Detcon 700 User manual

Model 700

Remote Sensor/Alarm Relay Module

Operator’s Installation and Instruction Manual

700 RAM I.M.

700 RAM I.M. ii

This page left intentionally blank

700 RAM I.M.

700 RAM I.M. iii

Table of Contents

1. Introduction ..................................................................................................................................................1

1.1 Description.......................................................................................................................................... 1

1.2 Installation........................................................................................................................................... 1

1.3 Field Wiring........................................................................................................................................ 3

2. Operator Interface.........................................................................................................................................5

3. Set-up and Normal Operation.......................................................................................................................7

3.1 View Sensor Status............................................................................................................................. 8

3.2 Set AutoSpan Level ............................................................................................................................ 8

3.3 Set Serial ID........................................................................................................................................ 9

3.4 Set-up for Relay Outputs .................................................................................................................... 9

3.5 Signal Output Check......................................................................................................................... 10

4. RS-485 Modbus™Protocol.........................................................................................................................11

5. RAM Electronics Warranty........................................................................................................................11

6. Specifications .............................................................................................................................................12

6.1 Spare Parts ........................................................................................................................................ 12

6.2 Revision Log......................................................................................Error! Bookmark not defined.

Table of Figures

Figure 1 700 RAM ............................................................................................................................................... 1

Figure 2 RAM Mounting...................................................................................................................................... 2

Figure 3 Mounting RAM with 700 Sensor........................................................................................................... 2

Figure 4 Exploded View of Assembly ................................................................................................................. 3

Figure 5 Interface connections on terminal board................................................................................................ 3

Figure 6 Installation with 700 Gas Sensor ........................................................................................................... 4

Figure 7 Remote 700 Gas Sensor with RAM....................................................................................................... 4

Figure 8 RAM Software Flowchart...................................................................................................................... 7

700 RAM I.M.

700 RAM I.M. iv

This page left intentionally blank

700 RAM I.M.

700 RAM I.M. Rev. 1.1 Page 1 of 12

1. Introduction

1.1 Description

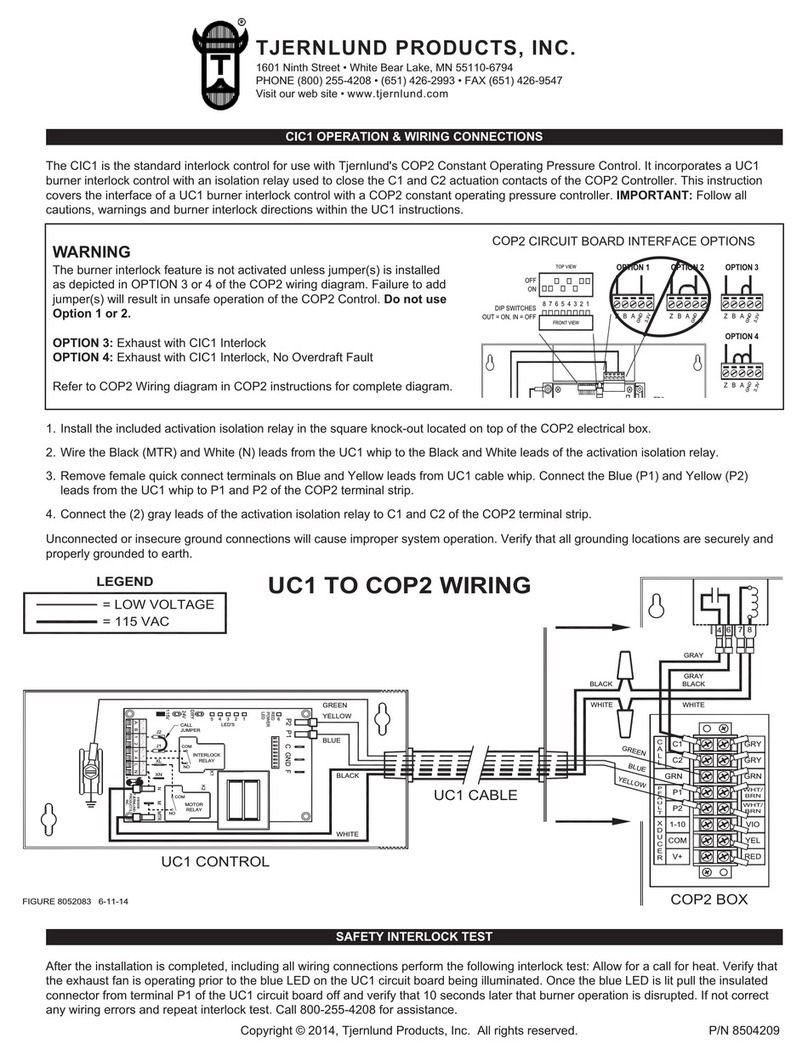

The Model 700 Remote Sensor/Alarm Relay Module (known as the Remote Alarm Module or RAM) is sold

separately as an accessory for Model 700 Gas Sensors. It is a universal design and can be used with any of

the Model 700 Gas Sensors. The RAM is provided in an explosion-proof junction box constructed of either

epoxy-painted aluminum (Figure 1) or 316 stainless steel and includes a glass-viewing window.

