• Do not use Type 11 (flaring cup) wheels on this tool. Using

inappropriate accessories can result in injury.

• Before using, inspect recommended accessory for cracks

or flaws. If such a crack or flaw is evident, discard the

accessory. The accessory should also be inspected when-

ever you think the tool may have been dropped. Flaws may

cause wheel breakage.

• When starting the tool with a new or replacement wheel, or

a new or replacement wire brush installed, hold the tool in

a well protected area and let it run for one minute. If the

wheel has an undetected crack or flaw, it should burst in less

than one minute. If the wire brush has loose wires, they will be

detected. Never start the tool with a person in line with the

wheel. This includes the operator.

• Avoid bouncing the wheel or giving it rough treatment. If this

occurs, stop the tool and inspect the wheel for cracks or flaws.

•Direct sparks away from operator, bystanders or flammable

materials. Sparks may be produced while using a sander or

grinder. Sparks may cause burns or start fires.

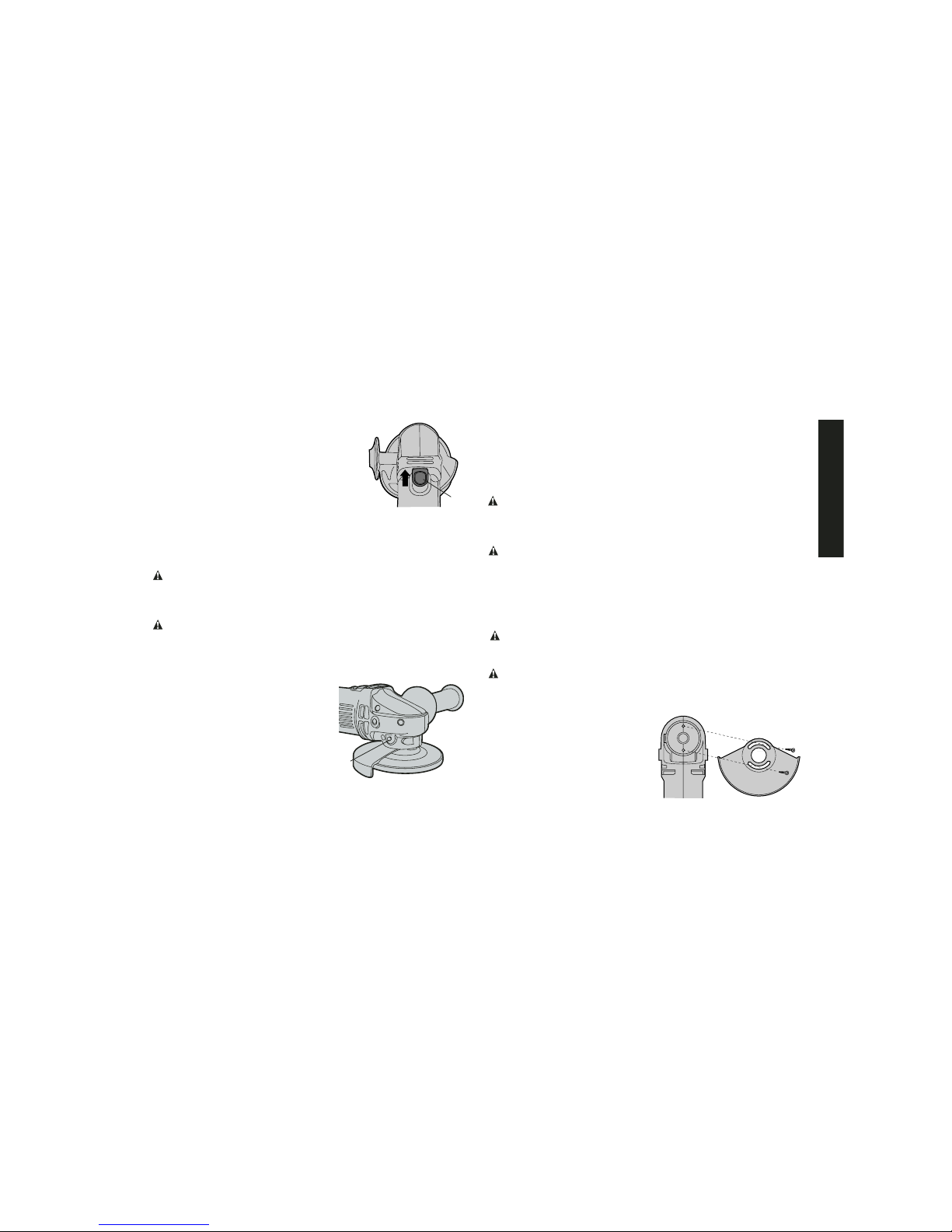

• Always use side handle. Tighten the handle securely. The

side handle should always be used to maintain control of the tool

at all times.

• Clean out your tool often, especially after heavy use. Dust

and grit containing metal particles often accumulate on interior

surfaces and could create an electric shock hazard.

