DG Flugzeugbau DG-1000T User manual

Other manuals for DG-1000T

1

Other DG Flugzeugbau Aircraft manuals

DG Flugzeugbau

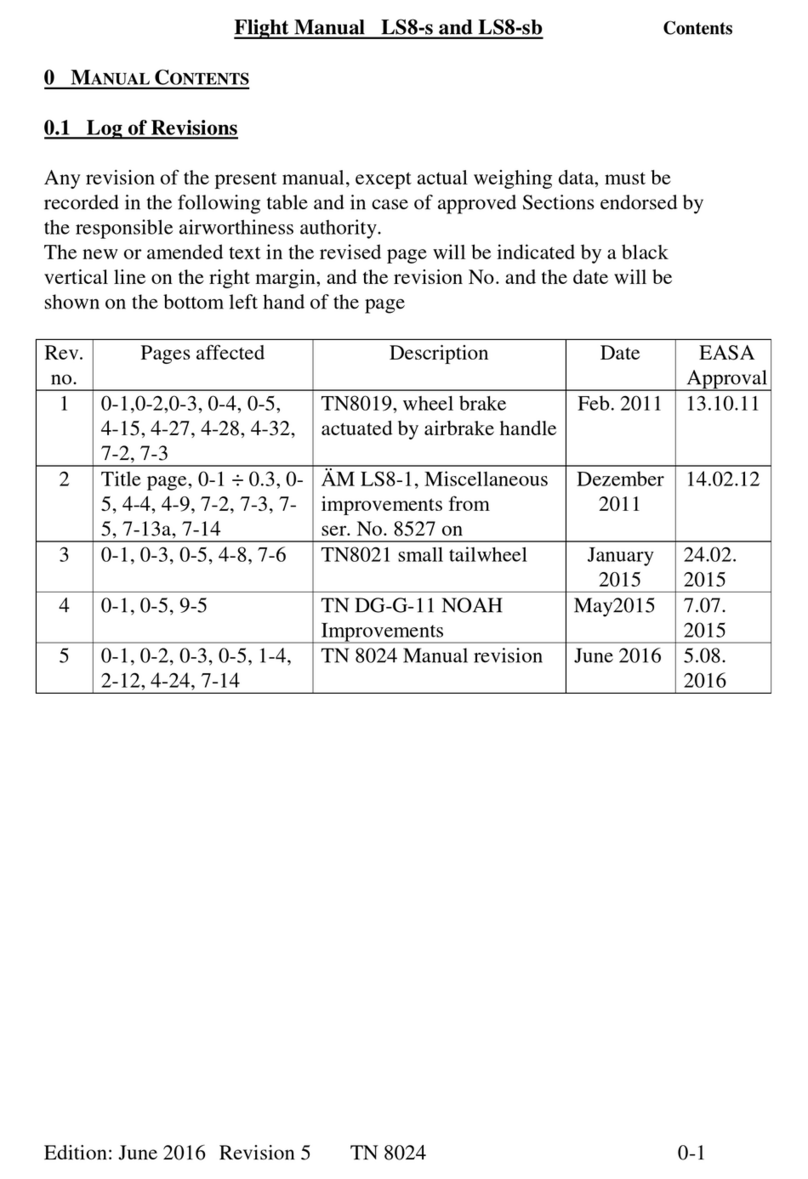

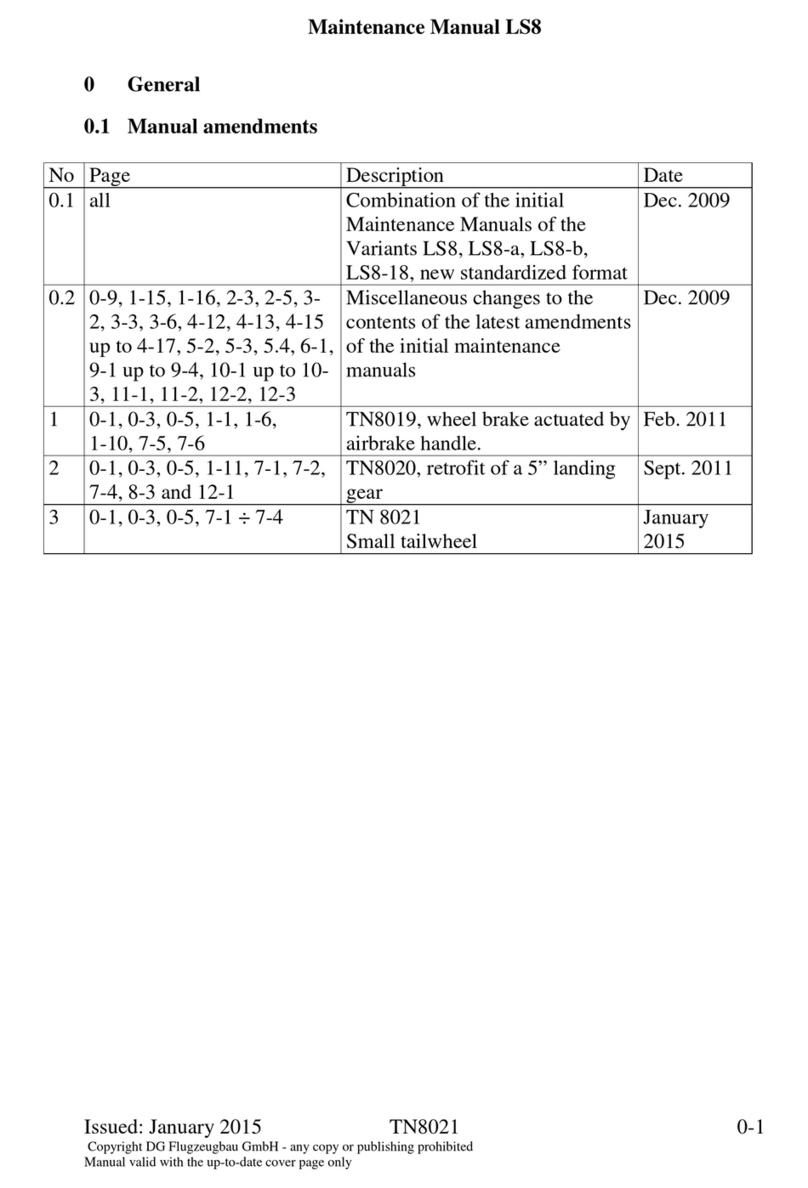

DG Flugzeugbau LS8 Series Technical specifications

DG Flugzeugbau

DG Flugzeugbau LS8 Series User manual

DG Flugzeugbau

DG Flugzeugbau DG-1000S Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-500MB Technical specifications

DG Flugzeugbau

DG Flugzeugbau LS8-st User manual

DG Flugzeugbau

DG Flugzeugbau DG-1000M Technical specifications

DG Flugzeugbau

DG Flugzeugbau LS10-s Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-800A User manual

DG Flugzeugbau

DG Flugzeugbau DG-500 ELAN Orion Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-1000 Operating instructions

DG Flugzeugbau

DG Flugzeugbau DG-1001M Technical specifications

DG Flugzeugbau

DG Flugzeugbau LS10-s User manual

DG Flugzeugbau

DG Flugzeugbau DG-500 ELAN Orion Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-1000 Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-1000 Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-800A Technical specifications