Figure 1 700 RAM

The RAM performs two main functions. The first function is to set gas alarm levels and to configure the

three local relay contacts. The second function is to operate a Model 700 Gas Sensor remotely. The remote

sensor function is typically used when the sensor must be mounted in a position where it cannot be viewed or

accessed readily. Both functions can be used at the same time.

The RAM provides the 4-20mA output directly from the Model 700 Gas Sensor. The RAM acts as a

Modbus™master to the Model 700 Gas Sensor in order to display the reading and execute the remote

control functions. It acts as a Modbus™slave to any master control device and simply repeats the

Modbus™output from the 700 Gas Sensor it is connected to.

1.2 Installation

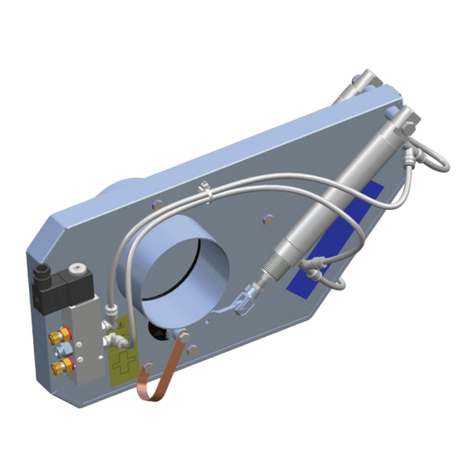

The RAM can be installed as a wall mount or pipe mount using the mounting holes of the explosion-proof

junction box. It should be oriented such that the LED display is horizontal. If the 700 Gas Sensor is

mounted directly to the RAM, use 0.5” spacers underneath the mounting holes to provide access clearance

for the 700 Gas Sensor (Figure 3).

NOTE:

Block any unused ¾” NPT holes with the proper Plug. (Detcon P/N 8522-750)

700 RAM I.M.

700 RAM I.M. Rev. 1.1 Page 2 of 12

5.5"

5.2"

5.825" Ø0.2750 x2

Mounting

Bolt

Wall (or other

mounting surface)

4.35"

Three - ¾" NPT Fittings

Explosion Proof Enclosure

Junction-Box

Mounting Holes

Figure 2 RAM Mounting

PGM2

SPAN

Explosion Proof Enclosure

Junction-Box

Sensor Assembly

Splash Guard

(Aluminun Junction-Box shown)

Use Spacers to move

the J-Box and Sensor

Assembly away from the

wall at least 0.25-0.5" to

allow access to Sensor

Wall (or other

mounting surface)

Spacer

PGM2

SPAN

detcon inc.

MODEL

XX-700

PGM1

ZERO

Ø0.275 x2

5.2"

5.5"

5.195"

5.825"

7.76"

2"

12.945"

2.115"

Mounting Holes

Mounting

Bolt

4.35"

Sensor

¾" NPT x3

Figure 3 Mounting RAM with 700 Sensor

The RAM Electronics package consists of three printed circuit assemblies (PCAs). The top two PCAs (RAM

display and RAM connector board) and the RAM faceplate are enclosed in a molded plastic retaining guard

and can be accessed by removing the junction box cover and using the brass pull knobs to pull the package

directly out of the enclosure. The bottom PCA (terminal board) will remain attached to the bottom of the

700 RAM I.M.

700 RAM I.M. Rev. 1.1 Page 3 of 12

junction box via two machine screws allowing the RAM display and RAM connector board to unseat from

the 12-pin plug-in connector and provide access to the terminal board connectors (Figure 5). To install the

electronics package, properly align the 12-pin plug-in connector and gently push the RAM in until it is fully

seated to the terminal board. The RAM faceplate will be even with the top of the junction box when installed

properly. The RAM top should be flush with the top of the enclosure before screwing down the junction box

cover.

