TB-3060 Page 1 of 5 © 2018 DESCO INDUSTRIES INC

Employee Owned

DESCO WEST - 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178

DESCO EAST - One Colgate Way, Canton, MA 02021-1407 • (781) 821-8370 • Website: Desco.com

Made in the

United States of America

Full-Time Continuous Monitor

Installation, Operation and Maintenance

Description

Leading companies use continuous monitors as a cost

effective component in satisfying the paragraph 6.1.3

Compliance Verification Plan requirements of ANSI/

ESD S20.20. The Desco Full Time Continuous Monitor

provides 100% monitoring of both the operator and the work

surface. This unit provides continuous monitoring of:

• One user wearing a wrist strap

• ESD worksurface

• Ground

• AC outlet

Note: Worksurface must have a conductive layer such as

Dual Layer Rubber, Dissipative 3-Layer Vinyl or Micastat®

Dissipative Laminate with conductive buried layers. Desco

Continuous Monitors are not recommended for use with

homogeneous matting.

If the unit detects that the elements are outside industry

standards, the continuous monitor will alarm woth both an

audible alarm and an illuminated red LED to notify the user

of a problem.

Unlike many units, the Full Time Continuous Monitor also

continuously verifies ground (AC outlet ground). When the

Power Cord is plugged in, a self-test runs automatically.

If the AC outlet is wired incorrectly, both red LEDs will

illuminate and the audible alarm will sound. The unit has an

additional ground point for a user or supervisor.

The Full Time Continuous Monitor is available in two

models:

Item Input Voltage Power Cord

19325 120VAC North America

19326 220VAC United Kingdom

July 2018

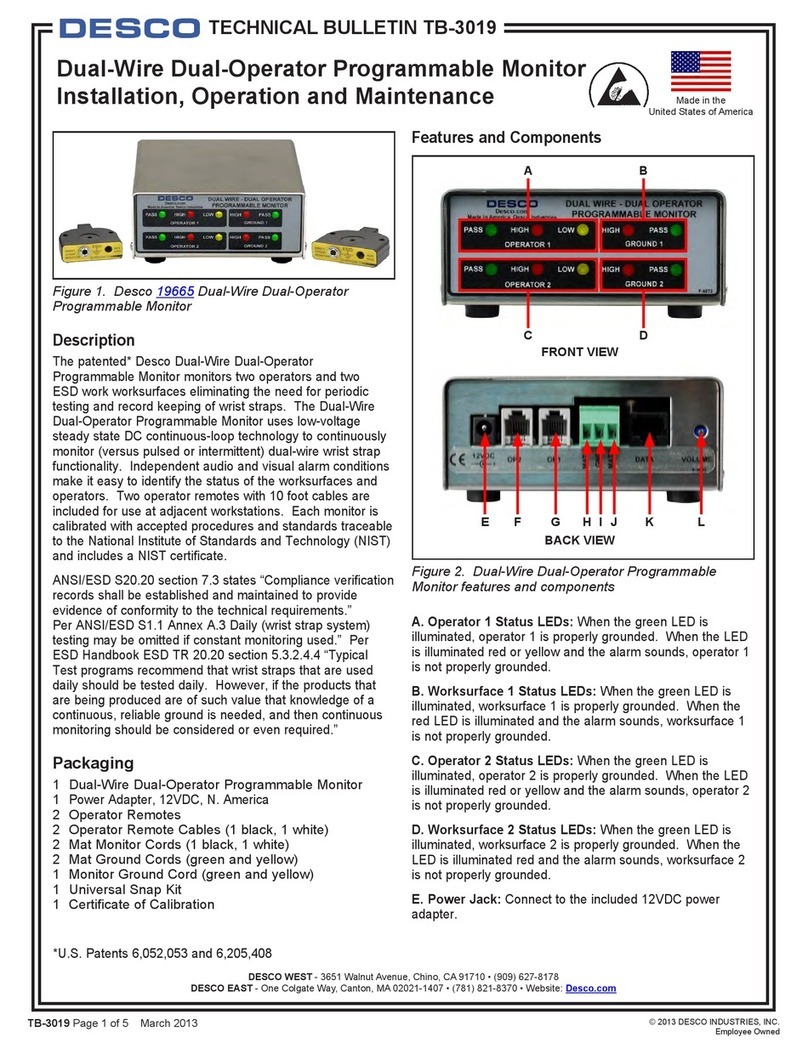

Figure 1. Desco Full-Time Continuous Monitor

ADVANTAGES OF WORKSTATION CONTINOUS

MONITORING OVER PERIODIC TESTING

Many customers are eliminating periodic testing and are

utilizing workstation continuous monitoring to better ensure

that their products were manufactured in an ESD controlled

environment. Full time workstation continuous monitoring is

superior to pulsed monitoring as well as periodic testing, and

can save a significant amount of money in testing costs and

rejected products. Periodic testing detects failures after

ESD susceptible products have been manufactured. The

costs of dealing with the resulting catastrophic or latent

defects can be considerable. Full Time Continuous Monitors

eliminate the need for users to test wrist straps and log the

results; by their function, these monitors satisfy the ISO

9000 and ANSI/ESD S20.20 Paragraph 6.2.2.2. test logging

requirements. Per ESD-S1.1 paragraph 6.1.3 Frequency

of Functional Testing “Daily (Wrist Strap) testing may be

omitted if constant monitoring is used.”

Per ESD Handbook TR 20.20 paragraph 5.3.2.4.4 Test

Frequency “Because wrist straps have a finite life, it is

important to develop a test frequency that will guarantee

integrity of the system. Typical test programs recommend

that wrist straps that are used daily should be tested daily.

However, if the products that are being produced are of

such value that knowledge of a continuous, reliable ground

is needed, and then continuous monitoring should be

considered or even required.”

WAVE DISTORTION DETECTION TECHNOLOGY

PROVIDES TRUE 100% CONTINUOUS MONITORING

Desco utilizes wave distortion technology for the Full Time

Continuous Monitor, which is an Impedance type monitor.

Per ESD TR12-01 section 2.2 Impedance (or single wire)

constant monitors “The capacitance type of monitor is

also known as an impedance monitor. They both work on

the same theory, however the impedance monitor uses

a detection circuit designed to reduce false alarms and

eliminate adjustments. ‘Single Wire’ or ‘impedance type’

monitors use the phase difference between current and

voltage to detect changes in impedance of the cord, band

and person. A very low AC voltage is used for constant

sensing. Any standard wristband and coiled cord can be

used.”

Thus the wave distortion circuitry monitors current/voltage

phase shifts and provides true 100% continuous monitoring.

Electrical current will lead voltage at various points due to

the combinations of resistance and capacitive reactance.

By monitoring these “distortions” or phase shifts, the wave

distortion Full Time Continuous Monitor will reliably determine

if the circuit is complete.

TECHNICAL BULLETIN TB-3060