DGFLOW STEADYPRES 2.0 M/M 8.5 User manual

25

SAFETY STANDARDS

Safety important instructions.

This symbol warns that failure to comply with the prescription leads

to a risk of electric shocks.

This symbol warns that failure to comply with the prescription leads to a

risk of injury/damage to persons/objects.

Before installation and use of the product:

- read this manual completely and thoroughly

- Check that the nameplate data are those desired and appropriate to the system,

and in particular that the rated current of the motor is compatible with the rated

current of the inverter

- Installation and maintenance must be carried out by qualified staff, responsible

for performing the hydraulic and electric connections according to the applicable

Standards in force

- The manufacturer declines all responsibility for damage deriving from improper

use of the product and is not liable for damage caused by maintenance or repairs

that are carried out by unqualified staff and/or using non-original spare parts

- The use of non-original spare parts, tampering or improper use, make the

product warranty null and void.

During first installation or when carrying out maintenance make sure that:

- the electric power supply network is not live

- The power supply network is equipped with protections and in particular of high-

sensitivity differential switch (30 mA in class A for domestic application, class

B for industrial applications) and grounding comply with the Standards.

- Before removing the inverter cover or starting interventions on it, the system

must be disconnected from the mains electricity and you must wait for 5 mins

until the intermediate circuit condensers, have the time to discharge via the built-

in discharge resistors.

- do not disconnect the pumps if STEADYPRES is in operation; before you

disconnect the pumps, stop the control and disconnect the power supply.

- WARNING: out of service (flashing red LED) STEADYPRES remains in tension;

prior to any work on the pump or inverter is required, cut off power from the

group.

Emergency stop

An emergency stop can be performed while the inverter is running, by pressing the

START/STOP key.

In parallel inverters installations, only the MASTER inverter stops the whole system.

EN

26

INDEX

- Safety standards …………………………………………………………. 25

PART 1 – QUICK INSTALLATION GUIDE

o

Preliminary checks 27

o

Installation and hydraulic connections 27

o

Power connections 28

o

Signal connections 29

o

Starting-up 30

o

Access to main menu 30

o

Access to parameters 30

o

MENU structure 31

o

BASIC parameters 32

Set pressure quick adjustment 32

o

ADVANCED parameters 33

o

Display the operating parameters 35

o

Test 36

o

Priming and starting up 36

o

Connection of inverter MASTER and SLAVE 36

o

Alarms 37

- PART 2 – OPERATOR’S AND MAINTENANCE MANUAL

o

General remarks 38

o

Working limits 39

o

Technical data 39

o

Dimensions and weight 40

o

Product identification code 40

o

Surge tank 40

oInstallation (for connections see

QUICK INSTALLATION GUIDE

) 41

o

Self-limiting overload 41

o

Connection of the submersible single-phase motor 41

o

Starting up 42

o

Light signals 42

o

Menu inspection (INSP) 42

o

Troubleshooting 43

o

Maintenance 44

Replacement of the pressure sensor 44

Calibration of the pressure sensor 45

Fitting the expansion board 45

o

Spare parts diagram 46

o

Warranty 47

o

Disposal 47

o

Declaration of Conformity 47

EN

27

PART 1 - QUICK INSTALLATION GUIDE

PRELIMINARY CHECKS

During the initial installation and maintenance, make sure that ends of the line wires are not

live.

During the initial installation and maintenance, make sure that the system is not under

pressure

to ACCESS THE DRIVE WIRING, open the front cover as shown on p. 5

DO NOT OPEN INVERTER COVERS, except for the connector cover

Models T / T (three-phase IN / three-phase OUT) do not have the switch on board, for these

models the inverter supply line must be protected in accordance with the regulations

- Install the inverter in a place:

oprotected from the elements

oventilated, free from excessive humidity or excessive dust

oas close as possible to the pump

omake sure that does not receive harmful vibrations or mechanical stress from connected

