Makita LS0714 User manual

Other Makita Saw manuals

Makita

Makita DJR187 User manual

Makita

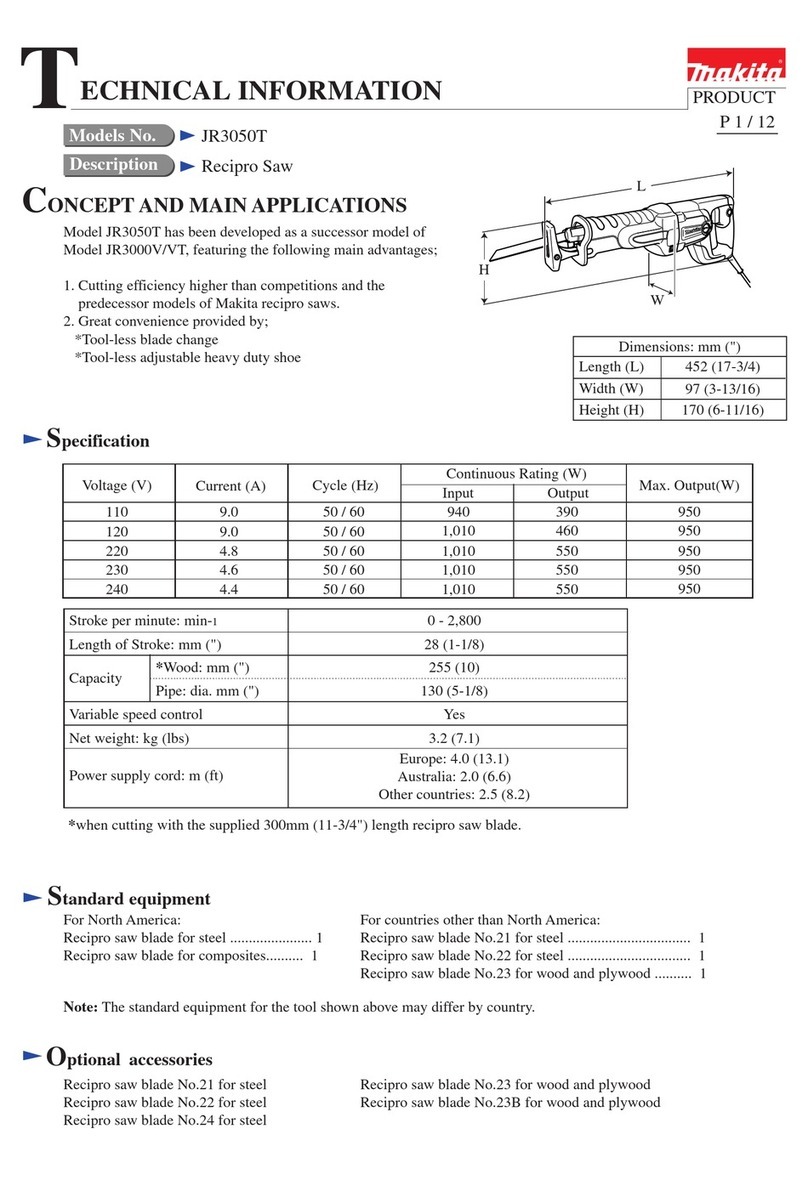

Makita JR3050T User manual

Makita

Makita LC1230 User manual

Makita

Makita 5104 User manual

Makita

