DI BLASI R7-E Installation guide

OPERATION

AND

MAINTENANCE

Ò

Mod. R7-E

FOLDING MOTORBIKE

INDEX

Brakes (adjustments) 5.3

Cable (throttle) 5.4

Diagnosis 8

Expanding pulley (disassembling) 6.2

Folding 3

Fuel 4.2

Handlebar hinge (adjustement) 5.2

Handlebar hook (adjustment) 5.1

Headlamp (adjustment) 5.6

Horn 4.6

Idling 5.5

Lights 4.5

Magnetowheel 5.8

Reduction unit (disassembling) 6.1

Riding 4.4

Running in 4.1

Servicing 5.9 - 7

Spark plug 5.7

Technical specifications 1

Tyre pressure 4.3

Turn signal lamps 4.7

Unfolding 2

Wheels (disassembling) 6.1 - 6.3

Wiring diagram 5.10

6

- manufacturer & model DI BLASI M1

- single cylinder, two stroke

- bore 39 mm

- stroke 41,8 mm

- cylinder capacity 49.9 cc

- compression ratio 8,65 : 1

- maximum power 0,92 KW at 3700 RPM

- maximum torque 2,56 Nm at 3000 RPM

- spark plug BOSCH W7A

or AC43F

or N.G.K. B6HS

- carburetor DELL'ORTO SHA 14-12

main jet size: 53

choke tube: 12 mm

- fuel regular gasoline

with 2% of 2 stroke oil

- primary drive V-Belt variator

ratios: min 1:1,577

max 1:3,736

- secondary drive timing belt

ratio 22/102 = 1 : 4,636

- starting foot kick starter

Engine

1. SPECIFICATIONS

Dimensions

- Open:

Overall length 128 cm (50“)

Wheel base 93 cm (37“)

Width 58 cm (23“)

- Folded:

Length 78 cm (30“)

Width 36 cm (14“)

Height 61 cm (24“)

6Unladen mass 32 kg (69 Lbs)

6Rim size (front & rear) 5“

6Tyre size (front & rear) 4.00 - 5“

6Brakes drum diameter 90 mm (front & rear)

6Electrical equipment 12V - 65W

6Tank capacity 3 litres (3 quarts)

6Fuel consumption 50 km/lt (approx)

(130 mls per gallon)

6Maximum speed 50 km/h (30 mph)

6Seating capacity 1

6

Notice

Pictures and drawings of this manual have the sole

aim to illustrate the operations described herein:

however, they may not correspond exactely to your

vehicle.

INDEX

Brakes (adjustments) 5.3

Cable (throttle) 5.4

Diagnosis 8

Expanding pulley (disassembling) 6.2

Folding 3

Fuel 4.2

Handlebar hinge (adjustement) 5.2

Handlebar hook (adjustment) 5.1

Headlamp (adjustment) 5.6

Horn 4.6

Idling 5.5

Lights 4.5

Magnetowheel 5.8

Reduction unit (disassembling) 6.1

Riding 4.4

Running in 4.1

Servicing 5.9 - 7

Spark plug 5.7

Technical specifications 1

Tyre pressure 4.3

Turn signal lamps 4.7

Unfolding 2

Wheels (disassembling) 6.1 - 6.3

Wiring diagram 5.10

6

- manufacturer & model DI BLASI M1

- single cylinder, two stroke

- bore 39 mm

- stroke 41,8 mm

- cylinder capacity 49.9 cc

- compression ratio 8,65 : 1

- maximum power 0,92 KW at 3700 RPM

- maximum torque 2,56 Nm at 3000 RPM

- spark plug BOSCH W7A

or AC43F

or N.G.K. B6HS

- carburetor DELL'ORTO SHA 14-12

main jet size: 53

choke tube: 12 mm

- fuel regular gasoline

with 2% of 2 stroke oil

- primary drive V-Belt variator

ratios: min 1:1,577

max 1:3,736

- secondary drive timing belt

ratio 22/102 = 1 : 4,636

- starting foot kick starter

Engine

1. SPECIFICATIONS

Dimensions

- Open:

Overall length 128 cm (50“)

Wheel base 93 cm (37“)

Width 58 cm (23“)

- Folded:

Length 78 cm (30“)

Width 36 cm (14“)

Height 61 cm (24“)

6Unladen mass 32 kg (69 Lbs)

6Rim size (front & rear) 5“

6Tyre size (front & rear) 4.00 - 5“

6Brakes drum diameter 90 mm (front & rear)

6Electrical equipment 12V - 65W

6Tank capacity 3 litres (3 quarts)

6Fuel consumption 50 km/lt (approx)

(130 mls per gallon)

6Maximum speed 50 km/h (30 mph)

6Seating capacity 1

6

Notice

Pictures and drawings of this manual have the sole

aim to illustrate the operations described herein:

however, they may not correspond exactely to your

vehicle.

