TB-2084 Page 4 of 4

© 2001 DESCO INDUSTRIES INC.

Employee Owned

Whenever the coil cord is accidentally withdrawn from the

monitor, or if continuity from the user to the monitor is not

maintained, the alarm sounds, the green Operator LED

turns off and the red Operator LED turns on.

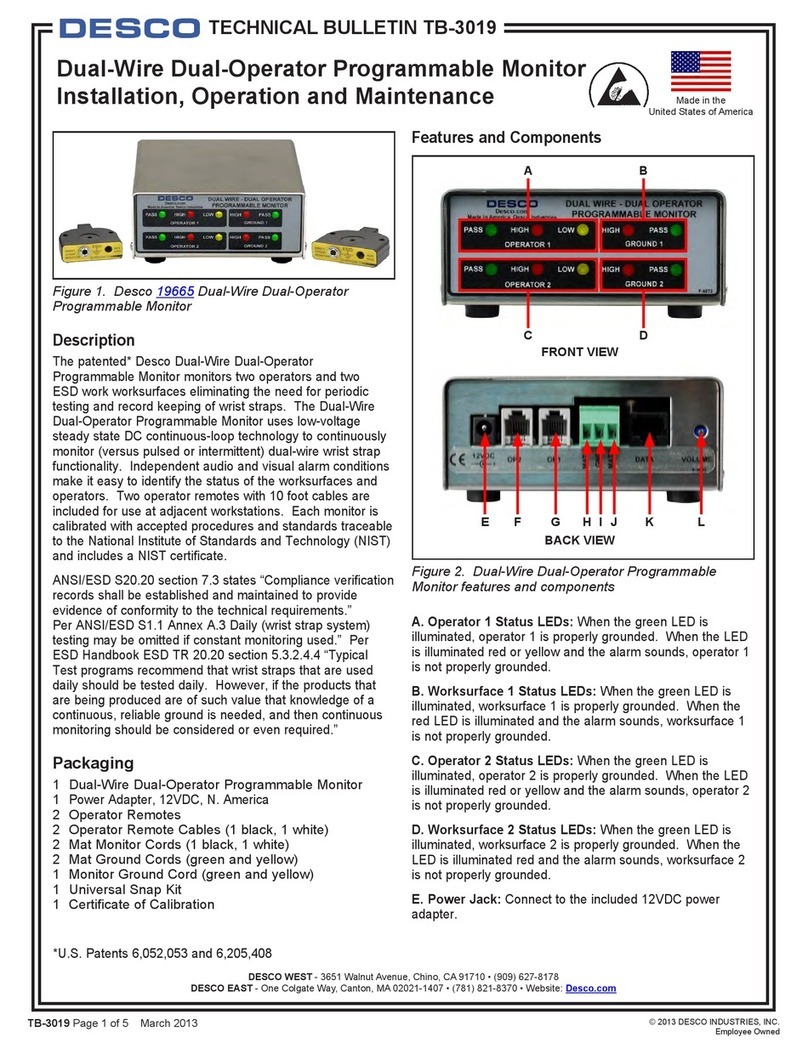

COMPUTER INTERFACE

The model 19208 monitor also incorporates logic output

circuitry. The unit is designed with an open collector circuit

that can be set up to activate remote sirens, alarms or

interface with a computer. The open collector circuit is

accessible through the terminal screw on back of the

monitor. See figure 4 for location.

WORK SURFACE CHANNEL

The 19208’s Work Surface monitoring circuitry is sufficiently

sensitive to detect extremely low current, allowing it to be

used with mats having a resistance of up to 5 x 108

ohms.

When the monitor is connected to a static dissipative

work surface, the amount of current that flows is a function

of the total resistance between the monitor and through the

work surface to ground. When the resistance of the work

surface is below a present threshold, the monitor will

indicate good. Conversely, if the resistance level is high

when compared to the monitor’s reference, the unit will

alarm. This is an integrating resistance measuring circuit,

therefore it is relatively insensitive to externally induced

electromagnetic fields. The resistance threshold is factory

set to 500 megohms. Custom worksurface range available

upon request. Call for details.