The RAM display and

RAM connector board

External Wiring

12-Pin Plug-In

Connector

Input Port

The terminal

board sets on

the stand-offs in

the enclosure

Provide at least

a 6" Service

Loop for all

wiring

6"

Input Port

Note: Retaining Guard

removed for clarity

RAM faceplate

Explosion Proof Junction Box

Figure 4 Exploded View of Assembly

1.3 Field Wiring

The field wiring connections are made to the bottom PCA (terminal board) of the RAM using a series of

connector blocks. There is a 6-pin terminal block for connection to the 700 Gas Sensor (labeled SENSOR), a

9-pin terminal block for connection to the 3 relay contacts (labeled RELAY OUTPUT), a 6-pin terminal

block for connection of power, mA output and Modbus™interface to the host device (labeled IN) and a 6-

pin terminal block for connection of power and Modbus™interface to an additional device (labeled OUT).

700 Sensor

Connections

ALM1ALM2 FLT

NO NC COM NO NC COM NO NC COM

J7

J2

J1

J4

IN

SENSOR

OUT

+

+mA A B

mA

A

B +

A

B

K1

K3

K2

Input Power and

mA Output

Alarm Relay

Connections

Output

Power

Modbus™

Interface to Host

Modbus™

Interface

U1

Figure 5 Interface connections on terminal board

The user will typically connect the 700 Gas Sensor directly to the RAM if there is no requirement for remote

sensor separation (Figure 6). In this case, the 700 sensor will not require its own junction box and it is not

700 RAM I.M.

700 RAM I.M. Rev. 1.1 Page 4 of 12

necessary to install/use the Transient Protection Module shipped with the 700 sensor. The 700 sensor may

arrive from the factory pre-assembled with the RAM in the j-box, but only if it is ordered in this

configuration. In this configuration, the wires from the 700 sensor will be directly connected to the 6-pin

terminal block labeled “SENSOR” on the terminal board.

NOTE:

If the 700 sensor and RAM are directly connected, it is not necessary to install/use the

Transient Protection Module that is shipped with every 700 Gas Sensor.

PGM2

SPAN

detcon inc.

MODEL

XX-700

PGM1

ZERO

Sensor

Power Input

mA Output

Modbus™Interface

Fault

Annunciator

Alarm 1

Annunciator

Alarm 2

Annunciator

Figure 6 Installation with 700 Gas Sensor

If remote sensor separation is required, the RAM will be separated from the 700 sensor. Remote separation

distances of up to 1000 feet are possible with the recommended cables.

NOTE:

It is highly recommended to install the interconnecting cabling inside rigid metal

conduit to eliminate potential EMI and RFI interference.

mA Output

700 RAM

Module

Cabling to/from

Remote 700 Sensor

Remote 700 Sensor

Transient Protection

Module in Detcon

standard J-Box

Power Input

Sensor

detcon inc.

MODEL

XX-700

PGM1

ZERO

PGM2

SPAN

Modbus™Interface

Power & Modbus™

Figure 7 Remote 700 Gas Sensor with RAM

The recommended cable for remote sensor separation is Belden 8770 (18AWG shielded 3-wire cable) for

connection of power and mA signal return and Belden 9841 (24AWG shielded twisted pair) for serial

Modbus™communications.

700 RAM I.M.

700 RAM I.M. Rev. 1.1 Page 5 of 12

(+)

mA

(-)

A(+)

B(-)

Wiring to

Sensor Assembly

Wht

Blu

Red

Grn

Blk

Remote

Explosion Proof

Junction Box

with Sensor

(+)

mA

(-)

A(+)

B(-)

Customer

Supplied Wiring

Transient Protection Module

(TPM) P/N 500-003087-100

Modbus RS-485 to

Host Control Device

Power from and 4-20mA

out to Control Device

ALM1ALM2 FLT

NO NC COM NO NC COM NO NC COM

J7

J2

J1

J4

IN

SENSOR

OUT

+

+mA A B

mA

A

B +

A

B

K1

K3

K2

Explosion Proof

Junction Box

with RAM Module

(+)

mA

(-)

A(+)

B(-)

Figure 8 Remote Sensor Wiring

NOTE:

Both the 3-wire power/mA cable and the 2-wire Modbus™serial communications

cable are required when remote wiring between the RAM and the 700 Gas Sensor.

NOTE:

The same recommended cables should be used for the connection between a

Modbus™master control device and the RAM. However, if only the 4-20mA signal is being

used by the master/host controller, then only the 3-wire cable is required.

2. Operator Interface

The operator interface of the RAM is very similar to the Model 700 Gas Sensor. It uses the identical LED

display, same programming magnet, and has the same magnetic programming switches (PGM1/ZERO and

PGM2/SPAN). The main difference is that the 700 RAM has LED indicators for the 3 relays (ALM1,

ALM2 and FAULT) and a CAL LED to indicate when the 700 sensor is in calibration or being polled

serially by a master control device.

