E-6

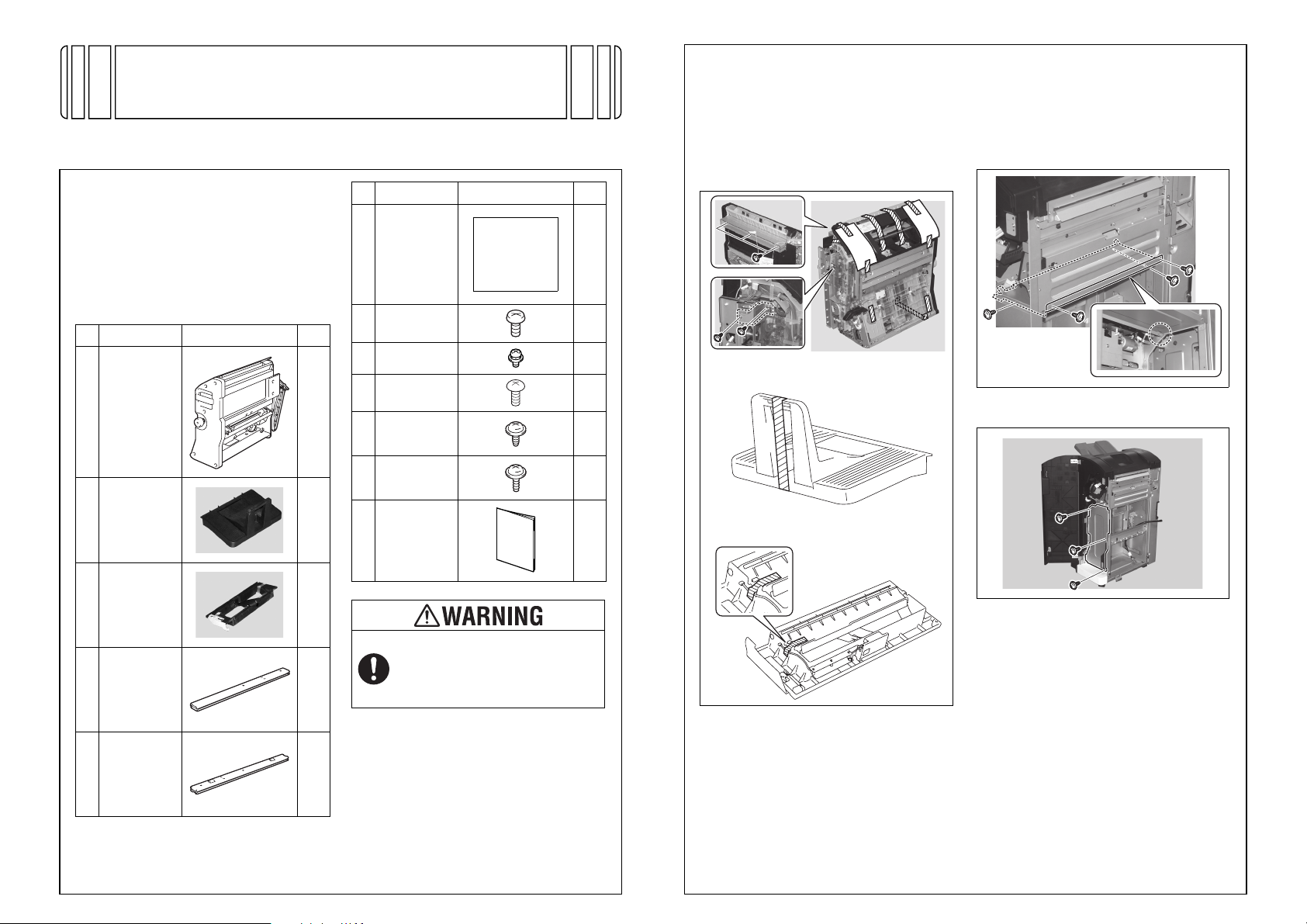

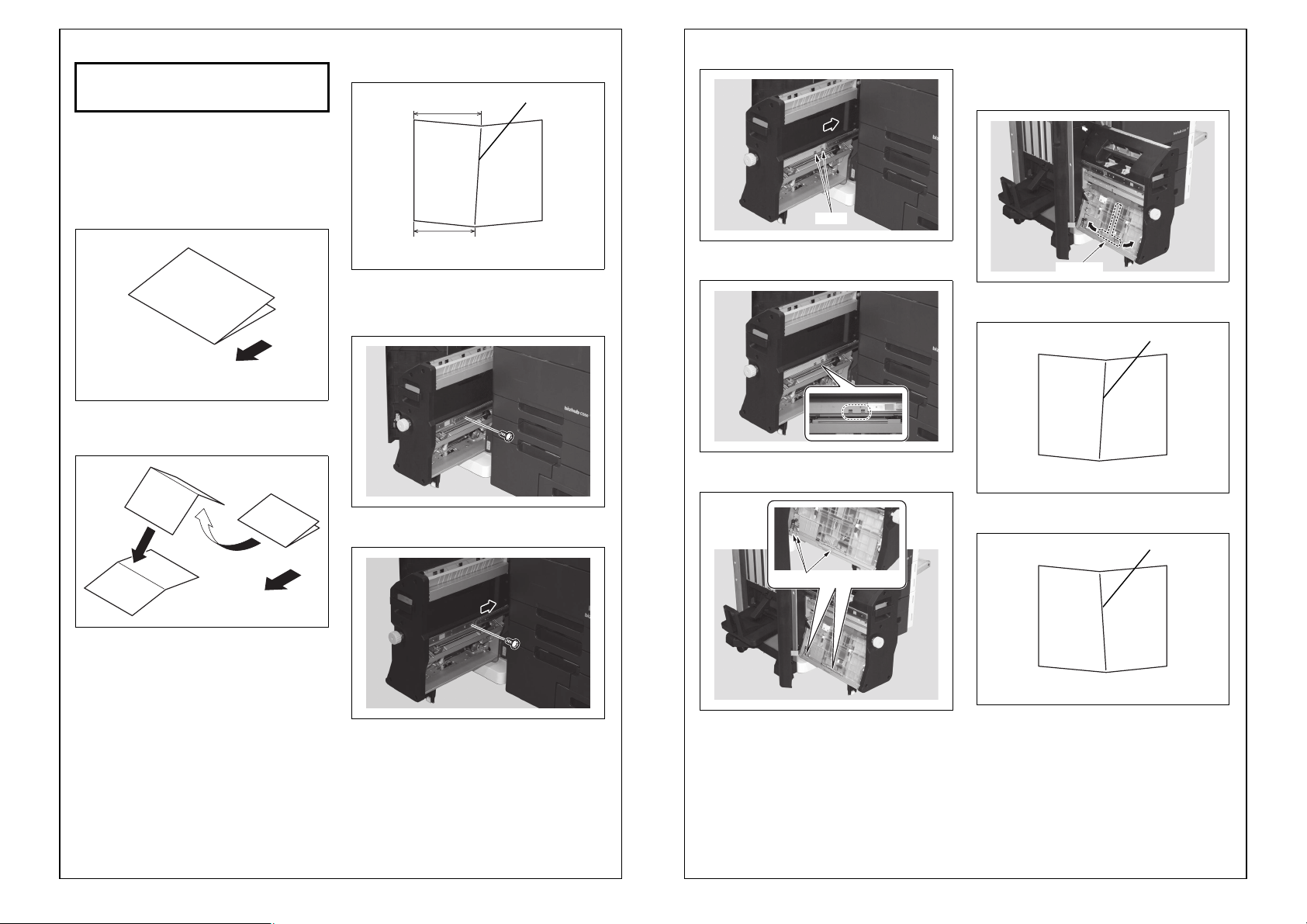

<Half-fold position adjustment>

1. Unfold the paper that exits the machine and lay

the paper with the ridge facing up.

2. Fold the paper shown in step 1 in half and unfold

it again.

3. Check the crease for deviation

(Measure width A).

Reference: 0 ± 1.0 mm

4. Display the Service Mode screen.

(For details of how to display the Service Mode

screen, see the Service Manual.)

5. Touch “Finisher.”

6. Touch “FS-FN adjustment.”

7. Touch “Half-Fold Position.”

8. Check that “ALL” is displayed in reversed.

[If the crease deviates as shown below]

Using the key, set the numeric value and

touch “OK.”

[If the crease deviates as shown below]

Using the key, set the numeric value and

touch “OK.”

9. Touch “OK.”

10. Touch “Exit” on the Service Mode screen.

11. Make copies again and check the crease posi-

tions deviate.

