7

ENGLISH

10 . Connect dust extractionequipment.

ʵ If devices are provided for the connection of dust

extraction and collecting equipment, ensure these are

connected and properlyused.

11 . Do not abuse thecord.

ʵ Never yank the cord to disconnect it from the socket.

Keep the cord away from heat, oil and sharp edges. Never

carry the tool by itscord.

12 . Securework.

ʵ Where possible use clamps or a vice to hold the work. It

is safer than using your hand and it frees both hands to

operate thetool.

13 . Do notoverreach.

ʵ Keep proper footing and balance at alltimes.

14 . Maintain tools withcare.

ʵ Keep cutting tools sharp and clean for better and safer

performance. Follow instructions for lubricating and

changing accessories. Inspect tools periodically and if

damaged have them repaired by an authorized service

facility. Keep handles and switches dry, clean and free

from oil andgrease.

15 . Disconnecttools.

ʵ When not in use, before servicing and when changing

accessories such as blades, bits and cutters, disconnect

tools from the powersupply.

16 . Remove adjusting keys andwrenches.

ʵ Form the habit of checking to see that adjusting keys and

wrenches are removed from the tool before operating

thetool.

17 . Avoid unintentionalstarting.

ʵ Do not carry the tool with a finger on the switch. Be sure

that the tool is in the “off” position before pluggingin.

18 . Use outdoor extensionleads.

ʵ Before use, inspect the extension cable and replace

if damaged. When the tool is used outdoors, use

only extension cords intended for outdoor use and

markedaccordingly.

19 . Stayalert.

ʵ Watch what you are doing. Use common sense. Do not

operate the tool when you are tired or under the influence of

drugs oralcohol.

20 . Check for damagedparts.

ʵ Before use, carefully check the tool and mains cable to

determine that it will operate properly and perform its

intended function. Check for alignment of moving parts,

binding of moving parts, breakage of parts, mounting

and any other conditions that may affect its operation. A

guard or other part that is damaged should be properly

repaired or replaced by an authorized service centre

unless otherwise indicated in this instruction manual.

Have defective switches replaced by an authorized

servicecentre. Do not use the tool if the switch does not

turn it on and off. Never attempt any repairsyourself.

WARNING: The use of any accessory or attachment or

performance of any operation with this tool other than

those recommended in this instruction manual may

present a risk of personalinjury.

21 . Have your tool repaired by a qualifiedperson.

ʵ This electric tool complies relevant safety rules. Repairs

should only be carried out by qualified persons using

original spare parts; otherwise this may result in

considerable danger to theuser.

Additional Safety for Metal Saws

• Do not use saw blades which are damaged or deformed;

• Use only saw blades recommended by the manufacturer

which conform to EN 847-1;

• Do not use saw blades manufactured from high speed steel;

• Wear suitable personal protective equipment when necessary,

this could include:

ʵ hearing protection to reduce the risk of induced hearing

loss;

ʵ eye protection;

ʵ respiratory protection to reduce the risk of inhalation of

harmful dust;

ʵ gloves for handling saw blades (saw blades shall be

carried in a holder wherever practicable) and rough

material;

Maintenance and Servicing

• Operator’s instructions on factors influencing exposure to

noise (e.g. use of saw blades designed to reduce the emitted

noise, saw blade and machine maintenance);

• Report faults in the machine, including guards or saw blades,

as soon as they arediscovered.

Safe Operation

• Select the correct saw blade for the material to be cut;

• Do not use the saw to cut other materials than those

recommended by the manufacturer;

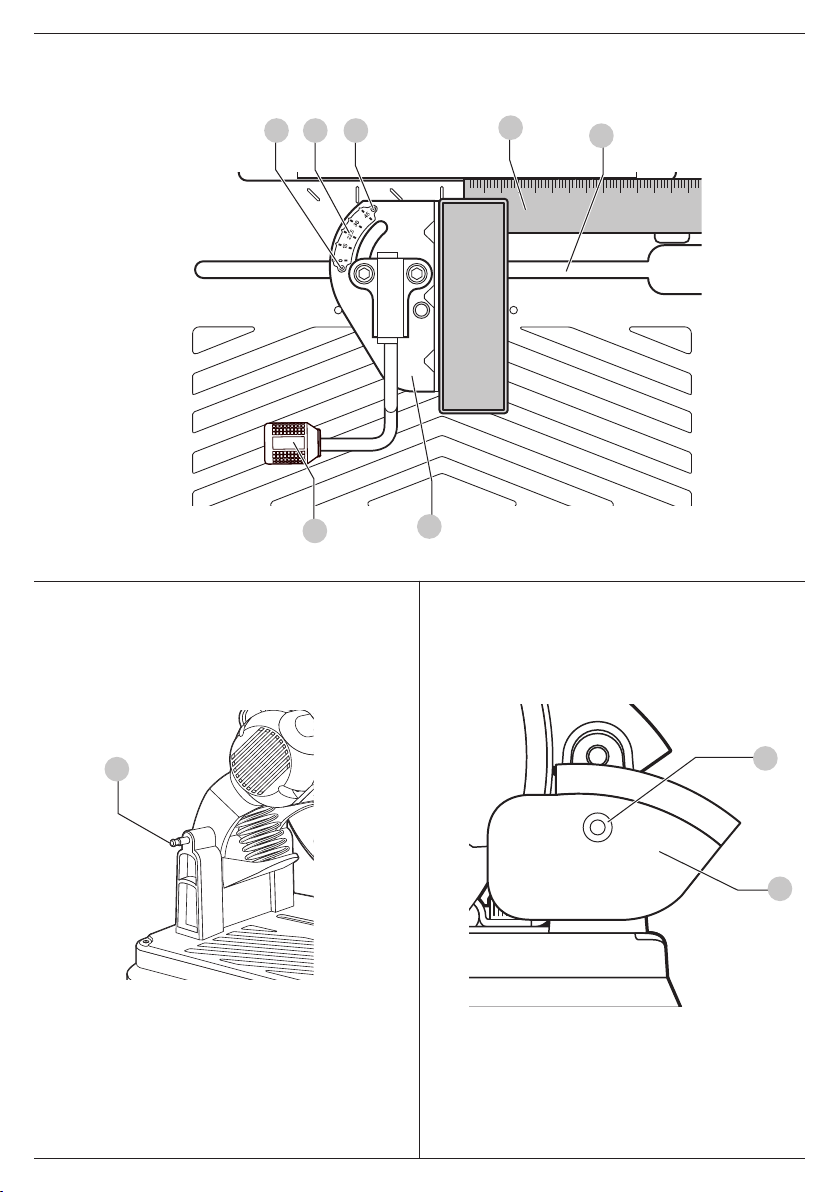

• Lifting and transportation information. To lift and support the

metal saw see FigureF.

• Do not use the saw without the guards in position, in good

working order and properly maintained;

• Keep the floor area around the machine level, well maintained

and free of loose materials e.g. chips and cut-offs;

• Provide adequate general or localised lighting;

• The operator is adequately trained in the use adjustment and

operation of the machine;

• Use correctly sharpened saw blades. Observe the maximum

speed marked on the saw blade;

• Ensure that any spacers and spindle rings used are suitable for

the purpose as stated by the manufacturer;

• Refrain from removing any cut-offs or other parts of the

workpiece from the cutting area while the machine is running

and the saw head is not in the rest position;

• Ensure that the machine is always stable and secure. (e.g. fixed

to a bench)