Page 4 SB-2-605-F

CLEANING

Note

For

routine

cleaning,

it

is

not

nee¥

essary to remove

cup

from

gun.

Do

not

remove washer (26)

from

gun.

If washer

(26)

is removed, it

must

be

replaced.

The

cup

lid

is

designed to be disposable

but

may

be cleaned and reused

if

slightly

contaminated

with

-overspray.

If

lid

becomes

tight, or does

not

fit,

it is due

to

extended

soaking

in

solvent,

Let lid air

dry

overnight

and

the

lid

should

return

to

its

original

size

and

fit.

some

solvent

to

be

flushed

through

gun.

Remove

lid

and

pour

out

dirty

solvent.

Add

a

small

amount

of

clean solvent and repeat

procedure.

Wipe

exterior

of

lid

with

aclean

doth

and

clean solvent.

[~~~T!?:~:J

Remove

lid

and

properly

dispose

of

any

excess paint. Pour in a small

amount

of

clean solvent. The

amount

will

vary

with

different

coatings

and solvents. Reinstall

lid. Shake cup

to

wash

down

the inside

surfaces. Hold

lid

while

shaking

to

prevent

lid

from

coming

off. Pull

trigger

to

allow

If

a

paint

filter

was

used

in

the

bottom

of

the

cup

outlet,

it

should

be

removed

and

cleaned

or

replaced

at

thfs

time.

Dispose

of

used

cup

lid

if

contaminated

and

replace

with

new.

Do

not

soak

the

lid

in

solvent

for

extended

periods

of time. Doing

so

could

cause

cup/lid

sealing

problems

and leakage.

