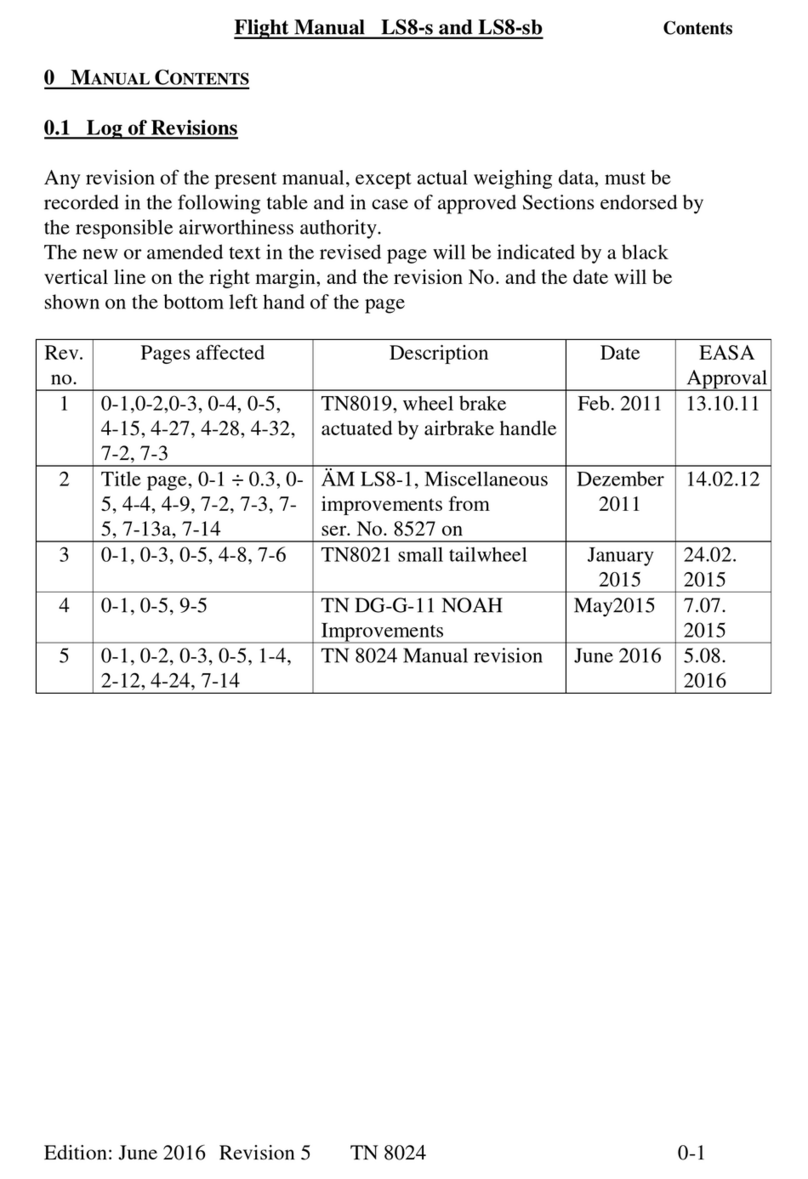

DG Flugzeugbau LS8-st User manual

Other DG Flugzeugbau Aircraft manuals

DG Flugzeugbau

DG Flugzeugbau LS10-s User manual

DG Flugzeugbau

DG Flugzeugbau DG-800S Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-1000T User manual

DG Flugzeugbau

DG Flugzeugbau LS8-s Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-1000S Technical specifications