The gas reading, gas units, and fault status reported by the RAM will mimic that of the 700 Gas Sensor. The

Modbus™output from the RAM repeats the Modbus™output from the 700 Gas Sensor.

NOTE:

If the Model 700 Gas Sensor is directly connected to the RAM and junction box, then

the gas sensor operation should be exercised through the 700 Gas Sensor (and not the RAM).

This is the recommended practice since the RAM contains a limited number of sensor

operational control functions. If the RAM and 700 Gas Sensor are separated, then normal

remote gas sensor operation should be exercised through the RAM.

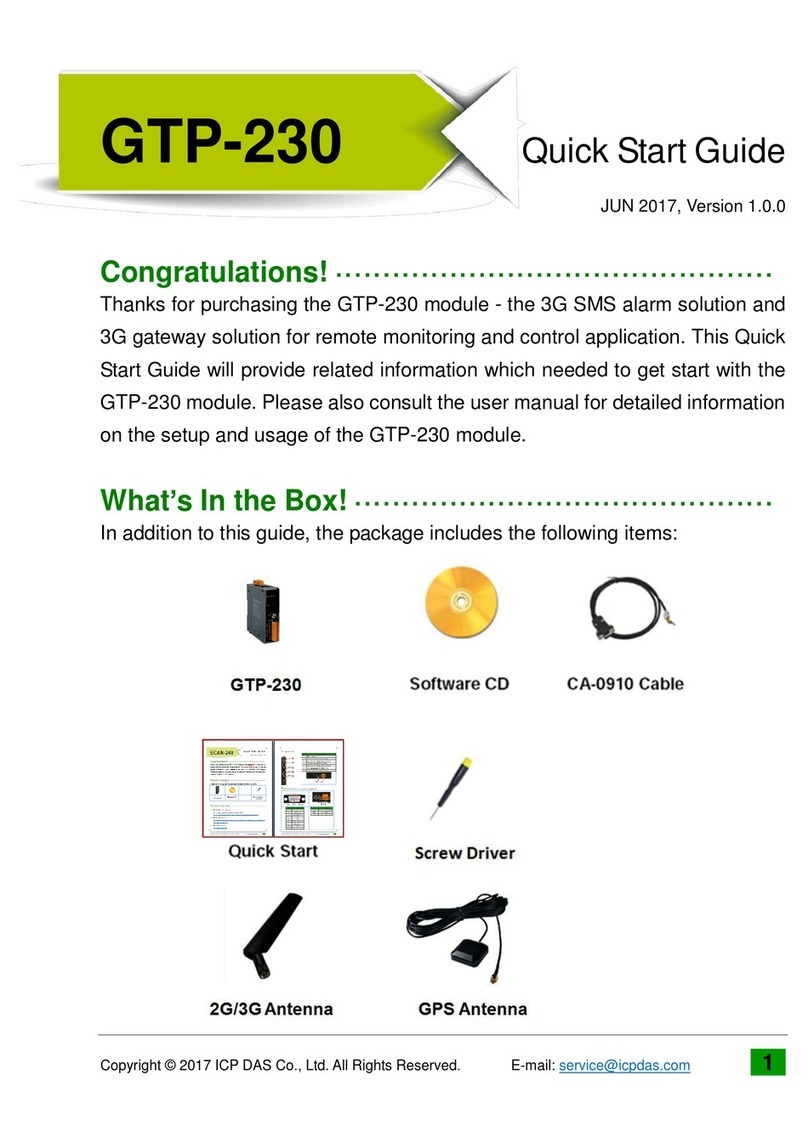

The operating interface is menu-driven via the two magnetic program switches located under the target

marks on the RAM faceplate. The two switches are referred to as “PGM1” and “PGM2”. The menu list

consists of three major items that include sub-menus as indicated below. (Refer to the complete Software

Flow Chart Figure 9)

Normal Operation

Current Reading and Fault Status

700 RAM I.M.

700 RAM I.M. Rev. 1.1 Page 6 of 12

Calibration Mode

AutoZero (if applicable)

AutoSpan

Program Mode

View Sensor Status (representative of whichever Model 700 Gas Sensor is attached)

Set AutoSpan Level

Set Serial ID

Alarm 1 Settings

Alarm 2 Settings

Fault Settings

Signal Output Check

The user interface of the RAM is designed to mimic that of the Model 700 Gas Sensor. However, only the

functions deemed critical for normal remote sensor operation are available. The 5 menu functions that are

available for the remote control of the 700 Gas Sensor are:

AutoZero – used to perform AutoZero remotely

AutoSpan – used to perform AutoSpan remotely, user is required to apply span gas flow to remote gas

sensor

View Senor Status – displays the complete list of sensor status and diagnostic indicators

Set AutoSpan Level – used to change the span gas concentration

Signal Output Check – used to generate simulated outputs from the sensor for system diagnostic purposes

NOTE:

For any other required operational changes, the 700 Gas Sensor must be accessed

directly.

