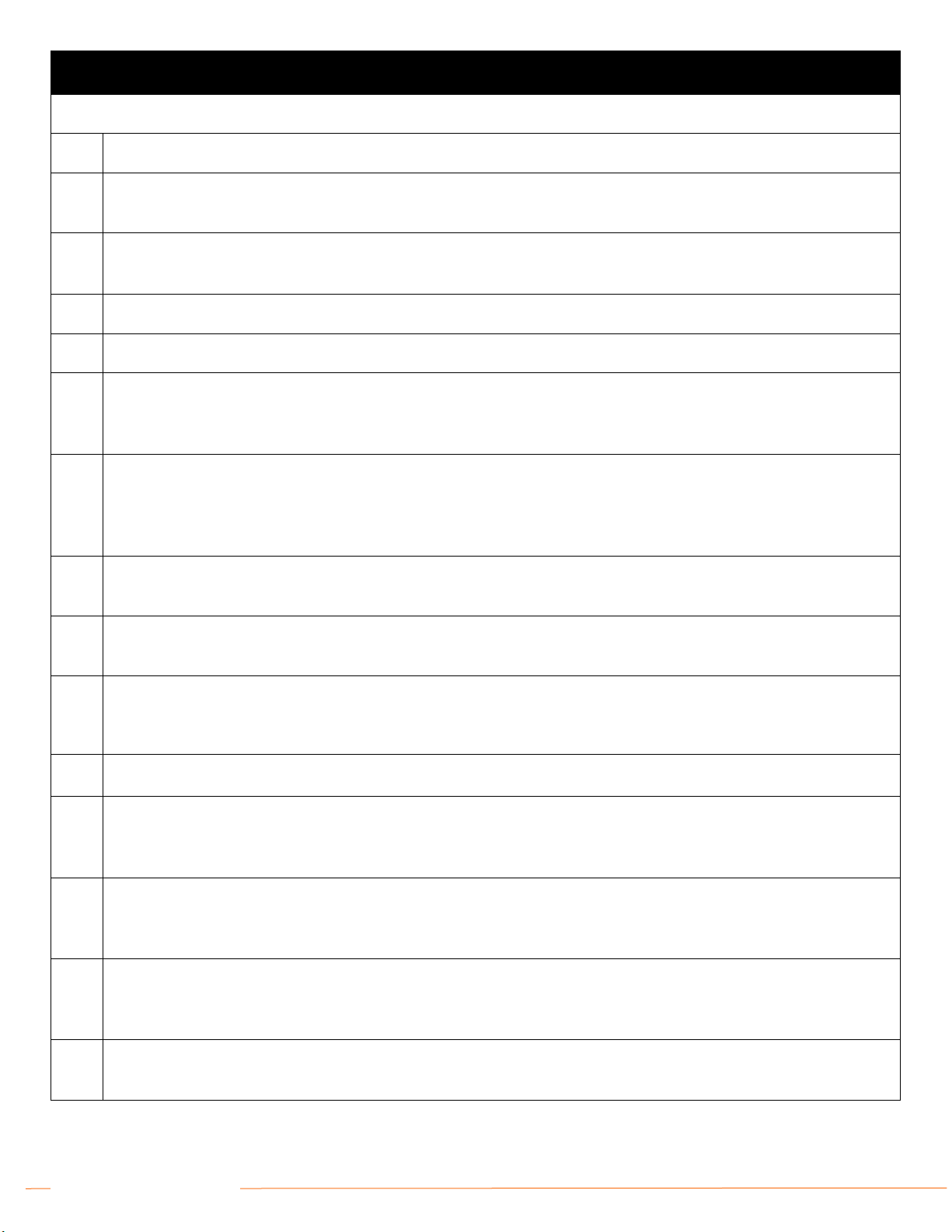

TABLE OF CONTENTS

1UNDERSTANDING SAFETY AND WARNING SIGNS........................................................................................................................ 3

2CONTACT INFORMATION AND DISCLAIMERS................................................................................................................................ 4

3GENERAL INTRODUCTION ............................................................................................................................................................... 5

