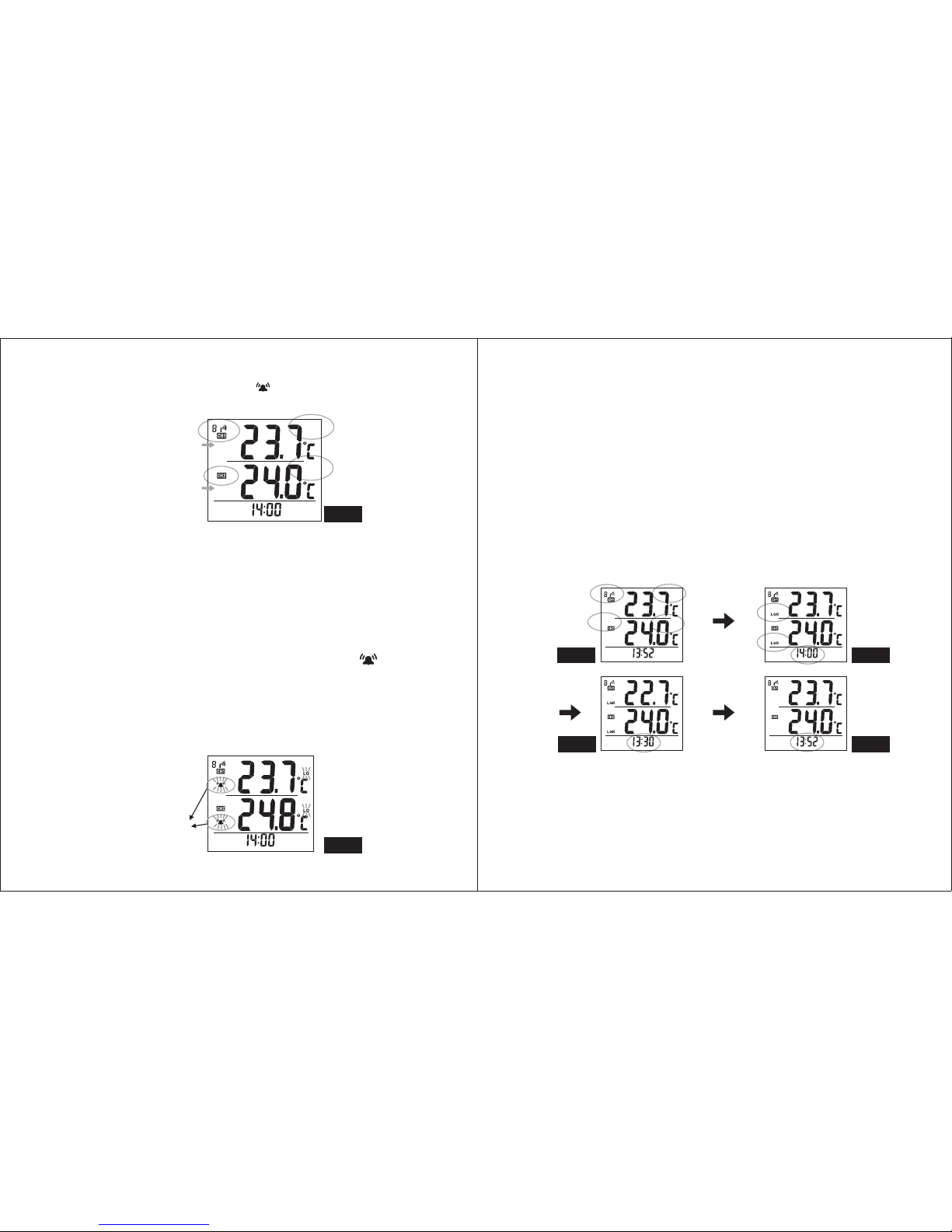

Upper layer : display CHI temperature and functions from sensor unit

Middle layer: display CH2 temperature and functions from sensor unit

Bottom layer: display clock (24 hours)

Total 8 I.D. codes for set (from 1 to 8)

Antenna symbol in moving means main unit is searching the

transmission signal from sensor unit

Battery power at sensor unit is low and need to replace with new

batteries

Recording symbol to indicate 24 records of temperature change at

CH1 in past 12 hours.

Shift reading MAX & MIN temperature value measured at CH1

Display CH1 temperature

Indicate data received from CH1 (A plug) and CH2 (B plug) of

sensor unit

Blinking and beeping indicates temperature at CH1/CH2 is

over (higher or lower) the range set by user.

