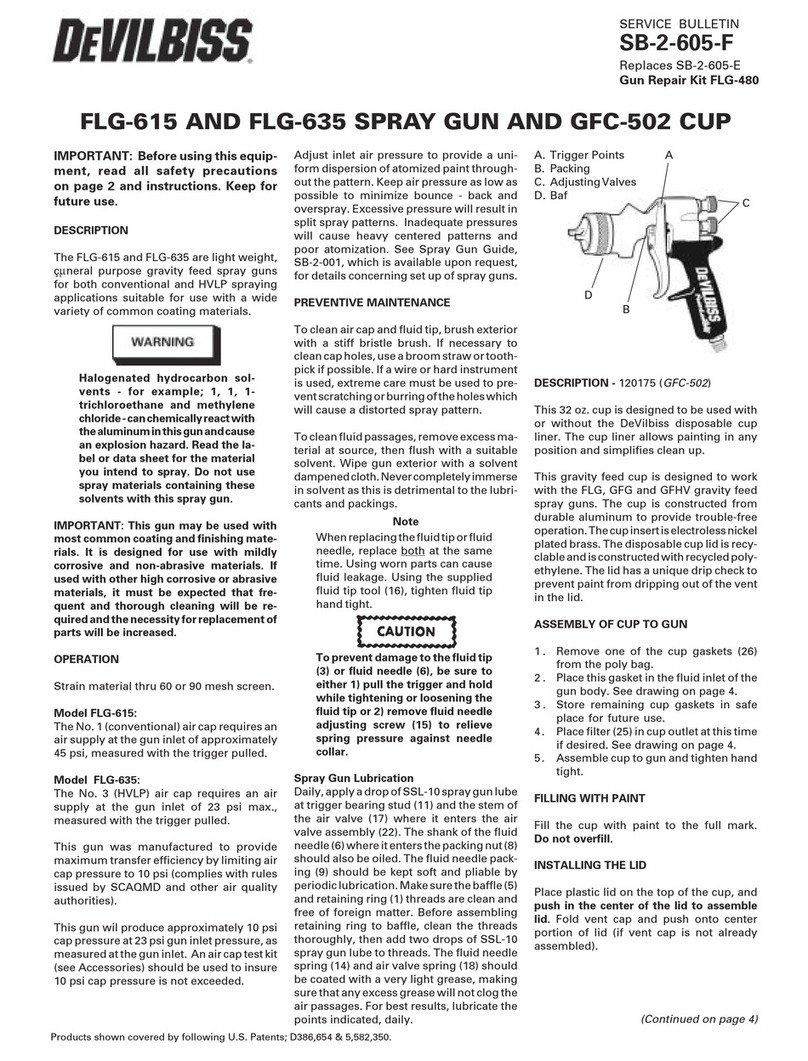

DESCRIPTION

This gun is designed for light-duty spray-

ing—specifically for working with small

compressors in workshops, homes,

farms, schools, etc.

Gun is non-bleeder type, for use only

with a pressure feed metal cup directly

attached to it using an air pressure not

over 40 PSI (2.7 kgs/cm2).

This gun can be converted to bleeder

type by exchanging parts (23) and (16).

It can be used with internal mix cap at 40

PSI maximum pressure or with external

mix cap at 25 PSI maximum pressure.

CLEANING

Unscrew cup a little without removing it

from gun. Hold a clean cloth over air cap

(10 or 12). Pull trigger (19) and air pres-

sure will force material back into cup.

Remove cup (15) from gun body. Empty

material from cup and add a small quan-

tity of suitable clean solvent. Replace

cup on gun and spray in usual manner

until clear solvent appears and gun is

thoroughly clean.

Remove cup from gun body again and

clean the gasket (13) of the cup lid.

Loosen and remove the air cap (10 or 12)

and clean it with a soft brush.

Gasket (13) should be cleaned with a

solvent-soaked cloth. Let it dry before

reinstalling in gun body.

Use a brush with solvent for clean-

ing inside the cup lid. Wipe gun

outside with a solvent-soaked cloth.

