Desin Instruments HS-7000 Series Instruction manual

GENERAL

INSTRUCTIONS

HS-7000 SERIES

MULTIVARIABLE

CONTROL

PROCESSORS

PAC

HS-7500

HS-7300

HS-7200

PROGRAMMABLE BY

FUNCTION

BLOCKS

PARAMETRIZATION

AND

CONFIGURATION BY

KEYPAD

2

GENERAL INDEX

HS-7000 SERIES OPERATION INSTRUCTIONS ............................................................ 5

BASIC RECOMMENDATIONS ...................................................................................... 6

INTRODUCTION ......................................................................................... 6

Check packing contents ............................................................................ 6

Considerations about these instructions ................................................... 7

Structure of these instructions .................................................................. 7

Complete menu of models with display ..................................................... 7

HS-7000 Series Description ...................................................................................... 8

Description ......................................................................................... 8

Formats ......................................................................................... 9

Identification ....................................................................................... 10

INSTALLATION ....................................................................................... 11

Mounting precaution ............................................................................... 11

Mounting, Dimensions and panel cutout.................................................. 11

WIRING ....................................................................................... 12

Wiring precautions .................................................................................. 12

Description of terminals .......................................................................... 14

DESCRIPTION OF FRONT PANEL .............................................................................. 18

OPERATION INSTRUCTIONS OF MAIN MENU FUNCTIONS .......................................... 21

GENERAL INSTRUCTIONS ....................................................................................... 22

Initial presentation of the Display ............................................................ 22

Messages of safety functions ................................................................. 23

OPERATION OF MAIN MENU FUNCTIONS .................................................................. 24

CONTROL SETPOINTS SP 1, SP 2, AND SP 3 .......................................... 24

REMOTE SETPOINT SP r .......................................................................... 25

RAMP SETPOINT ..................................................................................... 25

AUTO-MANUAL STATIONS AM 1, AM 2 AND AM 3 .................................... 27

ALARM SETPOINTS AL 1, AL 2, AL 3, AL 4, AL 5 AND AL 6 ..................... 28

AUXILIRY SETPOINTS STR 1, STR 2, STR 3 AND STR 4 ........................... 30

PASSWORDS ....................................................................................... 31

PID CONTROL SUBMENU ....................................................................................... 32

Input to PID 1, PID 2 and PID 3 ............................................................... 32

PID Autotuning (AUTOTUNING) ................................................................. 33

Fuzzy-Logic ....................................................................................... 36

PID Manual Settings ............................................................................... 37

3

OTHER MANUAL CONTROL SETTINGS ...................................................................... 39

RS-485 Modbus Communications ............................................................................ 40

OPERATION INSTRUCTIONS OF SPECIFIC FUNCTIONS ..................................................... 41

MAIN APPLICATIONS ....................................................................................... 42

General purpose basic Indicator .............................................................. 43

Indicator with automatic or manual Tare .................................................. 45

Indicator with instant, peak or valley Hold ............................................... 46

Psychrometric %RH Indicator ................................................................... 47

Pulse Counter ....................................................................................... 48

Frequency-meter ..................................................................................... 50

Period-meter ....................................................................................... 50

Derivator ....................................................................................... 51

Integrator Totalizer .................................................................................. 52

MODBUS Communication ........................................................................ 53

Continuous Control by current modulation ............................................... 54

Discontinuous Control by time modulation ............................................... 55

Step by Step Control ............................................................................... 57

Controller Positioner ............................................................................... 62

Bimodal (Heat- Cool) Control ................................................................... 63

Remote Setpoint Controller ..................................................................... 64

HS-7000 SERIES BASIC CONFIGURATION USING KEYPAD............................................... 65

GENERAL CONFIGURATION SYSTEM ....................................................................... 66

PARAMETERS MODIFICATION PROCEDURE .............................................................. 68

Analog Input Configuration ...................................................................... 69

Analog Output Configuration .................................................................... 76

Digital Output Configuration (Relays) ....................................................... 78

Analog HOLD, Peak or Valley ................................................................... 80

Analog Integrator .................................................................................... 82

Analog Derivator ..................................................................................... 85

Timers ....................................................................................... 86

Linearization ....................................................................................... 88

Analog Alarms ....................................................................................... 91

PID Control ....................................................................................... 93

Control Setpoint SP ................................................................................ 96

Displays ....................................................................................... 98

Access passwords to Submenus (Password) ........................................... 99

CONFIGURATION OF OTHER FUNCTIONS OF HS-7000 ................................................... 100

TABLE OF CODES OF ANALOG FUNCTION BLOCK OUTPUTS ........................................... 102

TABLE OF CODES OF LOGIC FUNCTION BLOCK OUTPUTS .............................................. 103

4

This page has been left blank intentionally.