pipelines

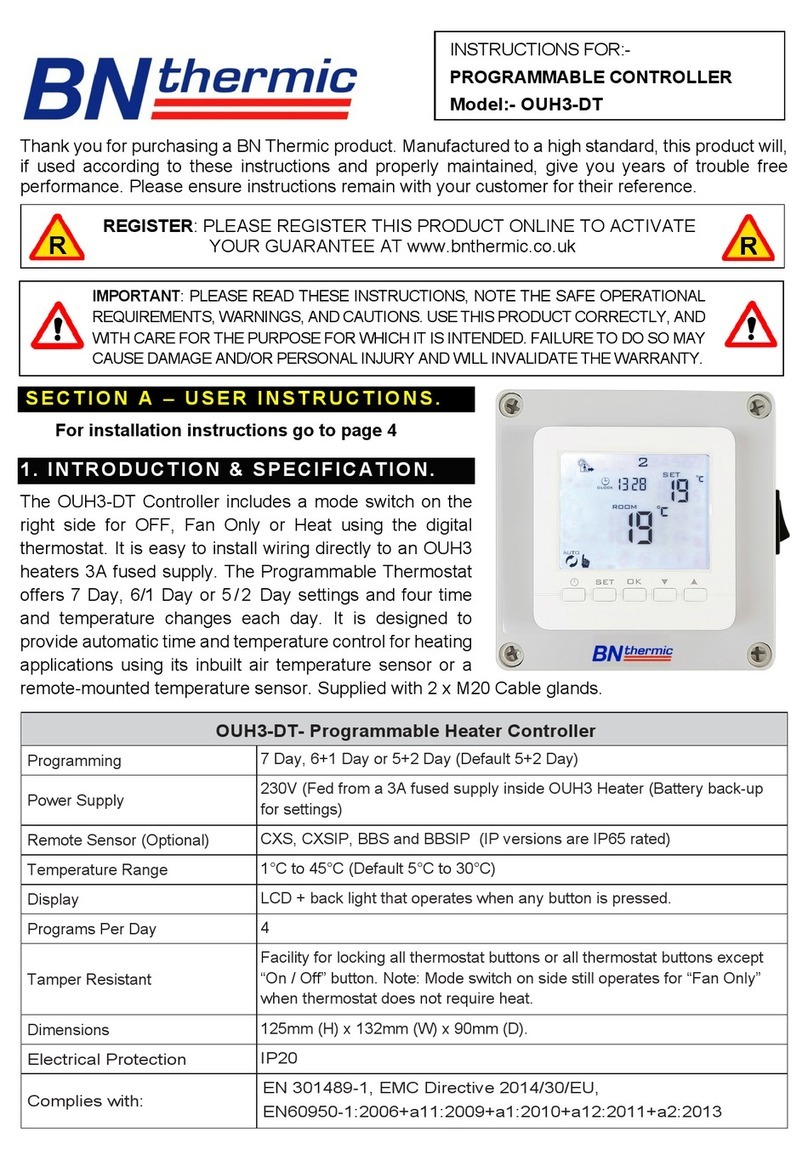

- Control panel:

1- START/STOP button

2- Red LED (power)

3- Green LED (status)

4- Display

5- SET button

6- Confirm button

7- Scrolling UP / DOWN

/ RIGHT / LEFT

INSTALLATION AND HYDRAULIC CONNECTIONS

OUT

IN

OK

Install in a

vertical

position

NO

Do not install

in a horizontal

position

O-RING

NO SEALING

NO CANAPA

NO TEFLON

O-RING

Do not use

sealant in the

three-pieces

joint; are

already

equipped

with O-Ring

The freezing of the

liquid contained in the

inverter body causes

irreversible damage

to the inverter

1

3

4

5

6

7

2

28

POWER CONNECTIONS

Open the side cover

(4 screws)

Wire the cables as indicated in the

diagrams below:

A = inverter supply cable

B = output motor cable

Insert the connector and close

the side cover.

CAUTION : to overcome problems associated with long cables (between Inverter

and pump motor) , evaluate the application of inverter output sinusoidal filter. It aids

smooth running of motors eliminating negative effect of voltage peaks

GND

L

N

GND

V

W

U

LINE

MOTOR

N

L

SINGLE-PHASE IN (line)

SINGLE-PHASE OUT (motor)

( M / M )

Pump supply voltage:

230 V single-phase

(or 115 V single-phase)

GND

N

L

GND

LINE

MOTOR

U

W

V

SINGLE-PHASE IN (line)

THREE-PHASE OUT (motor)

( M / T )

Pump supply voltage:

230/400 V three-phase

Motor connection : DELTA

S

V

U

W

GND

R

LINE

T

GND

MOTOR

THREE-PHASE IN (line)

THREE-PHASE OUT (motor)

( T / T )

Pump supply voltage:

230/400 V three-phase

Motor connection : STAR

A

B

29

SIGNAL CONNECTIONS

Expansion board: is located in the back of the inverter (see fig. below)

1

2

3

4

5

6

7

8

9

10 JP3

JP4

JP5

Terminal clamp operation description:

10: not connected

9: RS 485 +

8: RS 485 -

7: not connected

6: not connected

5: level input

4: GND

3: NC output signal

2: comune C

1: NO output signal

JP3: bridged, no function

JP4: bridged, no function

JP5: no function

- LEVEL SIGNAL CONNECTION

10

9

8

7

6

5

4

3

2

1

(or other input signal)

Connect the signal cable to clamps

4 e 5

In applications with parallel inverters,

the wiring must be carried out on the

MASTER

- RS485 SIGNAL CONNECTION

10

9

8

7

6

5

4

3

2

1

10

9

8

7

6

5

4

3

2

1

10

9

8

7

6

5

4

3

2

1

Connect the terminals

n°8 of the inverters in

parallel (RS 485 –)

Connect the terminals

n°9 of the inverters in

parallel (RS 485 +)

as shown aside.

- ALARM SIGNAL CONNECTION

(In applications with parallel inverters, the wiring must be carried out on the MASTER)

10

9

8

7

6

5

4

3

2

1

Logic NC

(normally

closed)

Connect the

signal cable to

terminals 2 and 3

10

9

8

7

6

5

4

3

2

1

Logic NO

(normally

open)

Connect the

signal cable to

terminals 1 and

2

The maximum load for connection is 2 A at 250 Vac

30

STARTING UP

Switch on

(the switch is

not present

in models

T/T)

and wait the

STARTING

time (ab. 10

sec.)

By pressing

the button

START

STOP

you put

IN SERVCE

OUT OF SERVICE

the inverter.

ACCESS TO MAIN MENU

MAIN MENU

BASIC MENU

parameters

BASIC PARAMETERS for the configuration of the drive.

ADVANCED MENU

parameters

ADVANCED PARAMETERS for the detailed configuration of

the drive.

INSPECTION MENU

parameters

INSPECTION PARAMETERS, display the hours of work, the

number of starts, alarm history, etc..

TEST

mode

(only in

OFF

mode)

TEST mode allows you to start and stop the pump in manual mode (START

/ STOP button) and change the frequency in steps of 1 Hz.

It also allows to control the operating parameters of the motor and inverter.

WARNING: DURING MANUAL OPERATION, AUTOMATIC CONTROLS

ARE EXCLUDED, AND THE OPERATOR MUST AVOID ANY

INCORRECT OPERATION.

