DeZurik WILLAMETTE VBL-2600 User manual

WILLAMETTE VBL-2600

BALL VALVES

Instruction D12001

December 2012

DeZURIK

Willamette VBL-2600 Ball Valves

D12001 Page 2 © 2012 DeZURIK, Inc.

Instructions

These instructions provide installation, operation and maintenance information for Willamette VBL-2600

Ball Valves. They are for use by personnel who are responsible for installation, operation and

maintenance of Willamette VBL-2600 Ball Valves.

Safety Messages

All safety messages in the instructions are flagged with an exclamation symbol and the word Caution,

Warning or Danger. These messages indicate procedures that must be followed exactly to avoid

equipment damage, personal injury or death. Safety label(s) on the product indicate hazards that can

cause equipment damage, personal injury or death.

Safety label(s) on the product indicate hazards that can cause equipment damage, personal injury or

death. If a safety label becomes difficult to see or read, or if a label has been removed, please contact

DeZURIK for replacement label(s).

Personnel involved in the installation or maintenance of valves should be constantly

alert to potential emission of pipeline material and take appropriate safety precautions.

Always wear suitable protection when dealing with hazardous pipeline materials. Handle

valves, which have been removed from service with suitable protection for any potential

pipeline material in the valve.

Inspection

Your Willamette VBL-2600 Ball Valve has been packaged to provide protection during shipment;

however, it can be damaged in transport. Carefully inspect the unit for damage upon arrival and file a

claim with the carrier if damage is apparent.

Parts

Recommended spare parts are listed on the assembly drawing. These parts should be stocked to

minimize downtime. Order parts from your local DeZURIK sales representative, or directly from

DeZURIK. When ordering parts please choose from the following:

If the valve has a DeZURIK APCO nameplate please include the 7-digit part number and 4-digit

revision number (example: 9999999R000) located on the data plate attached to the valve assembly.

Also include the part name, the assembly drawing number, the balloon number and the quantity stated

on the assembly drawing.

If there isn't any nameplate visible on the valve, please include Valve Model number, the part name,

and item number from the assembly drawing. You may contact your local DeZURIK APCO

Representative to help you identify your valve.

DeZURIK Service

DeZURIK service personnel are available to maintain and repair all DeZURIK products. DeZURIK also

offers customized training programs and consultation services. For more information, contact your local

DeZURIK sales representative or visit our website at www.dezurik.com.

DeZURIK

Willamette VBL-2600 Ball Valves

December 2012 Page 3 D12001

Table of Contents

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

Handling and Storage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Fusion/Powder Coated Valves - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Maintenance and Operation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

Lubrication - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Power Supply for Operating Valves- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Troubleshooting- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

DeZURIK

Willamette VBL-2600 Ball Valves

D12001 Page 4December 2012

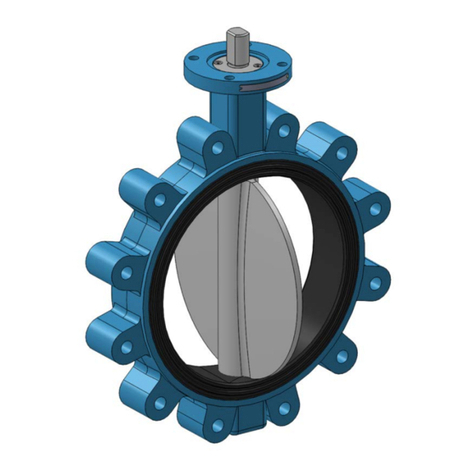

Description (Metal Seated Valves)