DG Flugzeugbau

DG Flugzeugbau DG-1000T User manual

DG Flugzeugbau

DG Flugzeugbau DG-500M User manual

DG Flugzeugbau

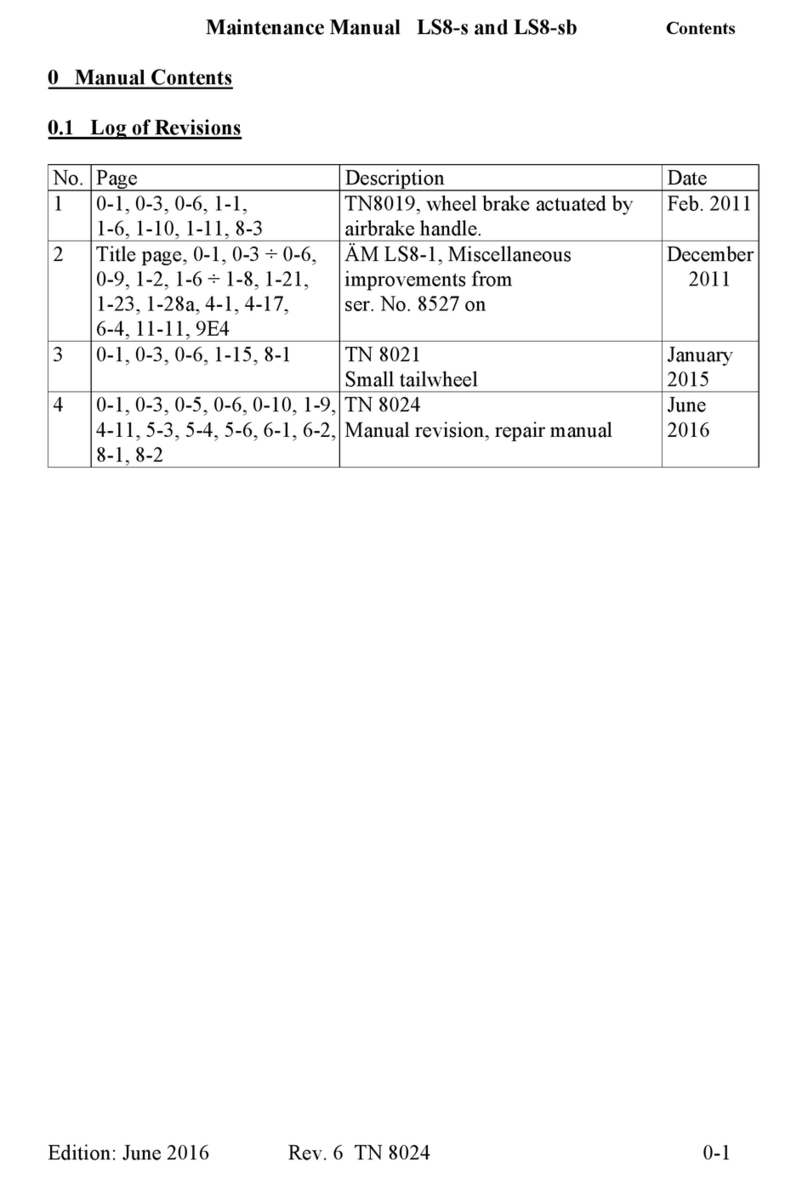

DG Flugzeugbau LS8-s User manual

DG Flugzeugbau

DG Flugzeugbau DG-800S Operating instructions

Popular Aircraft manuals by other brands

Aquila

Aquila A211 Pilot operating handbook

Squirrel

Squirrel Aura 2 user manual

BOMBARDIER

BOMBARDIER SD3-60 Maintenance manual

EVEKTOR-AEROTECHNIK

EVEKTOR-AEROTECHNIK EV-97? EUROSTAR ?model 2000 version R Pilot operating handbook