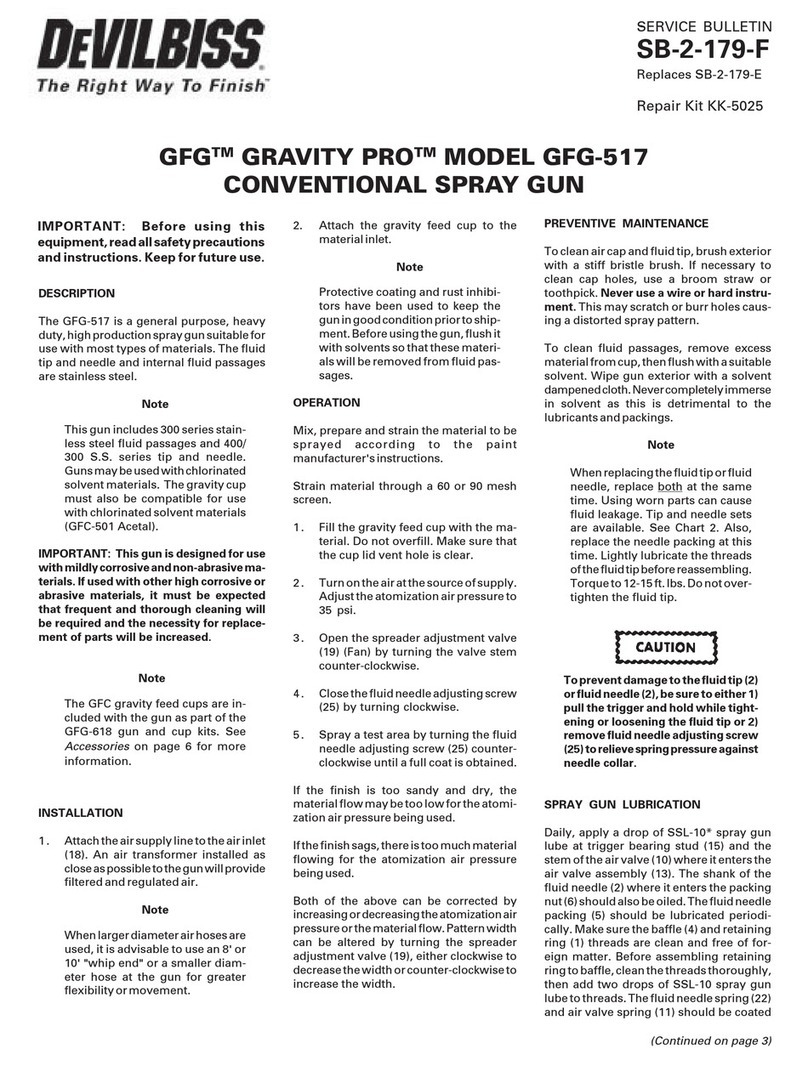

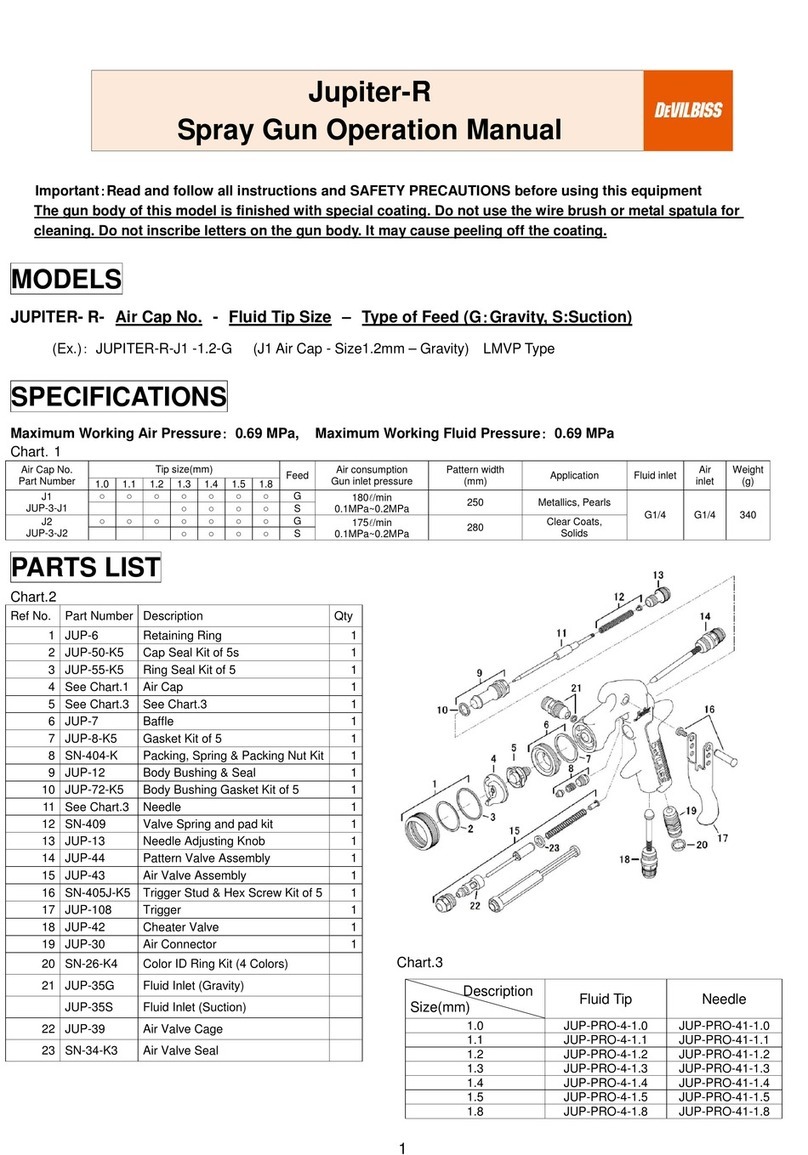

Chart

1 For

Model

Numbers

FLG-615 and FLG-635

Gravity

Feed

Spray

Guns

Spray

Gun

Spray

Gun No. on

Ref.

No.2

Ref.

No.3 Fluid

Model

Computer

Air Air

Cap

Fluid Tip

Tip

Number

Number

Cap

Part

No.

Computer

No.

Part

No.

Computer

No.

Size

FLG-615-114 611101 1 FLG-1-1 690000 FLG-102-141< 690003 1.4 (Std.)

FLG-635-316 611103 3 FLG-1-3 690001 FLG-102-16K 690004 1.6 !Std.)

FLG-1 02-14K 690003 1.4 (Std.)

FLG-102-18K 690005 1.8 (Opt.)

FLG-102-22K 690006 2.2 (Opt.)

