Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety-Alert Symbol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

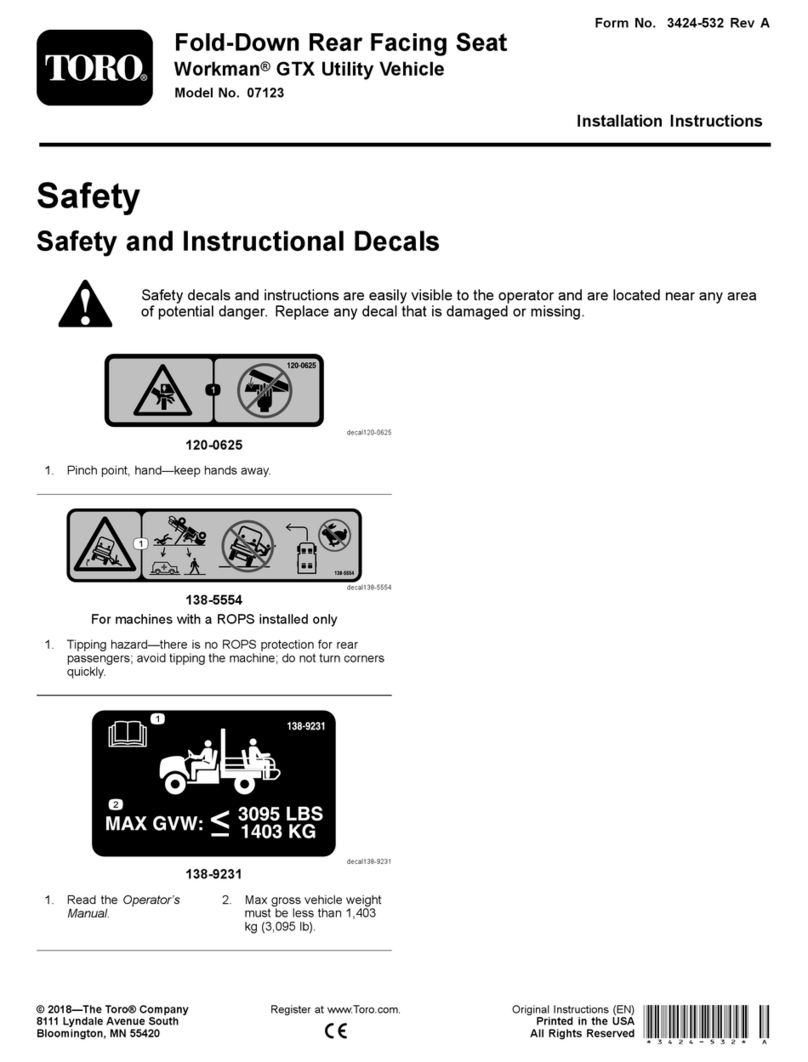

Safety and Instructional Decals . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1 Installing the Steering Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Charging the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 Checking the Fluid Levels and T ire

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4 Burnishing the Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Attachments/Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Before Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Before Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Performing Daily Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Checking the T ire Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Breaking in a New Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

During Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

During Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

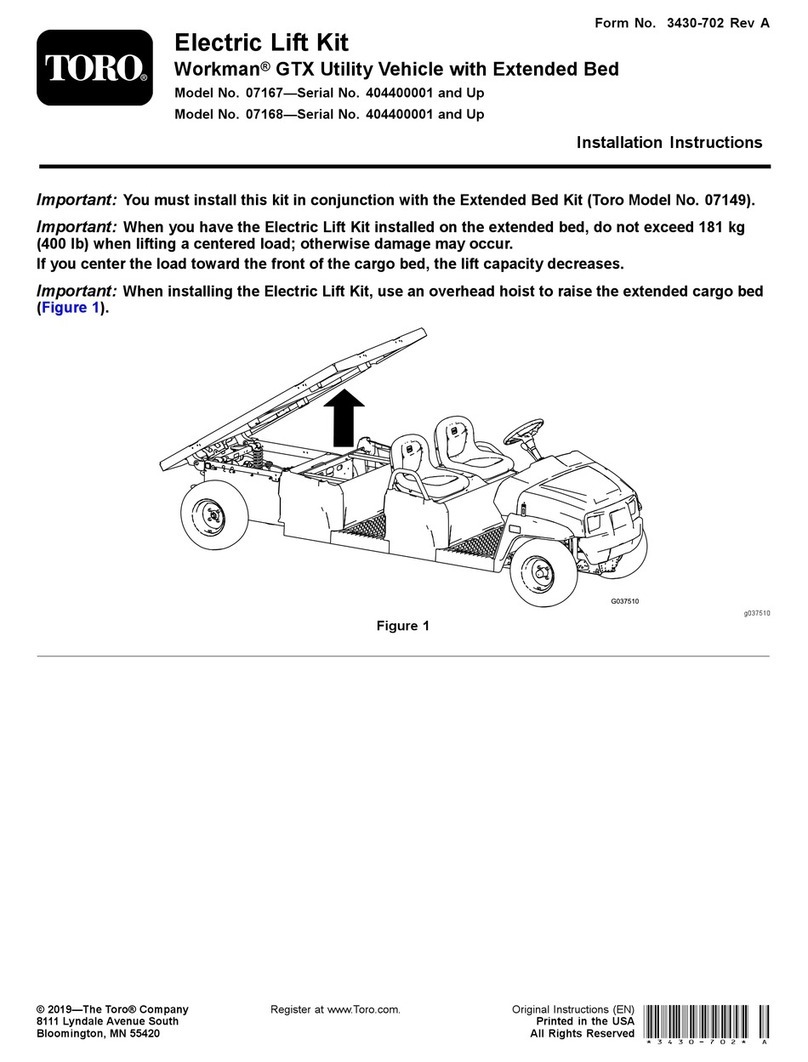

Operating the Cargo Bed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Monitoring the Battery-System Charge

Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Stopping the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Loading the Cargo Bed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

After Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

After Operation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Hauling the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

T owing the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

T owing a T railer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

T ransporting the Lithium-Ion Batteries . . . . . . . . . . . . . . 25

Understanding the Lithium-Ion Battery

Charger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Maintenance Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

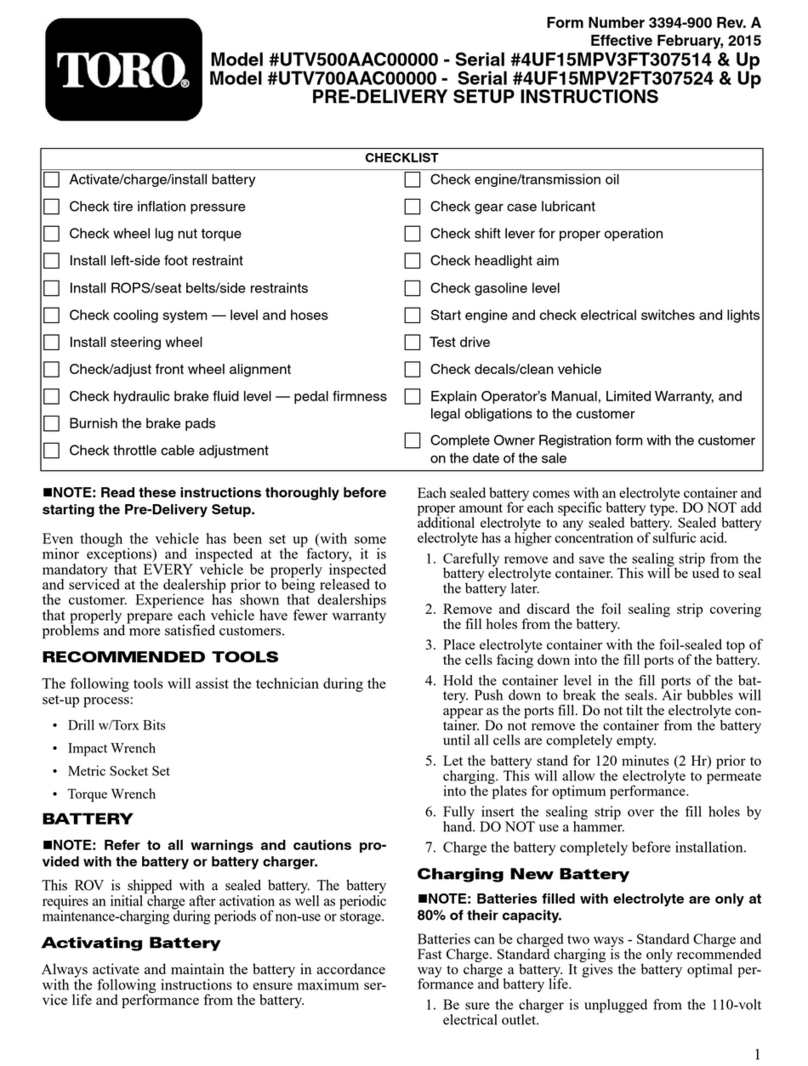

Recommended Maintenance Schedule(s) . . . . . . . . . . . 27

Daily Maintenance Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Maintaining the Machine under Special

Operating Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Pre-Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Preparing the Machine for Maintenance . . . . . . . . . . . . 30

Lifting the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Accessing the Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Greasing the Front Wheel Bearings . . . . . . . . . . . . . . . . . . 31

Electrical System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Using the Battery-Disconnect Switch . . . . . . . . . . . . . . . . 34

Servicing the Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Maintaining the Lithium-Ion Batteries . . . . . . . . . . . . . . . . 34

Maintaining the Battery Charger . . . . . . . . . . . . . . . . . . . . . . . 34

Locating the Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Maintaining the Headlights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Drive System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Maintaining the T ires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Inspecting the Steering and Suspension

Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Adjusting the Front Wheel Alignment . . . . . . . . . . . . . . . . 37

Checking the T ransaxle-Fluid Level . . . . . . . . . . . . . . . . . . 38

Changing the T ransaxle Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Brake Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Inspecting the Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Checking the Brake-Fluid Level . . . . . . . . . . . . . . . . . . . . . . . . 40

Changing the Brake Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Chassis Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Adjusting the Cargo-Bed Latches . . . . . . . . . . . . . . . . . . . . . 41

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

W ashing the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Storage Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Storing the Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Battery Storage Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 42

3