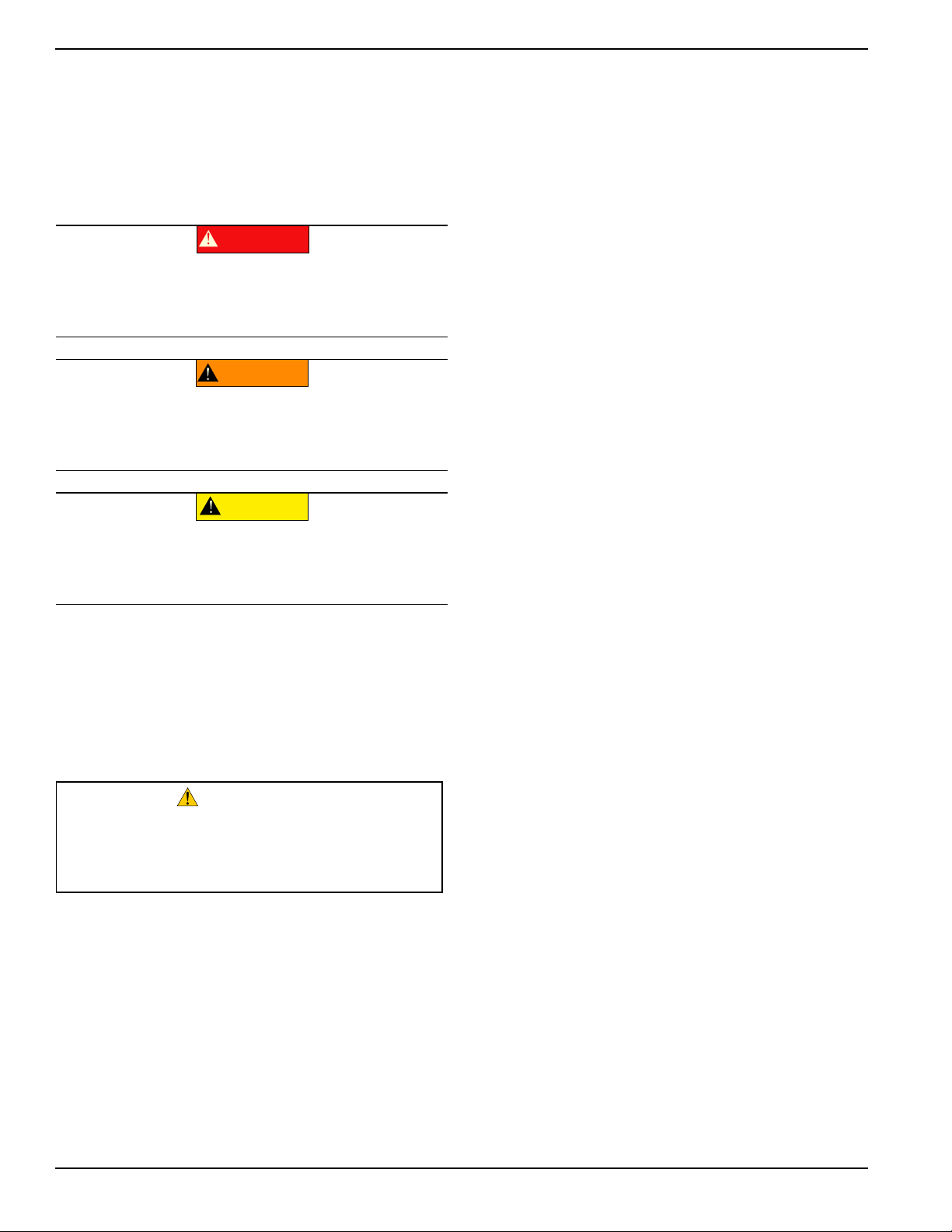

Diagnostic Repair Manual iii

Table of Contents

Safety ....................................................................... ii