2. TO UNFOLD THE VEHICLE

When the vehicle is folded, it stands up alone. Rotate the handlebar on the stem hinge until it is

locked by the hook.

Important Caution: make sure that both springs

which pull the hook are functionning properly and

that the hook itself is properly positioned (sec.5.1).

When rotating the handlebar, do not turn the wheel,

because the muffler pipe is still in the way. .

Holding the handlebar with the left hand, with the

right hand pull and then backwards the rear edge of

the saddle until...

... the frame is locked automatically by the hook

located on its right side under the saddle.

Place the vehicle on its stand.

Unfold the foot rest. Unfold the rearview mirror.

Before riding, read sec. 4.4.

Fig. 1 Fig. 2 Fig. 3 Fig. 4

2. TO UNFOLD THE VEHICLE

When the vehicle is folded, it stands up alone. Rotate the handlebar on the stem hinge until it is

locked by the hook.

Important Caution: make sure that both springs

which pull the hook are functionning properly and

that the hook itself is properly positioned (sec.5.1).

When rotating the handlebar, do not turn the wheel,

because the muffler pipe is still in the way. .

Holding the handlebar with the left hand, with the

right hand pull and then backwards the rear edge of

the saddle until...

... the frame is locked automatically by the hook

located on its right side under the saddle.

Place the vehicle on its stand.

Unfold the foot rest. Unfold the rearview mirror.

Before riding, read sec. 4.4.

Fig. 1 Fig. 2 Fig. 3 Fig. 4

Close the fuel tap (A-fig.9) by turning the lever to

OFF (pointing backword) . Closing of the tank air

vent hole is automatic. If you need to store the

moped on it’s side, run the engine until it consumes

all the fuel in the carburetor reservoir.

3. TO FOLD THE VEHICLE

Fold the rearview mirror.

Push the vehicle off its stand.

Turn the steering fully to the right.

Release the frame hook located on the right side

under the saddle and .....

......push the rear edge of the saddle forward until it

is almost at the same level with the filler cap.

Unhook the handlebar and lower it.

Fold the foot rest.

The vehicle stands up alone.

Fig. 5 Fig. 6 Fig. 7 Fig. 8

Close the fuel tap (A-fig.9) by turning the lever to

OFF (pointing backword) . Closing of the tank air

vent hole is automatic. If you need to store the

moped on it’s side, run the engine until it consumes

all the fuel in the carburetor reservoir.

3. TO FOLD THE VEHICLE

Fold the rearview mirror.

Push the vehicle off its stand.

Turn the steering fully to the right.

Release the frame hook located on the right side

under the saddle and .....

......push the rear edge of the saddle forward until it

is almost at the same level with the filler cap.

Unhook the handlebar and lower it.

Fold the foot rest.

The vehicle stands up alone.

Fig. 5 Fig. 6 Fig. 7 Fig. 8

6Open the throttle slightly, by twisting the right

handlebar grip (B-fig.12).

6Start the engine by pushing down the kick starter

lever with the foot.

6A few seconds after that the engine as started,

release the choke to its open position by opening

the throttle completely and immediately closing

it. Prolonged operation with the choke on will

cause spark plug fouling. Use caution to insure

that the vehicle is on its stand and apply the

front brake while the throttle is opened

completely.

6Get on the vehicle assuming the riding position.

6With the throttle in the closed position, apply the

rear brake before pushing the vehicle off its

stand.

6Once started, the vehicle is driven at the desired

speed solely by use of the twist grip throttle (B-

fig12)

4.6 Horn

The push button for the horn (color blue) is located on

the left side of the handlebar (fig.12 - E).

4.7 Turn signal lamps

The switch (T) for the turn signal lamps is located:

6In European mopeds: on the right of the

handlebar (fig.12 EU);

6In USA mopeds: on the left of the handlebar

(fig.12 US);

4 OPERATING INSTRUCTIONS

4.1 Running-in

During the first 500 km (300 mls), use a mixture of

regular gasoline with 4% two stroke oil and do not

operate at more than 3/4 throttle. At about 500 km

(300 mls) check all bolts and nuts for proper tightness

and tighten the cylinder head nuts at 10 Nm torque.