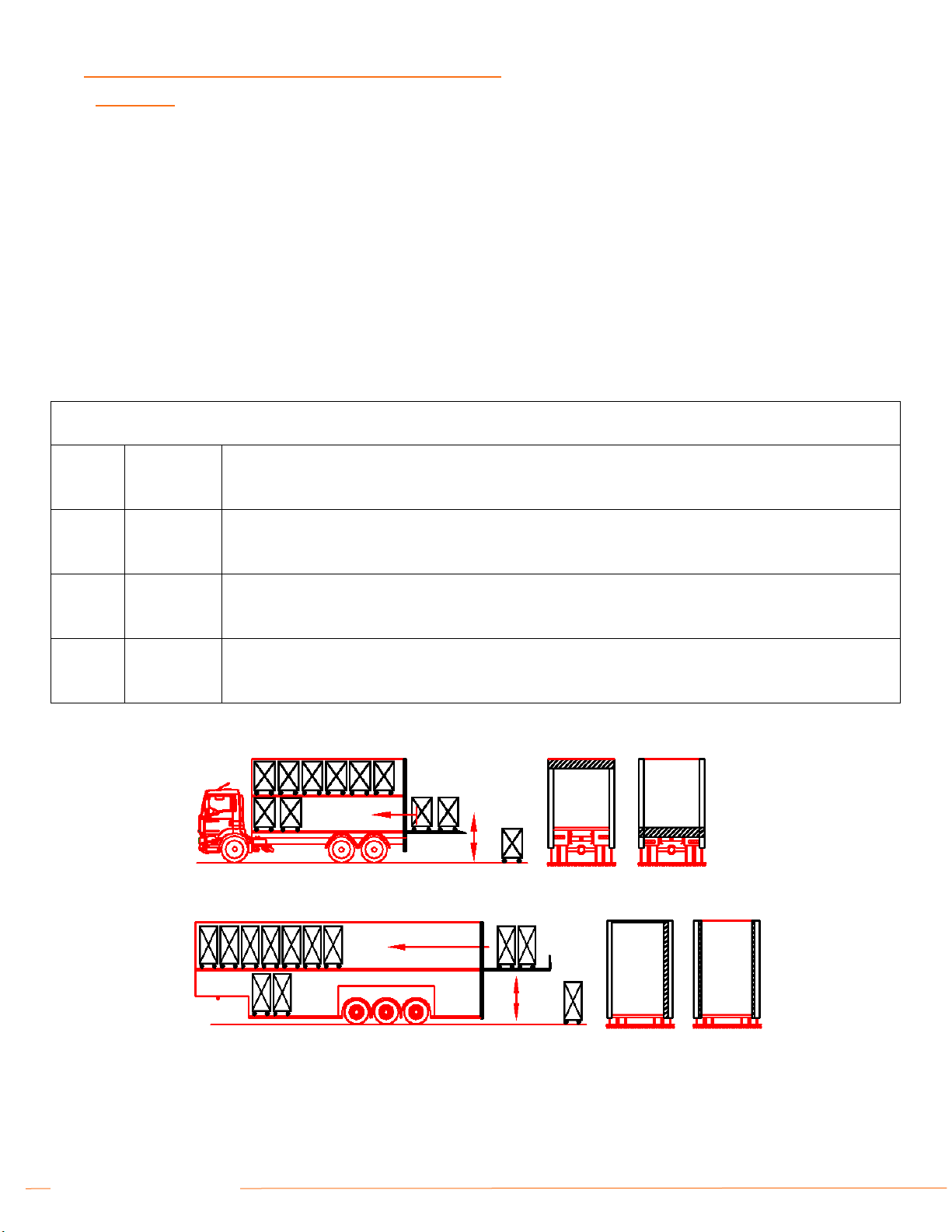

4INTENDED USE .................................................................................................................................................................................. 5