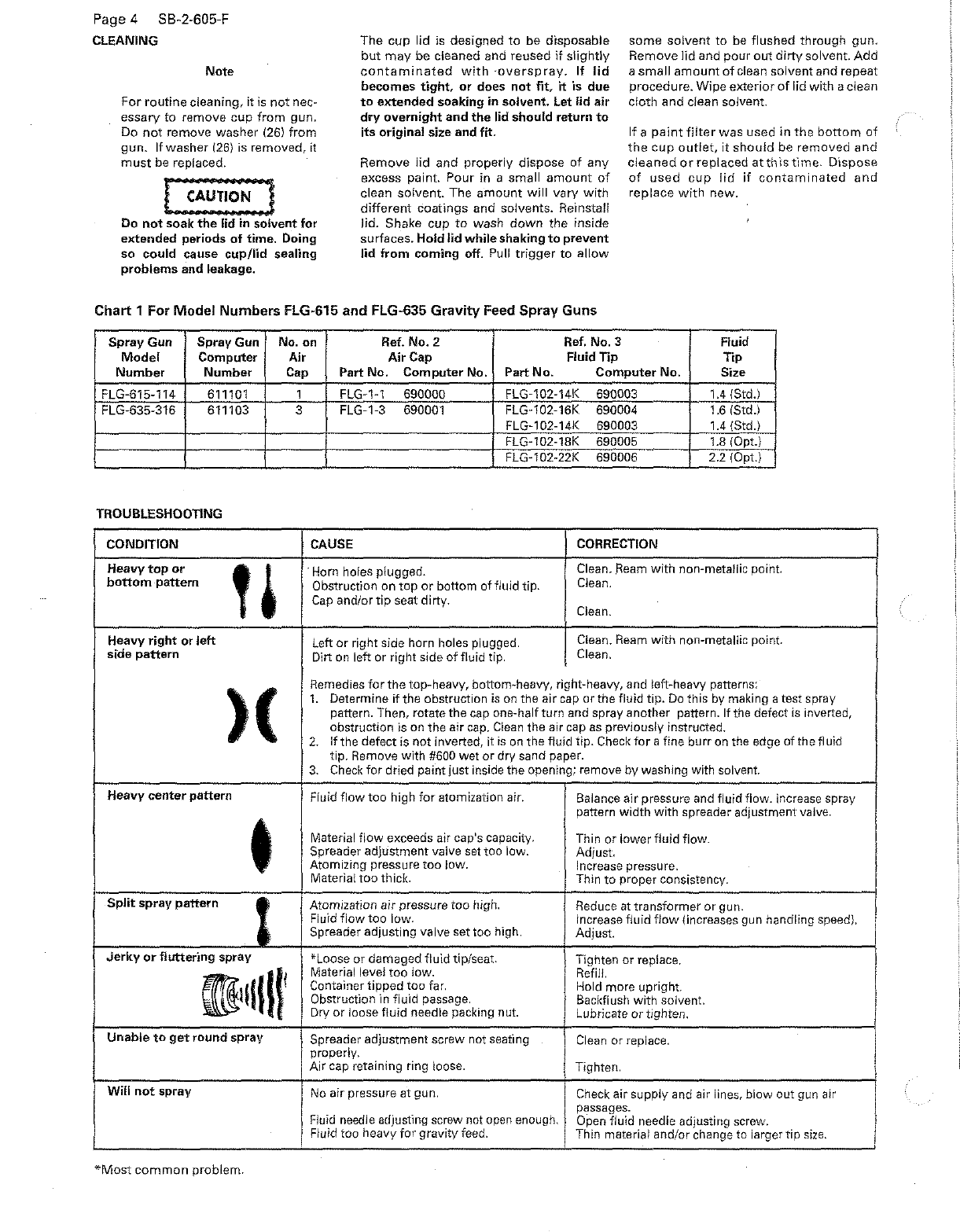

TROUBLESHOOTING

CONDITION CAUSE CORRECTION

Heavy

top

or

'

•·Horn holes plugged. Clean.

.Ream

with non-metaHic point.

bottom

pattern

Obstruction on

top

or

bottom

of

fluid tip. Clean.

Cap

and/or

tip

seat dirty. Clean.

Heavy

right

or

left

Left

or

right side horn holes plugged. Clean.

Ream

with

non-metallic point.

side

pattern

Dirt on left or right side

of

fluid tip. Clean.

)( Remedies

for

the top-heavy, bottom-heavy, right-heavy, and left-heavy patterns:

1.

Determine

if

the obstruction

is

on the air

cap

or

the fluid tip.

Do

this

by

making atest spray

pattern. Then, rotate the cap one-half turn and spray another pattern. If the defect is inverted,

obstruction is on the air cap.

Clean

the air cap

as

previously instructed.

2. If the defect is

not

inverted,

it

is

on

the fluid tip. Check

for

a fine burr

on

the edge of the fluid

tip. Remove with

#600

wet

or

dry sand paper.

3.

Check

for

dried paintjust inside the opening; remove

by

washing with solvent.

Heavy

center

pattern

Fluid

flow

too high

for

atomization air. Balance air pressure and fluid flow. increase spray

t pattern width with spreader adjustment valve.

Material

flow

exceeds air cap's capacity. Thin

or

lower fluid flow.

Spreader adjustment valve set too low.

Adjust

Atomizing pressure

too

low. Increase pressure.

Material

too

thick. Thin

to

proper consistency.

Split

spray

pattern

Atomization

air

pressure

too

high. Reduce at transformer

or

gun.

Fluid

flow

too low. Increase fluid

flow

{increases gun handling speed).

Spreader adjusting valve set too high. Adjust.

Jerky

or

fluttering

spray *Loose

or

damaged fluid tip/seat. Tighten or replace.

~~~~~~~~

Material level

too

low. Refill.

Container tipped too far. Hold more upright.

Obstruction in fluid passage. Backflush with solvent.

Dry

or

loose fluid needle packing nut.

lubricate

or

tighten.

I

Unable

to

get

round

spray

Spreader adjustment screw not seating

Clean

or

replace.

properly.

Air cap retaining ring loose. Tighten.

Will

not

spray

No

air pressure at gun.

Check

air supply and air lines, blow out gun air

passages.

Fluid needle adjusting screw not open enough. Open fluid needle adjusting screw.

Fluid too heavy

for

gravityfeed. Thin material and/or change to larger

tip

size.

*Most

common

problem.

I

I