ACCESS TO PARAMETERS

BASIC

ADV

INSP

TEST

To ACCESS the

four main MENU

Press the SET

button for 3 sec.

To SCROLL the 4

MAIN MENU

use the buttons

To ACCESS and

EXIT the MAIN

MENU

use the buttons

To MODIFY the

parameters

use the buttons

To SCROLL the

parameters

use the buttons

To ENTER and EXIT

the parameters

use the buttons

31

MENU STRUCTURE

SET

BASIC

P SET PRESSURE

2P SECOND SET PRESSURE

A MOTOR CURRENT

RO MOTOR DIRECTION OF ROTATION (models with three-phase output)

ADV

d DIFFERENTIAL PRESSURE FOR RESTART

MF NOMINAL MOTOR FREQUENCY

LF MINIMUM OPERATION FREQUENCY

HF MAXIMUM OPERATION FREQUENCY

Td STOP DELAY FOR DRY RUNNING

PF MINIMUM POWER FACTOR (only T/T models)

TPF STOP DELAY FOR POWER FACTOR (only T/T models)

TP RESTART INTERVAL FOR DRY RUNNING

TF STOP DELAY FOR NO FLOW

RF INVERTER REACTIVITY

FS MODULE SWITCHING FREQ

US NO GRIP STARTUPS

EI INPUT SIGNAL

EO OUTPUT SIGNAL

AI RECYCLE FUNCTION

AT RECYCLE ACTIVATION TIME

W INVERTER ADDRESS

V MAINS POWER SUPPLY VOLTAGE

Pd iDRY PRESSURE (%)

FM FLAT MODULATION

SET.F RESTORE FACTORY SETTINGS

INSP

WH OPERATING HOURS

TH TOTAL OPERATING HOURS

NS NO. START-UPS

SH AVERAGE NO. START-UPS

E1 LAST FAULT

E1H TIME OF LAST FAULT

……..

E4 FOURTH LAST FAULT

E4H TIME OF FOURTH LAST FAULT

EE ERROR RESET

TEST

32

BASIC PARAMETERS

The basic parameters for the configuration of the inverter must necessarily be set during installation

Param. description m.u.

Default

Min Max

Step

BAS

IC P 3.5 SET

PRESSURE

(bar)

Sets the constant

working pressure in the

system.

bar 3,5 1 10 0,1

psi 50 15 130

1,5

2P 2.5 SECOND SET

PRESSURE

(bar)

Sets a second working

pressure. To activate

configure parameter EI in

ADV. parameters.

bar 2,5 1 10 0,1

psi 35 15 130

1,5

A 6.0 MOTOR

CURRENT

(A)

Sets the motor rated current at the inverter output (rated

current of the motor)

At low supply voltages, the current set should leave a margin

(eg. + 15%) to compensate for the low voltage.

m.u. Default Min Max Step

M/M 8.5

A

8.5

1

8,5

0,1

M/M 11

A

11

1

11

0,1

M/M 16

A

16

1

16

0,1

M/T 7

A

7

1

7

0,1

M/T 12

A

12

1

12

0,1

T/T 6

A

6

1

6

0,1

T/T 8

A

8

1

8

0,1

RO

MOTOR DIRECTION

OF ROTATION ONLY FOR THREE-PHASE OUTPUT - Set the direction

of rotation of the three-phase motor (CW / CCW)

Set pressure quick adjustment

To increase 0,1 bar press

SIMULTANEOUSLY

To decrease 0,1 bar press

SIMULTANEOUSLY

display the firmware version (FW)

To display the FW version of the

CONTROL BOARD (FWI) and the

POWER BOARD (FWP)

Bring

STEADYPRES out

of service (OFF)

Press

simultaneously

P_3.2

P_3.

3

ENTER

P_3.

1

ENTER

33

ADVANCED PARAMETERS

Listed below the ADVANCED PARAMETERS for the configuration of the inverter

Param. description u.m. Default Min Max Step

ADV

d 0.40

DIFFERENTIAL

PRESSURE

FOR RESTART

Sets the difference between the

selected pressure (SETPOINT)

and the effective restart pressure

bar 0,5 0,4 1,0 0,1

psi 6 6 15 1,5

MF 50

NOMINAL

MOTOR

FREQUENCY

Sets the nominal frequency of the

motor

The set value MUST be the same

as the value indicated on the

motor plate

Hz 50 50 60 -

LF30

MINIMUM

OPERATION

FREQUENCY

Sets the minimum operating

frequency

Hz 30 25 40 1

HF 50

MAXIMUM

OPERATION

FREQUENCY

Sets the maximum operation

frequency.

CAUTION!! Increasing the

maximum frequency above the

nominal frequency may cause

significant motor overload.

Hz MF MF-

5

MF

3

1

Td 10

STOP DELAY

FOR DRY

RUNNING

Sets the pump stop delay under

dry running conditions

CAUTION: high values of the stop

delay may damage the pump

sec 10 1 100

1

PF .50

MINIMUM

POWER

FACTOR

(only T/T

models)

Sets the minimum value for the

power factor below which the inverter

stops the pump.

By setting the minimum power factor

value, read the value of the motor

running with closed valves and

deducting 0.03 to it;

- 0.50 0.50 0.99 0.01

TPF 0

STOP DELAY

FOR POWER

FACTOR

(only T/T mod )

Sets the time delay before the

drive will perform the minimum

power factor alarm.

