TABLE OF CONTENTS

1UNDERSTANDING SAFETY AND WARNING SIGNS...................................................................................................................... 3

2INTRODUCTION, CONTACT INFO AND DISCLAIMERS................................................................................................................. 4

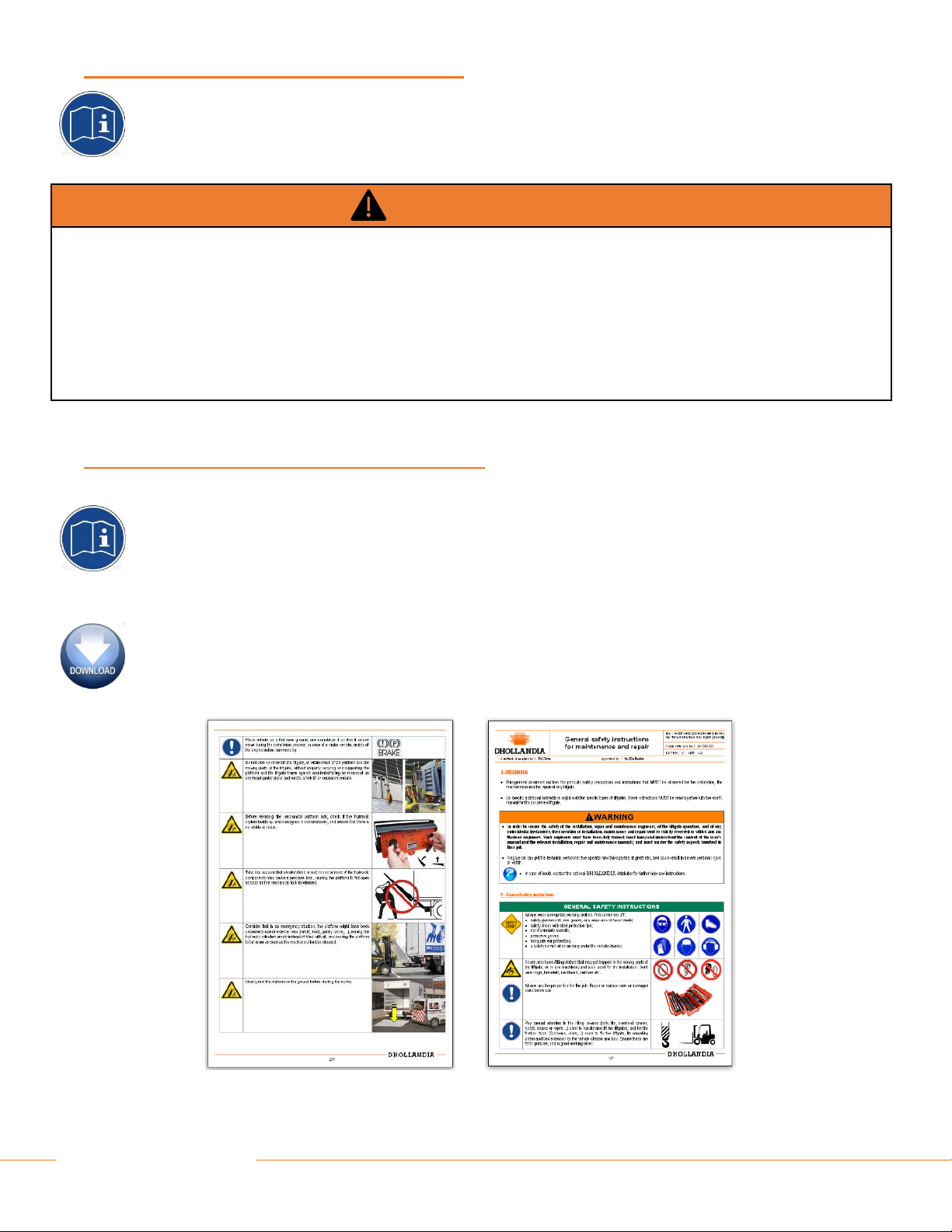

3SAFETY PRECAUTIONS FOR OPERATION ................................................................................................................................... 6

4SAFETY PRECAUTIONS FOR INSTALLATION............................................................................................................................... 6