General

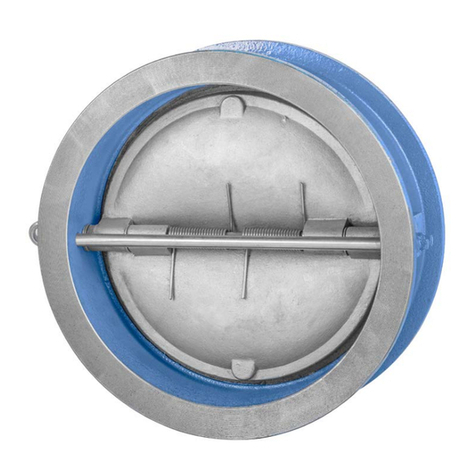

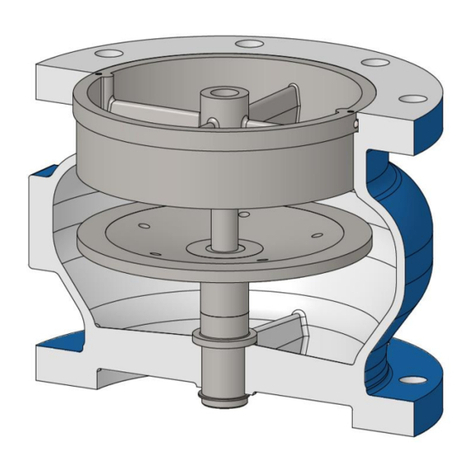

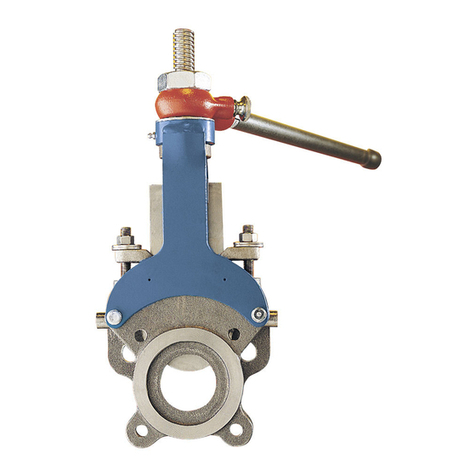

The Willamette VBL-2600 Ball Valve is a plug type, quarter-turn valve with a full-ported circular

waterway through the body and ball plug in the open position. Each ball valve consists of four (4) main

elements: A pressure vessel (body), a rotatable closing element (ball), a torque unit, and an operator.

The "Standard" materials of construction for the body and ball are ductile iron (Ball valve construction is

in complete accordance with AWWA standard C507-11 for ball valves 6-inches through 60-inches with

metal seats per section 4.2.2.2.

Body

The "Standard" body has ANSI B16.1 CL125 or CL250 flanges and houses the ball. The body has

integrally cast trunnions and provides rigid means for supporting the torque unit (without the necessity

of additional supports). There are two (2) pipe connections, one for an air vent and the other for drain.

The body has rigidly attached corrosion resistant metal seat(s). Maximum seat bearing pressure does

not exceed 1,000 lbs/sq inch.

Ball

The ball has bronze bushed trunnions. An extension of one trunnion, called the operating shaft, passes

through a sealing device (O-ring retainer) and connects to the torque unit. The operating shaft is

stainless steel. The sealing device is capable of being removed and having its seaIs replaced without

removing the valve from the line.

The ball has corrosion resistant metal seat(s) rigidly attached and fully adjustable to provide drop-tight

sealing in one direction or both directions, as an option. The ball shaft is designed for a factor of safety

for all combined stresses of at least five to one. Maximum deflection does not exceed 1/6 degree per

foot of unsupported length using a seat coefficient of friction of 0.5 and a bearing coefficient of friction of

0.3.

Torque Unit (Valve Operating Mechanism)

The torque unit employs a traveling crosshead to impart positive rotary movement to the ball by means

of a link and lever connected to the ball shaft. A ball shaft support bearing is supplied on the cover. The

torque unit is designed such that during the first 50 percent of stroke in closing, the flow area is reduced

by approximately 81 percent. The remaining flow area is gradually reduced to a complete shutoff

throughout the last 50 percent of closing stroke. All materials of the torque unit subject to rubbing are of

different hardness. The torque unit is capable of being inspected, lubricated, removed and repaired

without removing the valve from the pipeline.

Handling and Storage

Lifting the valve improperly may damage it. Do not fasten lifting devices to the actuator, ball or through

the seat opening in the body. Lift the valve with slings, chains or cables fastened around the valve

body, or fastened to bolts or rods through bolt holes in the flanges.

If installation will be delayed, place valve indoors in secure, weather tight storage. If temporary outside

storage is unavoidable, make sure a vermin proof rain cover (water shedding tarp, etc.) is secured

around/over the equipment to keep off rain and mud. Skid and set the assembly on a flat, solid, and

well drained surface for protection from ground moisture, runoff and pooled rain water.