Exit direction

A10DIXC049DA

A10DIXC050DA

A10DIXC052DA

A

Crease produced in step 2

Crease

A10DIXC052DA

A

A10DIXC053DA

A

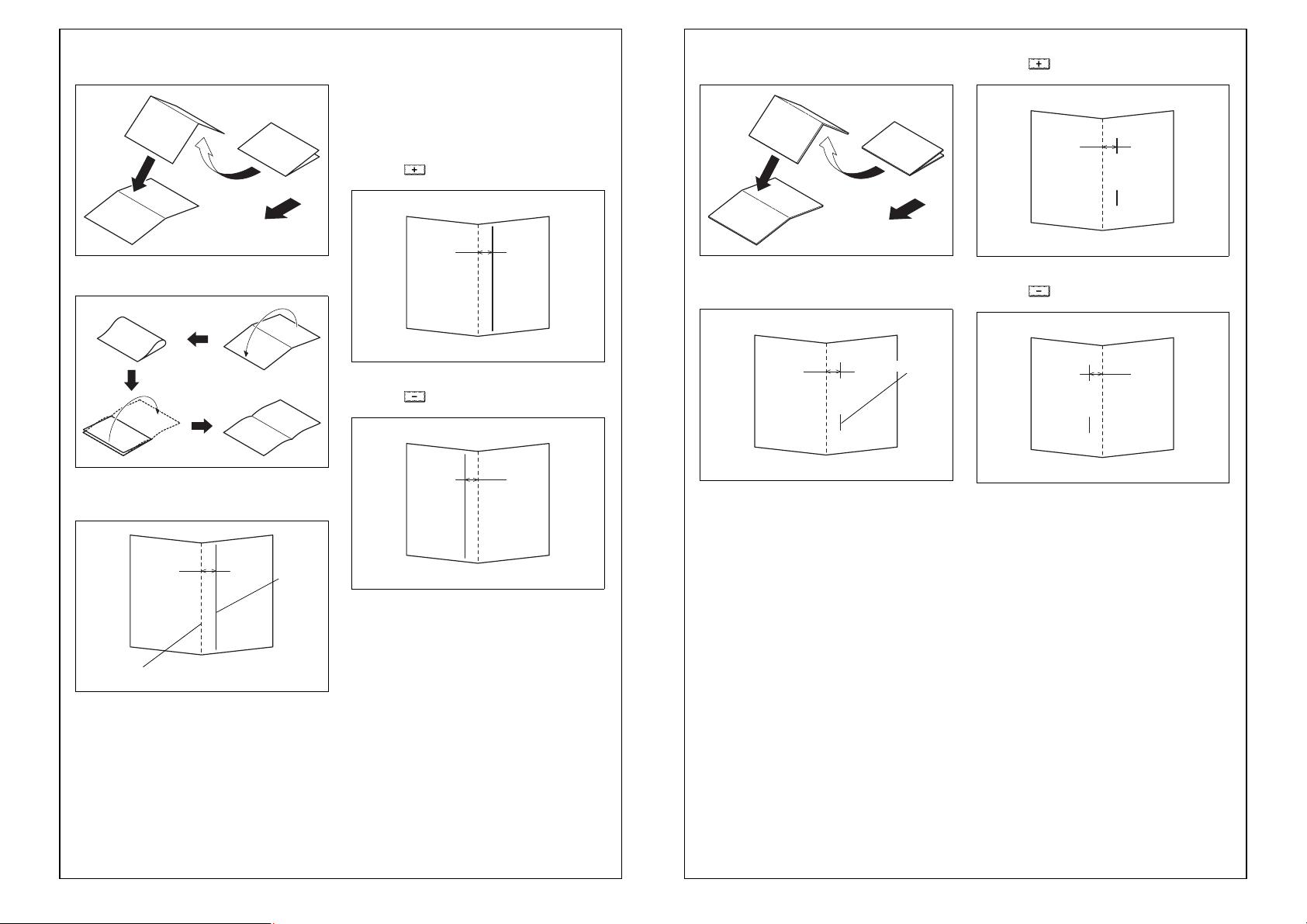

<Center staple position adjustment>

1. Unfold the paper that exits the machine and lay

the paper with the ridge facing up.

2. Check the staple position for deviation from the

crease (Measure width A).

Reference: 0 ± 1.0 mm

3. Display the Service Mode screen.

(For details of how to display the Service Mode

screen, see the Service Manual.)

4. Touch “Finisher.”

5. Touch “FS-FN adjustment.”

6. Touch “Center Staple Position.”

7. Check that “ALL” is displayed in reversed.

[If the Staple positions deviate as shown below]

Using the key, set the numeric value and

touch “OK.”

[If the Staple positions deviate as shown below]

Using the key, set the numeric value and

touch “OK.”

8. Touch “OK.”

9. Touch “Exit” on the Service Mode screen.

10. Make copies again and check the staple posi-

tions deviate.

Exit direction

A10DIXC051DA

A10DIXC054DA

AStaple position

A10DIXC054DA

A

A10DIXC055DA

A