Setting the value to 0 (zero)

disables this feature.

sec 0 0 3 1

TP10

RESTART

INTERVAL

FOR DRY

RUNNING

Sets the interval between two

successive automatic attempts to

restart following stops for "dry

running"

Setting the value to “0” excludes

attempts for automatic restarts

min

10 0 100

1

TF 3 STOP DELAY

FOR NO FLOW

Sets the pump stop delay under

no flow conditions

sec 3 1 15 1

RF 4 INVERTER

REACTIVITY

Sets the inverter response speed

to pressure changes

The response value selected

depends on the characteristics of

the system

- 3 1 5 1

34

Param. description u.m. Default Min Max Step

ADV

FS 10

MODULE

SWITCHING

FREQ

Sets the switchover frequency for the

power module.

In case of long power cable, without a

sinusoidal filter, set this value at the

minimum

kHz 8 4 12 2

US 0 NO GRIP

STARTUPS

Sets the interval between two

consecutive automatic “no grip” start-

ups (When the pump will be inoperative

for a long).

Setting the value to “0” disables the

function.

min 0 0 999

1

EI 0

INPUT

SIGNAL Sets the digital input FUNCTION (clean

contact type)

- 0 0/ 1/ 2/ 3/ 4/ 5

EI = 0: NO FUNCTION; the input state is ignored

EI = 1: WATER LEVEL; Level signal input with NC logic

EI = 2: EXT ENABLE; Start and disabling by external signal (NC)

EI = 3: PRESS SET 2; enabling the second pressure level SETPOINT2 (NC).

EI = 4: EXTERNAL LEVEL SIGNAL INPUT with NC logic; replaces the signal from

the non-ret rn valve.

EI = 5: ALARM RESET SIGNAL INPUT

EO 0 OUTPUT

SIGNAL

Sets the digital output FUNCTION

(clean contact type)

- 0 0/ 1/ 2/ 3

Max 2 A @ 250 Vac

Max 1 A @ 30 Vdc

EO = 0: NO FUNCTION; the state of the output is never activated.

EO= 1: ALARM OUTPUT; condition of stop due to fault.

EO = 2: PUMP OPERATING OUTPUT; there is at least one operating pump.

EO = 3: recirculation; activates the relay output time intervals defined by param. AI

AI 60 RECYCLE

FUNCTION

Sets the output activation interval (clean

contact type) configured as recycle

function (Eo=3)

min 60 1 999

1

AT 10 RECYCLE

TIME

Sets the duration of the activation of the

output signal (clean contact type)

sec 10 1 999

1

W NC INVERTER

ADDRESS

Activates communication between two

or more inverters, defining the function

of each unit: MS (MASTER unit) , S1/S2

(SLAVE unit), NC (operation with a

single inverter)

- NC NC/ MS/ S1/ S2

V 230

MAINS

POWER

SUPPLY

VOLTAGE

Sets the mains power supply voltage.

230 V for single phase power supply

versions

400V for three phase power supply

versions

V

Pd 70 iDRY

PRESSURE

(%)

Sets the minimum pressure value

(expressed as % of the SET pressure)

that must be reached in no flow,

otherwise an alarm of dry running

% 70 10 100

1

FM

FLAT

MODULATI

ON

Enable / disable the FLAT mod lation; FLAT

mod lation red ces the heating of the

power components of the inverter

- 1 0 1 1

SET.F RESTORE

FACTORY

SETTINGS

Base and Advanced menu will be factory restored. CAUTION: DO NOT USE

THIS FUNCTION in the pumping unit UPV-OS as these models have a

special setting. To reset the factory parameters, press the ENTER key and

hold until "OK" appears on the display (ENTER

****

OK)

35

DISPLAY THE OPERATING PARAMETERS

During

operation To display the parameters on the

display Scroll the

parameters

through the

keys

Pressing the key You go back to the system pressure (only

for MASTER inverter)

Display Description m.u..

P 3.2 SYSTEM PRESSURE

Displays the system pressure (only for MASTER inverter)

bar

F 45 OPERATING FREQUENCY

Displays the motor revolution Frequency.

Hz

A 6.5 ABSORBED CURRENT

Displays the motor absorbed current (RMS value)

CAUTION! Standard ammeter may read input and output current values different

from the one shown by inverter.

A

V 230 DYNAMIC VOLTAGE

It matches to the power supply ‘voltage value’ - only with pump in standby.

V

PF .85 Power factor (COSFI):

Shows the instantaneous value of the power factor (only T/T models)

Tm 50 POWER MODULE TEMPERATURE

Displays the inverter’s electronic module temperature.

°C

Ti 30 INVERTER BOX INTERNAL TEMP.

Displays the box internal Temperature (only T/T models)

°C

Tc 50 INVERTER BOX INTERNAL TEMP.

Displays the box internal Temperature (only T/T models)

°C

In 0 INPUT ACTIVATION STATUS

Displays the input signal activation Status

1= enabled input / 0= input not enabled

Ou 0 OUTPUT ACTIVATION STATUS

Displays the output relay activation Status

1= enabled input / 0= input not enabled

S1-S2 STATUS RS 485 (SLAVE connection)

Displays the status of the inverter SLAVE connected to the inverter MASTER.

The parameter is not displayed in applications STAND-ALONE

(parameter W = NC).