5

HS-7000 SERIES

OPERATION

MANUAL

VERY IMPORTANT

Some explanations are related specifically to the models

provided with front keypad.

For the HS-7500 Processor (w/out keypad) it is necssary to

use the LoopWin Software.

HS-7300

HS-7200

6

Please read carefully

before handling

the instrument

INTRODUCTION

CHECK PACKING CONTENTS

Should includes:

- 1 HS-7000 device.

- 2 Clamps to fix to panel (except for the converter HS-7500).

- 1 Instruction sheet.

- 3 Shunts 3,74 Ohm for mA inputs.

- 1 CJC Sensor for thermocouple Cold Junction Compensation.

Optional: In special under request models, may include:

- 1 Input Voltage Divider (for input signals greater than 75 mV).

- 1 Adapter for feedback potentiometer input.

- 1 General Instruction Manual.

- 1 CD including software and LoopWin and Proasis DCS-Win utilities.

- 1 Advanced Instruction Manual.

BASIC RECOMMENDATIONS

This Manual is addressed to the instrumentist responsible of programming and configuration and

start-up of these instruments.

NOTE: These instruments are provided, from factory, with protection level allowing the access

to the display parameters. The access to the submenus is protected with Passwords, to avoid

any misuse which may alter the configuration already stored in memory.

These INSTRUCTION MANUALS are continuously improved

by our publication’s department, generating updated

versions in PDF format available on our website:

www.desin.com

7

CONSIDERATIONS ABOUT THESE INSTRUCTIONS

●

The instruments of the HS-7000 Series are fully programmable processors, so that, all the

function provided in its Function Blocks can be enabled or disabled by key pad or by software,

to fit the application requirements. The Function Blocks of the HS-7000 can be linked to each

other, allowing infinity of control structures to fit almost every application.

●

This feature makes the menu in the HS-7000 Series to be non-linear one, so that it is

impossible to explain how it operates following the pre-established structure of menu.

●

Moreover, these functions represented as symbols on the display, can be assigned to any

of the three loops or to any Password level available in the instrument, so that it can be

located, in the menu, in different positions according to the programmer and the application’s

requirements.

●

This is why the display of the HS-7000 is different from other displays, since it can display

between 6 and 15 different values by multiplexing the screens on the display. These screens

are identified and presented as Meauring or Control Loops L1, L2 and L3, to which, can be

assigned any measured or calculated signal. Every loop can be selected by using the key

from any position of the MAIN MENU.

●

Thus, in the HS-7000, one display may shows the one input signal, the other one the Total

of a flow measurement and the third one may displays a hold value, or one setpoint, or the

control output value, etc.

●

Those instruments, because of its versatility, performances, accuracy and fast response are

considered as high range instruments of its segment.

The operation instructions are organized in different sections to ease the operation of

Parameterization, Configuration and Specific Applications, as follows:

STRUCTURE OF THESE INSTRUCTIONS

These instructions are structured in different sections:

INSTRUCTIONS FOR WIRING, MOUNTING AND CONTROL KEYPAD

●

Inputs, Outputs, Displays and Keypad.

OPERATION OF FUNCTIONS OF MAIN MENU

●

SP, A/M, Alarms, Auxiliary Setpoints, Integrator, Counter, Hold, PID, Communications, etc.

SPECIFIC APPLICATIONS OF SOME OF MAIN FUNCTIONS

●

Indicator types, Counter, Frequency, Type of Controllers, Special models, etc.

BASIC CONFIGURATION BY KEYPAD OF MAIN FUNCTIONS

●

Allows, without using the LoopWin software, using the keypad to modify the most common

functions of the HS-7000 Series such as: Input, Output, Hold, Integrator, Derivator, Timers,

Linearizers, Alarms, PID, Setpoint SP, Password

COMPLETE MENU OF MODELS WITH DISPLAY

For any model of HS-7000 with display, with all its functions enabled, and indistinctly of the

assignation to the dispaly, or in which Loop or Password the function is located, when the key

8

HS-7000 SERIES DESCRIPTION

DESCRIPTION

The HS-7000 Series is a new range of programmable Multivariable Control Processors.