DeZURIK

Willamette VBL-2600 Ball Valves

December 2012 Page 5 D12001

Installation

•Before starting installation, the contractor must have an approved drawing showing the

side of the line on which the operator is to be installed.

•Before installation, remove foreign material such as weld spatter, oil, grease, and dirt

from the pipeline.

•Prepare pipe ends and install valves in accordance with the pipe manufacture’s

instructions for the joint used.

Do not deflect the pipe-valve joint. Minimize bending stresses in the valve end

connection with pipe loading.

If excessive seat leakage occurs during start-up, recheck the installation and

eliminate any distortion to the valve body.

•Ensure the valve and pipeline flanges are concentric to ensure proper flange sealing

and seat leakage control.

•Tighten the flange bolts or studs in a crisscross pattern and minimum of four stages.

•Do not anchor support legs or pads of the valve. The integral valve supports are

intended to support the weight of the valve and actuator only. The connecting piping

must be self-supporting and a flexible connector be installed on the valve’s seat side.

•A single seated valve will seal in only one direction. The seating surfaces are on the

downstream or lower pressure side of the closed valve. Higher upstream, pressure in

the valve body cavity of a closed valve pushes the ball towards the downstream body

seat. The flexible metal ball seat provides a tight seal with the body seat. On a double

seated valve, the upstream seat surfaces are not in contact and do not seal.

•Pump stop and check service is a normal pumping condition. Single seated valves

should be used for this service where possible with the seat on the pump side of the

valve.

Fusion/Powder Coated Valves

Valves with fusion/powder coated exterior paint require flat washers to be installed

under the flange nuts when installing the valve to the pipeline flange to prevent the

paint from cracking or chipping.

DeZURIK

Willamette VBL-2600 Ball Valves

D12001 Page 6December 2012

Maintenance and Operation

All valves should be stored in the closed position and should remain closed until they are installed in

the line. The valve should only be opened or closed using the supplied actuator. Do not use any other

manual or mechanical means to open or close the valve. If the ball does not rotate freely – see

troubleshooting section. When the valve is bolted into the line, the bolts should be retightened after

the first week of in-line service. Periodically check the bolting connecting the operator support brackets

to the valve body.

Operator

All bearings and moving parts are carefully lubricated during assembly, and for normal service should

give years of trouble free operation without further maintenance.

Basic Valve and Torque Unit

The basic ball valve is equipped with water lubricated trunnion bearings and requires no maintenance.

The torque unit is lubricated at assembly and for normal service gives years of trouble free

maintenance.

Shaft Seal Replacement (Closed Position)

The operating shaft of the valve is equipped with O-Ring seals. The O-Rings may be replaced while the

valve is installed. The procedure for replacing rings in the closed position is as follows:

Servicing the valve while the pipeline is under pressure can cause personal injury or

equipment damage. Relieve pipeline pressure before servicing the valve.

1. Relieve the pressure in the pipeline and close the valve.

2. Drain oil, if any from the torque unit housing and remove indicator and cover.

3. Tighten up the plug adjusting screw by turning it ½ turn maximum, pushing the ball against the

thrust washers. This accomplishes two things: It seals leakage and it locks the ball in position

4. Remove link pin.

5. Run crosshead to top of stroke in order to get links out of the way.

Accidental operation of power actuator can cause personal injury or equipment

damage. Disconnect and lock out power to actuator before servicing.

6. If the actuator is powered, disconnect and lock out the pneumatic, hydraulic, or electrical power

to prevent accidental operation of the actuator.

7. Loosen clamp bolts in lever and remove lever from operating shaft. Carefully de-burr sharp

edges of dowel pin hole in shaft and all other surfaces over which O-rings will pass during

disassembly and assembly.

DeZURIK

Willamette VBL-2600 Ball Valves

December 2012 Page 7 D12001

Maintenance and Operation (Continued)

8. Remove lock ring from housing and retract O-ring retainer.

9. Install new O-rings, re-insert O-ring retainer and lock ring and re-install lever.

10. After lever is reinstalled; connect power to the actuator, run crosshead back to closed position

making sure that all mechanisms are in proper alignment.

11. Replace link pin cotters (if used) and be sure to brad over.

12. Release adjusting screw just enough so that the ball can turn freely and retighten sealing and

locknut on plug adjusting screw.

