that perform all the communication, command, and

control functions for the system. It includes all the

required operator interface controls for a fire alarm

system (silence, acknowledge, reset, isolate),

annunciation relays, a local information display, and

communication interfaces for computer based

configuration and monitoring of the system.

LOCAL OUTPUT UNIT (LIOU)

The LIOU consists of a rack controlled by the LCU that

can hold up to six FenwalNet 2000 modules. These

modules allow the control of Notification Appliance

Circuits (NACs), fire suppression agent release (CO

2

,

Halon, FM200) using supervised relays, as well as

unsupervised relays for other needs.

THEORY OF OPERATION

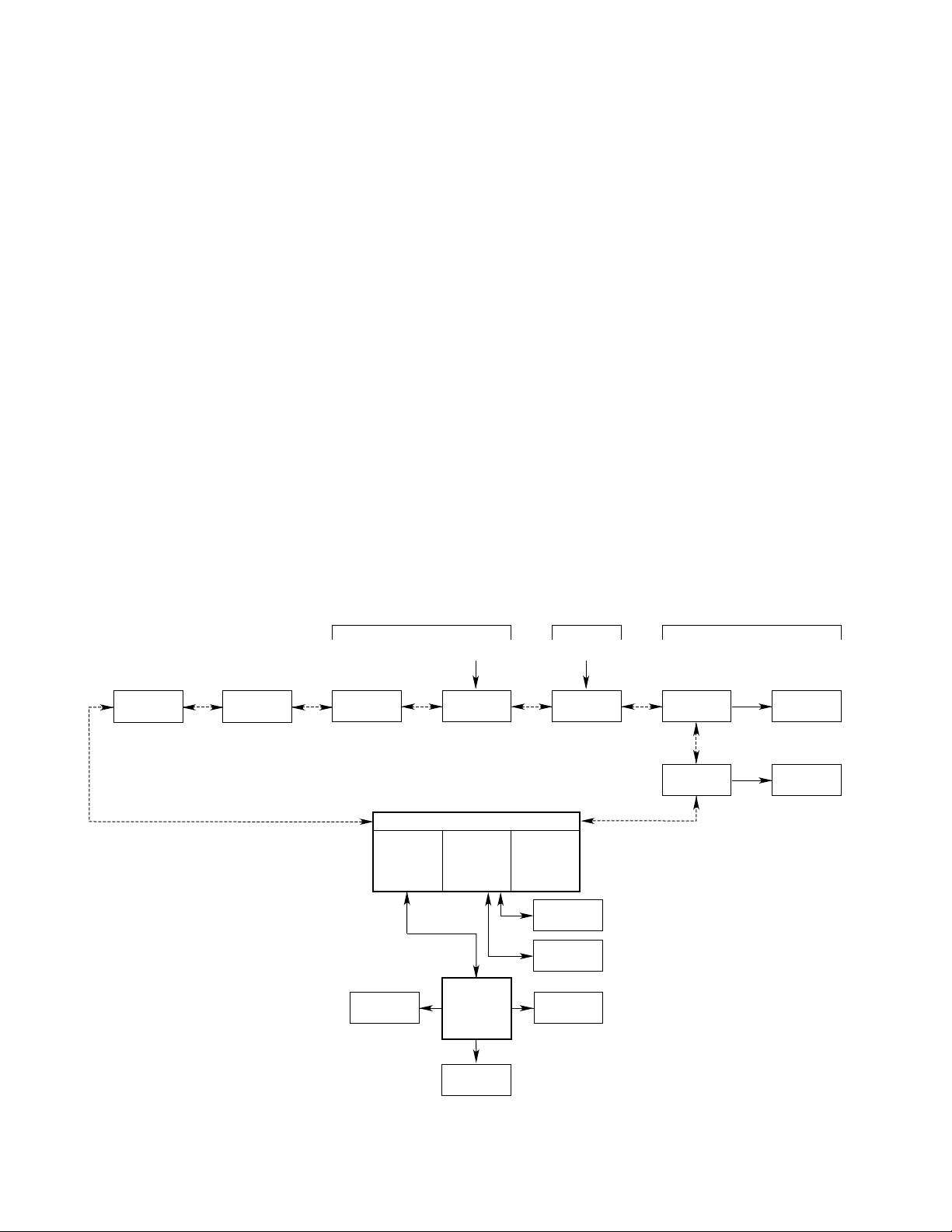

During normal operation, each node on the network

monitors its attached sensor or other input, determines if

it has an alarm condition, analyzes its own health,

checks network integrity, and then packages up this

information for transmission to the communication

gateway, located in the LCU. This Standard Periodic

Report (SPR) contains 16 pieces of “discrete”

information on the status of the node and, where

applicable, also contains the analog value of its sensor.

At the time of node configuration, the report rate of the

SPR can be set to anywhere between 1 and 10

seconds.

In the LCU the Communication Gateway collects all of

the incoming SPRs from the field devices and puts the

information into “datatables.” Datatables are organized

areas of memory in the gateway that can be “read” by

external “host devices” using one of the gateway’s serial

ports. If any of the SPRs indicate an out of tolerance

condition, the gateway will display this information on its

integrated faceplate display. The gateway also has four

programmable relays whose action can be

programmed to events in the SPRs of the monitored

nodes.

In addition to SPRs, nodes used as a part of the fire

detection and suppression system, such as fire

detectors or Initiating Device Circuits (IDCs) interfaced

with heat detectors, manual call points, etc. send a

separate Standard Supervisory Report (SSR) to the

Logic Controller, located in the Local Control Unit. The