XX-XX = no SLAVE inverter connected

S1-XX = inverter SLAVE1 connected

XX-S2 = inverter SLAVE2 connected

S1-S2 = inverter SLAVE1 e SLAVE2 connected

36

TEST

to start and

adjust the

pump

manually

Enter the

TEST mode

see ACCESS

TO MAIN

MENU

Proceed as

shown below to

start and adjust

the pump speed

During the test you can view all

the operating parameters (see

DISPLAY OF OPERATING

PARAMETERS)

CAUTION: TEST mode is not active on the SLAVE unit; to make a TEST on the SLAVE unit,

switch off temporarily the MASTER unit, so that the SLAVE unit becomes independent and is able to

perform the TEST normally

Key instruction display

in TEST mode the word “TEST” is displayed

start the pump by pressing the START / STOP button, the

pump starts at the minimum frequency

Display the operating frequency by scrolling with the

RIGHT arrow

set the operation frequency by pressing the keys

(step 1 Hz)

display the operating parameters by pressing the keys

To stop the TEST, press the A START / STOP button

PRIMING AND STARTING UP

- Do not run pumps dry

- Before starting the pump, make the filling of all pumps

- In the pressure units, the filling is for single pump by turning off all other pumps

- When the pump is completely filled with water, bring in TEST mode (manual operation) and prime the

pump by opening the discharge valve gradually

- When the pump is primed, stop the manual mode by pressing STOP and switch to automatic mode by

pressing START.

CONNECTION OF INVERTER MASTER AND SLAVE

- set the parameter W (see page 34) of the inverter 1 to MS (will be MASTER)

- set the parameter W (see page 34) of the inverter 2 to S1 (will be SLAVE 1)

- Connect MASTER and SLAVE as shown at page 29

- after the connection only the MASTER takes any set and drives the SLAVE

- the SLAVE only can be put out of service through START/STOP button

F_30

START

P_2.0

F_35

OFF

STOP

A 3.5

TEST

37

ALARMS

OVER

CURRENT % The current exceeded the allowable tolerance on the current set.

The inverter stops the pump, the rearm is only manual.

CURRENT

LIMIT The current exceeded the module current capacity.

The inverter stops the pump, the rearm is only manual.

i DRY

Occurs if, in the absence of flow, the pump cannot reach the SET pressure, but can

reach at least a pre-determined percentage of the SET pressure, defined through

the parameter Pd. The inverter does not stop the pump, which continues to work with

the message “i-DRY” on the display.

DRY RUNNING

Occurs if, in the absence of flow, the pump fails to reach the pressure of the set but

does not even reach a predetermined percentage of the SET pressure, expressed

by the parameter Pd; the inverter stops the pump.

The error is reset after the time TP and the inverter re-starts in automatic mode.

LOW PRESS Occurs if the pump is running at maximum frequency (50/60 Hz), in the presence of

flow, and the pressure doesn’t reach 0.3 bar; the inverter stops the pump.

The error is reset after the time TP and the inverter re-starts in automatic mode.

LOW VOLTAGE a voltage drop has occurred beyond minimum operating threshold. The inverter stops

the pump. The error is reset after one minute, and the inverter re-starts in automatic

mode.

HIGH VOLTAGE a voltage peak has occurred beyond maximum operating threshold. The inverter stops

the pump. The error is reset after one minute, and the inverter re-starts in automatic

mode.

HIGH TEMP.

BOX (only T/T mod.)

The temperature inside the inverter has reached 65 °C; is automatically limited the

maximum frequency of 5 Hz but the drive continues to run, the error is reset below

60 °C

OVER TEMP.

BOX (only T/T mod.)

The temperature inside the inverter has reached 80 °C, the inverter stops the

pump, the error is reset below 60 °C and the drive will restart automatically

HIGH

TEMPERATURE

MOD

The module temperature has reached the first alarm threshold; the maximum

working frequency is automatically limited, but the drive continues to run, the error

is reset when the module temperature returns below 70 °C

OVER TEMP

MOD The module temperature has reached the second alarm threshold, the inverter stops

the pump, the error is reset when the module temperature returns below 70 °C and the

drive will restart automatically

INPUT ERROR There has been a reversal of the power connections / output to the motor. the

inverter is locked, the error is reset by connecting the cables correctly in the terminal

COM ERROR

communication has been interrupted between the control board and the power

board; the causes could be the integrity of the cable and of the connection ports or an

electronic board fault.

PHASE ERROR

(only for models with three-phase output) lack of a phase towards the motor during

operation. The inverter stops the pump ; reset is manual only.

LOW LEVEL this occurs when the digital input EI is configured as “WATER LEVEL” (level signal)

and there is no signal. When the signal returns, the message disappears and the

inverter operates normally again.

EXT OFF this occurs when the digital input EI is configured as “EXT ENABLE” (control

enabled from outside) and there is no signal. When the signal returns (external

enabling) the message disappears and the inverter operates normally again.

OFF It occurs when the supply voltage is disconnected; the capacitors are discharged, for

security reasons, from the discharge resistors. The process takes about 10 sec

38

PART 2

O

OP

PE

ER

RA

AT

TO

OR

R’

’S

S

A

AN

ND

D

M

MA

AI

IN

NT

TE

EN

NA

AN

NC

CE

E

M

MA

AN

NU

UA

AL

L

GENERAL REMARKS

STEADYPRES is a speed controller with the following features:

- Powered by AC single-phase or three-phase

- Output AC single-phase or three-phase

- It maintains the system at constant pressure (VARIABLE SPEED CURVES)

- It carries out continuous controls on electric and functioning parameters, saving the pumping unit from all

common failures (over-currents, dry running, etc)

- It works in stand-alone configuration or in parallel with other units, through serial connection.

- applications in parallel, with a MASTER inverter and SLAVE inverters, controlled by the MASTER.

- The MASTER receives the programming of the parameters and controls the operating data, and activates

and deactivates the SLAVE as needed.

If the MASTER is turned off, the SLAVE becomes independent and will continue to operate independently.