700 RAM I.M.

700 RAM I.M. Rev. 1.1 Page 7 of 12

dec

dec

Yes

/No

Set Energized

PGM1/2 (S)

PGM1/2 (3)

Yes

/No

Yes

/No

inc

Set Ascending

PGM1/2 (3)

PGM1/2 (S)

Set Latching

PGM1/2 (3)

PGM1/2 (S)

Set Level - XX

Set Alarm 2

Auto Time-Out

PGM2 (S)

PGM1/2 (3)

PGM1 (S)

PGM1/2 (M)

PGM1/2 (3)

Calibration Mode

(Auto Span)

View Sensor Status

Auto Time-Out

PGM1/2 (M)

PGM1/2 (3)

inc PGM1 (S)

PGM1/2 (3)

Set AutoSpan Level

PGM1/2 (M)

PGM1/2 (3)

PGM2 (S)

XX

AutoTime-out

PGM2 (3)

PGM1 (3)

Normal Operation

PGM2 (3)

PGM1 (3) Calibration Mode

(Auto Zero)

PGM1 - Program Switch Location X1

PGM2 - Program Switch Location X2

Signal Output Check

Auto Time-Out

(S) - Momentary Swipe

(M) - Momentary hold of Magnet during text

scroll until arrow prompt appears, then

release

(3) - 3 second hold from arrow prompt

(10) - 10 second hold from arrow prompt

Auto Time-out - 5 seconds

inc - Increase

dec - Decrease

X, XX, XXX - numeric values

Set Energized

Auto Time-Out

Yes

/No PGM1/2 (3)

Yes

/No PGM1/2 (3)

PGM1/2 (S)

PGM1/2 (M)

Set Latching

PGM1/2 (S)

PGM1/2 (3)

Set Fault

LEGEND:

Simulation

PGM1/2 (3)

PGM1/2 (M)

PGM2 (10)

Set Energized

Set Latching

Set Ascending

Auto Time-Out

Set Level - XX

Auto Time-Out

PGM1 (S)

PGM1/2 (3)

inc

PGM1/2 (3)

PGM2 (S)

XX

Set Serial ID

PGM1/2 (M)

dec

Yes

/No

Yes

/No

Yes

/No

inc

PGM1/2 (3)

PGM1/2 (3)

PGM1/2 (S)

PGM1/2 (3)

PGM1/2 (3)

PGM1/2 (S)

PGM1/2 (S)

PGM1/2 (3)

PGM2 (S)

PGM1 (S) dec

Set Alarm 1

PGM1/2 (M)

Voltage X.XXVDC

Temp XXC

mA Output XX.XX

Sensor Diags

Serial ID XX

Sensor Life XX%

Last Cal XX Days

Range XXX

Auto Span XX

Version X.XX

Model Type

Alarm 2 Settings

Alarm 1 Settings

Fault Settings

Figure 9 RAM Software Flowchart

3. Set-up and Normal Operation

In normal operation, the RAM display continuously shows the current sensor reading, which will typically

appear as “ 0 ”. Once every 1 minute the LED display will flash the sensor’s measurement units and gas type

(i.e. % LEL). If the 700 Gas Sensor or RAM is actively experiencing any diagnostic faults, a “Fault

Detected” message will flash on the display once every minute. When the unit is in “Fault Detected” mode

with the red Fault LED on, PGM1 or PGM2 can be swiped to invoke a display of the active faults.

In normal operation, the 4-20mA current output from the RAM corresponds with the present gas

concentration and full-scale range. The RS-485 Modbus™serial output provides the current gas reading and

fault status on a continuous basis when polled.

700 RAM I.M.

700 RAM I.M. Rev. 1.1 Page 8 of 12

Successful Modbus™communications between the RAM and the RS-485 Master Controller will be

indicated by a blinking “CAL” LED. If the Modbus™communication between the RAM and the 700 Gas

Sensor is not functioning the RAM will display “COMM” and the “FLT” LED will be illuminated.

NO

TE:

The 700 Gas Sensor must be set to Serial ID = 01 for proper communications set-up

with the RAM.