Shaft Seal Replacement (Open Position)

The valve can be packed in the open position using the following procedure:

Servicing the valve while the pipeline is under pressure can cause personal injury or

equipment damage. Relieve pipeline pressure before servicing the valve.

1. Relieve the pressure in the pipeline.

2. Drain oil, if any from the torque unit housing and remove indicator and cover.

3. Tighten up the plug adjusting screw by turning it ½ turn maximum, pushing the ball against the

thrust washers.

4. Loosen the clamp bolts in lever and remove key, or dowel.

5. Run crosshead down to closed position.

6. Remove link pin.

7. Run crosshead back to top of stroke in order to get links out of way.

Accidental operation of power actuator can cause personal injury or equipment

damage. Disconnect and lock out power to actuator before servicing.

8. If the actuator is powered, disconnect and lock out the pneumatic, hydraulic, or electrical power

to prevent accidental operation of the actuator.

9. Remove lever from operating shaft. Carefully de-burr sharp edges of dowel pin hole in shaft and

all other surfaces over which O-rings will pass during assembly and disassembly.

10. Remove lock ring and O-ring retainer and install new O-rings using same procedure as

described in repacking valve in closed position.

11. Re-install lever, connect power to the actuator, run cross head back to closed position and

reconnect links. Replace link pin cotter (if used) and be sure to brad over.

DeZURIK

Willamette VBL-2600 Ball Valves

D12001 Page 8December 2012

Maintenance and Operation (Continued)

12. Run complete operating mechanism back up to open position, rekey and tighten up clamp bolts

on lever, making sure that all of the operating mechanisms are properly aligned.

13. Release adjusting screw just enough so that ball can turn freely and retighten sealing and

locknut on plug adjusting screw.

Lubrication

General

Trunnion bronze bushings receive a significant amount of water lubrication from the media itself. For

those ball valves equipped with grease fitting lubrication points on the body assembly – each lubrication

point should be greased with a hand-pump gun (Caution! do not use air-operated grease guns). Use

one of the approved lubricants from Table A.

Table A: Approved Lubricants

Manufacture Type

Mobil Mobilgrease FM221

Fiske Brothers Lubriplate #110

Fiske Brothers Lubriplate # 130A

Richfield Rocolub # 1

Shell Alvania #1

Texaco Marfak # 1

Stewart Warner Co. Alernite Temprite #1

Standard Oil Co., (Ind) Stanolith Grease #42

Ball Valve

Lubricate twice annually (more often if valve is operated frequently or in harsh duty conditions) using

one of the approved lubricants from Table A. Use approximately 4 ounces of grease per bushing per

re-lubrication event. Check with the factory in the event that a special application prevents the use of

the approved lubricants.

Torque Unit

Lubricate twice annually (more often if valve is operated frequently) or any time the cover is removed.

Wipe out old lubricant and replace with new lubricant using one of the lubricants from Table A. Spread

lubricant on the crosshead side members; crosshead guides, leadscrews, all rotating and sliding areas,

bearings, exposed steel or cast iron machined parts, etc. See Table B for recommended amount of

lubricant for the various size units.

Table B: Torque Unit Lubrication Requirements

Unit Size

Amount of Lubricant (lbs.)

T-3000

2 ½

T-2000 & T-1100 2

T-578 & T-315 1 ½

T-176, T-70 & T-22

1

DeZURIK

Willamette VBL-2600 Ball Valves

December 2012 Page 9 D12001

Lubrication (Continued)

If a hydraulic cylinder is provided, Table C shows the recommended hydraulic fluids.

Table C: Hydraulic Fluids

Manufacturer Hydraulic Fluid

Atlantic-Richfied Co. Duro AWS-150

Shell Tellus #32

Standard of California Chevron EP-9

Texaco Rando HD-A

Mobil DTE 24

Castrol Hyspin AW32

Power Supply for Operating Valves

It is essential that a continuous and reliable source of power, whether it be liquid, gas, or electrical be

provided for operating the valve. The line which conveys the power to the controls must be of ample

size so that sufficient pressure and volume can be delivered directly to the power port of the controls.

The differential pressure between the top and bottom of the piston in the actuating cylinder causes the

piston rod to move. It is essential that both the power and exhaust line be of ample size to provide

adequate speed.

