TB-3072 Page 1 of 4 © 2017 DESCO INDUSTRIES, INC.

Employee Owned

DESCO WEST - 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178

DESCO EAST - One Colgate Way, Canton, MA 02021-1407 • (781) 821-8370 • Website: Desco.com

Mini Monitor

Installation, Operation and Maintenance

Description

The Desco Mini Monitor is a single workstation

continuous monitor. It continuously monitors the

path-to-ground integrity of one operator and one ESD

worksurface. The Mini Monitor eliminates the need for

periodic testing and record keeping of wrist straps.

The Mini Monitor is designed with Wave Distortion

Technology which provides stable continuous monitoring

of the path-to-ground and presence of 1 megohm

resistance of an operator’s wrist strap. Audio and visual

alarms activate (in less than 50 milliseconds) when the

operator unintentionally disconnects from the monitor or

the wrist strap connection points are intermittent. The

Mini Monitor also serves as a ground point for an ESD

worksurface and monitors for a path-to-ground of less

than 500 megohms. All Mini Monitors are calibrated to

NIST standards and include a certificate.

April 2017

Wave Distortion Technology is the Most Reliable

Technology for the Continuous Monitoring of

Single-Wire (Conductor) Wrist Straps

“Wave Distortion” or vector impedance works by

applying a continuous test voltage of 1.2 volts

peak-to-peak at 1 to 2 microamperes (0.000002

amperes) to the wrist strap that is connected to the

continuous or constant monitor. The test voltage

creates a sine wave that the monitor circuit compares

to established patterns. By monitoring the “distortions”,

or shape of the sine wave, Wave Distortion Technology

determines if the monitored circuit is complete - the

operator is in the circuit and the total equivalent DC

resistance is within specifications. Wave Distortion

Technology produces a very fast alarm time (<50

milliseconds) and minimal false alarms.

ANSI/ESD S20.20 section 7.3 states “Compliance

verification records shall be established and maintained

to provide evidence of conformity to the technical

requirements.” Per ANSI/ESD S1.1 Annex A.3 Daily

(wrist strap system) testing may be omitted if constant

monitoring used.” Per ESD Handbook ESD TR 20.20

section 5.3.2.4.4 “Typical Test programs recommend

that wrist straps that are used daily should be tested

daily. However, if the products that are being produced

are of such value that knowledge of a continuous,

reliable ground is needed, and then continuous

monitoring should be considered or even required.”

The Mini Monitor and its accessories are available as

the following item numbers:

Item Description

19239 Mini Monitor, Black, North America

19242 Mini Monitor, Blue, with Jewel® Wrist Strap,

North America

19243 Mini Monitor, Black, Universal Power Adapter

19258 Power Adapter, 100-240VAC Input, 24VDC

150mA Output, IEC Inlet

19260 Power Adapter, 100-240VAC Input, 24VDC

150mA Output, North America Plug

98220 Calibration Unit, for Wave Distortion Monitors

Packaging

1 Mini Monitor

1 09100 Jewel® Elastic Wrist Strap (19242 only)

2 Push and Clinch Snaps

1 Power Adapter, 24VDC

1 Certificate of Calibration

Made in the

United States of America

TECHNICAL BULLETIN TB-3072

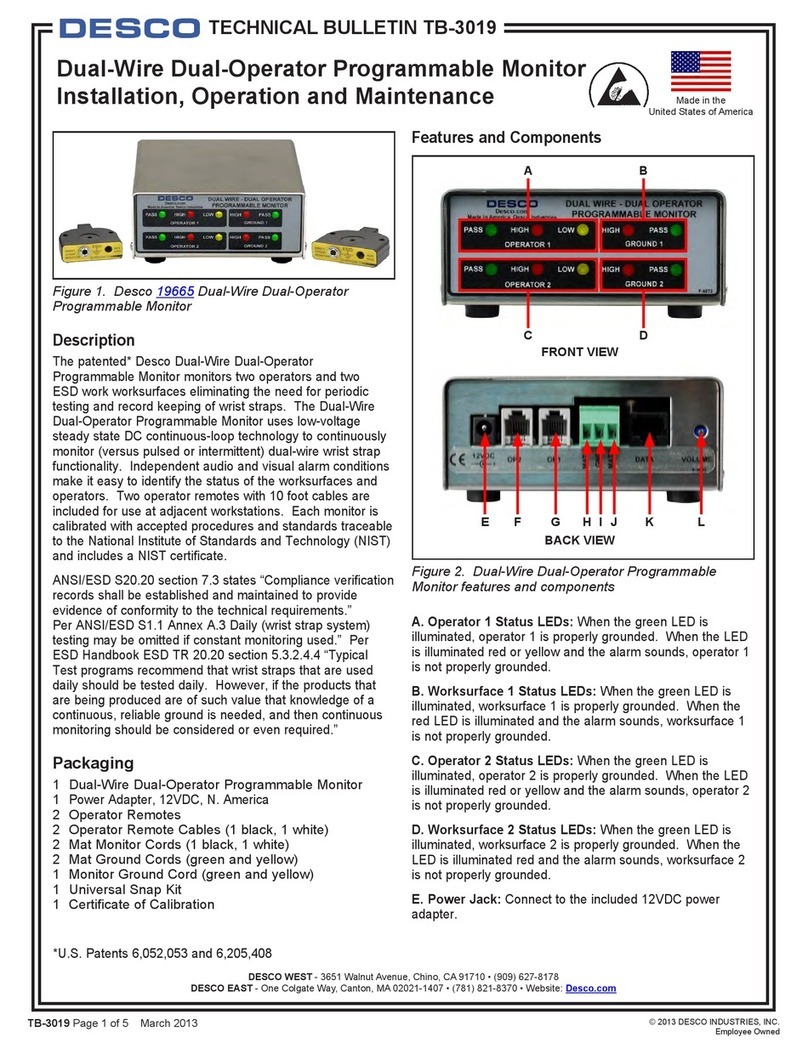

Figure 1. Desco Mini Monitor