3.1 View Sensor Status

View Sensor Status displays all current configurational and operational parameters from the 700 Gas Sensor

attached to it. These typically include sensor type, software version number, detection range, AutoSpan

level, days since last AutoSpan, estimated remaining sensor life, sensor diagnostics, input voltage, 4-20mA

output, and sensor ambient temperature.

To access the View Sensor Status menu, hold the magnet over PGM2 () until the arrow prompt appears

and then hold continuously for 3 seconds. This will display the View Sensor Status text scroll. From the

“View Sensor Status” text scroll, hold the magnet over PGM1 () or PGM2 () until the arrow prompt

appears and then hold continuously for an additional 3 seconds. The display will scroll the complete list of

sensor status parameters sequentially:

Current Software Version (of the RAM)

Sensor Model Type

Range of Detection

Serial ID address

AutoSpan Level

Days Since Last AutoSpan

Remaining Sensor Life

Sensor Diagnostics (varies by sensor type)

4-20mA Output

Input Voltage Supply

Sensor Temperature

Alarm 1 Settings

Alarm 2 Settings

Fault Settings

When the sensor status list sequence is complete, the RAM will revert to the “View Sensor Status” text

scroll. The user can then choose to either: 1) review list again by executing another 3 second hold, 2) move

to another menu item by executing a momentary hold, or 3) return to Normal Operation via 15 second

automatic timeout.

3.2 Set AutoSpan Level

Set AutoSpan Level is used to set the span gas concentration level that is being used to calibrate the sensor.

This level is adjustable from 10% to 100% of range. The current setting can be viewed in View Sensor

Status.

The menu item appears as: “Set AutoSpan Level”

From the “Set AutoSpan Level” text scroll, hold the magnet over PGM1 () or PGM2 () until the arrow

prompt appears and then hold continuously for an additional 3 seconds. The display will then switch to

“XX” (where XX is the current gas level). Swipe the magnet momentarily over PGM2 to increase or PGM1

to decrease the AutoSpan Level until the correct level is displayed. Hold the magnet over PGM1 or PGM2

for 3 seconds to accept the new value. The display will scroll “AutoSpan Level Saved”, and revert to “Set

AutoSpan Level” text scroll.

700 RAM I.M.

700 RAM I.M. Rev. 1.1 Page 9 of 12

The user can then choose to either: 1) move to another menu item by executing a momentary hold, or 2)

return to Normal Operation via 15 second automatic timeout.

3.3 Set Serial ID

The RAM can be polled serially via the RS-485 Modbus™interface. It repeats the Modbus™output from

the 700 Gas Sensor it is connected to. The RAM Serial ID # should be set as a slave device to a master

polling device. The Serial ID # of the RAM is independent of the Serial ID # of the Model 700 Gas Sensor.

NOTE:

The Serial ID # of the Model 700 Gas Sensor connected to the RAM must be set to ID

= 01 for proper communication between the two devices.

Set Serial ID is used to set the Modbus™serial ID address of the RAM. It is adjustable from 01 to 127 in

hexadecimal format (01-7F hex). The current serial ID can be viewed in View Sensor Status using the

instruction given in Section 3.1 View Sensor Status.

The menu item appears as: “Set Serial ID”

From the “Set Serial ID”text scroll, hold the programming magnet over PGM1 () or PGM2 () until the

arrow prompt appears and then hold continuously for an additional 3 seconds. The display will then switch

to “XX” (where XX is the current ID address). Swipe the magnet momentarily over PGM2 to increase or

PGM1 to decrease the hexadecimal number until the desired ID is displayed. Hold the magnet over PGM1

or PGM2 for 3 seconds to accept the new value. The display will scroll “New ID Saved”, and revert to “Set

Serial ID” text scroll.

The user can then choose to either: 1) move to another menu item by executing a momentary hold, or 2)

return to Normal Operation via 15 second automatic timeout.

3.4 Set-up for Relay Outputs

The user interface allows for the setting and configuration of the three relay contacts of the RAM. The three

relays can be optionally configured as follows:

Alarm 1: 1) gas level, 2) ascending/descending, 3) latching/non-latching and 4) energized/de-energized

Alarm 2: 1) gas level, 2) ascending/descending, 3) latching/non-latching and 4) energized/de-energized

Fault: 1) latching/non-latching and 2) energized/de-energized

The three menu items for relay output set-up are Alarm1 Settings,Alarm2 Settings, and Fault Settings.

They are used to set the gas alarm levels and relay status for ascending/descending, latching/non-latching,

and energized/de-energized.The gas concentration level for alarms can be set between 1-95% of the full-

scale range of the 700 Gas Sensor. The current relay configurational settings can be viewed in View Sensor

Status menu.