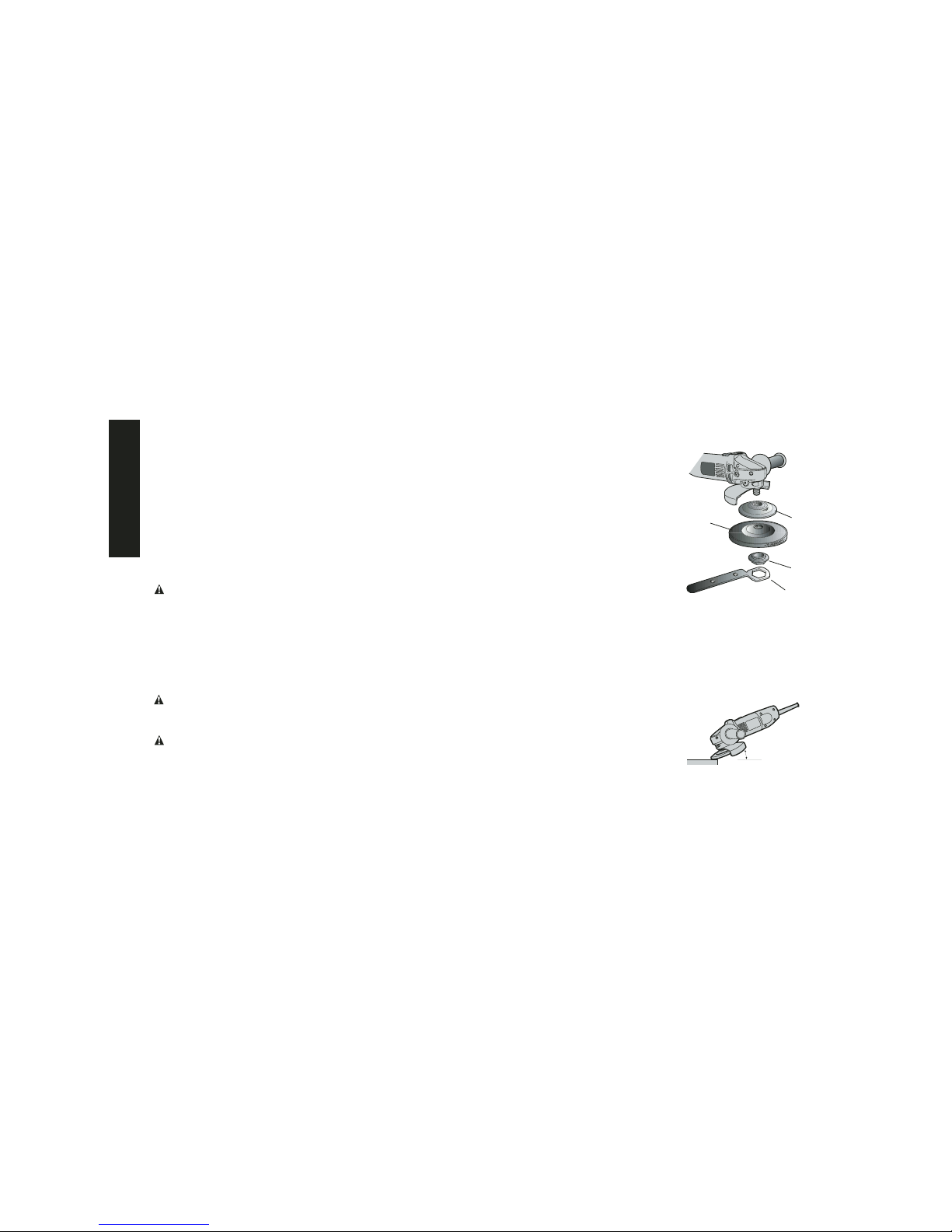

CAUTION: Type 1 Abrasive and Diamond Cut-Off Wheels may

not be used on this tool. A Type 1 Cut-Off Wheel Guard is not avail-

able for the DW400.

• The label on your tool may include the following symbols.

V ..............volts A............amperes

Hz ............hertz W ..........watts

min ..........minutes ..........alternating current

........direct current no ..........no load speed

..............Class II Construction ..........safety alert symbol

..............

earthing terminal .../min ....revolutions or

.................. ..............per minute

CAUTION: Use extra care when grinding into a corner as a

sudden, sharp movement of the grinder may be experienced

when the wheel contacts a secondary surface.

CAUTION: Wear appropriate personal hearing protection

during use. Under some conditions and duration of use, noise

from this product may contribute to hearing loss.

WARNING: Some dust created by power sanding, sawing,

grinding, drilling, and other construction activities contains chem-

icals known to cause cancer, birth defects, or other reproductive

harm. Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry

products, and

• arsenic and chromium from chemically-treated lumber

(CCA).

Your risk from these exposures varies, depending on how often you

do this type of work. To reduce your exposure to these chemicals:

work in a well ventilated area, and work with approved safety equip-

ment, such as those dust masks that are specially designed to

filter out microscopic particles.

•Avoid prolonged contact with dust from power sanding,

sawing, grinding, drilling, and other construction

activities. Wear protective clothing and wash exposed

areas with soap and water. Allowing dust to get into your

mouth, eyes, or lay on the skin may promote absorption of

harmful chemicals.

English

3