Each model of this series is provided with:

●

2 Analog inputs for TC, Pt 100 and mV or mA. (Note: Only one input could be used for TC)

●

1 Analog input for mV or mA

●

2 Analog outputs mA, for control or signal retransmission

●

2 Logic inputs 24 V, (1 for counting and 1 function activation)

●

4 Relay or Logic outputs for the activation of exteranl elements

●

2 RS-485 communication ports

●

1 Transmitter power supply output, 24 Vdc 60 mA.

Its 56 Function Blocks, could be linked allowing infinity of measurement and control strategies.

●

3 Analog input blocks

●

2 Analog output blocks

●

3 PID bimodal control blocks

●

3 Independent Setpoint blocks

●

6 Alarm loops

●

4 Digital output blocks

●

2 User Linearization blocks

●

1 Integrator block

●

2 Derivator blocks

●

1 Pulse counter up to 2,5 Khz

●

1 Logic input block

●

4 Configurable Timers

●

4 Analog constants wih decimals and 4 integer analog constants

●

1 Hold function instantaneous, Peak or Valley

●

4 Arithemtic Blocks each one is provided with square root extraction, 4ºPolynomials,

Psychrometric function, etc.

●

6 Logic operators And, Or, Xor, Set-Reset and Flip - Flop

●

2 Selectors of analog signals

●

2 Remote Logic input / output blocks

●

3 Configurable Display blocks

●

1 Front panel LED block

9

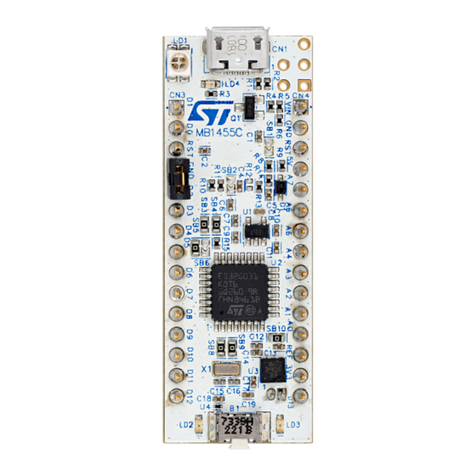

FORMATS

This Series is presented in 3 different formats, provided with the same functions, the only

difference between the models is the format.

HS-7200 1/8 DIN Horizontal Indicator, with dual 6 and 4-digit

display respectively. Suitable for displaying

measured and calculated variables.

HS-7300 1/8 DIN Vertical Controller, with 3 x4-digit display.

Suitable for multivariable process control.

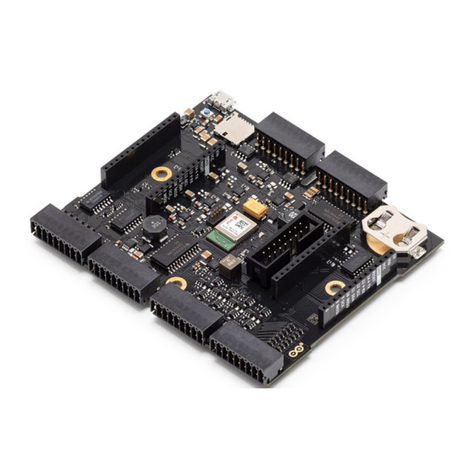

HS-7500 DIN Rail mounting processor, without display and

keypad format.

Suitable remote multivaraible control from PC.

The HS-7200 and HS-7300 could be programmed from front keypad or from PC using the

LoopWin Programming Tool Software.

The HS-7500 can only be programmed by LoopWin, since it is not provided with keypad.

These devices are provided with 2 independent RS-485 ports, having same address and

communication speed rate to be Controlled, conneced to a Modbus terminal in the field, and

at the same time, Supervised by the Proasis DCS-Win or Proasis LAN-Win software as well as

by any other SCADA software Modbus compatible.

These instructions describes models provided with factory standard configuration. Modifications

could be done by the user by LoopWin or keypad, depending on the model used.

STANDARD CONFIGURATIONS:

HS-7200 3 mV or mA inputs (2 configured as TC and Pt 100); with 6 alarms and 4 relay

outputs, and 2 signal retransmission 4-20 mA outputs.

HS-7300 3 mV or mA inputs (2 configured as TC and Pt 100); with 3 PID loops, 6 alarms and

4 relay outputs, and 2 control 4-20 mA outputs.

HS-7500 3 mV or mA inputs (2 configured as TC and Pt 100); and 2 signal retransmission

4-20 mA outputs.

NOTE: Only one of the two inputs is used for TC input, since the second one is used for CJC (Cold

Junction Compensation using a Pt 100).