Battery power at main unit is low and need to replace with new

batteries

-04-

Temperature

1. Check battery power of main unit and sensor unit before

using. Do not place sensor unit and main unit from each other

over the limit distance to prevent the fail transmission. And

keep away from the interference objects or signals.

2. The limit distance between main unit and sensor unit is

typically 100M (330 feet) in open space.

3. The distance between main unit and sensor unit is shorter

than 100M while there are barriers between the set up

positions of units. The optimum distance depends on the

material of barrier or the construction of building.

-05- -06-

DE - 33 T

K-Type

WIRELESS

THERMOMETER

TRANSMITTER

A B

1 2 3 4

O

N

S G M

5

3

1

2

3

4

5

6

7

8

1 2 3

(C) Sensor unit – appearance and placing

⑰

⑱

⑲

⑳CH2

Recording symbol to indicate 24 records of temperature change at

CH2 in past 12 hours.

Indicate temperature range set at HI or LO at CH1 & CH2

Display CH2 temperature

Shift reading MAX & MIN temperature value measured at CH2

Temperature

K-type thermocouple

4. Do not put sensor unit into fridge or the metallic sealed

equipment (enclosure) directly for measurement. Because the

signal of sensor unit is blocked and can't transmit to main unit

successfully.

5. For measuring fridge temperature only put the thermocouple

wire tip in fridge.

6. A & B input socket (A → as CH1 on main unit display and B →

as CH2) can take 2 K-type thermocouples for measurement.

Apply the different temperature range of K-type thermocouple

to work with the need. The applicable range is -200°C ~

+1370°C.

7. Set up I.D. of sensor unit

※ 8. Install batteries -– always install main unit first and complete

I.D. set from panel keys and then install batteries into

sensor unit and complete I.D. set from switch in battery slot.

The I.D. code of main and sensor unit should be the same.

9. To ensure the data to be captured by the main unit the initial

transmission from sensor unit acts aggressively by every 6

seconds once set up. After the 9th data, the transmission of

sensor unit and the receiving of main unit is parallel

corresponding to each other.

Attention: do not attempt to

loose those 2 screws.

hanger

battery door

switch 4 is void

I.D. switch in battery slot

I.D. code

(1 ~ 8)

switch

in transmission

the light is blinking

N

N

W

-07- -08-

DE-3 3 T

K-Type

WIRE LE SS

THER MO ME TE R

TRAN SM IT TE R

●

application environment or barriers where main unit and

sensor unit located. And the electronic interference will affect

the transmission and signal and may display incorrect data on

main unit. Therefore, please prevent those elements may

affect the transmission.

● In extreme high or low temperature environment, the

transmission may be slow or creeping.

● Besides battery door, please do not attempt to loose other

screws in order to make sure the thermometer operates in

good condition.

● Take the batteries out of the thermometer if it will be left idle

for a long time.

Transmission and transmission distance is affected by

Attention:

Ⅲ. Power on process

Demonstration of measurement

water temperature

of aquarium

put thermocouple tip in fridge,

water or soil for measurement

thermocouple tip

Simultaneously measuring and

monitoring temperature of fridge

and aquarium.

(A). Battery installation

Always install main unit first and then sensor unit. Follow

instruction of A & B as below to enable transmitting and

receiving in good work.

1. Battery (alkaline) life time for main and sensor unit is one

year round which mainly depends on the application in

different temperature and environment. Use 2 AA size

alkaline batteries each for main and sensor unit.

2. Battery life time depends on the working condition. Such

as repeat search for signal (because of interruption) or

frequent alarm will cut down the battery life time. Need

to replace the new batteries while the low battery symbol

(sensor unit) or (main unit) display.

3. Do not attempt to loose the screws marked on drawing.

4. Main unit has no power switch and can be power off from

removing batteries exclusively.

5. Contact the maker or deliver the thermometer back to the

maker for checking if it can't work after the batteries

installation process is completed.

+

+

AA (1.5V )No .3

AA (1.5V )No.3

A. Battery installation of main unit

1. Open battery door and install batteries.

Attention: do not attempt to loose

those 4 screws.

follow arrow direction to

pull out the battery door

AA size battery (1.5V)

install batteries with

correct polarity marked

in battery slot

sensor unit with

thermocouple

-09- -10-

B. Battery installation of sensor unit

Follow the steps from dwg#1 to dwg# 7 to complete the

installation.