The power source must be suitable for cylinder use. Use of a filter or strainer where needed is

recommended. In the case of air, a continuous and reliable source of filtered air is required to operate

the cylinder. The air should be clean and reasonably dry (free from moisture). A lubricator may be used,

if desired for maximum cylinder life. Locate the lubricator as close to the control supply port as practical.

Avoid excessive oil flow settings which flood the components with oil. Reduce settings if oil coalesces

(form pools in the bottom of the lines) or drips from the exhaust port. Carefully evaluate the need for

lubrication prior to installing a lubricator. Most valve installations do not require an exceptional number

of cylinder cycles and the factory pre-lubrication will provide years of service without a lubricator.

Many valve positioners, transducers, and other special controls require that

instrument quality, dry, oil free air is used. Check all special controls for compatibility

with lubricated air prior to its use.

DeZURIK

Willamette VBL-2600 Ball Valves

D12001 Page 10 December 2012

Troubleshooting

Condition Possible Cause Corrective Action

Shaft seal leaks. O-ring is worn. Replace O-ring.

Valve leaks excessively from

one side of the ball to the other.

Foreign matter caught between

seats

Fully open valve to remove

object.

Closed position stop is set

incorrectly. Adjust closed position stop.

Valve body is distorted. Remove stress to valve body.

Loss of media’s seating

pressure. Apply media pressure.

Seat is worn or damaged. Repair seat or replace valve.

Valve leaks at flange joint.

Loose flange bolting. Tighten flange bolting.

Blown flange gasket. Replace flange gasket.

Miss-alignment or damage to

field piping and supports.

Adjust miss-alignment or repair

piping or supports.

Damaged flange face/s or

improper flange connections.

Repair flange, replace valve

body or adjust flange

connections.

Valve does not fully close.

Object is wedged between seat

and ball.

Fully open valve to remove

object.

Closed position stop is not set

correctly. Adjust closed position stop.

Valve does not fully open. Open position stop is not

adjusted correctly. Adjust open position stop.

Valve fails to operate from open

to close position or from closed

to open.

Object is wedged between seat

and ball.

Fully open or close valve to

remove object.

Torque unit low on lubricant. Add lubricant.

Torque unit component failure. Repair or replace torque unit.

Actuator component failure. Repair or replace actuator.

Printed in U.S.A.

Guarantee

Products, auxiliaries and parts thereof of DeZURIK, Inc. manufacture are warranted to the original purchaser for a period of twenty-four (24)

months from date of shipment from factory, against defective workmanship and material, but only if properly installed, operated and serviced

in accordance with DeZURIK, Inc. recommendations. Repair or replacement, at our option, for items of DeZURIK, Inc. manufacture will be

made free of charge, (FOB) our facility with removal, transportation and installation at your cost, if proved to be defective within such time,

and this is your sole remedy with respect to such products. Equipment or parts manufactured by others but furnished by DeZURIK, Inc. will

be repaired or replaced, but only to the extent provided in and honored by the original manufacturers warranty to DeZURIK, Inc., in each

case subject to the limitations contained therein. No claim for transportation, labor or special or consequential damages or any other loss,

cost or damage shall be allowed. You shall be solely responsible for determining suitability for use and in no event shall DeZURIK, Inc. be

liable in this respect. DeZURIK, Inc. does not guarantee resistance to corrosion, erosion, abrasion or other sources of failure, nor does

DeZURIK, Inc. guarantee a minimum length of service. Your failure to give written notice to us of any alleged defect under this warranty

within twenty (20) days of its discovery, or attempts by someone other than DeZURIK, Inc. or its authorized representatives to remedy the

alleged defects therein, or failure to return product or parts for repair or replacement as herein provided, or failure to install and operate said

products and parts according to instructions furnished by DeZURIK, Inc., or misuse, modification, abuse or alteration of such product,

accident, fire, flood or other Act of God, or failure to pay entire contract price when due shall be a waiver by you of all rights under this

warranty.

The foregoing guarantee shall be null and void if, after shipment from our factory, the item is modified in any way or a component of another

manufacturer, such as but not limited to, an actuator is attached to the item by anyone other than DeZURIK, Inc. Factory Service personnel.