Makita LS1017 User manual

Makita

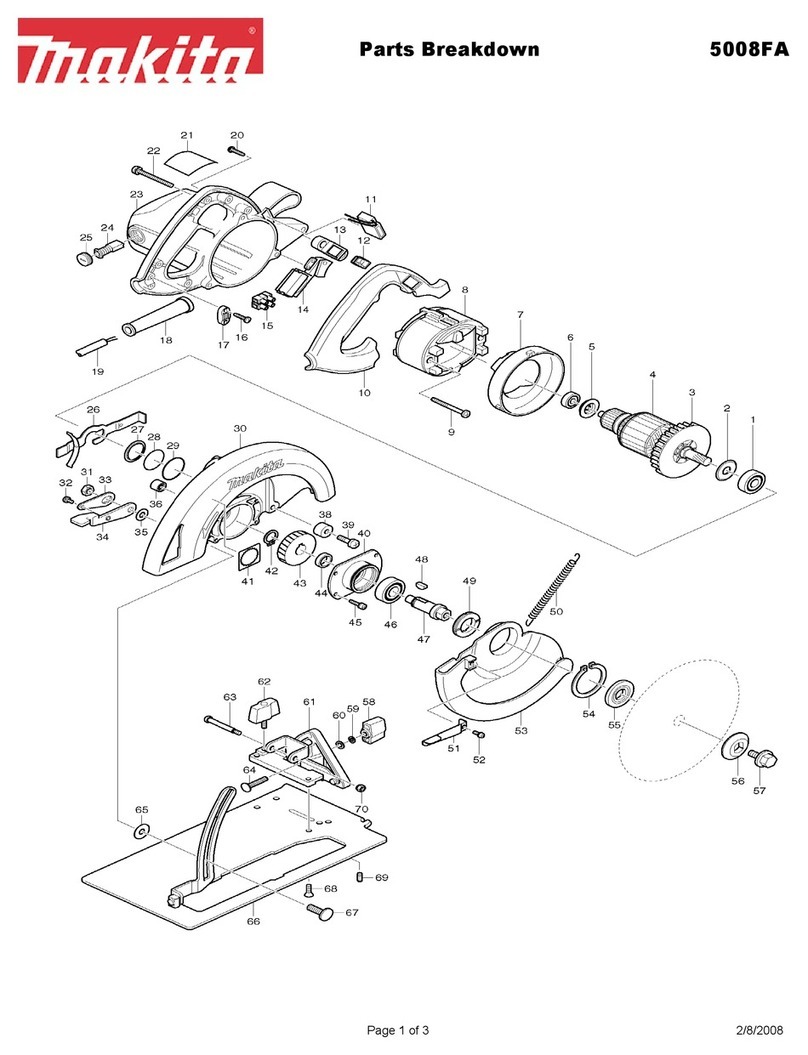

Makita 5008FA Quick start guide

Makita

Makita SP6000J1X User manual

Makita

Makita JR3050T Manual

Makita

Makita BJR181 User manual

Makita

Makita DLW140 User manual

Makita