(1) Loose 2 screws on battery door with Philips screw driver.

(2) Do not attempt to loose 4 crews marked on dwg#2.

(3) Choose I.D. by changing the switch in the battery slot before

installing batteries. I.D. code from 1 to 8 (refer to page 6

(C)-7.). The I.D. should be the same as the main unit for

transmitting and receiving recognition.

(4) Fasten screws on battery door after installing batteries.

(1.5V AA size battery * 2) Be sure to put with the correct

polarity as marked in the slot.

(5) After battery installation, the light on sensor unit is flashing to

identify I.D. Then the light is flashing every 6 seconds and

transmitting the data of each flashing. After the 9th data, the

transmission of sensor unit and the receiving of main unit is

corresponding to each other and go into regular cycle by

transmission/receiving every 3 minutes. Each flash of light

means transmission is working and main unit refresh display

of CH1 & CH2 every 3 minutes as well.

(6) In 1 minute after battery installation, check main unit if

display any reading of temperature from sensor unit. If not,

please make sure if I.D. of main and sensor unit is the same.

And check if batteries are well installation and light is

flashing during transmission of data. If all those are positive

but still can’t find any reading on main display, please

contact the maker for problem remove or deliver the

thermometer back to the maker for checking.

2. Once batteries are installed the full segment will display on LCD

for 2 seconds.

CH1 temperature

CH2 temperature

clock

If display as above means no signal

is received and clock is not set yet.

3. Push MODE key to shift the display from (1) to (3)

display (1) display (2) display (3)

If no reading on display of main unit after the batteries are

installed completely which means sensor unit is not ready.

(refer to page 10)

The bottom layer is clock (refer to page 12 for clock set).

Check the battery installation is correct or not If can't shift the

display from (1) to (3). If the installation is surely correct

please contact the maker for problem remove or deliver the

instrument back to the maker for checking if necessary.

(B). Set up I.D. (identity code)

Choose I.D. of main unit:

Push MODE & MAX/MIN keys simultaneously for 3 sec. until

display and flashing. Push MAX/MIN key to choose

I.D. code from 1 to 8. Push MODE key to complete setting

after chosen.

1

1 2 3 4

O

N

S G M

5

3

1 2 3 4

O

N

SGM

5

3

DE-3 3 T

K-Type

WIRE LESS

THER MOMET ER

TRAN SMITT ER

-11- -12-

+

+

dwg#1

dwg#5

dwg#6 dwg#7

set I.D.

(1~8)

Attention: Do not attempt to

loose the screws marked.

light of transmission:

one flashing to identify I.D. after batteries are

installed and flashing every 6 seconds in

transmission. After the 9th data the

transmission become stable on regular basis

with transmission / receiving every 3 minutes.

Main unit automatically

searches signal from sensor

unit (or push SEARCH key

for manual search)

Main unit automatically searches

signal from sensor unit in 5 minutes

if no reading on display. Refer to

page 5 Sensor unit appearance and

placing

Set up time

(refer to page 12)

(C). Set up time (clock)

After power on must set up clock immediately enable to work

with the relevant functions

1. Hold MODE key for 3 seconds to access time set function

as dwg#2.

2. Push MAX/MIN key to adjust time and push SEARCH to

change position. Set hour and minute as dwg# 2 & 3

(clock starting from 00:00 with 24 hours).

3. Push MODE key to complete time set or if no pushing

MODE key, it will automatically confirm the time set in 15

sec. as dwg#4.

4. Push MODE key to shift display and check if clock

displays in good condition in different mode as dwg#5. If

not, please operate from step 1 to 3 again.

dwg#1dwg#2

dwg#3dwg#4

dwg#5

no symbol

display is in

normal operation

push MODE key for 3 seconds

until display as dwg#2 .

push SEARCH key

to change position

push MAX/MIN key to adjust time

push MODE key to complete time

set as dwg.#4

push MODE key to check

clock if display in different

mode.

push MODE key to shift display as dwg#5 to check clock display

hour minute

dwg#2

dwg#3 dwg#4

(A) Key function:

MODE key shift 4 modes display

1. Simple measuring mode - CH1 and CH2 temperature

display (°C) (dwg#1)

It's set as the initial display at manufactory. To operate

any other function must go back to the simple measuring

mode first.