Ascending/Descending - In ascending mode, the alarm will trigger when the gas concentration

detected is greater than or equal to the alarm set point. In descending mode, the alarm will trigger

when the gas concentration detected is lesser than or equal to the alarm set point.

Latching/Non-Latching - In latching mode, the relay remains active when the alarm status has

cleared. In non-latching mode, the relay is deactivated when the alarm status is cleared.

Energized/De-Energized - In energized mode, the normally open contact is closed if the alarm level

has not been reached. In non-energized mode, the normally open contact is open if the alarm level

has not been reached. Energized mode provides for fail-safe operation since a loss of power or cable

failure will cause the contact to be open.

700 RAM I.M.

700 RAM I.M. Rev. 1.1 Page 10 of 12

The menu item appears as: “Alarm1 Settings”

From the “Alarm1 Settings” text scroll, hold the magnet over PGM1 () or PGM2 () until the arrow

prompt appears and then hold continuously for an additional 3 seconds. The display will switch to “Set

Level” followed by “XX” (where XX is the current set-point level). Swipe the magnet momentarily over

PGM2 to increase or PGM1 to decrease until the correct level is displayed. Hold the magnet over PGM1 or

PGM2 for 3 seconds to accept the new value. The display will scroll “Saved”.

The display will then scroll “Set Ascending” and show “Yes” or “No”. Use a swipe of PGM1 to select

choice (yes = ascending and no = descending). Use PGM1 for a 3 second hold to accept the selection. The

display will scroll “Saved”.

The display will then scroll “Set Latching” and then show “Yes” or “No”. Use a swipe of PGM1 to select

choice (yes = latching and no = non-latching). Use PGM1 for a 3 second hold to accept the selection. The

display will scroll “Saved”.

The display will then scroll “Set Energized” and then show “Yes” or “No”. Use a swipe of PGM1 to select

choice (yes = energized and no = non-energized). Then use PGM1 for a 3 second hold to accept the

selection. The display will scroll “Saved”.

At this point, configuration settings for Alarm1 are complete and the menu will shift back to “Alarm1

Settings”. The user can then choose to either: 1) move to another menu item by executing a momentary hold

at the end of the text scroll, or 2) return to Normal Operation via 15 second automatic timeout.

Follow the identical instructional sequence for the menu function “Alarm2 Settings”. The menu function for

“Fault Settings” is similar except that it does not have a selection for gas level and ascending/descending. It

only has choice selections for latching/non-latching and energized/de-energized.

NOTE:

The Fault relay is typically set-up as energized so that it will change states during an

unexpected power loss.

NOTE:

The relay contacts can be wired at the RAM’s connector PCA for either Normally

Open or Normally Closed.

3.5 Signal Output Check

Signal Output Check provides a simulated 4-20mA output and RS-485 Modbus™output. The simulation

allows the user to conveniently perform a functional system check of the entire safety system, and can be

initiated at the RAM. This signal output simulation aids in performing troubleshooting of signal wiring

problems.

This menu item appears as: “Signal Output Check”.

From the “Signal Output Check” text scroll, hold the magnet over PGM1 () or PGM2 () until the arrow

prompt appears and then hold continuously for an additional 3 seconds. Once initiated, the display will

continuously scroll “Simulation Active” until the function is stopped. During simulation mode, the 4-20mA

value will be increased from 4.0mA to 20.0mA (in 1% of range increments at a 1 second update rate) and

then decreased from 20.0mA to 4.0mA. The same simulation sequence is applied to the Modbus™output

gas reading.

700 RAM I.M.

700 RAM I.M. Rev. 1.1 Page 11 of 12

NOTE

:

Signal Output Check

stays active indefinitely until the user stops the function. There

is no automatic timeout for this feature.

To end simulation mode, hold magnet over PGM1 () or PGM2 () until the arrow prompt appears and

then hold continuously for an additional 3 seconds. The display will revert to either the prior menu item or

the next menu item respectively.

The user can then choose to either: 1) move to another menu item by executing a momentary hold, or 2)

return to Normal Operation via 15 second automatic timeout.

4. RS-485 Modbus™Protocol

The RAM module provides a Modbus™compatible communications protocol and is addressable via the

program mode. This Modbus™output is exactly repeated from the specific Model 700 sensor that is

attached. Communication is two-wire, half duplex RS-485, 9600 baud, 8 data bits, 1 stop bit, no parity, with

the sensor set up as a slave device. An RS-485 Master Controller up to 4000 feet away can theoretically poll

up to 256 different RAM’s. This number may not be realistic in harsh environments where noise and/or

wiring conditions would make it impractical to place so many devices on the same pair of wires. If a multi-

point system is being utilized, each RAM must be set for a different address. Typical address settings are:

01, 02, 03, 04, 05, 06, 07, 08, 09, 0A, 0B, 0C, 0D, 0E, 0F, 10, 11…etc.