Read This Manual Thoroughly ................................. ii

Replacement Parts .................................................. ii

Section 1 Capacitive Discharge (Brushless) ............... 1

Introduction ..............................................................1

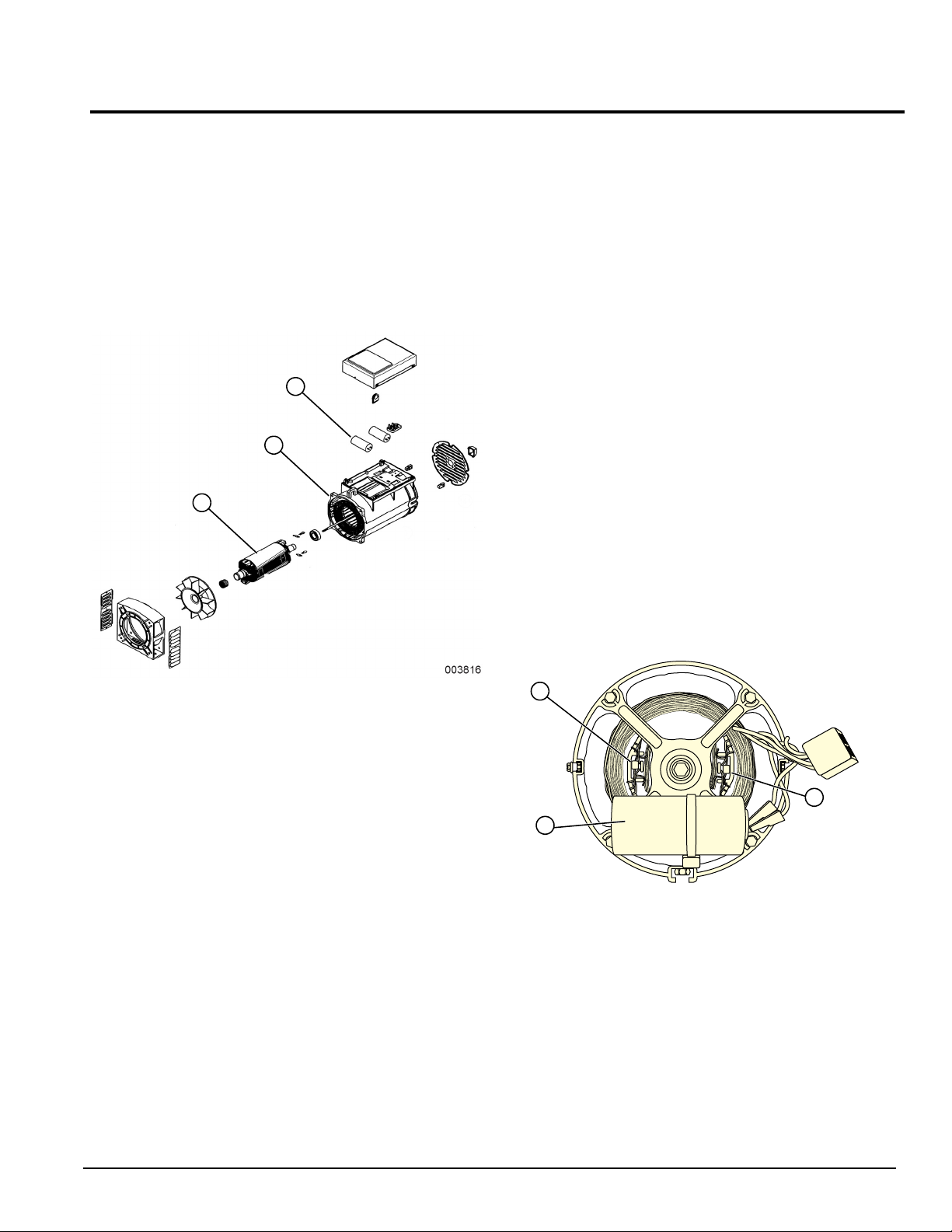

Rotor Assembly ........................................................1

Stator Assembly .......................................................1

Circuit Breakers .......................................................2

Operation .................................................................2

Troubleshooting Flowcharts .....................................3

If Problem Involves AC Output ..........................3

Problem 1 – Generator Produces Zero

Voltage or Residual Voltage ..............................3

Problem 2 – Voltage & Frequency Are

Both High or Low ...............................................4

Problem 3 – Excessive Voltage/Frequency

Droop When Load is Applied ............................4

Problem 4 – Generator Produces High

Voltage at No-Load ...........................................4

AC Diagnostic Tests ................................................5

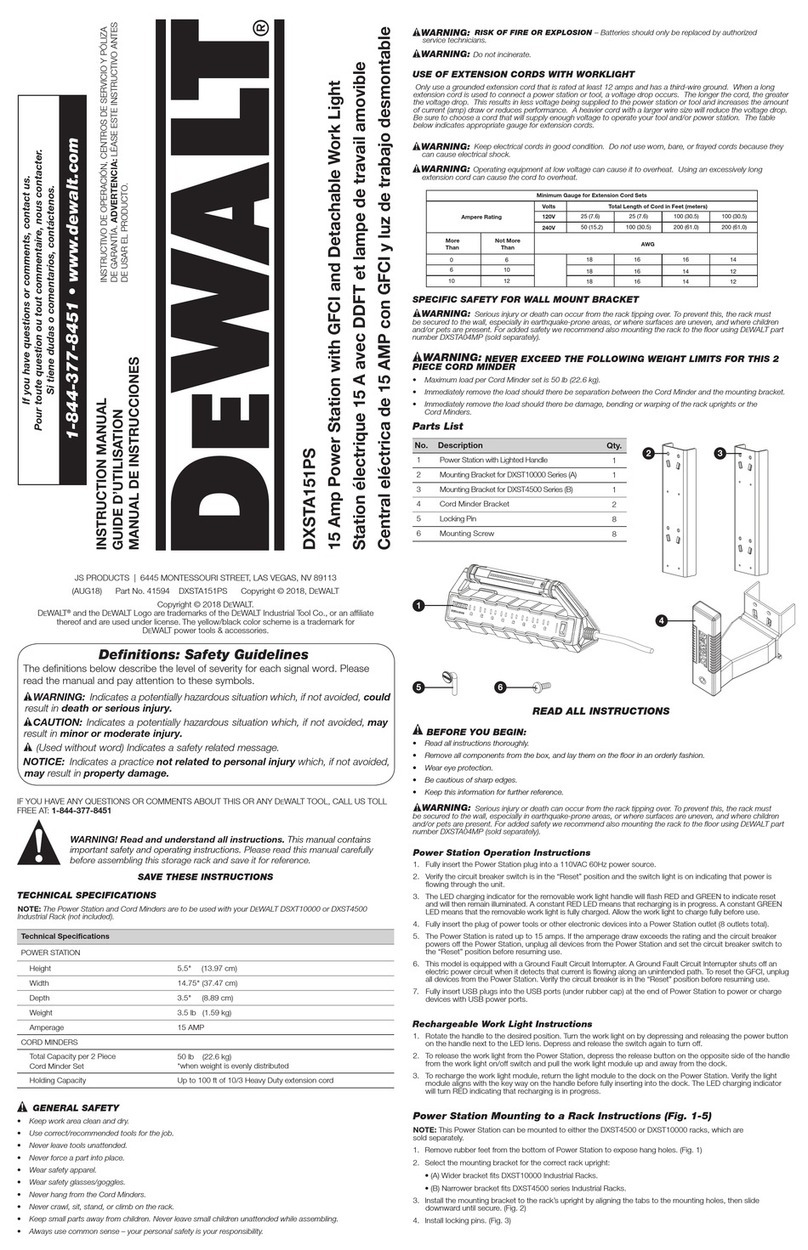

Test 1 – Check No-Load Voltage and Frequency ....5

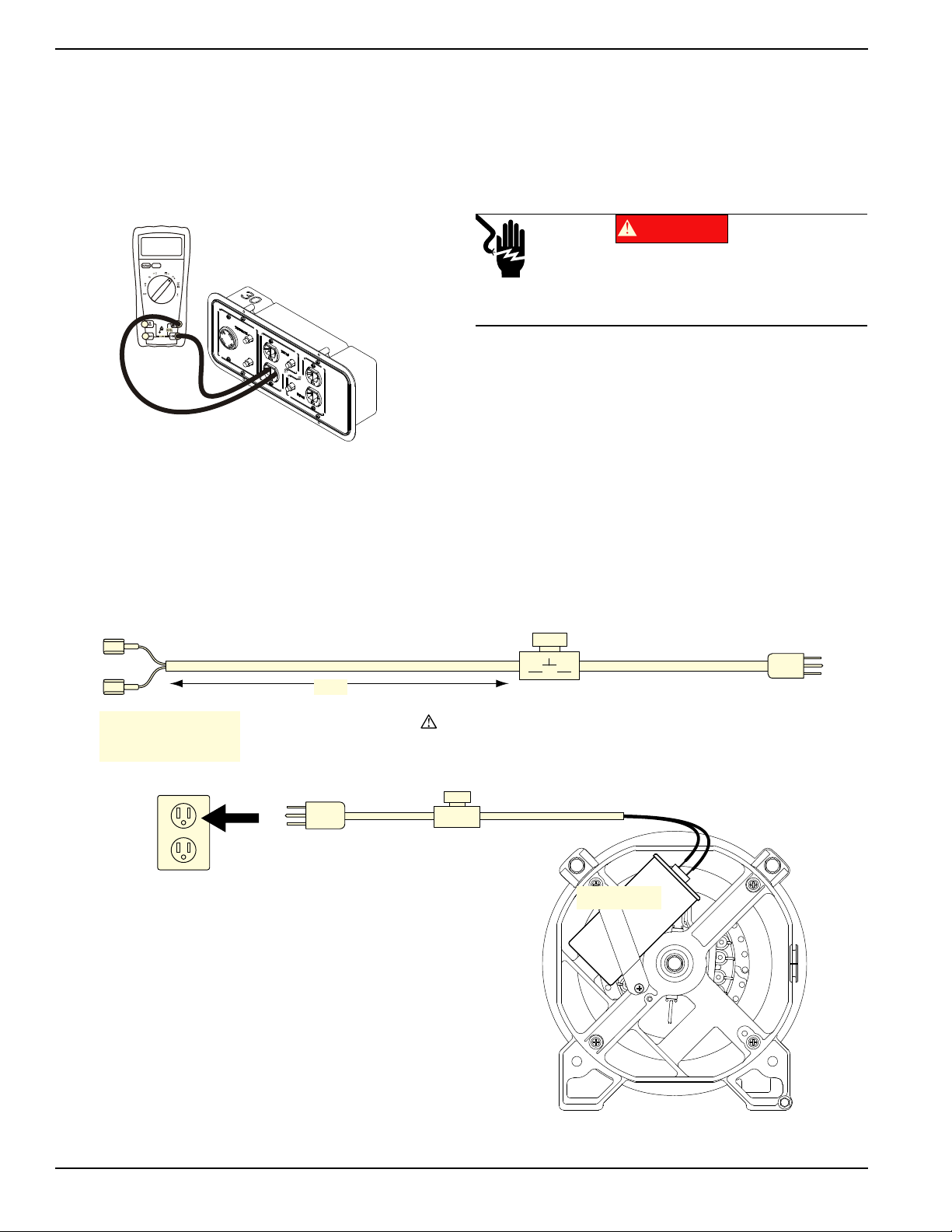

Test 2 – Check Main Circuit Breaker .......................5

Test 3 – Check Continuity of Receptacle Panel .......5

Test 5 – Field Flash Alternator .................................6

Test 6 – Check Capacitor ........................................7

Test 7 – Test Brushless Excitation Winding .............7

Test 8 – Test Brushless Stator Windings .................8

Test 10 – Check Load Voltage and Frequency ........8

