ADVANTAGES OF WAVE DISTORTION AND

SINGLE-WIRE TECHNOLOGY

The Desco Multi-Mount Continuous Monitor allows the use

of any standard, single-wire wrist strap and coil cord. The

monitor/wrist strap/cord system life-cycle costs are by far

lower than alternative systems which require expensive &

fragile dual-wire cords and special wrist straps. Dual-wire

cords are expensive and are the weak link of the system,

the most likely component to need replacement. Over a

five year period, this can make the dual-wire system three

to five times as expensive as a system utilizing single-wire

wrist straps and cords. See Maintenance and Calibration

(page 4) to minimize life-cycle costs.

The dictionary defines constant as uniform and unchanging,

and continuous as uninterrupted. Nonetheless, some

dual-wire resistance monitors utilize a pulsed test current

and do not really provide continuous monitoring. For

example, during each 2.2 second pulse cycle of a leading

“constant” resistive monitor, electrical current is pulsed for

only 0.2 seconds followed by an unmonitored interval of

2 seconds. This leaves the user/wrist strap unmonitored

for over 90% of each cycle. Damaging static charges can

easily occur in the portion of the time in between the pulses.

The off period of 2 seconds equals 2 billion nanoseconds,

and “it takes only about 25 volts applied for 100

nanoseconds to blow most memories or microprocessors.*

The dual-wire system does not reliably meet all industry

specifications, as the cords do not meet the EOS/ESD

S-1.0 paragraph 4.1.6, 1 to 5 pound “breakaway force”

requirement for operator safety.

By using the reliable wave distortion technology to

determine if the circuit is complete, there are no false

alarms. There is no need to adjust or tune the monitor to

a specific user or installation. The miniscule amount of

electrical current (less than 1 volt coil cord signal) required

to generate the waveform has never caused reported skin

irritation and is extremely safe for use in voltage sensitive

applications such as disk drive manufacturing.

WORKSURFACE CHANNEL

The Multi-Mount Continuous Monitor’s circuitry is

sufciently sensitive to detect extremely low current,

allowing it to be used with mats having a resistance

of up to 1.0 x 10E7 ohms RTG. When the Monitor is

connected to an ESD Mat worksurface, the amount of

current that ows is a function of the total resistance

between the monitor and through the worksurface to

ground. When the resistance of the worksurface is

below a pre-set threshold, the monitor will indicate

good. Conversely, if the resistance level is high when

compared to the monitor’s reference, the unit will

alarm. This is an integrating resistance measuring

circuit, therefore it is relatively insensitive to externally

induced electromagnetic elds. The resistance

threshold is factory set to 10 megohms. (It can be

special ordered to other limits. Limits can be varied

and set to 1 gigohm maximum).

Packaging

1 Multi-Mount Monitor

1 24VAC Power Adapter

1 6' Mat Monitor Cord (Black)

1 6' Mat Ground Cord (Green and Yellow)

2 Push and Clinch Snaps

2 Mounting screws

2 Countersink Washers

1 Set of hook and loop fasteners

1 Certificate of Calibration

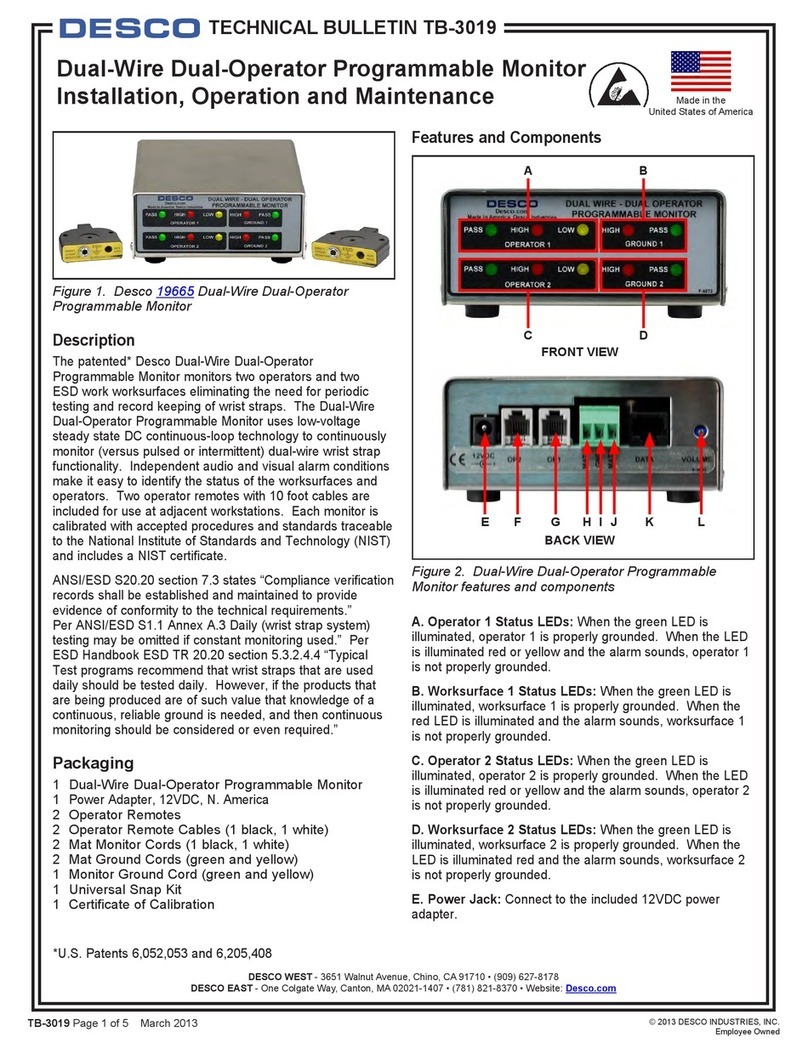

Features and Components

TB-3054 Page 2 of 4

*1981 article by Donald E. Frank - Electrical Overstress / Electronic

Discharge Symposium Proceedings

© 2011 DESCO INDUSTRIES INC.

Employee Owned

DESCO WEST - 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178 • Fax (909) 627-7449

DESCO EAST - One Colgate Way, Canton, MA 02021-1407 • (781) 821-8370 • Fax (781) 575-0172 • Web Site: Desco.com

A

B

EDC

H

G

F

Figure 2. Multi-Mount Continuous Monitor features and

components

A. Status LEDs: When the green LED is illuminated,

the operator is properly grounded. When the red LED is

illuminated, the operator is not properly grounded.

B. Monitored Operator Jack: Where the operator inserts

the wrist cord banana plug.

C. Worksurface Ground LEDs: When the green LED

is illuminated, the worksurface mat is properly grounded.

When the red LED is illuminated, the worksurface mat is not

properly grounded.

D. Operator Ground LEDs: When the green LED is

illuminated, the operator is properly grounded. When

the red LED is illuminated, the operator is not properly

grounded.

E. 4mm Parking Snap: When touched by the operator, this

snap will deactivate the alarm for six seconds. This allows

time for the operator to disconnect the coil cord from the

wrist band and park it on this snap. While parked, the coil

cord disables the alarm, allowing the operator to leave the

workstation. The OPERATOR GROUND LED will remain off

while the cord is parked. Upon returning and removing the

coil cord from the parking snap, the operator has six seconds

to hook up to the wrist band before the alarm sounds.