Successful Modbus™communications between the RAM and an RS-485 Master Controller is indicated by a

blinking “CAL” LED. If the Modbus™communication between the RAM and the 700 Gas Sensor is not

functioning, the RAM will display “COMM” and the “FLT” LED will be illuminated.

NOTE:

The 700 Gas Sensor must be set to Serial ID = 01 for proper communications set-up

with the RAM.

RS-485 ID numbers are factory default to 01. These can be changed in the field via the Operator Interface

described in Section 3.3, Set Serial ID.

NOTE:

Refer to the Model 700 Gas Sensor Instruction Manual for details on the Modbus™

protocol registers.

5. RAM Electronics Warranty

Detcon Inc. warrants, under intended normal use, each new Model 700 RAM module to be free from defects

in material and workmanship for a period of two years from the date of shipment to the original purchaser.

All warranties and service policies are FOB the Detcon facility located in The Woodlands, Texas.

Terms & Conditions:

Shipping point is FOB the Detcon factory.

Net payment is due within 30 days of invoice.

Detcon, Inc. reserves the right to refund the original purchase price in lieu of RAM replacement.

700 RAM I.M.

700 RAM I.M. Rev. 1.1 Page 12 of 12

6. Specifications

Inputs

Any Model 700 Gas Sensor

Outputs

4-20mA signal

Relay Contacts - Three Form C contacts rated for 5A @ 30 VDC/250 VAC

RS-485 Modbus™RTU

Input Voltage

11-30VDC

Power Consumption (excluding 700 Gas Sensor)

< 0.5 Watts at 24VDC (Normal)

< 1.0 Watts at 24VDC (Maximum)

Operating Temperature

-40°C to +75°C

Electrical Classification

Class 1, Division 1 Groups BCD

Class 1, Zone 1, Group IIC

Enclosure Classification

NEMA 7 and NEMA 4X

6.1 Spare Parts

Part Number Spare Parts

500-005136-100 RAM Display PCA

500-005135-100 RAM Connector Board

500-005134-100 Termination Board PCA

897-850901-010 Aluminum Condulet w/Glass Lens Cover

897-850901-316 SS Condulet w/Glass Lens Cover

8522-750 ¾” NPT Plug

960-202200-000 Condensation Prevention Packet

306-175705-100 6-Pin Connector

306-175708-000 9-Pin Connector

6.2 Spare Parts

Revision Date Changes made Approval

1.0 03/16/2011 Made changes to reflect new RAM assembly. LU

1.1 11/06/14 Update Remote Wiring Diagram LU

Table of contents

Popular Control Unit manuals by other brands

Klark Teknik

Klark Teknik QFLEX ISOLATOR quick start guide

Danfoss

Danfoss PVG 120 technical information

SAJ

SAJ eSolar AIO3 Quick installation guide

Kentec Electronics

Kentec Electronics XT+ installation manual

TJERNLUND

TJERNLUND CIC1 Operation manual

Bucher Hydraulics

Bucher Hydraulics VF-iValve VF-i250 Series operating instructions

STIEBEL ELTRON

STIEBEL ELTRON HUV 1 Operating and installation

Lutron Electronics

Lutron Electronics QSGRK-3PCE Quick installation and operation guide

GBD

GBD CB24 Instructions for installations

Siemens

Siemens SIMADYN D T400 Brief description

UNICORECOMM

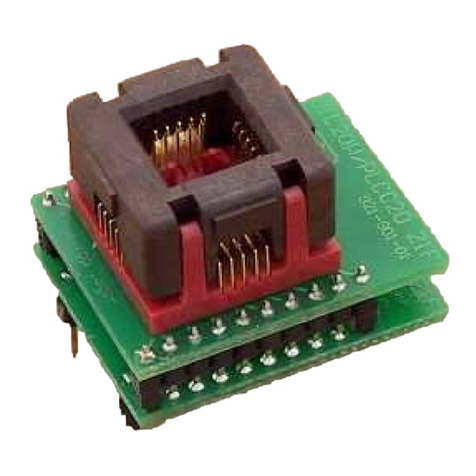

UNICORECOMM UM980 Installation and Operation User Manual

Elnec

Elnec DIL20W/PLCC20 ZIF manual