4.2 Fuel

After the first 500 km (300 mls) use a mixture of regu-

lar gasoline with 2% two stroke oil.

CAUTION: an improper mixture or just fuel without

oil will cause damages and voids all warranties.

4.3 Tyre pressure

Front: 1,2 atm (18 psi)

Rear: 1,8 atm (26 psi)

4.4 Riding

6Place the vehicle on its stand and make sure that

the rear wheel is rised from the ground.

6Open the fuel tap placed under the tank turning

the lever straight down to ON or straight up to

reserve (fig.9).

6If the engine is cold, push down the choke lever

located on the carburetor (A-fig.10).

6In USA mpeds only: move the red switch (S-fig.

12 US) located on the right side of the handlebar

into RUN position.

6To slow down, close the throttle and, if necessary,

apply the brakes.

6The vehicle is equipped with two brakes. The

front wheel brake is controlled by the lever on

the right side of the handlebar (C-fig 12). The

rear wheel brake is controlled by the lever on the

left side of the handlebar (D-fig.12). Under

normal stopping conditions, use the rear brake

only. Use the front brake only if necessary and in

conjunction with the rear brake: in any case very

softly and with extreme caution. Hard, sudden

use of the front brake can be very dangerous.

6With the throttle in the closed position, the engine

will run while the vehicle is stationary.

6To stop the engine:

- In European mopeds: close the throttle and

press the red button (S) located on the left

side of the handlebar (fig.12 EU).

- In USA mopeds: close the throttle and move

the red switch (S), located on the right side of

the handlebar, into STOP position (fig.12 US).

4.5 Lights

The switch for the lights is located on the left side of

the handlebar (L-fig.12)

6In European mopeds: the three positions of the

switch correspond to: off, low, high beam.

6In USA mopeds: lights are always switched on

when engine runs. The three positions of the switch

correspond to: low beam, high beam, flashing.

Fig. 9 Fig. 10 Fig. 12 EU

Fig. 12 US

B

B

A

A

C

B

C

D

E

F

FG

L

S

T

B

C

D

E

FF

G

LST

6Open the throttle slightly, by twisting the right

handlebar grip (B-fig.12).

6Start the engine by pushing down the kick starter

lever with the foot.

6A few seconds after that the engine as started,

release the choke to its open position by opening

the throttle completely and immediately closing

it. Prolonged operation with the choke on will

cause spark plug fouling. Use caution to insure

that the vehicle is on its stand and apply the

front brake while the throttle is opened

completely.

6Get on the vehicle assuming the riding position.

6With the throttle in the closed position, apply the

rear brake before pushing the vehicle off its

stand.

6Once started, the vehicle is driven at the desired

speed solely by use of the twist grip throttle (B-

fig12)

4.6 Horn

The push button for the horn (color blue) is located on

the left side of the handlebar (fig.12 - E).

4.7 Turn signal lamps

The switch (T) for the turn signal lamps is located:

6In European mopeds: on the right of the

handlebar (fig.12 EU);

6In USA mopeds: on the left of the handlebar

(fig.12 US);

4 OPERATING INSTRUCTIONS

4.1 Running-in

During the first 500 km (300 mls), use a mixture of

regular gasoline with 4% two stroke oil and do not

operate at more than 3/4 throttle. At about 500 km

(300 mls) check all bolts and nuts for proper tightness

and tighten the cylinder head nuts at 10 Nm torque.

4.2 Fuel

After the first 500 km (300 mls) use a mixture of regu-

lar gasoline with 2% two stroke oil.

CAUTION: an improper mixture or just fuel without

oil will cause damages and voids all warranties.

4.3 Tyre pressure

Front: 1,2 atm (18 psi)

Rear: 1,8 atm (26 psi)

4.4 Riding

6Place the vehicle on its stand and make sure that

the rear wheel is rised from the ground.

6Open the fuel tap placed under the tank turning

the lever straight down to ON or straight up to

reserve (fig.9).

6If the engine is cold, push down the choke lever

located on the carburetor (A-fig.10).

6In USA mpeds only: move the red switch (S-fig.

12 US) located on the right side of the handlebar

into RUN position.