- Adapts to any type of system pressurization, even existing

- Limits the peak currents during starts and operation, energy-saving.

- Allows the selection of the power supply and output voltage.

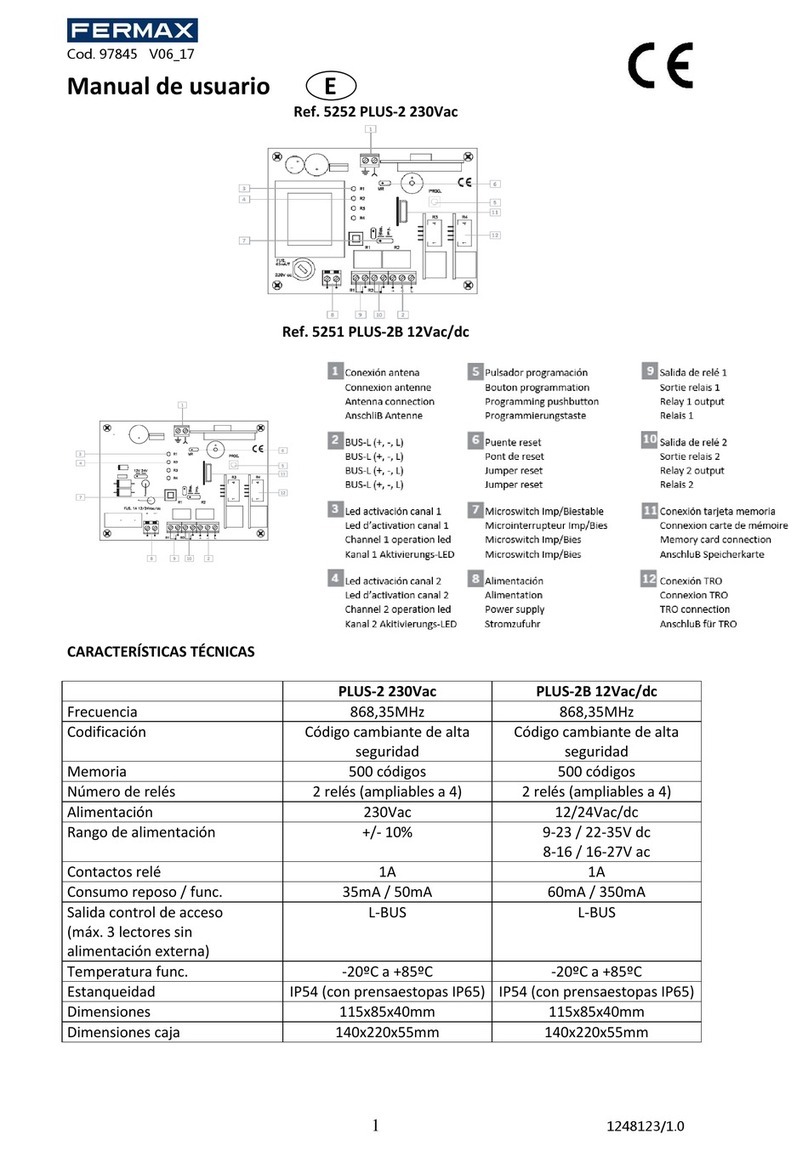

PART LIST

1- control system

2- removable electric connector

3- I/O power cable bushing

4- power board cover

5- three-piece joint

6- tecnica data plate

7- master switch (not present in T/T

models)

8- fuse (not present in T/T models)

9- non-return valve unit

10- expansion board cover

11- capacitors box

NOTE: master switch and fuse are only

available in versions with single-phase

power supply, while the models with

three-phase power supply (T/T models)

are without.

For the T/T models the inverter supply

line must be protected by suitable

devices in conformity with applicable

standards.

12

3

4

5

5

11

8

IN

OUT

11

6

10

9

7

8

- In applications in parallel, there is a MASTER inverter that controls one or two SLAVE inverter.

The MASTER receives the programming of the parameters and controls the operating data, and

activates and deactivates the SLAVE as needed.

If the MASTER is turned off, the SLAVE goes back to being self-employed and will continue to operate

independently

When working in parallel with other inverters, STEADYPRES controls the alternation of starting to

make the use of the pumps uniform.

39

WORKING LIMITS

- maximum working pressure: 10 bar (140 p.s.i)

- fluids accepted: clean water and liquids that are chemically non-aggressive. If there are

impurities in the liquid, install a strainer upstream

- fire / explosion: inverters STEADYPRES ARE NOT SUITABLE for operation in environments

with risk of explosion.

- Maximum ambient temperature: 40 °c; D

- minimum ambient temperature: 0 °C

- max liquid temperature: 55 °C

- min liquid temperature:: 0 °C

- supply voltage tolerance: + / - 10%

compared to the nameplate data

- flow rates and pressure drops: in side

figure is represented the loss of load (in

mH2O) through the inverter, to vary the

flow rate

TECHNICAL DATA

main voltage

supply

230

+/

-

10%

Vac single-phase (models M/M e M/T) WARNING: IN CASE OF

LOW VOLTAGE

(NOMINAL VALUE -10% )

OVERCURRENTS CAN

OCCUR DURING

STARTING OR FULL

LOAD OPERATION.

400

+/

-

10%

Vac three-phase (models T/T)

output voltage 230 Vac single-phase (models M/M)

230 Vac three-phase (models M/T)

400 Vac three-phase (models T/T)

frequency 50 – 60 Hz

enclosure IP 65

working position vertical, with the liquid inlet from the bottom and top exit.