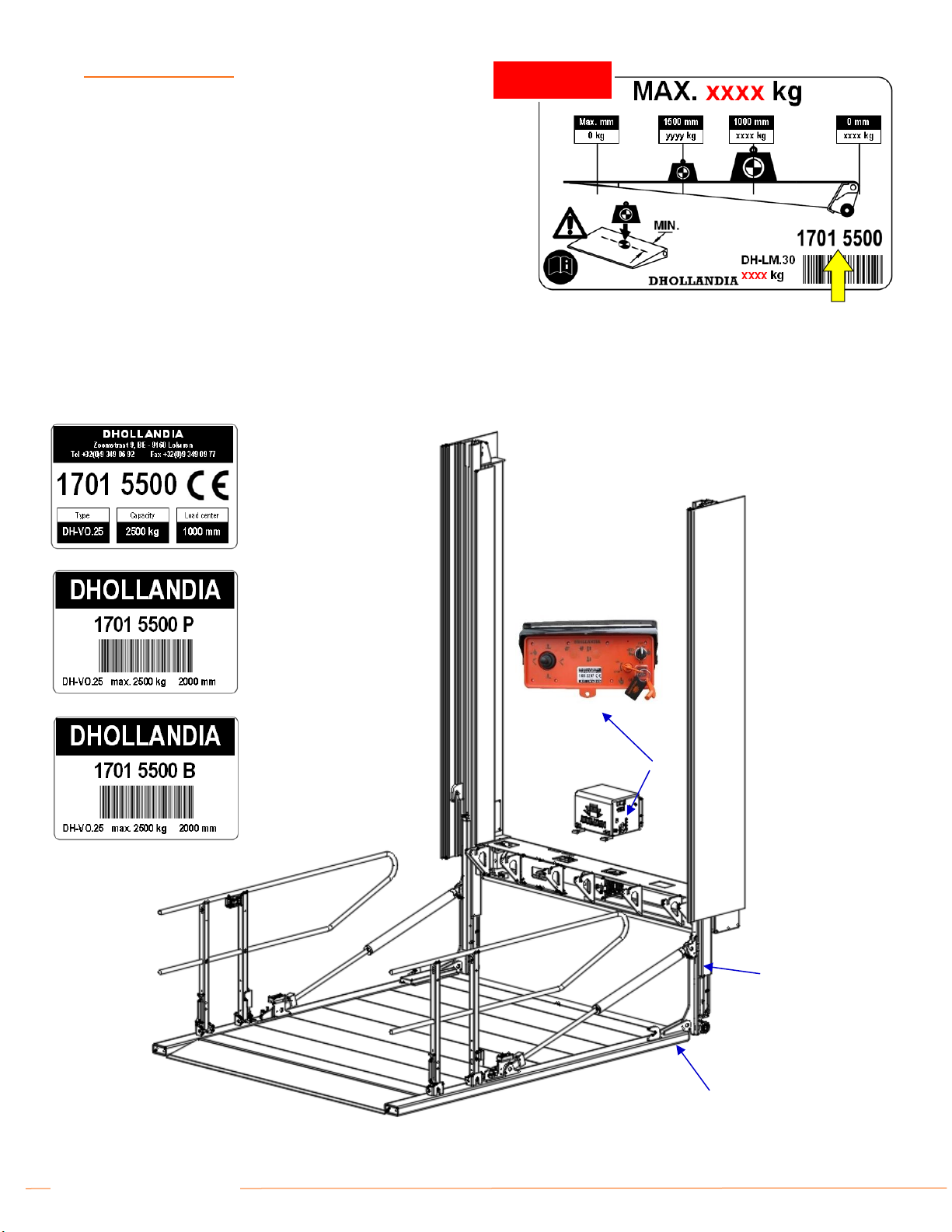

5IDENTIFICATION ................................................................................................................................................................................ 6

6DESCRIPTION AND LIFTGATE TERMINOLOGY .............................................................................................................................. 7

6.1 General ....................................................................................................................................................................................... 7

7SAFETY INSTRUCTIONS FOR USING THE LIFTGATE.................................................................................................................. 18

7.1 DO NOT use liftgate without adequate safety and operator training......................................................................................... 18

7.2 General safety instructions........................................................................................................................................................ 18

7.3 Danger zones, risk of crush and shear injury............................................................................................................................ 23

7.4 Additional risks of lifting above the vehicle floor level................................................................................................................ 26

7.4.1 Risk of falling ........................................................................................................................................................................ 26

7.4.2 Risk of other persons standing under the platform ............................................................................................................... 27

7.4.3 Risk of crushing and shearing............................................................................................................................................... 28

7.4.4 At the vehicle roof................................................................................................................................................................. 30

7.4.5 Special attention for overhead cross tube between the lift runners ...................................................................................... 30

7.5 Safe operator position ............................................................................................................................................................... 31

7.6 Instructions for working at loading docks .................................................................................................................................. 34

7.7 Recommended daily pre-trip inspection.................................................................................................................................... 37

7.8 Importance of preventative maintenance .................................................................................................................................. 39

8LOAD CHARTS AND CORRECT LOADING PROCEDURES........................................................................................................... 40

9OPERATING INSTRUCTIONS –PRINCIPLES AND PROCEDURES.............................................................................................. 43

9.1 Platform ride.............................................................................................................................................................................. 43

9.2 Main external control boxes ...................................................................................................................................................... 44

9.3 Auxiliary controls....................................................................................................................................................................... 47

9.4 Switching the main power ON / OFF......................................................................................................................................... 49

9.5 Operation of the standard multi-deck column lift with hydraulic closure.................................................................................... 50