Specifications

Work Surface Limit* Set to 500 Megohms

Operating Voltage 120 VAC, 50-60 Hz

Response time to alarm < 50 mS

Operating Temperature 0 - 40°C

Long Term Drift <0.5% per Decade

(1st Decade is 1 hr)

Size (less bracket) 3.25 x 4.75 x 1.1

OPEN COLLECTOR OUTPUT

Fail-Safe: For fail safe operation, an active low is required.

If the monitor detects an operator-grounding fault, the open

collector port goes low (with respect to the green wire

ground).

One-Wire: Since the monitor detects that there is a low

resistance between the green wire ground and the neutral

conductor in the branch circuit, less than 1K ohms, the

green wire ground serves as the reference or the second

wire between the monitor and its remote warning device.

The open collector port is the other.

DESCO WEST - 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449

DESCO EAST - 90 Hudson Road, Canton, MA 02021-1407 • (781) 821-8370 • Fax (781) 575-0172 • Web Site: http://www.desco.com

*Limits can be varied and set to 1 gigohm maximum.

Limited Warranty

Desco expressly warrants that for a period of five (5) years from the

date of purchase Desco Continuous Monitors will be free of defects in

material (parts) and workmanship (labor). Within the warranty period,

a credit for purchase of replacement Desco Continuous Monitors, or,

at Desco's option, the Continuous Monitor will be repaired or replaced

free of charge. If product credit is issued, the amount will be

calculated by multiplying the unused portion of the expected five year

life times the original unit purchase price. Call our Customer Service

Department at 909-627-8178 (Chino, CA) or 781-821-8370 (Canton,

MA) for a Return Material Authorization (RMA) and proper shipping

instructions and address. Please include a copy of your original

packing slip, invoice, or other proof of date of purchase. Any unit

under warranty should be shipped prepaid to the Desco factory.

Warranty replacements will take approximately two weeks.

If your unit is out of warranty, call our Customer Service Department

at 909-627-8178 (Chino, CA) or 781-821-8370 (Canton, MA) for a

Return Material Authorization (RMA) and proper shipping instructions

and address. Desco will quote repair charges necessary to bring your

unit up to factory standards.

Warranty Exclusions

THE FOREGOING EXPRESS WARRANTY IS MADE IN LIEU OF

ALL OTHER PRODUCT WARRANTIES, EXPRESSED AND

IMPLIED, INCLUDING MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE WHICH ARE SPECIFICALLY

DISCLAIMED. The express warranty will not apply to defects or

damage due to accidents, neglect, misuse, alterations, operator error,

or failure to properly maintain, clean or repair products.

Limit of Liability

In no event will Desco or any seller be responsible or liable for any

injury, loss or damage, direct or consequential, arising out of the use

of or the inability to use the product. Before using, users shall

determine the suitability of the product for their intended use, and

users assume all risk and liability whatsoever in connection therewith.

Specifications:

V (open circuit) <20 V

I (short circuit) 200 uA

Pull-up to 15V >50 uA (Active)

Pull-up to 5V >150 uA (Active)

Pull-down to 0.5V >400 uA (Active)

Third-state HiZ >100 K ohms (unit unplugged)

Maintenance and Calibration

The Dual Operator Workstation Continuous Monitor is solid

state and designed to be maintenance free. The 19208 and

19209 are calibrated to NIST traceable standards. There

are no user adjustments that can be made. Because of the

impedance sensing nature of the test circuit, special

equipment is required for calibration. We recommend that

calibration be performed annually, using the #98220

Continuous Monitor Calibration Unit. Prior to calibration,

disconnect Remote Jacks (if used) from the unit.

Remote Jacks may cause intermittencies in calibration.

The Calibration Unit is a most important product which

allows the customer to perform NIST traceable calibration

on continuous monitors. The #98220 is designed to be

used on the shop floor at the workstation, virtually

eliminating downtime, verifying that the continuous monitor

is operating within tolerances.