2. Activate temperature alarm function ( ) (dwg#2)

3. Read data in memory LGR symbol display (dwg#3)

4. Time setting (page 15 dwg#1 & 4)

-13- -14-

《ATTENTION》

a. Time set can only operate in simple measuring mode as

dwg#1. In MAX/MIN, LGR or alarm mode can't operate time

set as dwg.#6.

b. In case, accidentally push MAX/MIN key MAX, MIN symbol

display on LCD and get into MAX/MIN mode. Hold MAX/MIN

key for 2 sec. to cancel MAX/MIN mode as dwg#7.

c. Set sensor unit in position where is in the limit distance range

from main unit. If main unit can't receive the data from sensor

unit please check the distance if over the limit or having

interference. Refer to page 5~6 II-(C) Sensor unit

appearance and placing.

dwg#6 dwg#7

MAX, MIN symbol display

can't operate time set.

Hold MAX/MIN key for 2 seconds

to cancel MAX/MIN mode and

MAX, MIN symbol disappear.

(simple measuring mode).

if LGR symbol display

push MODE key

one time to resume

simple measuring

mode

push MODE key twice to

resume simple measuring

mode

if symbol display

In MAX/MIN, LGR or alarm mode can't operate time set.

Ⅳ. Application of thermometer

(1) CHI & CH2 temperature display ( C)°

simple measuring

mode display

dwg#1

dwg#2

dwg#3

push MODE key

one time

push MODE key

push MODE key

(resume to simple

measuring mode display).

(2) temperature alarm mode

(3) read data in memory (LGR CALL)

push SEARCH key to read the data at different time.

(B) Measurement of temperature

a. Change display to the simple measuring mode as dwg#1

below.

b. Upper layer display of CH1 is for the temperature

measured by the thermocouple at A socket. Middle layer

display of CH2 is for the temperature measured by the

thermocouple at B socket. Temperature unit is Celsius.

Bottom layer display is indicating clock.

c. The transmission from sensor unit is every 3 minutes and

refresh the data on main unit display.

d. I.D. set is from 1 to 8 by option. Hold MODE & MAX/MIN

key simultaneously for 3 seconds to enter I.D. setting.

I.D. number is flashing and ready for set. Push

MAX/MIN key to choose I.D. and push MODE key to

confirm the setting or no push MODE key in 15 seconds

will confirm the setting automatically.

e. is antenna symbol (dwg#1). “ ” is signal

disconnection (dwg#2) and need to push SEARCH key

to search signal. Check sensor unit location where has

interference or not. Refer to page 5~7 II-(C) Sensor unit

appearance and placing.

f. If push MAX/MIN key accidentally, the setting will

disable. Hold MAX/MIN key for 2 seconds to cancel

MAX/MIN mode and go back to the simple measuring

mode. (dwg#1)

《ATTENTION》

a. Before going ahead any function or setting, please always go

back to the simple measuring mode first. (dwg.#1)

b. If push MAX/MIN key, MAX/MIN symbol display and enter

MAX/MIN mode. Hold MAX/MIN key for 2 seconds to cancel

the function and back to the simple measuring mode. (dwg#1)

-15-

(1) CH1 & CH2 temperature display ( C)°

(4) time set

simple measuring

mode display

dwg#1

dwg#4

refer to page 12 III-(C)

SET up time (clock).

Hold MODE key

>3 seconds

Hold MODE key

>3 seconds

Push MODE key

once again

(1) CH1 & CH2 simple measuring mode ( C)°

Quick note of MODE key operation

push MODE key once

(2) Activate alarm function ( )

push MODE key again

(3)Reading data in memory (LGR CALL)