Test 11 – Check Load Watts and Amperage ...........8

Section 2 Direct Excitation (Brush Type) .................. 11

Introduction ............................................................11

Stator Assembly .....................................................11

Brush Holder and Brushes .....................................11

Voltage Regulator ..................................................11

Operation ...............................................................12

Troubleshooting Flowcharts ...................................13

If Problem Involves AC Output (Brush Type) ..13

Problem 5 – Generator Produces Zero

Voltage or Residual Voltage ............................13

Problem 6 – Voltage & Frequency Are

Both High or Low .............................................13

Problem 7 – Excessive Voltage/Frequency

Droop When Load is Applied ..........................14

Problem 8 – Generator Produces High

Voltage at No-Load .........................................14

AC Diagnostic Tests ..............................................15

Test 1 – Check No-Load Voltage and Frequency ..15

Test 2 – Check Main Circuit Breaker .....................15

Test 3 – Check Continuity of Receptacle Panel ....15

Test 4 – Fixed Excitation Test/Rotor

Amp Draw Test ......................................16

Test Brushed Stator Windings ...............................18

Test 10 – Check Load Voltage and Frequency .....18

Test 11 – Check Load Watts and Amperage .........18

Test 12 – Adjust Voltage Regulator .......................19

Section 3 Engine Diagnostic Tests ........................... 21

Introduction ............................................................21

Problem 9 – Recoil Cord Will Not Pull ............21

Problem 10 – Engine Starts Hard and Runs

