DG Flugzeugbau DG-500M User manual

Other DG Flugzeugbau Aircraft manuals

DG Flugzeugbau

DG Flugzeugbau DG-800S Operating instructions

DG Flugzeugbau

DG Flugzeugbau LS10-s User manual

DG Flugzeugbau

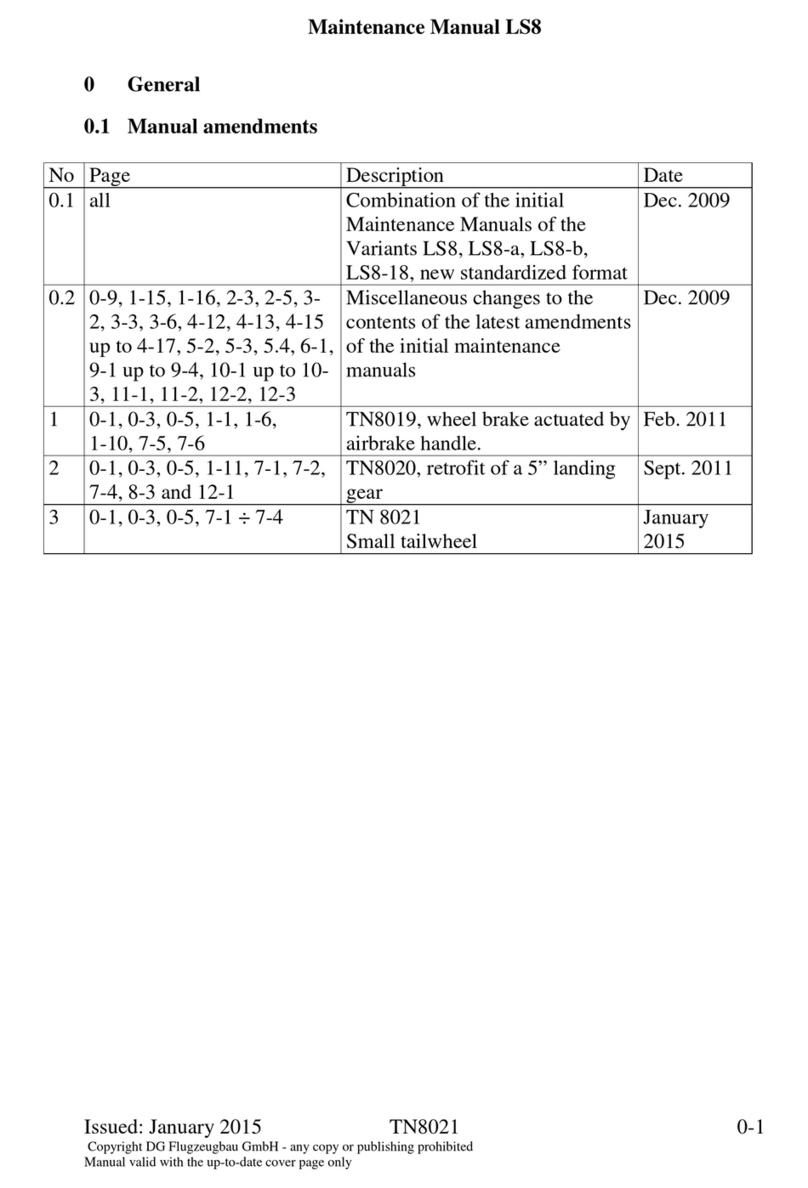

DG Flugzeugbau LS8 Series Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-800A Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-1000S Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-1000T User manual

DG Flugzeugbau

DG Flugzeugbau DG-500 ELAN Orion Technical specifications

DG Flugzeugbau

DG Flugzeugbau LS8 Series User manual

DG Flugzeugbau

DG Flugzeugbau DG-800B Technical specifications

DG Flugzeugbau

DG Flugzeugbau LS8 Series User manual

DG Flugzeugbau

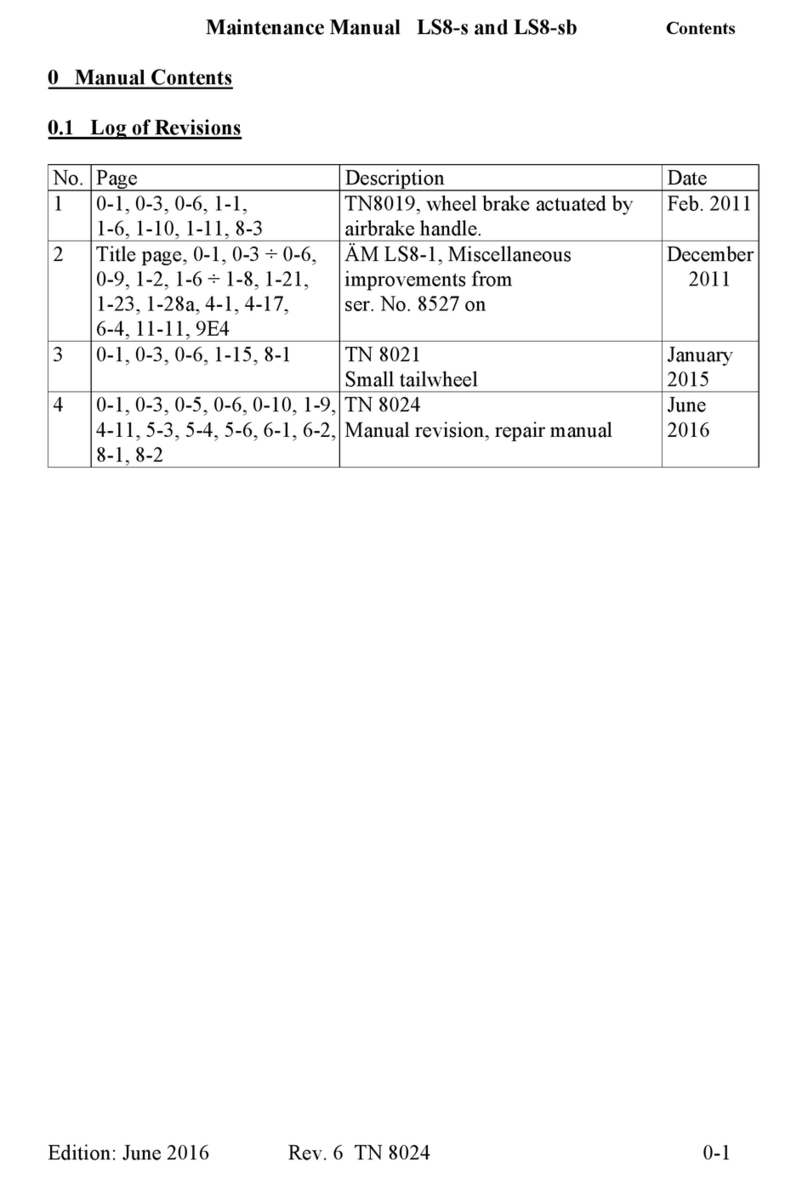

DG Flugzeugbau LS8-s User manual

DG Flugzeugbau

DG Flugzeugbau DG-800A User manual

DG Flugzeugbau

DG Flugzeugbau LS8-st User manual

DG Flugzeugbau

DG Flugzeugbau DG-500MB Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-1000M Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-1000 Operating instructions

DG Flugzeugbau

DG Flugzeugbau DG-800S Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-500 ELAN Orion Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-1001M Technical specifications

DG Flugzeugbau

DG Flugzeugbau LS8-s Technical specifications