(4)Clock Settting

I.D. number

dwg#1

dwg#2

upper layer display for CH1 temperature no symbol

display is in

the simple

measuring

mode

I.D and antenna symbol

middle layer display for CH2 termperature

bottom layer display is clock

signal disconnection

Push SEARCH key to search signal. Check

sensor unit location where has interference

or not or too far from main unit. Refer to

page 21 IV-(E) search temperature of sensor

unit

-16-

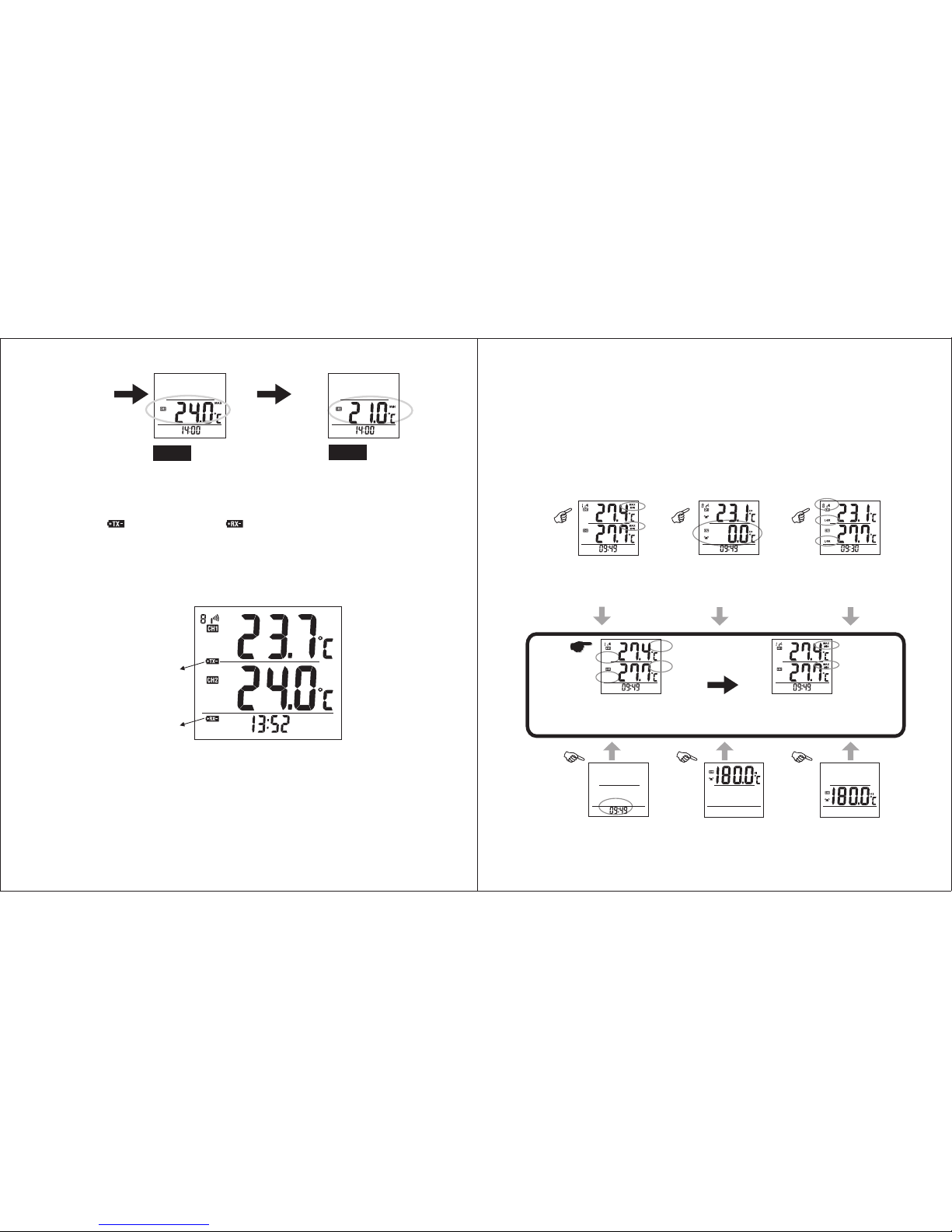

e. Set HI or LO temperature:

● Only one option to set alarm range at HI or LO

temperature.

● Set temperature only from dwg#1 to dwg#2. HI or LO

symbol is flashing and ready for setting. Push

MAX/MIN key to choose HI or LO (ex. set at LO)

● Push SEARCH key to change position and push

MAX/MIN key to choose number. (ex. 25°C).

(available temperature range for setting : -199.9°C ~

1372°C)

● Push MODE key or no push MODE key in 15 seconds

will confirm the setting automatically.

-17- -18-

(C) Set up alarm function ( ) :

(1) Set up temperature alarm of CH1 and CH2: in condition

of the temperature reaches and higher beyong ( ≧HI )

the temperature set at HI or lower below ( ≦LO ) the

temperature set at LO, the alarm function activates and

emit beep sound to alert the user.