Aviation Artur Trendak

Aviation Artur Trendak TERCEL Pilot operating handbook

Cessna

Cessna CITATION MUSTANG operating manual

Mooney

Mooney M20R - Ovation AIRPLANE FLIGHT MANUAL SUPPLEMENT

Reims Aviation

Reims Aviation Reims F 172 N Flight manual

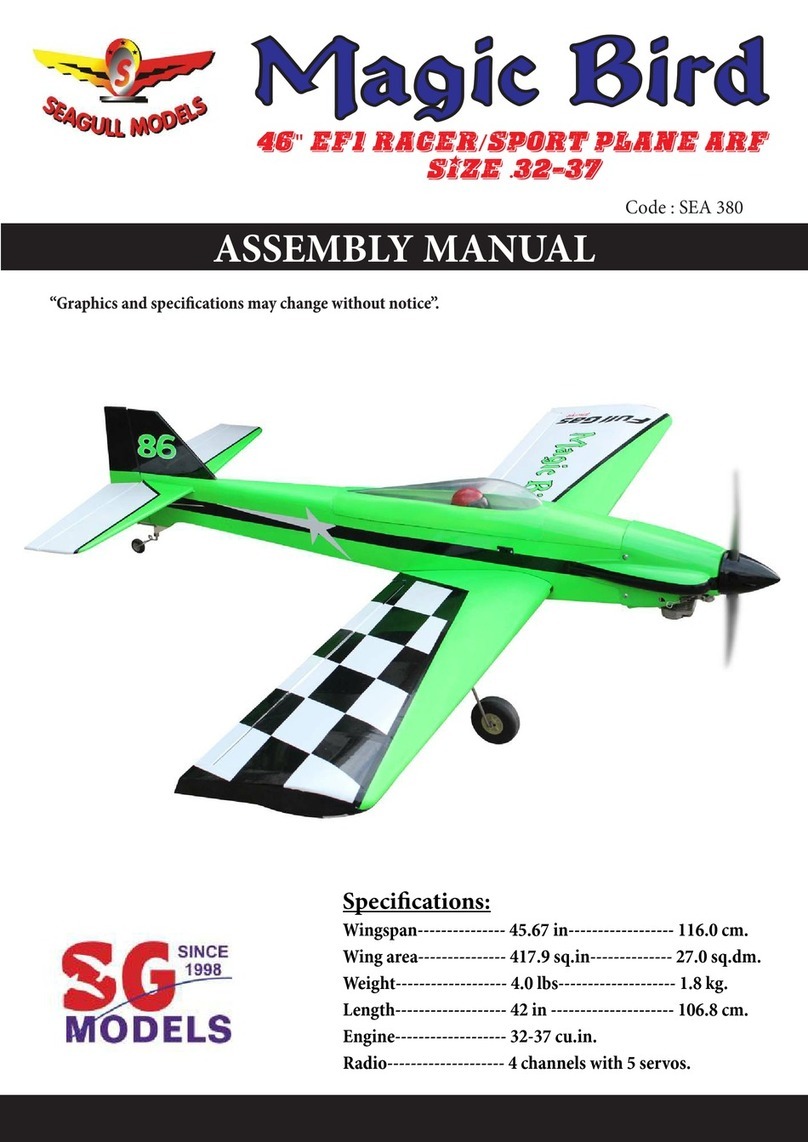

ROBBE

ROBBE BOO 2694 Instruction and user's manual

Piper Aircraft Corporation

Piper Aircraft Corporation Cherokee Lance PA-32R-300 Handbook

Nova

Nova MENTOR 4 manual

Opale-Paramodels

Opale-Paramodels Trike M user guide