10

is pressed, the access to the following options is allowed.

MNEMONIC DESCRIPTION INSTRUCTION

SP 1...3 Control Setpoint of each PID loop General

AM 1...3 Auto-Manual station of each PID loop General

di 2 Frequency-meter and Counter Specific

Int Integrator Specific

HLd Hold function Specific

AL 1...6 Alarm setpoints and hysteresis General

Str 1...4 Auxiliary setpoints (constants) Specific

PASS Access to menus of PID, Configuration and Calibration General

PID 1...3 PID Control loops. Parameters and control capabilities General

NOTE: The Menu configuration could be modified by LoopWin software, or by front keypad, to

fit the process structure.

VERY IMPORTANT:

●

If the HS-7000 were purchased with special programming or non programmed, refer to

ADVANCED PROGRAMMING INSTRUSTIONS.

●

If the HS-7000 were purchased with standard programming, refer to the OPERATION OF

FUNCTIONS OF MAIN MENU.

IDENTIFICATION

The instrument is identified by an adhesive label located on one side of the device. A marked boxes

allow to know: MODEL, INPUT (signal type) and RANGE in addition to, other informations useful for

maintenance .

These instruments are, usually, delivered with factory standard configuration.

HS-7000 SERIES FACTORY STANDARD CONFIGURATION

- Analog input 1: .................................................................................. Thermocouple «K»

- Analog input 2: ................................................................................................... Pt 100

- Analog input 3: ........................................... 0 - 75 mV or 4-20 mA with shunt 3,74 Ohm

- Range: .............................................................................................................. 0/1200

- Decimals: .................................................................................................... No decimal

- Unit: ......................................................................................................................... °C

- Analog outputs................................................... 4-20 mA. Control and Retransmission

- Logic inputs: ..................................................................................... To be programmed

- Digital outputs ...................................................................... 4 Relays. To be assigned

- Passwords: ................................................................................. 0123 in all passwords

- User Linearization: .......................................................................................... To be set

- PID parameters: ................................................................... Refer to table in PID group

- Functionality: .................................................................................... To be programmed

11

PANEL MOUNTING

The fixing in panel is

realized by the own

fittings of enclosure or

by the enclosed

brakets.

The panel wall should

be 0,8 to 2 mm (0.03 a

0.08 in) thick.

INSTALLATION

MOUNTING PRECAUTIONS

Avoid direct sources of light and heat. Locate the instruments away from corrosive vapours,

dripping, moisture, temperature over 50 °C, vibration, etc. Keep away of electromagnetic

radiation, radio frequency, microwave and high voltage sources, etc.

It is recommended to follow the GENERAL PRECAUTIONS indicatd in the instruction shhet

enclosed.

NO

Max. 50 °C / 125 °F

MOUNTING DIMENSIONS AND PANEL CUTOUT

HS-7200

HS-7500

90x45 +1

- 0

+.02

- 0

3.5x1.8

45x90

+1

- 0

+.02

- 0

1.8x3.5

HS-7300

12

WIRING

VERY IMPORTANT: These instruments are CE Marked, however, to avoid external

interferences, it is recommended to following wiring precautions.

WIRING PRECAUTIONS

Before connecting the main power or the inputs and outputs, check the data listed on the

manufacturer’s sticker carefully.

An improper installation could expose the device to transients and mains noise that may cause

frequent interruptions in display power with momentary display of [Erro] messages.

To avoid it, these instruments are provided with a safety element (Watchdog) that restores the

normal operation immediately after perturbances.

Please contact your distributor for further information.

CONNECTION TO MAIN POWER

●

The power supply for the instruments must be taken as directly as possible from the

general mains using a star connection (do not

supply several devices at the same power line).

●

Do not power relay coils, contactors, etc. with the

line used to power the instruments.

●

In the case of a very noisy power supply (due to

power units, i.e. thyristors), instrumentation should

be powered using an insulation transformer with a

grounded shield.

ANALOG INPUTS

●

Physically separate the signal lines (mV, Pt 100, 4-20 mA) along the entire length of the

power or relay command lines, contactors, servomotors, actuators, etc. (using separate,

independent racks or conduits).

●

Shielded, twisted pair wire must be used for extra-long signal cables.

IMPORTANT: The shield must be connected to Ground at a single point on the side

where the signal is received, i.e., at a grounding terminal close to the instrument (in star

grounding).

●

Thermocouple input:

Use an extension or compensation wire UNTIL THE DEVICE TERMINALS, observing the

polarity when connecting.