Logic Controller, which manages the fire suppression

logic, uses these SSR messages to verify that the nodes

used in the fire alarm and suppression logic are active

and able to communicate. If the Logic Controller does

not receive SSRs from a required node, it will

annunciate a “trouble” condition.

If a “Fire Alarm” is detected by a Flame Detector or

Initiating Device Circuit (IDC), the affected node will

send a special Acknowledged Exception Report (AER)

directly to the Logic Controller. The AER is transmitted

as soon as an alarm is detected to maximize system

performance. When the Logic Controller receives the

AER, it sends the originating node a message

acknowledging its receipt. If the node originating the

AER does not receive an acknowledgement, it will re-

transmit the AER until it receives an acknowledgement.

This exchange of messages is used to ensure that

critical messages are received at all appropriate

registers throughout the system.

Once the Logic Controller receives a Fire Alarm

message from a field device, “fixed logic” will activate

built-in annunciation circuits, which consist of both a

visible and audible alarm. The “programmable logic”

will execute any specified voting, timing, and/or zone

logic and subsequently activate the appropriate output

circuits for Notification Appliance Circuits (NACs), agent

release circuits, and unsupervised relay outputs.

The faceplate of the Logic Controller has two

pushbuttons. “ACKNOWLEDGE” will silence the built in

audible alarm and illuminate the “Acknowledge LED”

located on the faceplate next to the “Acknowledge”

pushbutton. “SILENCE” will silence selected NACs in

the field and illuminate the “Silence LED” located on the

faceplate next to the “Silence” pushbutton. The Logic

Controller also features a keyswitch to reset the system

after the event is over.

NETWORK OPERATION DURING A

FAULT CONDITION

The Eagle Quantum system utilizes a unique patented

technique for detecting problems in the communication

network wiring. This state-of-the-art feature minimizes

the possibility of a communication breakdown in the

event of a wiring fault in the communication loop and

can also serve as an aid in troubleshooting.