DG Flugzeugbau

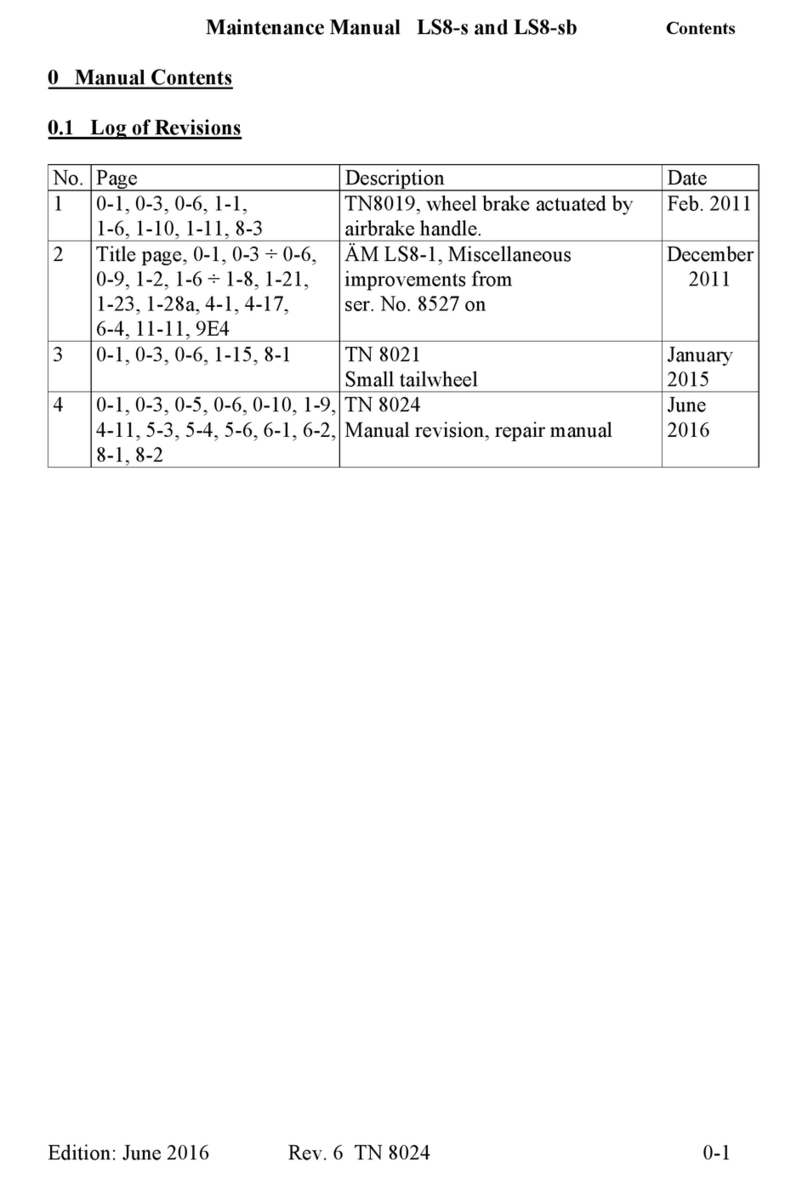

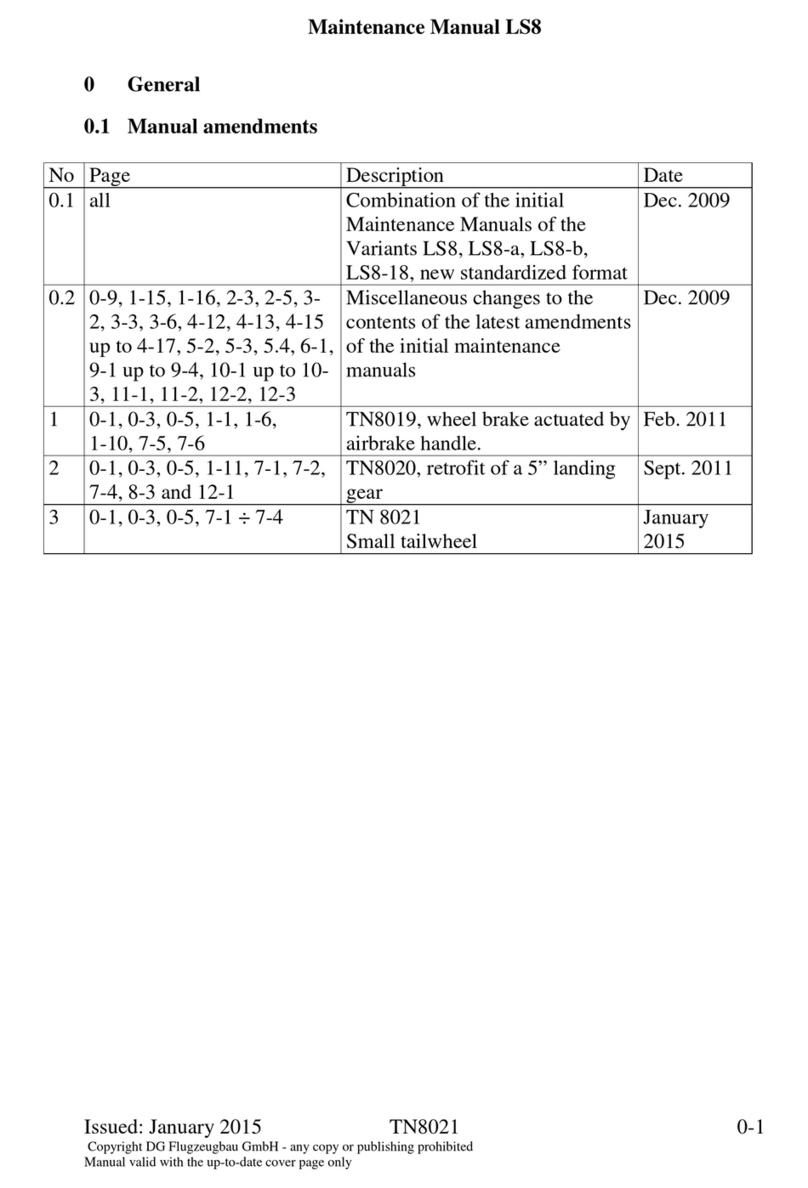

DG Flugzeugbau LS8 Series User manual

DG Flugzeugbau

DG Flugzeugbau DG-1000T User manual

DG Flugzeugbau

DG Flugzeugbau DG-500MB Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-500M User manual

DG Flugzeugbau

DG Flugzeugbau DG-1000 Technical specifications

DG Flugzeugbau

DG Flugzeugbau LS8 Series Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG200 Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-800S Operating instructions

DG Flugzeugbau

DG Flugzeugbau LS8 Series User manual

DG Flugzeugbau

DG Flugzeugbau DG-500 ELAN Orion Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-500 ELAN Orion Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-800B Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-1001M Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-1000 Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-500 ELAN Orion Technical specifications

Popular Aircraft manuals by other brands

Diamond Aircraft

Diamond Aircraft DV 20 E 2022 Airplane Maintenance Manual

Cessna

Cessna 1977 F 172N Service manual

CB model designs

CB model designs Mark II Construction manual

Diamond Aircraft

Diamond Aircraft DA20-A1 Maintenance manual

Flow Paragliders

Flow Paragliders freedom2 XS user manual

Flow Paragliders

Flow Paragliders Cosmos user manual