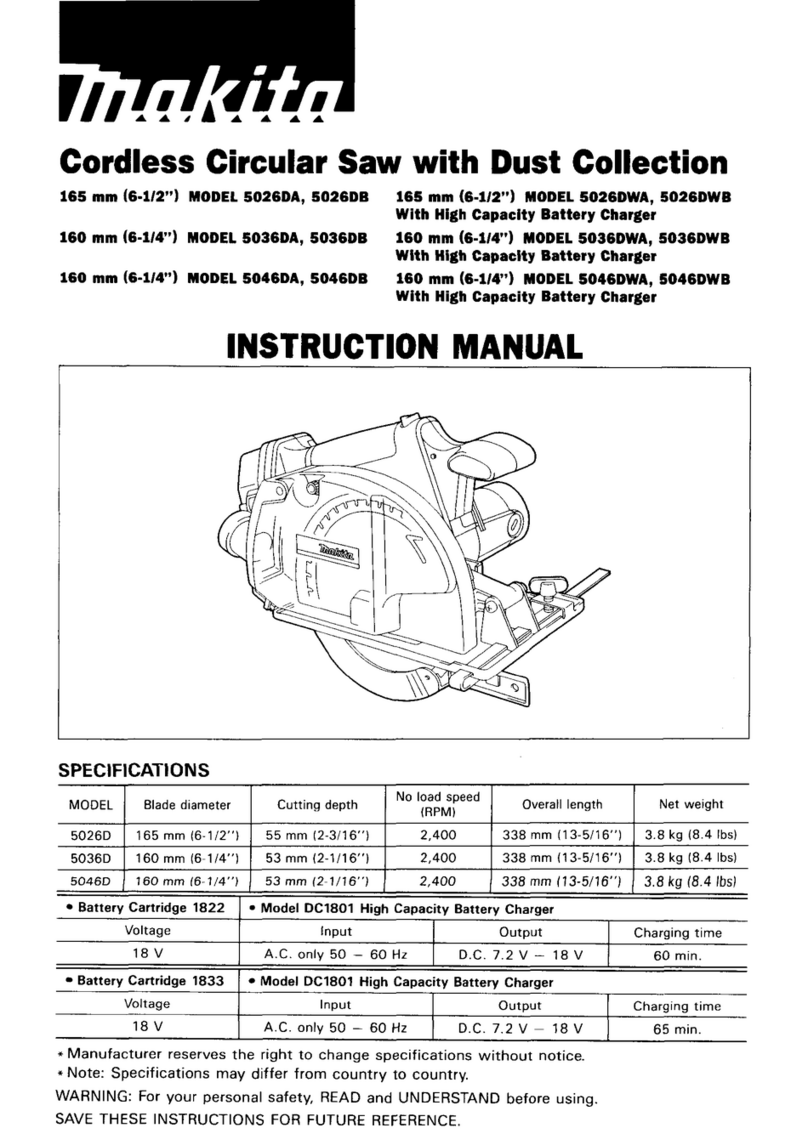

Makita 5026DWA User manual

Makita

Makita SP6000K User manual

Makita

Makita DLS713 User manual

Makita

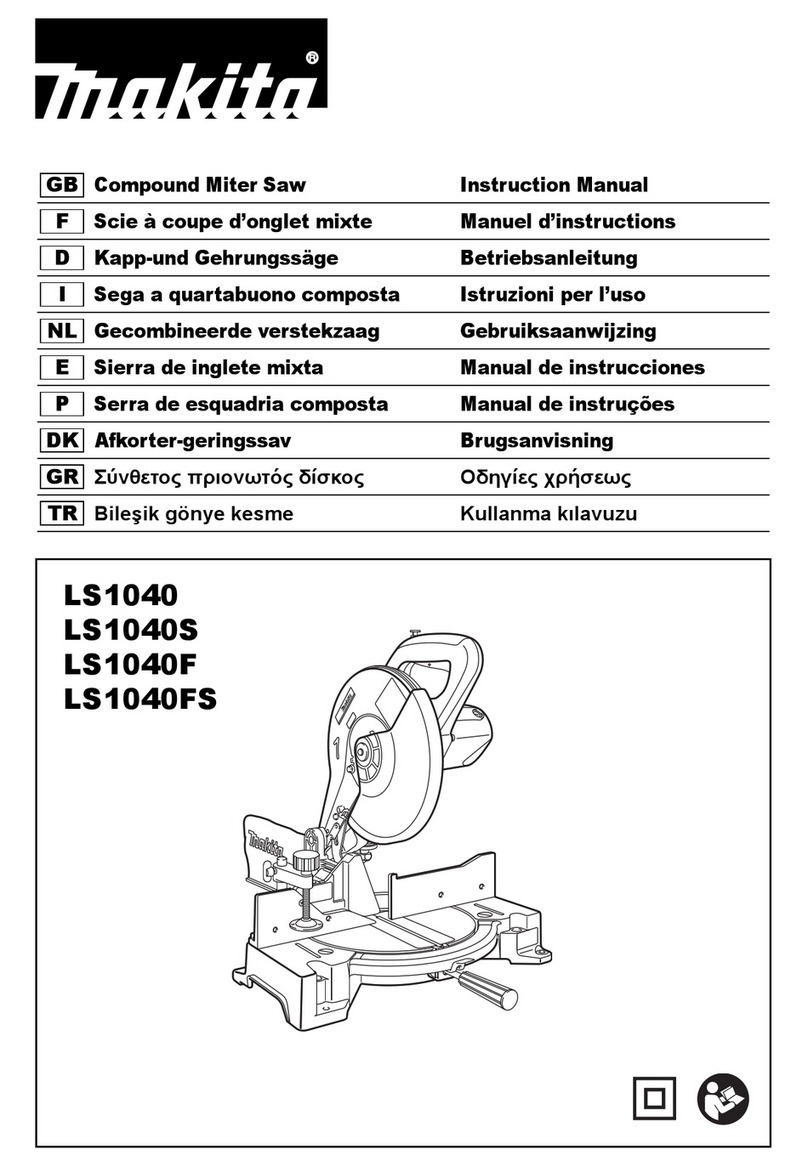

Makita LS1040 User manual

Makita

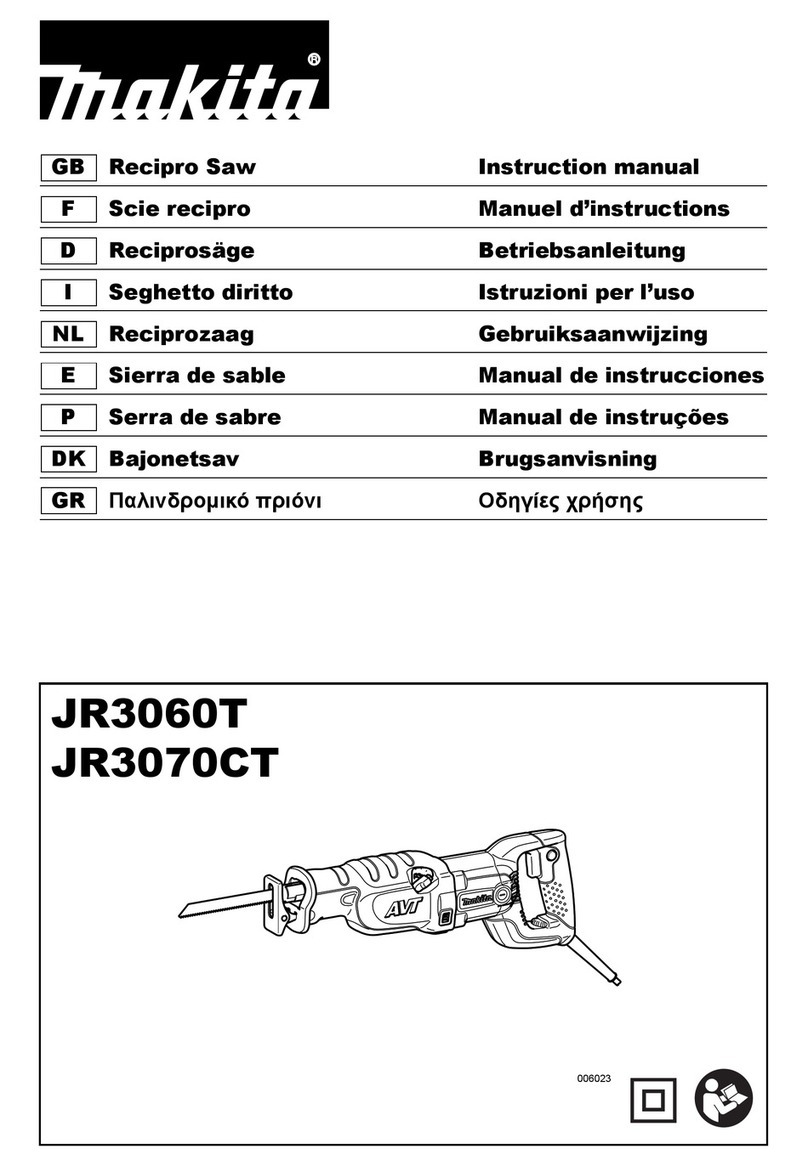