All orders accepted shall be deemed accepted subject to this limited warranty, which shall be exclusive of any other or previous Warranty,

and this shall be the only effective guarantee or warranty binding on DeZURIK, Inc., despite anything to the contrary contained in the

purchase order or represented by any agent or employee of DeZURIK, Inc., in writing or otherwise, notwithstanding, including but not limited

to implied warranties.

Metric fasteners should not be used with ASME Class 150/300 bolt holes and flange bolt patterns. If you use metric fasteners with ASME

Class 150/300 bolt holes and flange bolt patterns, it may lead to product failure, injury, and loss of life. DeZURIK Inc. disclaims all liability

associated with the use of metric fasteners with ASME Class 150/300 bolt holes and flange patterns, including but not limited to personal

injury, loss of life, loss of product, production time, equipment, property damage, lost profits, consequential damages of any kind and

environment damage and/or cleanup. Use of metric fasteners with ASME Class 150/300 bolt holes and flange bolt patterns is a misuse that

voids all warranties and contractual assurances. If you use metric fasteners with ASME Class 150/300 bolt holes and flange bolt patterns,

you do so at your sole risk and any liability associated with such use shall not be the responsibility of DeZURIK, Inc. In addition to the

foregoing, DeZURIK’s Manufacturer’s Conditions apply.

THE FOREGOING REPAIR AND REPLACEMENT OBLIGATIONS ARE IN LIEU OF ALL OTHER WARRANTIES, OBLIGATIONS AND

LIABILITIES, INCLUDING ALL WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE OR OF MERCHANTABILITY OR

OTHERWISE, EXPRESSED OR IMPLIED IN FACT OR BY LAW, AND STATE DEZURIK, INC.’S ENTIRE AND EXCLUSIVE LIABILITY

AND YOUR EXCLUSIVE REMEDY FOR ANY CLAIM IN CONNECTION WITH THE SALE AND FURNISHING OF SERVICES, GOODS

OR PARTS, THEIR DESIGN, SUITABILITY FOR USE, INSTALLATION OR OPERATIONS.

Limitation of liability

LIMITATION OF LIABILITY: IN NO EVENT SHALL DEZURIK, INC. BE LIABLE FOR ANY DIRECT, INDIRECT, SPECIAL OR

CONSEQUENTIAL DAMAGES WHATSOEVER, AND DEZURIK, INC.’S LIABILITY, UNDER NO CIRCUMSTANCES, WILL EXCEED THE

CONTRACT PRICE FOR THE GOODS AND/OR SERVICES FOR WHICH LIABILITY IS CLAIMED. ANY ACTION BY YOU FOR BREACH

OF CONTRACT MUST BE COMMENCED WITHIN 12 MONTHS AFTER THE DATE OF SALE.

Sales and Service

For information about our worldwide locations, approvals, certifications and local representative:

250 Riverside Ave. N., Sartell, MN 56377 ● Phone: 320-259-2000 ● Fax: 320-259-2227

DeZURIK, Inc. reserves the right to incorporate our latest design and material changes without notice or obligation.

Design features, materials of construction and dimensional data, as described in this manual, are provided for your information only

and should not be relied upon unless confirmed in writing by DeZURIK, Inc. Certified drawings are available upon request.

Table of contents

Other DeZurik Control Unit manuals

DeZurik

DeZurik PEC User manual

DeZurik

DeZurik BAW AWWA User manual

DeZurik

DeZurik D11040 User manual

DeZurik

DeZurik KGC-MC User manual

DeZurik

DeZurik APCO AVV-140 User manual

DeZurik

DeZurik APCO CSV-1600 User manual

DeZurik

DeZurik VPB V-PORT User manual

DeZurik

DeZurik KLS User manual

DeZurik

DeZurik APCO CVS-6000 User manual

DeZurik

DeZurik APCO CAC-8000 User manual

DeZurik

DeZurik BOS-CL User manual

DeZurik

DeZurik PEC User manual

DeZurik

DeZurik PTW User manual

DeZurik

DeZurik APCO CSD-800 User manual

DeZurik

DeZurik APCO AVV-1800 User manual

DeZurik

DeZurik PPE Series User manual

DeZurik

DeZurik PEC 3650 User manual

DeZurik

DeZurik RCV User manual

DeZurik

DeZurik APCO DAT User manual

DeZurik

DeZurik S2 User manual