HD2328 - 9 - V1.7

THE PROGRAMMING MENU

To access to the programming menu press simultaneously the DATA+(A-B) keys.

The items to be set are listed in this order:

1. Selection of the unit of measurement: the "SEL_MEAS_UNIT" message is

displayed in the comment line. The main line in the center of the display shows

the selected unit of measurement: Celsius (°C) or Fahrenheit (°F) degrees.:

•use the and arrows (respectively located above the HOLD and

REL keys) to modify the type of probe;

•press DATA/ENTER to confirm the modification and go onto the next

item;

•press CLR/ESC to cancel the modification;

•to exit the menu, press the A-B/MENU key again.

2. Selection of the type of Thermocouple: the "SEL" message is displayed in

the main line, while the type of probe is displayed in the comment line; in the

secondary line is shown the "tc" message.

The types of thermocouple that can be selected are: K, J, T, or E.

•use the and arrows (respectively located above the HOLD and

REL keys) to modify the type of thermocouple;

•press DATA/ENTER to confirm the modification and go onto the next

item;

•press CLR/ESC to cancel the modification;

•to exit the menu, press the A-B/MENU key again.

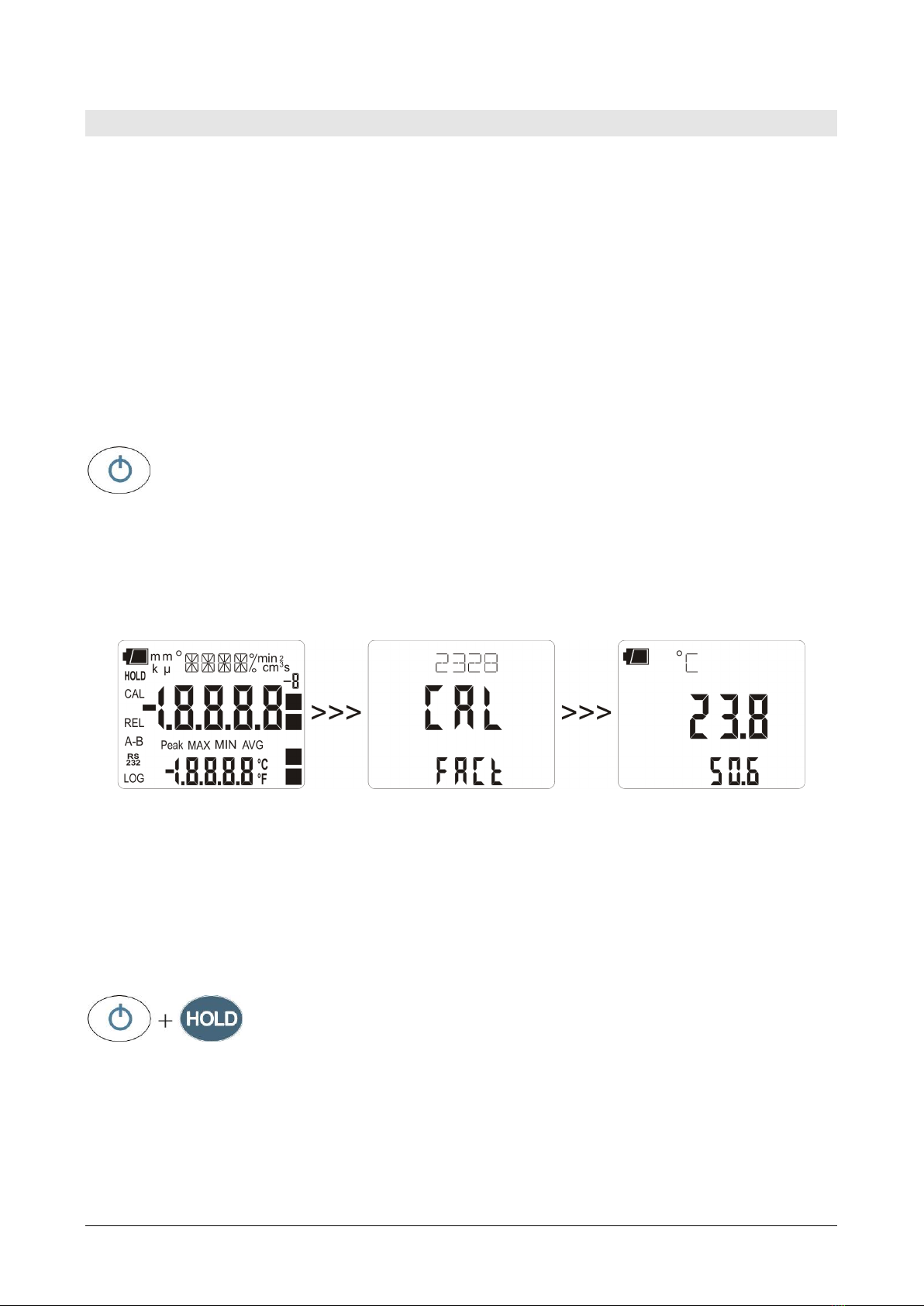

3. Starting the User calibration procedure: the ">>>_CAL_MODE" message

is displayed in the comment line, and "FACt" is displayed in the main line.

The instrument is provided with the factory ("FACt") calibration. It is also

possible to perform a "USER calibration" ("USEr")of instrument+probe. The

calibration information is saved in the instrument’s memory. The same

correction is applied to any probe connected to the input: therefore, the "USER

calibration" should only be used with the probe used for calibration and not with

other probes.

•use the and arrows (respectively located above the HOLD and REL

keys) and select USEr, to access the "USER calibration" procedure;

•press DATA/ENTER to confirm the modification;

•the "SEL_CHAN" message is displayed in the comment line;

•use the and arrows (respectively located above the HOLD and REL

keys) to select the input "A" or "B" in the main line;

•the "SEL_MEAS_1/2" message is displayed in the comment line;

•use the and arrows (respectively located above the HOLD and REL

keys) to select "0", "1" or "2" in the main line;

•press DATA/ENTER to confirm the modification;

•press CLR/ESC to cancel the modification;

•to exit the menu, press the UNIT/MENU key again.