(2) Go to alarm temperature set and alarm:

a. Hold MODE & SEARCH key simultaneously for 3

seconds to enter setting mode of CH1 as dwg#2:

temperate alarm range display.

b. If no push any key or MODE key in 15 seconds, it will

resume to the simple measuring mode automatically

as dwg#1.

c. Hold MODE & SEARCH key simultaneously for 6

seconds to enter setting mode of CH2 as dwg#3:

temperate alarm range display.

d. The initial temperature range is set 180°C at

manufactory.

no symbol display is

the simple measuring

mode.

dwg#1

dwg#2 dwg#3

Hold MODE & SEARCH key simultaneously

3 seconds. 6 seconds.

set HI or LO

push MODE key back to dwg#1 push MODE key back to dwg#1

dwg#1

dwg#2

no symbol display

is in the simple

measuring mode

set alarm at LO

set alarm temperature

point at 25 C°

follow (2)-a. enter CH1 or CH2 setting mode,

push SEARCH to change position and push

MAX/MIN to choose LO or HI.

(D) Read temperature record (LGR CALL)

(1) 12 hours auto data logging for CH1 and CH2

temperature corresponds with real time record.

Recording is every 30 minutes with 24 sets maximum.

Once capacity is full will start over the recording cycle

from the beginning and the old record will be replaced.

(Note: The record is made on every 30 minutes clock

time. If initial clock time set at 13:52, the first data is at

14:00 and if the initial time is 12:17 the first data is 12:30

and the 2nd is at 13:00 and so on.).

(2) Push MODE key twice to switch from dwg#1 to dwg#2.

The auto data logging function actuates once clock time

is set.

(3) Push SEARCH key to read the previous data in memory.

(dwg#2~4).

(4) Push MODE key back to the simple measuring mode.

f. Activate alarm function ( display):

● Push MODE key to switch dwg#1 to dwg#2

● Alarm function is available simultaneously at CH1

and CH2. Once activate alarm function (as dwg#2), if

temperature at CH1 or CH2 is over the temperature

alarm point (higher or lower) the audible beeper will

be on and lasting 2 minutes. Beeper will stop in 2

minutes automatically or push SEARCH key by

manual stop. Push MODE key twice to return the

simple measuring mode as dwg#1.

● Once temperature at CH1 or CH2 meets the alarm

condition will activate audible beeper and “ ” and

“HI” or “LO” symbols are flashing. Even stop beeping

(automatically or manually) , the symbols are

remained flashing to alert the user the temperature

ever exceeds the alarm point. If the next coming

data is still over the alarm point the beeper will

generate again to repeat beep for 2 minutes and

symbols are flashing.

-19- -20-

dwg#1

CH1 temperature

Ch2 temperature

push MODE key to dwg#2

dwg#2

flashing in beeping

dwg#1 dwg#2

dwg#3 dwg#4

push MODE key twice to dwg#2 push SEARCH key to dwg#3

push SEARCH key to dwg#4 push MODE key to back to dwg#1

(5) In LGR mode, push MODE key to go back to the simple

measuring mode. Or it will shift back to the simple

measuring mode automatically if no operation in 5

minutes.

(6) If display “no” at CH1 or CH2 means the poor contact of

the thermocouple, disconnection of thermocouple or

temperature is over the maximum range 1372°C.

(E) Search temperature of sensor unit

(1) Push SEARCH key for manual search of signal from

sensor unit. Every search is lasting 5 minutes. If 5

minutest search is failed the radius symbol ( )

disappears which means the transmission or receipt

interrupts. Push SEARCH key once again to activate

manual search function until the signal can be found.

(2) Once power on main unit and sensor unit, if no signal

( ) in transmission the auto search function will

generate in 30 minutes and regenerate every 30

minutes if still can't find signal. Manual search is also

available for option.

(3) Antenna radius symbol ( ) in flashing means main unit

receives signal from sensor unit in good condition. If

the radius symbol stops flashing means in searching for

signal (search for 5 minutes).

(4) In normal operation if transmission is temporarily

interrupted or change location of main unit or sensor

unit to cause the interruption of signal, CH1 and CH2

temperature display becomes “---“. Need to check if

have any interference while change the location of units

and remove the problem.

-21- -22-

(F) MAX / MIN temperature

(1) Maximum / Minimum temperature recording function

(set clock before entering MAX/MIN mode). Set

MAX/MIN mode starting from dwg#1.