9.6 Operation of the internal column lift without tilt cylinders........................................................................................................... 53

9.7 Operation of the DH-VOH.D4 removal lift ................................................................................................................................. 56

9.8 The use of stabilizing legs......................................................................................................................................................... 61

9.9The use of cart stops................................................................................................................................................................. 62

10 DECALS............................................................................................................................................................................................. 65

10.1 Regular decals .......................................................................................................................................................................... 65

10.2 Use of the ‘WARNING. LIFTGATE OUT OF SERVICE. DO NOT ATTEMPT TO OPERATE’ sign .......................................... 69

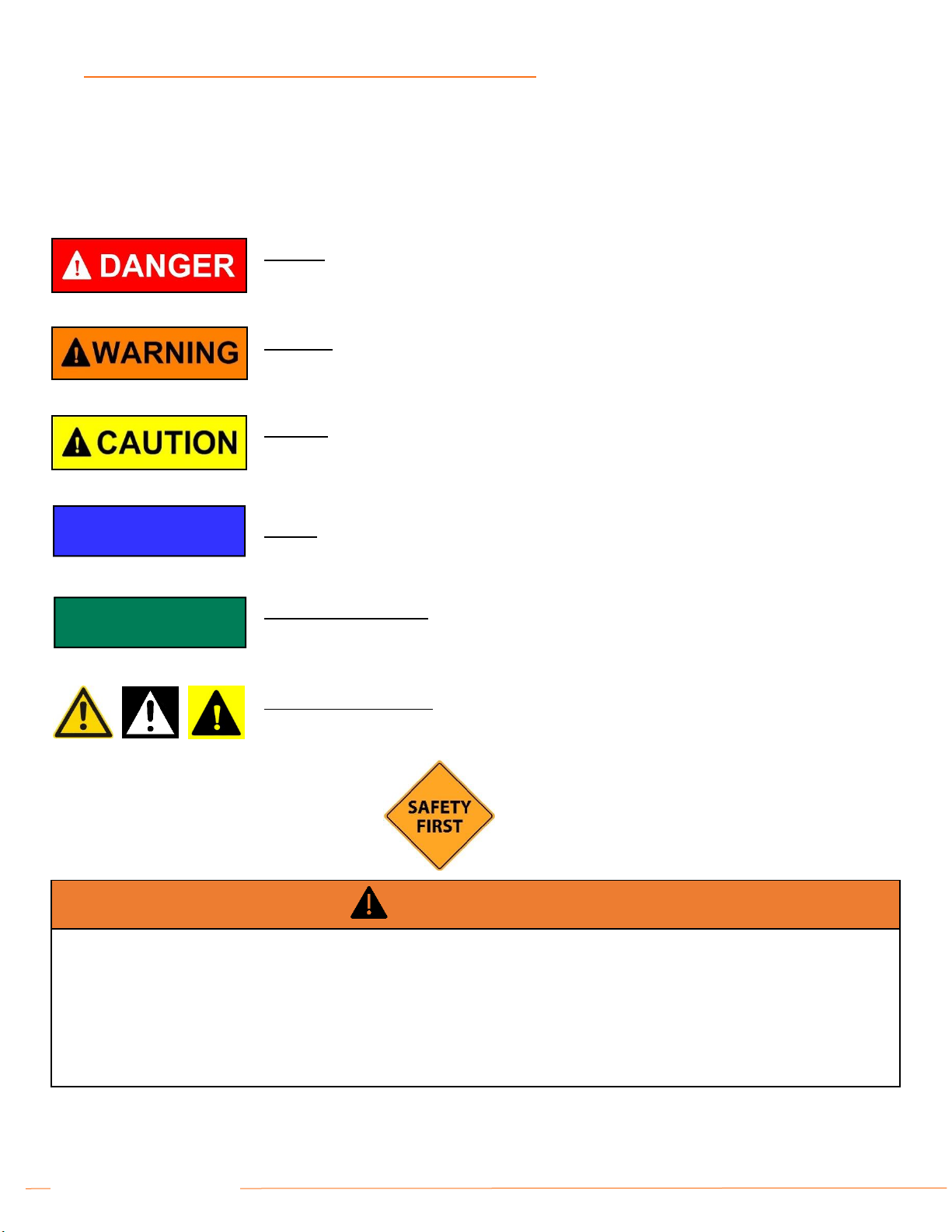

11 MEANING OF SAFETY AND WARNING SIGNS .............................................................................................................................. 70

12 END NOTE ........................................................................................................................................................................................ 72