DESCO WEST - 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178

DESCO EAST - One Colgate Way, Canton, MA 02021-1407 • (781) 821-8370 • Website: Desco.com

TB-3078 Page 1 of 6 © 2019 DESCO INDUSTRIES INC

Employee Owned

Zero Volt Monitor

Installation, Operation and Maintenance

Description

The Desco 19668 Zero Volt Monitor is a dual

workstation continuous monitor. It continuously monitors

the path-to-ground integrity of two operators and two

ESD worksurfaces. It also will indicate if voltage greater

than ±1.25 V is induced onto the operator. Audio

and visual alarms activate in failure situations. The

Desco Zero Volt Monitor provides stable continuous

monitoring of the path-to-ground and presence of two

1 megohm resistors of an operator’s dual-wire wrist

strap. Audio and visual alarms activate (in less than 500

milliseconds) when the wrist strap connection points

are intermittent. The Desco Zero Volt Monitor also

monitors for a worksurface path-to-ground less than 3.5

megohms. All Desco Zero Volt Monitors are calibrated

to NIST standards and include a certificate. A calibration

unit is available to preform compliance verification at the

workbench without taking the monitor out of service.

Desco Zero Volt Monitor Technology

The Desco Zero Volt Monitor uses electrical loop

resistance technology. Dual test signals are placed

onto each of the dual-wire wrist strap's conductors

to negate finger-tip voltage. Resistance is monitored

with a continuous split test signal sent through both

conductors, across the skin of the operator, and

returning to the monitor through the opposite conductor.

Desco Zero Volt Monitors determine that the operator’s

path-to-ground is between the 2 megohms lower limit

and 10 megohms upper limit. Additionally, the Desco

Zero Volt Monitor determines if voltage greater than

±1.25 V has accumulated on the operator.

March 2019

ANSI/ESD S20.20 section 7.3 states “Compliance

verification records shall be established and maintained

to provide evidence of conformity to the technical

requirements.” Per ANSI/ESD S1.1 Annex A.3 Daily

(wrist strap system) testing may be omitted if constant

monitoring used.” Per ESD Handbook ESD TR 20.20

section 5.3.2.4.4 “Typical Test programs recommend

that wrist straps that are used daily should be tested

daily. However, if the products that are being produced

are of such value that knowledge of a continuous,

reliable ground is needed, and then continuous

monitoring should be considered or even required.”

The Zero Volt Monitor and its accessories are available

in the following item numbers:

Item Description

19668 Zero Volt Monitor

50524 Limit Comparator

50529 Replacement Operator Remote Kit, Black

50530 Replacement Operator Remote Cable, Black

50531 Replacement Operator Remote Kit, White

50532 Replacement Operator Remote Cable, White

50533 Replacement Operator Remote

50534 Replacement Hardware Kit

19262 Replacement Power Adapter, 12 VDC

Packaging

1 Zero Volt Monitor

1 Power Adapter, 12 VDC, with interchangeable plugs

(North America, UK/Asia, Europe)

2 Operator Remotes

1 Operator Remote Cable, Black

1 Operator Remote Cable, White

1 Monitor Ground Cord, Green

1 Mat Monitor Cord, Black

1 Mat Monitor Cord, White

2 Mat Ground Cords, Green

1 Hardware Kit

1 Certificate of Calibration

Made in the

United States of America

TECHNICAL BULLETIN TB-3078

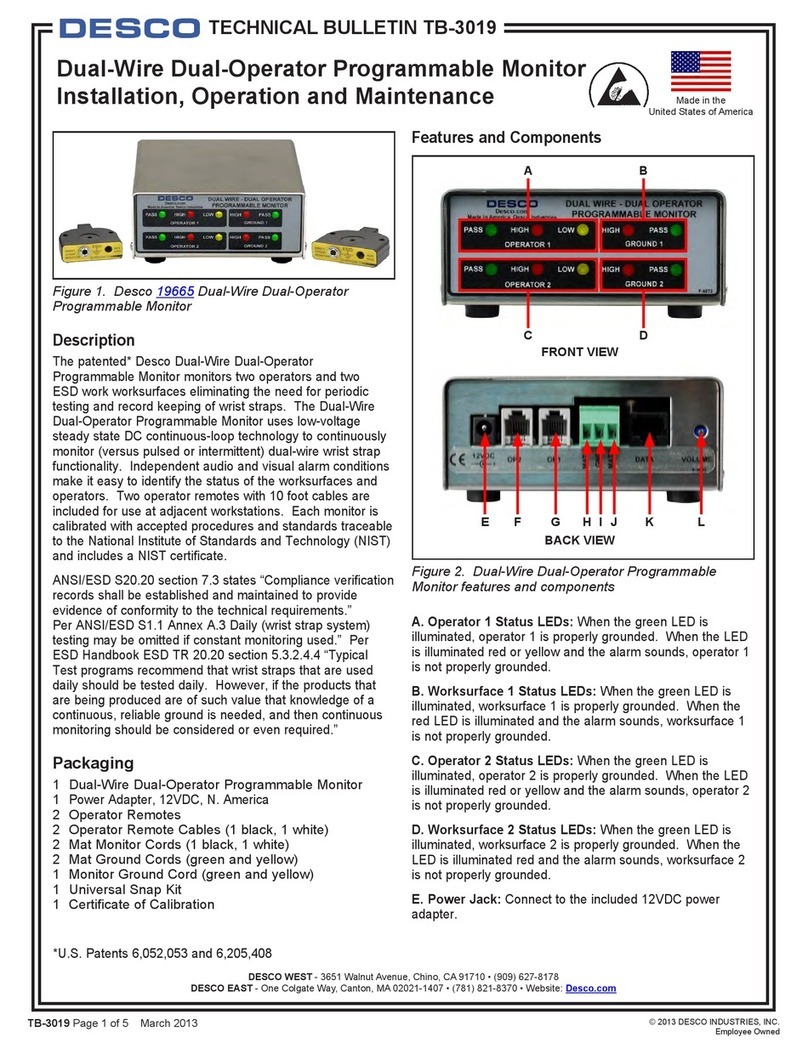

Figure 1. Desco 19668 Zero Volt Monitor