Current and power table

Model V in V out A out Fuse (A) P2 max (kW) P2 max (HP)

M/M 8.5 1 ~ 230V 1 ~ 230V 8,5 20 1,1 1,5

M/M 11 1 ~ 230V 1 ~ 230V 11 25 1.5 2.0

M/M 16 1 ~ 230V 1 ~ 230V 16 25 2,2 3,0

M/T 7 1 ~ 230V 3 ~ 230V 7 20 1,1 1,5

M/T 12 1 ~ 230V 3 ~ 230V 12 25 2,2 3,0

T/T 6 3 ~ 400V 3 ~ 400V 6 no 2,2 3,0

T/T 8 3 ~ 400V 3 ~ 400V 8 no 3,0 4,0

40

DIMENSIONS AND WEIGHTS

76 135

211

110 167

277

235

1"

1"

Mod.

M/M 8.5

M/M 11

M/T 7

M/T 12

76 165

241

112 167

279

1"1/4 ÷ (1")

1"1/4 ÷ (1")

270 ÷ (235)

Mod.

M/M 16

T/T 6

T/T 8

Model connection weight

(kg) Packaging dimensions

(A x B x H - mm)

M/M 8.5 - M/M 11 – M/T 7 – M/T 12 1” 2,9 260 x 200 x H 260

M/M 16 – T/T 6 1” 3,7 260 x 200 x H 260

T/T 8 1” ¼ 4,1 260 x 200 x H 260

PRODUCT IDENTIFICATION CODE

ST M / T 10 P

SURGE TANK

-accumulates water under pressure to minimize the start-up of the pumps

- it is essential in the presence of small system leakages

- absorbs overpressures from the system

- the minimum tank volume, in liters (for diaphragm models) is approx. equal to 10% of the maximum

capacity of the single pump, expressed in l/min; example in a standard application:

Qmax = 80 l/min

V = 80 x 10% = 8 liters

rounded up to commercial size

- pre-charge: a. 70% of the working pressure: e.g.:

Pset = 4 bar

Ppre-charge = 2,8 bar

PRODUCT FAMILY

INVERTER SUPPLY: M = single-phase, T = three-phase

MOTOR OUTPUT: M = single-phase, T = three-phase

MODEL

Config ration: E = expandable,

P = parallelable

41

INSTALLATION

Before installing and using STEADYPRES:

- read this manual thoroughly and carefully and refer to the Safety Standards.

- Before making the connections, make sure that the ends of the line wires are not live.

- Make sure also that the electric power supply network is protected by thermal magnet and differential

protections according to the applicable Standard in force. The differential switch must be high-

sensitivity type (30 mA in class A for domestic application, class B for industrial applications)

- Ground connections must be in compliance with Standards.

- Check that the plate data is that required and suitable for the system

- The cable section (power supply cable and connection cable between the inverter and the

motor) must be dimensioned according to:

oVoltage (230 V single-phase, 230 V three-phase, 400 V three-phase)

oPump power

oCable lenght

- The power supply cable and the motor cable must be sized to curb any power voltage drop within

3%.

- The power supply cable and the motor cable must be suitably shielded to comply with EMC

standards.

- In case of long cables between Inverter and pump motor, evaluate the application of inverter output

sinusoidal filter. It aids smooth running of motors eliminating negative effect of voltage peaks

For CONNECTIONS see QUICK INSTALLATION GUIDE .

SELF-LIMITING OVERLOAD

If the

current

detected by

the inverter

Or the

temperature

of the

inverter

Exceed

the

safety

limits

STEADYPRES

proceeds to a

progressive reduction

in the frequency of

operation

As long as the

values are

returned within

the limits

While operating in self-limitation, DISPLAY and LED flash to indicate the fault status

CONNECTION OF 4-CABLE SUBMERSIBLE SINGLE-PHASE MOTOR

STARTING UP

- Before running, this Manual must have been carefully read and the instructions followed; wrong

settings and operations are thus prevented that could cause operating faults

- Before starting the system, the pumps must be primed (filling and air bleeding)

42

- After performing the operations described in the INSTALLATION chapter, the inverter can be started.

- When STEADYPRES is switched on, it enters the STARTING phase, which lasts 10 seconds, after

which STEADYPRES returns to the same operating conditions in which it was when it was last

switched off:

oin WORK mode if at the time of the last shutdown was IN SERVICE

oin OUT OF SERVICE mode if at the time of the last shutdown was OUT OF SERVICE

(OFF)

- In case of accidental fall of the power line, if it STEADYPRES was in serivce, when the power returns,

it automatically returns in service

- To put STEADYPRES IN SERVICE / OUT OF SERVICE, beat the START / STOP button.

- In applications with parallel inverters (MASTER / SLAVE) is just the MASTER inverter that receives input

from the keyboard

- SLAVE inverters operate independently only if the MASTER is turned off, in which case they receive input

from its own keyboard.

- In each group can be only one MASTER, one SLAVE 1 and one SLAVE 2.

- In normal operation, you can view the status parameters.

For visualization of the operating parameters see QUICK INSTALLATION GUIDE

LIGHT SIGNALS

keyboard

ON OFF BLINKING

POWER

STATUS

STEADYPRES does not detect power supply. WARNING:

cannot guarantee the absence of power supply, the

electronic board may be faulty, but under tension

POWE

R

STATUS STEADYPRES is live, but the pump is not running (STAND-

BY)

POWER

STATUS

STEADYPRES is live, and the pump is running

POWER

STATUS STEADYPRES is live, but out of serivce; the re-arm is only

manual

POWER

STATUS STEADYPRES is in ALARM mode, re-arm is only manual

INSPECTION MENU

the menu INSP (inspection) allows you to view the history of the inverter: the operating hours,

number of starts, alarm recording.