●

Pt 100 input:

Use 3-wire cable to compensate the effects of copper wire resistance (1.5-mm

2

cross-section or AWG15 gauge).

●

mV input:

Use 1.5-mm

2

copper-copper wire or AWG15 gauge. Ensure correct polarity.

Star

Serial

connection

YES NO

Mains

13

●

mA input:

Use 1.5-mm

2

copper-copper wire or AWG15 gauge. Ensure

correct polarity, and do not forget the 3.74 Ωparallel shunt

(included) in the terminals.

Relay output (CONTACTS)

●

To enlarge the life of the relay contacts, RC circuits (Resistance and Capacitaor in series)

are installed in parallel to the relay contacts.

ATTENTION: This may cause false effect of continuity between the output terminals

which do not mean that the relays are not operating properly.

●

Besides the RC circuits, in some cases, additional anti-noise circuits may be necessarily

wired at the terminals when strong inductive loads are operated, such as Auxilairy relays,

servomotors, contactors, etc.

4-20 mA output

●

Use of shielded twisted pair is recommended, with the shield

connected to Ground as explained above.

GROUND

●

If available, connect the shield of cables in star configuration to a single point of the

equipment (metal frame ground), using a conductor with the same cross-section as the

power supply or communication wires.

Shield Grounding

Communication lines grounding. Connect only

one end of the shield. Do not coonect additional

shields between the instruments.

Shields Grounding

14

DESCRIPTION OF TERMINALS

The wiring diagram and data related to input, output and range are indicated on an adhesive

label on the instrument enclosure.

VERY IMPORTANT: Check the input signal type, range and the power supply to be identical to

the data set on the label.

Power supply 85 Vac to 265 Vac

Ground

Transmitter power supply 24 Vdc 60 mA

COM1 RS-485 Modbus communication port

Output Y1. SPDT relay

Output Y2. SPST relay

24 Vdc 20 mA Logic output (optional)

Output Y3. SPST relay

24 Vdc 20 mA Logic output (optional)

Output Y4. SPST relay

24 Vdc 20 mA Logic output (optional)

Input DI 2. Logic input 24 Vdc

Input DI 1. Logic input 24 Vdc

COM2 RS-485 Modbus communication port

Output SA 1. Analog output 0..4-20 mA

Output SA 2. Analog outut 0..4-20 mA

Input AI 3.

Auxiliar Analog input mV and mA (3,74 Ω)

Input AI 2.

Analog input TC, RTD, mV and mA (3,74 Ω)

Input AI 1.

Analog input TC, RTD, mV and mA (3,74 Ω)

+

_

+

_

+

_

M

C

P

M

P

M

P

M

P

1 - 2

4 - 5

6 - 7

8

9

10

11

12

3

13

14

15

16

17-19

18-19

20-21

22-24

23-24

25

26

30

31

32

27

28

29

15

Thermocouple

Configuration in AI 2

Differenctial Thermocouple

Configuration w/out CJC

Factory standard Configuration:

Input AI 1 configurable for TC, Input

AI 2 as Pt 100 for CJC Cold Junction

Compensation.

Input AI 3 for mA used as remote

setpoint, feedback potentiometer,

etc.

Configuration identical to the

previous one, using input AI 1

for CJC.

TC Dual input w/out CJC for

differential temperature

measurement.

Input AI 3 for mA used as

remote setpoint, feedback

potentiometer, etc.

1 x RTD (Pt 100)

Configuration

Input AI 1 for Pt 100

Inputs AI 2 and AI 3 for mA.

1 x RTD (Pt 100)

Configuration in AI 2

Input AI 2 for Pt 100

Inputs AI 1 and AI 3 for mA.

2 x RTD (Pt 100)

Configuration

Inputs AI 1 and AI 2 for

Pt 100

Input AI 3 for mA.

ANALOG INPUTS WIRING

Thermocouple

Configuration

16

2 x TC

with remote CJC

(mA) signal

configuration

Inputs AI 1, AI 2 and AI 3 are connected to three 2-wire

4-20 mA transmitters powered by the transmitter

power supply of the device.

Two TC inputs with remote CJC using 4-20 mA signal.

Note: Inputs AI 1 and AI 2 are common mode type

inputs, isolated thermocouples should be used to

avoid Ground loop problems.

ANALOG INPUTS WIRING (continue)

3 x 4-20 mA, 2-Wire

Configuration

Two independent Logic inputs.