(2) Push MAX/MIN key, MAX/MIN symbol display and start

recording maximum / minimum temperature.

(3) Push MAX/MIN key to shift reading MAX/MIN

temperature at CH1 & CH2 respectively. (dwg# 3→6).

(4) After reading 4 values will back to MAX/MIN recording

mode (dwg#2). During reading MAX/MIN temperature,

if no push MAX/MIN key for 15 seconds will go back to

MAX/MIN recording mode automatically.

(5) Hold MAX/MIN key for 2 seconds to exit MAX/MIN mode

and back to the simple measuring mode (dwg#1).

《ATTENTION》

In MAX/MIN mode, other functions disable. To enable

other modes or functions must exit MAX/MIN mode by

holding MAX/MIN key for 2 seconds if in MAX/MIN mode.

dwg#1

dwg#2

(A) While1st disconnection once

power on will have auto

searching in 30 minutes.

(B) flashing ( ) is in

good receiving of signal

(C) stop flashing is in search of

signal from sensor unit (5

minutes).

no radius

symbol moving

is interruption

no temperature display

antenna symbol

stop moving is in

searching signal. push SEARCH key to search

signal from sensor unit and refer to

page 6 II-(C) sensor unit-

appearance and placing for

problem remove.

dwg#1 dwg#2

dwg#3 dwg#4

upper layer display -

CHI temperature

middle layer display -

CH2 temperatur

bottom layer display -

clock push MAX/MIN key

push MAX/MIN key

back to dwg#2

push MAX/MIN key

CH1 maximum temperature CH1 minimum temperature

(H) Trouble shooting of main unit

(1) Either in MAX/MIN mode, alarm mode or reading

temperature record (LGR) mode, can't operate

temperate range alarm setting or clock set. All functions

only enable at the simple measuring mode. (as below

drawing status 1 ~ 3)

(2) Before operating other functions (ex. temperate alarm

setting, clock, LGR) or go to MAX/MIN recording mode

must go back to the simple measuring mode first.

(G) Low battery symbol of main unit and sensor unit

(1) (sensor unit) or (main unit) symbol display

means battery power of sensor unit or main unit is low

and constant audible beep sounds to alert the user to

replace new batteries. To ensure operation in good

condition, replace 2 batteries of unit at the same time.

(2) Apply 2 AAA batteries (1.5V).

-23- -24-

dwg#5 dwg#6

CH2 maximum temperature CH2 minimum temperature

push MAX/MIN key push MAX/MIN key

push MAX/MIN key

back to dwg#2

low battery indication

of sensor unit

low battery indication

of main unit

status 1 status 2 status 3

status 4 status 5 status 6

simple

measuring

mode

hold MAX/MIN key to

cancel MAX/MIN mode

and MAX/MIN symbol

disappear

in alarm mode, push

MODE key twice to

back simple measuring

mode.

in LGR mode, push

MODE key to back

simple measuring

mode.

ready for setting all kinds of

function.

in simple measuring mode, push

MAX/MIN key to enter MAX/MIN

recording mode.

push MODE key to

back simple measuring

mode

push MODE key to

back simple measuring

mode

push MODE key to

back simple measuring

mode

-25- -26-

(I) Function table

Function Key Operation

Dwg#1

CH1 & CH2

simple

measuring

mode

Dwg#2

alarm function

activate

Dwg#3

LGR mode

Dwg#4

MAX/MIN

temperature at

CH1 & CH2

Dwg#5

Temperature

alarm set at

CH1

Dwg#6

Set clock

Initial setting of simple measuring mode to check CH1 & CH2

current temperature. To set dwg#2~6 must go back to

dwg#1. Main unit display temperatures measured at two

channels of sensor unit. Main unit is not equipped

temperature detecting function.

At dwg#1, push MODE key twice to activate alarm function.

Push SEARCH key to stop beeping. Push MODE key twice

to back simple measuring mode (dwg#1)

At dwg#1, push MODE key to enter reading data mode

(LGR). Push SEARCH to shift reading data in memory .

After reading, push MODE key to back simple measuring

mode (dwg#1)

At dwg#1, push MAX/MIN key to enter MAX/MIN recording

mode. Push MAX/MIN key to shift reading maximum &

minimum temperature at CH1 & CH2. Hold MAX/MIN key for

2 seconds to exit MAX/MIN mode and enable operating other

functions.