INSP WH OPERATING HOURS Operating hours with the pump running

TH TOTAL OPERATING HOURS Total No. Hours working

NS NO START-UPS total Number of start-ups

SH AVERAGE NO START-UPS Average number of start-ups per working hour.

E1 LAST FAULT last fault that occurred in chronological order

EH TIME OF LAST FAULT time at which the fault occurred (referred to TH)

EE ERROR RESET to reset the error log press the ENTER key and hold

until "OK" is confirmed on the display

(ENTER

****

OK)

43

TROUBLESHOOTING

- Check that the inverter has been correctly connected to the power line (which is on)

- Check that the motor pumps have been correctly connected to the inverter

- Check that all the cables and connections are operative.

PROBLEM

The pump is not feeded

Message

Ca se

intervention

none

Interr ption of power s pply Replace the power s pply

none

B rned f ses S bstit te the f ses

none

Intervention of the line protections Check the correct protecttions setting

INPUT ERROR

(only mod. T/T) - connections LINE and

MOTOR were reversed

Check the connections LINE and MOTOR and connect

correctly

PROBLEM

The current circuit breaker has tripped to protect the DGBOX power line

Message

Ca se

intervention

none

The resid al c rrent circ it breaker is

inadeq ate for inverter s pply

Replace the resid al c rrent circ it breaker with a model

s itable for the p lsating components and in direct c rrent

(class A)

PROBLEM

The pump fails to start

Message

Ca se

intervention

OFF

The p mp is o t of service (placed man ally

o t of service)

P t the p mp back into service by p shing START

PROBLEM

The p

ump stopped and fails to re

-

start

Message

Ca se

intervention

OVER

CURRENT

overc rrent absorption compared to set

val e (parameter A in BASE PARAMETER)

- check the correct c rrent setting

- check the power voltage nder load at p mp terminals (min -

15%)

- make s re the motor p mp is t rning freely and is not braked

- check the correct direction of rotation

- check the correct sizing of the wires

CURRENT

LIMIT

Serio s overc rrent absorption which

inverter cannot cope with

Make s re the motor p mp is not bl

ocked, red ce the motor

acceleration by means of the ACCELERATION parameter.

DRY

RUNNING

(DRY

RUNNING PF)

-

Lack of water at s ction

- p mp not primed

- s ction blocked

- wrong direction of motor rotation

-

Check correct s ction conditions

- prime the p mp

- check the s ction piping

- check the correct direction of motor rotation

LOW PRESS

The system does not reach the minim m

press re

Check that there are no broken pipes.

LOW

VOLTAGE

Deviation of the s pply voltage higher than

–15% of the plate voltage

Check the s pply voltage and the section and length of the

inverter power cables

HIGH

VOLTAGE

Deviation of the s pply voltage higher than

+15% of the plate voltage

Check the s pply voltage

OVER TEMP

BOX (solo

T/T)

internal overheating d e to overload or

excessive ambient temperat re

Make s re the air cooling channels are free and that the

fans are working, check the p mp load

OVER TEMP

MODULE

Mod le overheating d e to overload check the p mp load

COM ERROR

No comm nication between control board

and power board

Check the integrity of the connection cable and connections;

the power board co ld be damaged

LOW LEVEL

No level signal with level signal inp t on Make s re there is water at s ction or check level signal

operation

EXT OFF

Placing o t of service by means of external

signal

Check the external signal

none

Press re sensor fa lt

Check the display press re with a reference manometer, re

-

calibrate or s bstit te the press re sensor

44

PROBLEM

Pump always running even when not required

Message

Ca se

intervention

None

System leaks greater then 2 l/min Identify the leaks and repair

None

Flow sensor fa lt or locked open Inspect and check the flow sensor

PROBLEM

The pump stops too soon when requested

Message

Ca se

intervention

none

Flow rate sensor fa lt Check the flow rate sensor

Message

Ca se

Message

Ca se

intervention

none

Air inside s ction manifold Bleed the s ction system

none

P mp blocked or damaged Inspect the p mp and eliminate the problem

MAINTENANCE

Replacement of the CONTROL BOARD + PRESSURE SENSOR

- Disconnect the inverter main power supply and wait 2 minutes (capacitors discharge)

- Open the front cover and disassembly the pressure sensor and the control board as shown below

- Install the new control board with pressure sensor in reverse order of removal.

Open the front cover by unscrewing the 4 screws

Before removing the cover, disconnect the

ribbon cable of the display

Disconnect the wire communication with the power

board

Remove FIRST the PRESSURE SENSOR and

THEN the CONTROL BOARD by unscrewing the 5

screws indicated

Re-assemble the new BOARD+SENSOR in the same way but in reverse order:

-FIRST assemble the CONTROL BOARD

-THEN assemble the PRESSURE SENSOR

-connect the wire communication with the power board

-connect the ribbon cable of the display and close the front cover

ATTENTION:

This manual suits for next models

6

Table of contents

Other DGFLOW Controllers manuals

Popular Controllers manuals by other brands

SAMES KREMLIN

SAMES KREMLIN Airmix 120-10/120 instruction manual

AXIOMATIC

AXIOMATIC AX030210 user manual

SOLIS

SOLIS RHI-HV 5G Series user manual

Mitsubishi Electric

Mitsubishi Electric MELSEC iQ-R Series user manual

Mitsubishi Electric

Mitsubishi Electric MELSEC Q Series user manual

Belimo

Belimo SY U24-SR Series Wiring diagram