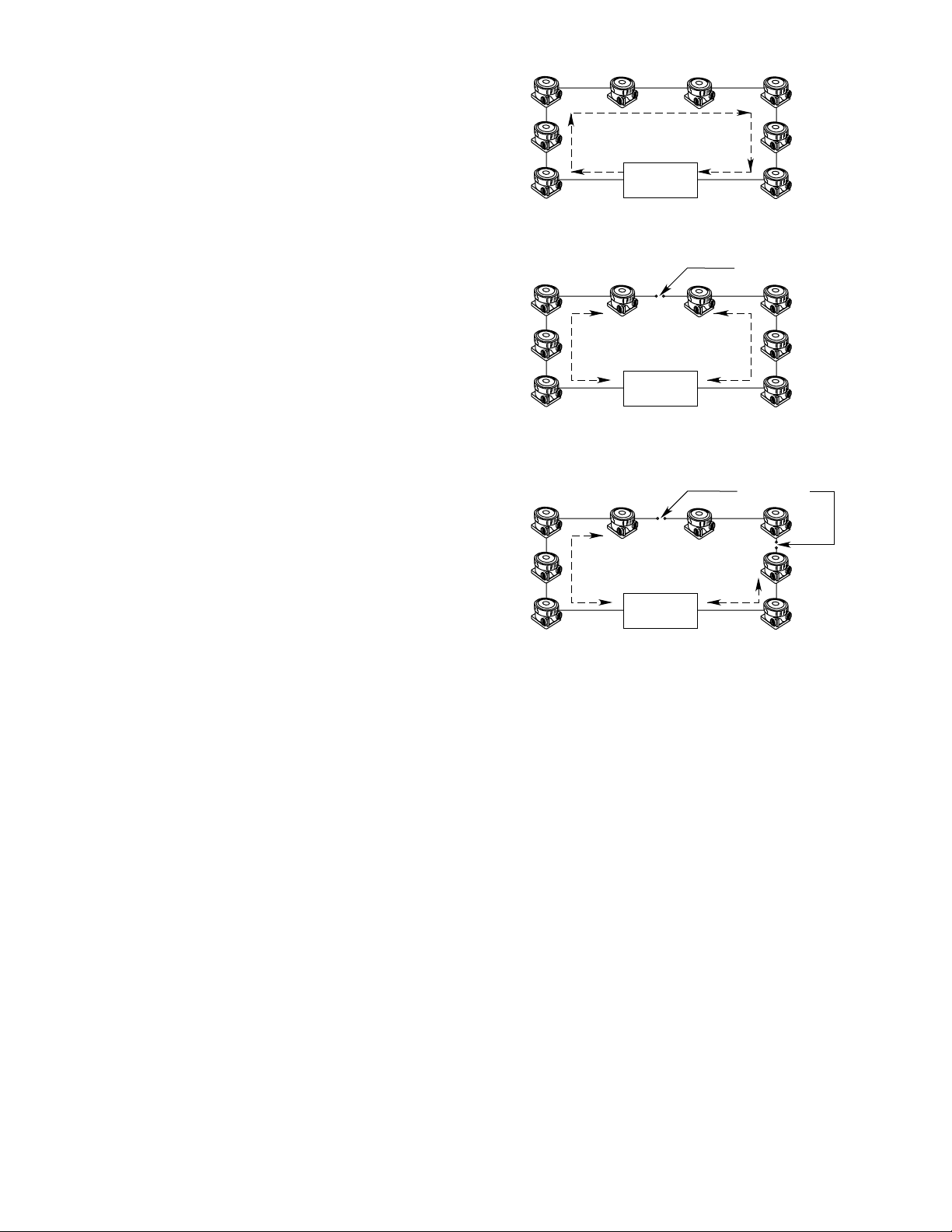

The communication network is constructed as a loop

that starts and ends at a pair of communication ports

located at the LCU. The nodes communicate with the

LCU over the LON/SLC as shown in Figure I-2.

Each field device node contains both the hardware and

software necessary to isolate and re-route

communication in the event of a network wiring fault.

When a problem occurs somewhere within the network

wiring, the communication gateway located in the LCU

annunciates the fault, while the fault isolation circuitry in

the affected nodes isolates the section of the network

where the fault has occurred. Communication is

I–3 95-8470