DI 2 Counting or Frequency up to 2,5 Khz

(for flow measurement, RPM, etc.)

DI 1 Up to 4 Hz.

Input signals from 8 Vdc to 24 Vdc. with

any polarity.

Terminal 19 is common for both inputs.

LOGIC INPUTS WIRING

Logic Inputs Contact type input

Two independent Logic inputs for external

operations (or counting in DI2).

To avoid ‘rebounds’of the contcats it is

necessary to connect capacitors (10 nF to

100 nF ) in parallel to the inputs.

Input signals from 8 Vdc to 24 Vdc. with

any polarity.

Terminal 19 is common for both inputs.

External contact used

to Start, Inhibit or

Reset the Totalizer

Pulse

Flowmeter

Input External Contacts

for operations as:

Start, Inhibit or

Integrator Reset,

Hold, etc.

17

Two independent Analog Outputs

For control or retransmission.

Provide mV, 0/20 or 4/20 mA signal.

Terminal 24 is common ( ).

CONTROL OR ALARM DIGITAL OUTPUTS WIRING

Analog Outputs

Relay Digital Output

Time Propertioning Control

4 Relay outputs

PWM output (optional)

Contactor

Alarm

STEP-BY-STEP AND POSITIONER CONTROL OUTPUT

Pulse Logic Output

For solid state and

power controllers firing

Power

controller

devices (SCR)

Alarm

Step by Step Control

PID control (dual loop or

Heat Cool) connection to

two motovalves without

feedback potentiometer

Pt 100

TP mV

10

8

9

11

12

30

27

28

29

31

32

mA

shunt

3,74 Ω

RED

NP

M

*

Feedback

potentiometer

Step by Step

or Positioner Control

PID control loop connection

to a motovalve with feedback

potentiometer

Feedback

potentiometer

value between

200 Ωand 10 KΩ.

NOTE: Add an

external R for fine

margen

adjustments(see

Manual).

18

DESCRIPTION

FRONT PANEL DESCRIPTION

HS-7200 HS-7300

➀

UPPER DISPLAY

Display the value of the Process Variable PV or any other assigned variable.

In MENU presents the value of the enabled parameters, messages and other options.

➁

MIDDLE DISPLAY

Display the value of the Control Setpoint SP or other assigned variable.

In MENU presents the parameter symbol of the upper display value.

➂

LOWER DISPLAY IN HS-7300

(not available in HS-7200 format)

Display the value of the Manipulated Variable %MV or other variables.

In MENU presents the parameter symbol of the upper display value.

➃➄➅

LED

S

L1 L2 L3

Loop number indicators

Indicate the Loop number displayed.

➆➇➈➉

LED

S

Y1 Y2 Y3 Y4

Light indicators

Programmed to indicate the Alarm status or the Control Action (depending on modelo).

For other functions refer to the Advanced Programming Manual.

19

LED

S

F1 and F2

Indicate the status of the Loop displayed at present.

F1 When On (lit), indicates Manual mode. When Off (unlit) indicates AUTO mode. When

flickering indicates Hold mode due to PID control failure.

F2 Indicates Remote Setpoint, and the signal in AI 3 is the current setpoint .

NOTE: All the LEDs Y or F can be used to indicate the status of any internal logic variable

. For other functions refer to the Advanced Programming Manual.

FUNCTION

Key

Allows to scroll, in the MENU, all the enabled functions.

Allows to exit from any parameter without saving the changes if any.

If pressed, cancels the PID Autotuning progress.

INCREMENT

Key

Allows to increase the value of the flickering digit.

During online edition, increase the value of the flickering parameter on the display.

In other functions, modify the option if allowed.

SHIFT Key

During edition, allows to select the digit to modify (flicker), shifting to the left digit by

digit.

During online edition, decreases the value of the flickering parameter on the display.

ENTER

Key

Used to access to a function or parameter of the MENU.

When a parameter is modified, save the changes realized.

PROGRAMMABLE

Key *

Allows to shift from Auto to Manual and vice versa, in Auto-Manu function of each loop.

Can be used to Activate, Inhibit, etc the Hold, Integrator, Counter, etc. functions.

By programming, any other action or function could be assigned to this key.

PROGRAMMABLE

Key #

Allows to shift from Local to Remote Setpoint and vice versa, in Local-Remote function

of each loop.

Can be used to Reset, Zeroing, etc. the Hold, Integrator, Counter, etc. functions.

By programming, any other action or function could be assigned to this key.

20

This page has been left blank intentionally.

This manual suits for next models

3

Table of contents