DG Flugzeugbau LS8-s User manual

Other manuals for LS8-s

1

This manual suits for next models

1

Other DG Flugzeugbau Aircraft manuals

DG Flugzeugbau

DG Flugzeugbau DG-500 ELAN Orion Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-800S Operating instructions

DG Flugzeugbau

DG Flugzeugbau LS8 Series User manual

DG Flugzeugbau

DG Flugzeugbau DG-1000 Technical specifications

DG Flugzeugbau

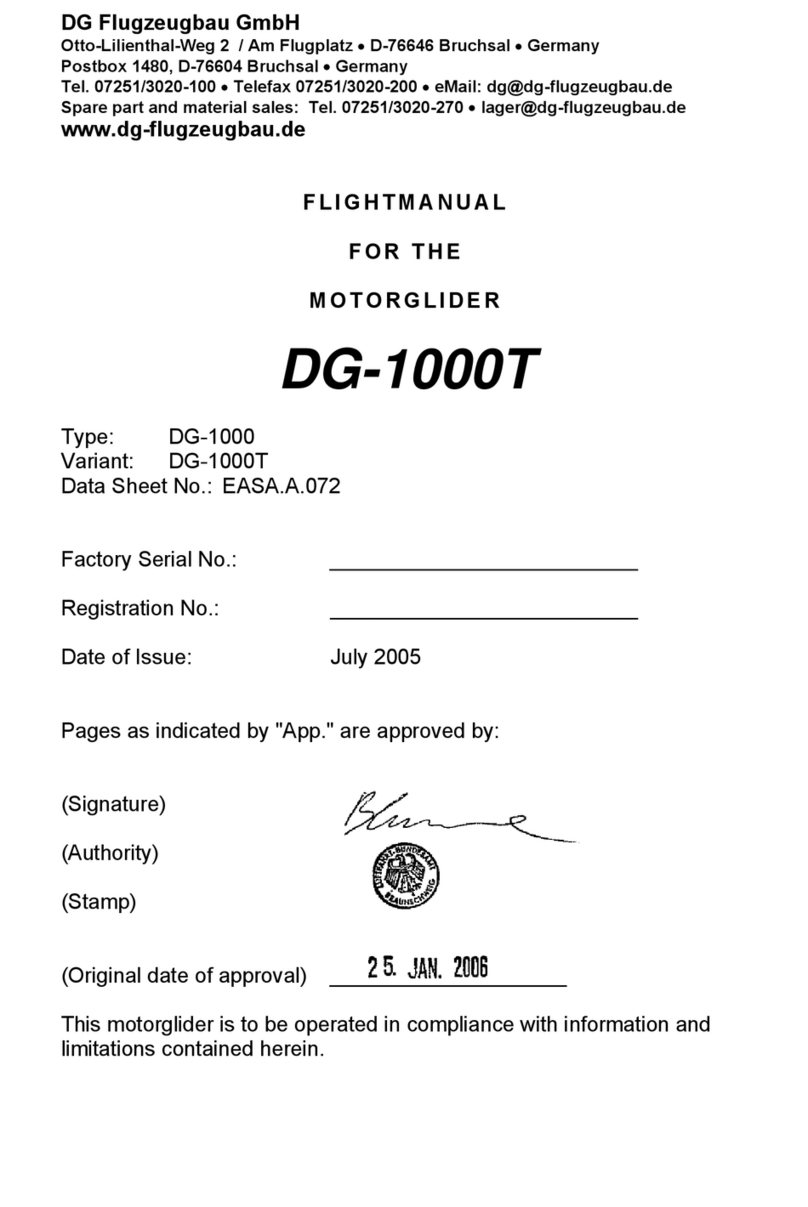

DG Flugzeugbau DG-1000T User manual

DG Flugzeugbau

DG Flugzeugbau DG-500M User manual

DG Flugzeugbau

DG Flugzeugbau DG-1001M Technical specifications

DG Flugzeugbau

DG Flugzeugbau LS8 Series User manual

DG Flugzeugbau

DG Flugzeugbau LS10-s Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-500MB Technical specifications

DG Flugzeugbau

DG Flugzeugbau LS8 Series Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-1000T User manual

DG Flugzeugbau

DG Flugzeugbau DG-1000 Operating instructions

DG Flugzeugbau

DG Flugzeugbau DG-1000S Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-500 ELAN Orion Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-1000 Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-800B Technical specifications

DG Flugzeugbau

DG Flugzeugbau LS10-s User manual

DG Flugzeugbau

DG Flugzeugbau DG-800A Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG200 Technical specifications

Popular Aircraft manuals by other brands

Mcc Aviation

Mcc Aviation STELVIA S owner's manual

Flylight Airsports

Flylight Airsports Skyranger Nynja 912UL Operator and maintenance manual

Kortel Design

Kortel Design Krisis Karré 100 user manual

SKY PARAGLIDERS

SKY PARAGLIDERS METIS 2 Series manual

Piper

Piper Turbo Saratoga PA-32-301T Pilot's manual

NORTH SAILS

NORTH SAILS J/24 Tuning guide