Rough .............................................................21

Problem 11 – Engine Turns Over But Will Not

Start ................................................................22

Problem 12 – Engine “Hunts” / Erratic Idle .....23

Problem 13 – Engine Will Not Crank ..............23

Problem 14 – Recoil Cord Will Not Pull

(If So Equipped) ..............................................23

Problem 15 – Engine Cranks But

Will Not Start ...................................................24

Problem 16 – Engine Starts Hard

and Runs Rough .............................................25

Problem 17 – Engine Starts Then

Shuts Down .....................................................25

Problem 18 – Battery Will Not Charge ............26

Problem 19 – Engine “Hunts” / Erratic Idle .....26

Problem 20 – Unit Will Not Idle .......................27

Problem 21 – Unit RPM Will Not Increase

From Idle .........................................................27

Problem 22 – No Display from Wattage/

Runtime Meter ................................................28

Problem 23 – Wattage/Runtime Meter

Display is Flashing Erroneous Data ................28

Introduction ............................................................29

Test 14 – Check Fuse ............................................29

Test 15 – Check Battery & Cables .........................29

Test 16 – Check Voltage at Starter

Contactor (SC) .......................................29

Test 17 – Check Start-Run-Stop Switch ................29

Test 18 – Test OFF-ON Switch .............................30

Test 19 – Check Starter Motor ...............................30

Test 20 – Check Ignition Spark ..............................31

Test 21 – Check Spark Plug(s) ..............................31