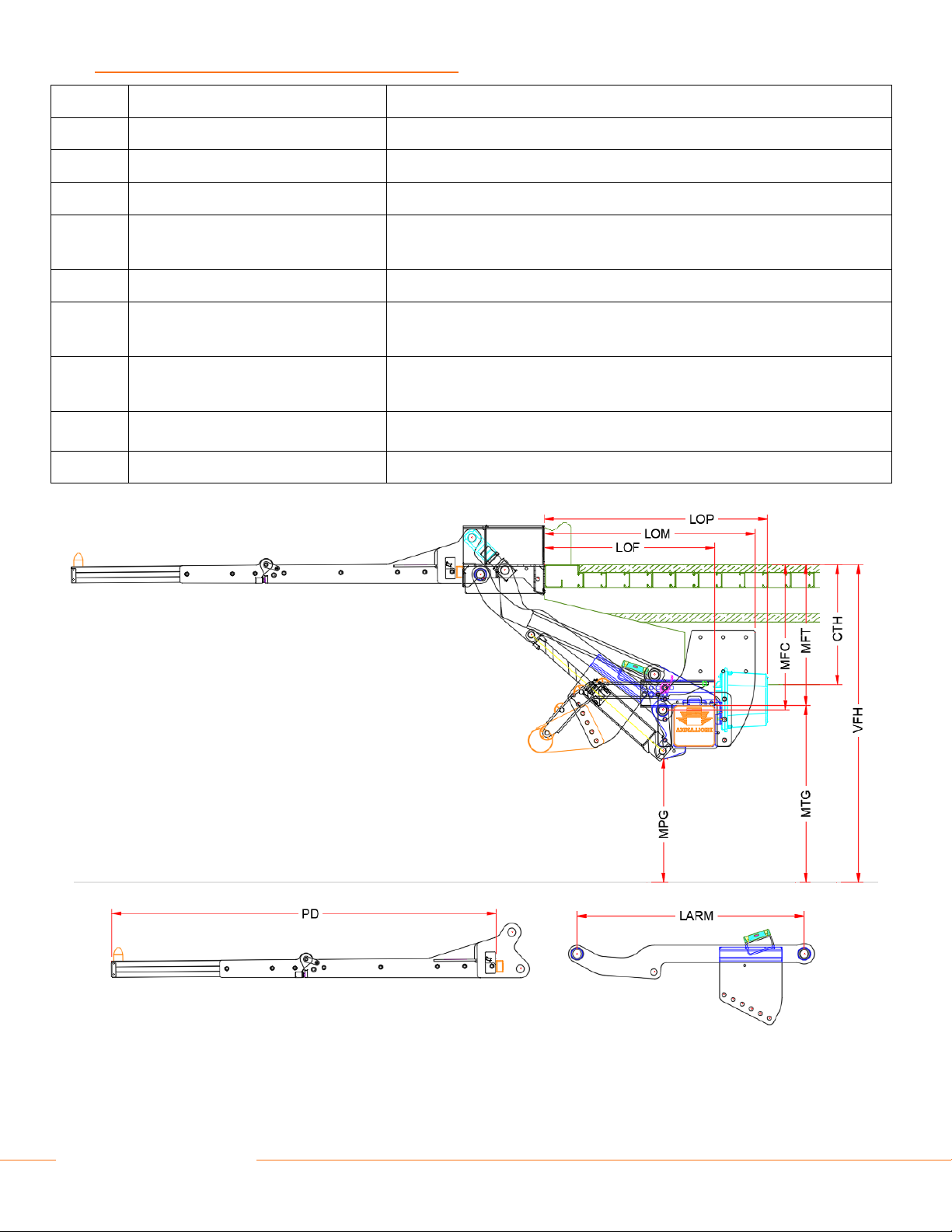

5LIFTGATE TERMINOLOGY .............................................................................................................................................................. 8

5.1 DH-RPL liftgate terminology...................................................................................................................................................... 8

5.2 Installation parameters terminology .......................................................................................................................................... 9

5.3 Getting started......................................................................................................................................................................... 11

6INSTALLATION DIMENSIONS AND GUIDELINES ........................................................................................................................ 12

6.1 Installation dimensions............................................................................................................................................................ 12

6.2 Installation resources .............................................................................................................................................................. 13

7BED EXTENSION AND CHASSIS CUT .......................................................................................................................................... 14

7.1 Rear sill cut ............................................................................................................................................................................. 15

8MOUNTING OF THE BED EXTENSION ......................................................................................................................................... 16

9MOUNTING OF THE LIFT FRAME (PREMOUNTED PLATFORM)................................................................................................ 18

10 FIXATION OF THE MOUNT PLATES ............................................................................................................................................. 22

10.1 Fixation of the mount plates OAM010..................................................................................................................................... 22

10.2 General remarks...................................................................................................................................................................... 25

11 INSTALLATION OF ELECTRICAL CONTROLS ............................................................................................................................. 26

11.1 Installation of the control switch (OAE015.PR –E0832.B)...................................................................................................... 26

11.2 Installation of the cabin switch (OAE510.15 –E0393.S.15).................................................................................................... 28

11.3 Installation of extra controls –2 button remote control (OAE001 –E0787.2.H)...................................................................... 29

12 ELECTRICAL INSTALLATION ........................................................................................................................................................ 31

12.1 Installation of the (+) battery cable and (-) ground cable......................................................................................................... 31

13 PUTTING THE LIFTGATE INTO SERVICE..................................................................................................................................... 34

14 PLATFORM ORIENTATION............................................................................................................................................................ 37

15 MOUNTING OF THE SIDE STEPS................................................................................................................................................. 39

15.1 Mounting the sides steps......................................................................................................................................................... 39

16 LUBRICATION INSTRUCTIONS..................................................................................................................................................... 41

17 QUALITY CONTROL AND PDI ....................................................................................................................................................... 42

18 DECALS .......................................................................................................................................................................................... 44

18.1 Use of the ‘WARNING. LIFTGATE OUT OF SERVICE. DO NOT ATTEMPT TO OPERATE’ sign ........................................ 46

19 APPENDIX....................................................................................................................................................................................... 47

19.1 Meaning of the safety and warning signs ................................................................................................................................ 47

19.2 Prescribed torque values for bolts and nuts ............................................................................................................................ 49

19.3 Electric and hydraulic requirements ........................................................................................................................................ 50

19.4 Safe operator position on the platform .................................................................................................................................... 52

19.5 End note.................................................................................................................................................................................. 53