-3-

GB

Contents

1 Kulzer cara Print Clean General Information ..............................................................................5

1.1 Declaration of CE Conformity................................................................................................................ 5

2 Instructions for Safe Use ..............................................................................................................6

2.1 Explanation of Symbols......................................................................................................................... 6

2.2 Transport Damage ................................................................................................................................. 7

2.3 Operator’s Obligations........................................................................................................................... 7

2.4 Operations and Maintenance Log Book................................................................................................ 7

2.5 Safety Information ................................................................................................................................. 7

3 Intended Use and Proper Operation............................................................................................9

3.1 Intended Use ......................................................................................................................................... 9

3.2 Proper Operation ................................................................................................................................... 9

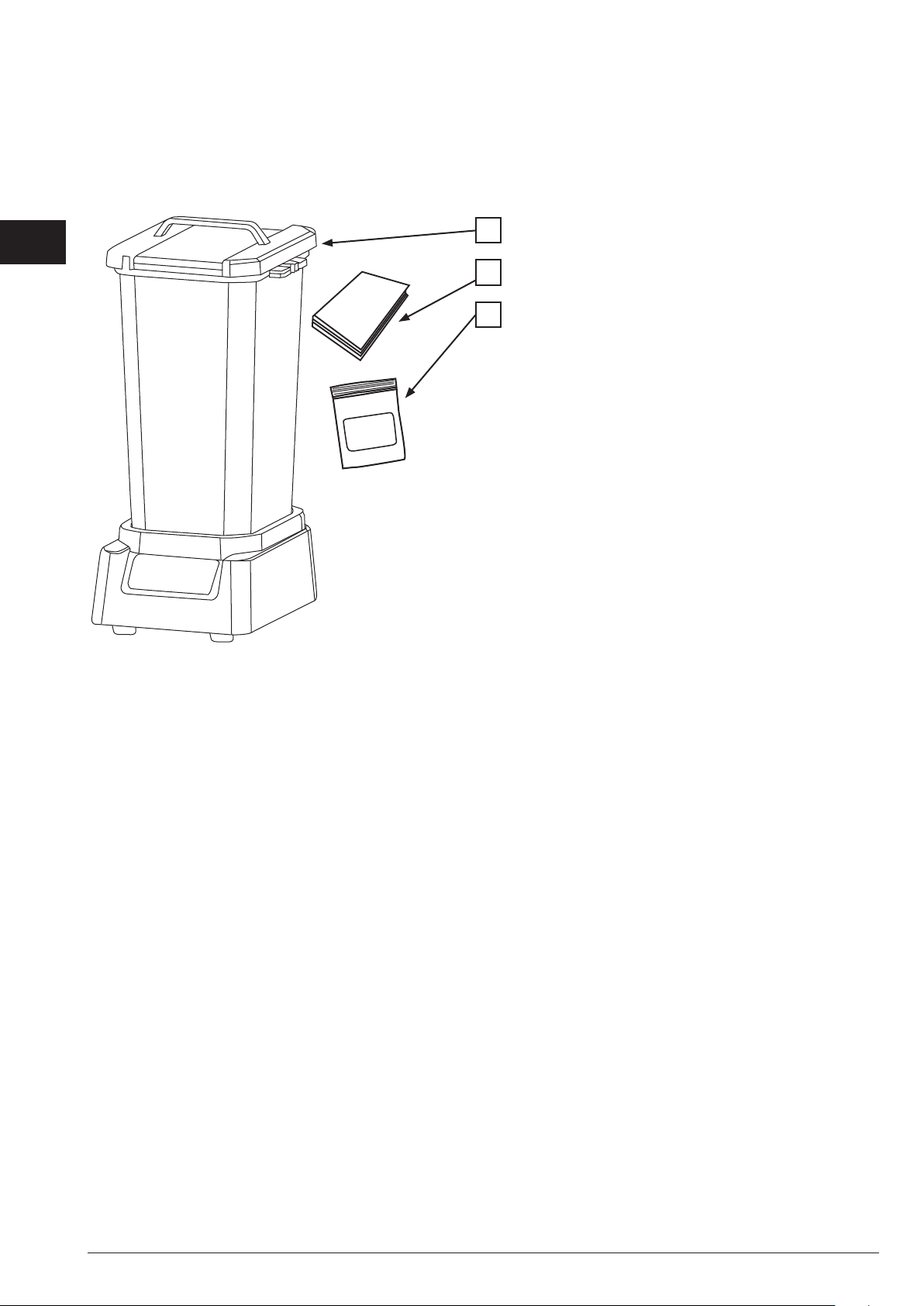

4 Scope of Delivery/Finishing Kit Components...........................................................................10

4.1 Scope of Delivery ................................................................................................................................ 10

5 Identification and Interface ........................................................................................................11

5.1 Product Identification .......................................................................................................................... 11

5.2 Control Interface.................................................................................................................................. 11

6 Transport and Installation...........................................................................................................12

6.1 Transport.............................................................................................................................................. 12

6.2 Hardware Setup................................................................................................................................... 12

7 Operation......................................................................................................................................13

7.1 Turning the unit “ON” and “OFF”......................................................................................................... 13

7.2 Filling with isopropyl alcohol ............................................................................................................... 14

7.3 Positioning the inner container drain plug ........................................................................................... 15

7.4 Placing the parts in the inner container............................................................................................... 15

7.5 Configuring the cleaning cycle settings .............................................................................................. 16

7.6 Prepairing cleaning cycle..................................................................................................................... 16

7.7 Starting the cleaning cycle .................................................................................................................. 16

7.8 cara Print Clean Cleaning Procedure...................................................................................................17

8 Safety............................................................................................................................................18

8.1 Isopropyl Alcohol Draining...................................................................................................................... 18

8.2 Isopropyl Alcohol Containment .............................................................................................................. 18

9 Maintenance, Care and Cleaning...............................................................................................18

9.1 Cleaning............................................................................................................................................... 18

9.1.1 Unit Cleaning ....................................................................................................................................... 18

9.1.2 Build Table Cleaning............................................................................................................................ 18

9.2 Isopropyl Alcohol................................................................................................................................. 18

9.2.1 Replacement ....................................................................................................................................... 18

9.2.2 Disposal............................................................................................................................................... 18

9.3 Non-Repairable Items.......................................................................................................................... 18

10 Technical Data .............................................................................................................................19

10.1 cara Print Clean Technical Specifications ........................................................................................... 19

10.2 Operating conditions ........................................................................................................................... 19

10.3 Information on Manufacturer and Electrical Specification – Product Label ........................................ 20

11 Troubleshooting Guide................................................................................................................20

12 Service..........................................................................................................................................23

12.1 WARRANTY STATEMENT ...................................................................................................................23

12.2 Electrical and Electronic Equipment Act (ElektroG) ............................................................................ 23

13 Tips ..............................................................................................................................................23

14 Document History........................................................................................................................24