At dwg#1, hold MODE & SEARCH keys simultaneously for 3

seconds (6 seconds for CH2) to enter alarm setting at CH1.

After setting the temperature point, in 15 seconds will go

back to simple measuring mode (dwg#1) automatically. (or

push MODE to complete setting).

At dwg#1, hold MODE key for 3 seconds to enter clock set

mode. In 15 seconds will go back to simple measuring mode

(dwg#1) automatically. (or push MODE to complete setting).

dwg#1 dwg#2 dwg#3

dwg#4 dwg#5 dwg#6

Ⅴ. Specification of main unit and sensor unit

(1) LCD display: clock, CH1 & CH2 temperature

(2) Transmission / Receiving interval time: every 3 minutes.

(3) Clock: 24 hours

(4) Features: MAX/MIN simultaneous recording with real time.

Auto data logging, Beeper function for over temperature

range.

(5) RF frequency: approx. 433MHz (depends on frequency set at

manufactory).

(6) Temperature range: -200°C~1370°C

(7) Power: AA battery (1.5V) x 2 pcs

(8) Dimension / Weight: 120(L) x 100(W) x 28.5(H)mm,

approx. 160g (without batteries)

K-Type WIRELE SS THERM OMETE R

DE-3 3R

MODE

OC LGR CALL

SEARCH MAX / MI N

RESET PUSH 2sec

DE -3 3T

K-Typ e

WIREL ESS

THERM OMETER

TRANS MITTER

main unit

sensor unit

main unit

sensor unit

(1) Featurs: 2 channels, transmit data to main unit.

(2) RF frequency: approx. 433MHz (depends on frequency set at

manufactory).

(3) Transmitting distance: approx. 100M (330 feet) in open

space.

(4) Power: AA battery (1.5V) x 2 pcs

(5) Dimension / Weight: 179(L) x 72(W) x 32(H)mm,

approx. 155g (without batteries)

Instruction manual .......................................................................1

AA batteries ................................................................................ 4

K-type thermocouple (NR-39B) ................................................... 2

Optional accessories (equipped with RS-232 plug at main unit)

RS-232 cable .............................................................................. 1

PC software CD .......................................................................... 1

※ PC software operation-refer to operation on PC software CD.

(6) Accuracy (23 )

(7) K-type thermocouple: NR-39B temperature probe is

applicable to -50°C~200°C (-58°F~392°F). For higher

temperature measurement need to contact manufacturer for

other option.

(8) Range: -199.9°C ~ 1370°C

(9) Input limit: max. 60VDC or 24Vrms AC

(10) Socket: applicable to standard thermocouple.

(11) Operation temp./humidity: 0°C~50°C (32°F~122°F) /

below 80% R.H. (no condensation)

(12) Storage temp./humidity: -10°C~60°C (-14°F~140°F) /

below 70% R.H. (no condensation)

(13) Pre-caution:

To avoid danger and damage happened during operation,

please read the instruction manual thoroughly before using

the thermometer. Put the instruction manual with the

thermometer together for reference in the future.

°C ± 5°C, 80% R.H. MAX.

-27- -28-

Type Measurement

Ranges(°C) Resolution

(°C) Accuracy

(%rdg+°C)

-199.9~0.0

0~199.9

200~1370

0.1

0.1

1

±(0.5+1)

±(0.2+0.5)

±(0.2+1)

K

WARNING

TO AVOID ELECTRICAL SHOCK, DO NOT APPLY INPUT

VOLTAGE OVER DC60V OR AC24V

WARNING

TO AVOID DAMAGE OR BURNS, DO NOT PUT THE

THERMOMETER IN MICROWAVE OVENS OR STOVE

F O R M E A S U R E M E N T O R A P P LY F O R T H E

MEASUREMENT OF ELECTRICAL USE.

Attention

The repeated sharp flexing can break the thermocouple

leads. To prolong lead lifetime, avoid sharp bend in the

leads, especially for the cable relief to connector.

ACCESSORIES

Maintance

Do not attempt to open case of sensor unit or main unit

(except battery door) to avoid the inaccuracy of

measurement. Keep dry hands while replacing batteries. Do

not use organic solvent to clean the thermometer but with soft

cloth if necessary.

Specifications and external appearance of the product may be

revised for modification without prior notice

Please contact our agents or distributors for a variety of

measuring instrument we produce under the strict quality

control requirement of ISO 9001

Table of contents