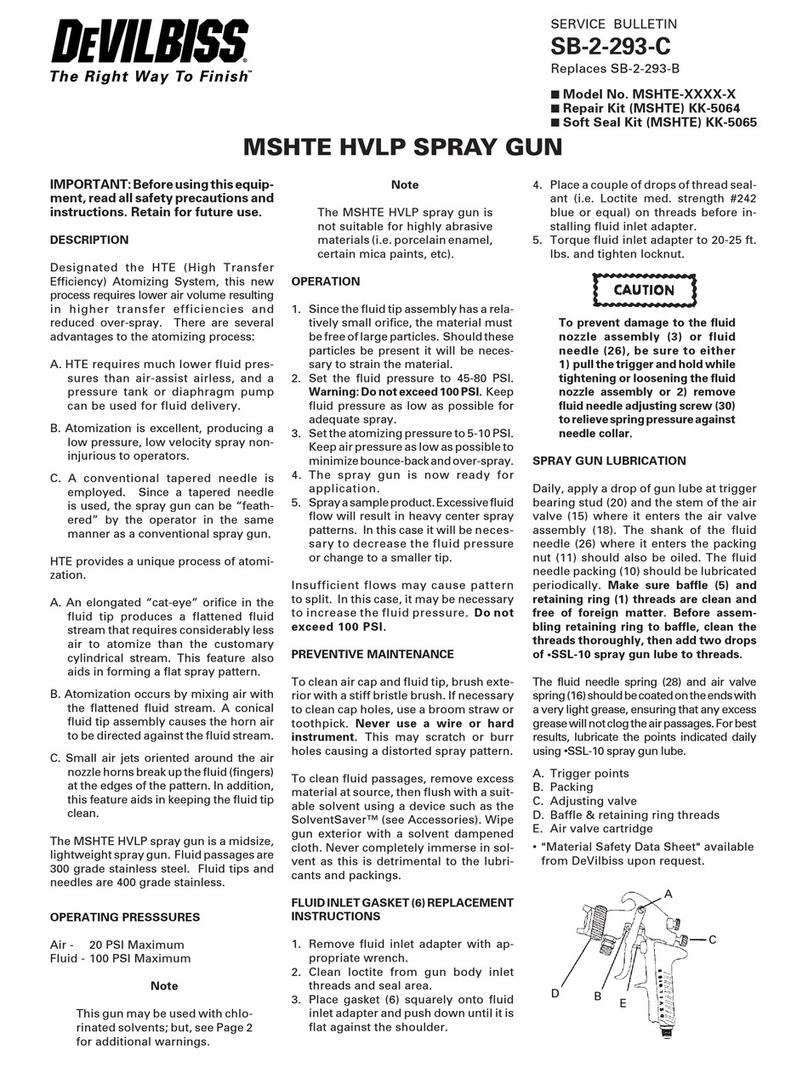

LUBRICATION

At the end of each day’s use, place a

drop of light oil at trigger bearing pin

(18) and on fluid needle packing (22).

To avoid damage to threads, use

proper tools. We suggest you use

the WR-103 multiple wrench.

HAZARD CAUSE SAFEGUARD

WARNING

Important safety information — A hazard that may cause serious injury or loss

of life. The following hazards may occur during the normal use of this equip-

ment. Please read the following chart before using this equipment.

!

NOTE

Before using this equipment, read all

safety precautions and instructions.

Retain for future use.

Fire

Explosion

Solvent

Spray

Inhaling

Toxic

Materials

Solvent and coatings can be

highly flammable or combusti-

ble, especially when sprayed.

During cleaning and flushing,

solvents can be forcefully

expelled from fluid and air pas-

sages. Some solvents can cause

eye injury.

Certain materials may be harm-

ful if inhaled, or if there is

contact with the skin.

Halogenated hydrocarbon sol-

vents – for example methylene

chloride and 1, 1, 1,

Trichloroethane can chemically

react with aluminum. The

chemical reaction caused by

these solvents reacting with

aluminum can become violent

and lead to an equipment

explosion.

Adequate exhaust must be provid-

ed to keep air free of accumula-

tions of flammable vapors.

Smoking must never be allowed in

the spray area.

Fire extinguishing equipment must

be present in the spray area.

Wear eye protection.

Follow the requirements of the

Material Safety Data sheet supplied

by your coating material manufac-

turer. Adequate exhaust must be

provided to keep the air free of

accumulations of toxic materials.

Use a mask or respirator whenever

there is a chance if inhaling

sprayed materials. The mask must

be compatible with the material

being sprayed and its concentra-

tion. Equipment must be as pre-

scribed by an industrial hygienist

or safety expert and be NIOSH

approved.

This gun is made of aluminum

and must NOT be used with any

materials containing these solvents.

Check all equipment items before

use and make sure they can also

be used safely with these solvents.

Read the label or data sheet for

the material you intend to spray.

If in doubt as to whether or not a

coating or cleaning material is

compatible, contact your material

supplier.

CAuTION

To prevent damage to cup, do not use

more than 40 psi inlet air pressure.

!

FLG-MGQ-700-FL SPRAY GUN

SB-2-006-A

Replaces SB-2-006

SERVICE BULLETIN

CAuTION

Never immerse gun assembly in solvent

as damage to packings could result.

!

NOTE

We recommend that you clean your

gun after each day’s use.