Makita JR3060T User manual

Makita

Makita RJ03 User manual

Makita

Makita 2704N User manual

Makita

Makita LS1018 User manual

Makita

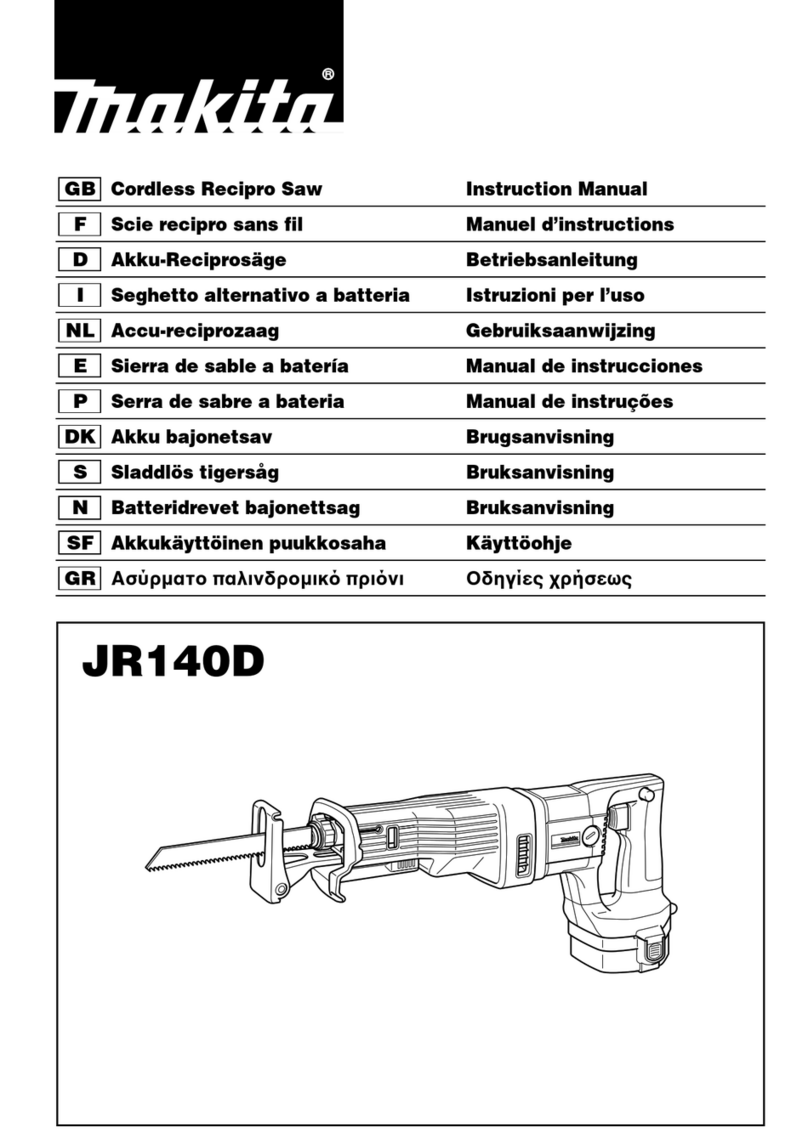

Makita JR140D User manual

Makita

Makita JR3050T User manual