6To slow down, close the throttle and, if necessary,

apply the brakes.

6The vehicle is equipped with two brakes. The

front wheel brake is controlled by the lever on

the right side of the handlebar (C-fig 12). The

rear wheel brake is controlled by the lever on the

left side of the handlebar (D-fig.12). Under

normal stopping conditions, use the rear brake

only. Use the front brake only if necessary and in

conjunction with the rear brake: in any case very

softly and with extreme caution. Hard, sudden

use of the front brake can be very dangerous.

6With the throttle in the closed position, the engine

will run while the vehicle is stationary.

6To stop the engine:

- In European mopeds: close the throttle and

press the red button (S) located on the left

side of the handlebar (fig.12 EU).

- In USA mopeds: close the throttle and move

the red switch (S), located on the right side of

the handlebar, into STOP position (fig.12 US).

4.5 Lights

The switch for the lights is located on the left side of

the handlebar (L-fig.12)

6In European mopeds: the three positions of the

switch correspond to: off, low, high beam.

6In USA mopeds: lights are always switched on

when engine runs. The three positions of the switch

correspond to: low beam, high beam, flashing.

Fig. 9 Fig. 10 Fig. 12 EU

Fig. 12 US

B

B

A

A

C

B

C

D

E

F

FG

L

S

T

B

C

D

E

FF

G

LST

5 CHECKS AND ADJUSTMENTS

5.4 Throttle cable

To take up slacks in the throttle cable, adjust device B

- fig. 10 or G - fig. 12 .Tighten the lock nut after

adjustment.

5.5 Idling

To adjust the engine idling speed (fig.10):

6increasing: turn clockwise

6decreasing: turn the screw C counterclockwise

5.6 Head lamp

The head lamp inclination may be adjusted after

loosening the two mounting screws.

5.7 Spark plug

The gap of the electrodes should be 0,3 0,4 mm.

Clean the spark plug with the wire brush located in

the tool box.

Tithening torque of the spark plug on the cylinder

head: 28 Nm

5.8 Magnetowheel

The spark plug ignition is provided by an electronic

magnetowheel.

The spark advance is 22° 24° corresponding to 2,30

2,45 mm before the top dead center.

the screw C

÷

÷

÷

5.9 Nuts and bolts

All nuts and bolts are equipped with locking

devices (lock nuts, self locking nuts, lock

washers). Nevertheless, check the tightening

periodically.

5.10 Wiring harness

See electric diagram:

6In the European mopeds: fig. 22 EU

6In the USA mopeds: fig. 22 US

5.1 Handlebar hook

The locking hook is secured by two springs (A-

fig.14). Before riding, be sure that both springs are

working properly.

The correct position of the hook is illustrated in

fig.14. If the hook goes out of adjustment (as

illustrated in fig.13 and 15), readjust as follows:

6loosen the screw (B) for a fraction of turn;

6turn the knurled eccentric ring (C) until the

hook assumes the position indicated in fig. 14;

6tighten again the screw (B)

5.2 Handlebar hinge

If the handlebar hinge feels loose, tighten the lock nut

(A-fig. 16) to take out the slack without

overtightening.

The handlebar stem must still swivel reasonable easy.

5.3 Brakes

The brakes may be adjusted at the handbrake levers

(F-fig. 12) and at the brake backing plate (A-fig.17)

After each adjustment tighten the correspondent nut.

With the brake levers in their normal position, the

wheels must turn freely.

To check the brake lining thickness, remove the

rubber plugs located in the brake backing plates (B-

fig. 17).

Fig. 13 Fig. 14 Fig. 15

A

BC

NO NOOK

Fig. 16 Fig. 17

A

A

B

B

5 CHECKS AND ADJUSTMENTS

5.4 Throttle cable

To take up slacks in the throttle cable, adjust device B

- fig. 10 or G - fig. 12 .Tighten the lock nut after

adjustment.

5.5 Idling

To adjust the engine idling speed (fig.10):

6increasing: turn clockwise

6decreasing: turn the screw C counterclockwise

5.6 Head lamp

The head lamp inclination may be adjusted after

loosening the two mounting screws.

5.7 Spark plug

The gap of the electrodes should be 0,3 0,4 mm.

Clean the spark plug with the wire brush located in

the tool box.

Tithening torque of the spark plug on the cylinder

head: 28 Nm

5.8 Magnetowheel

The spark plug ignition is provided by an electronic

magnetowheel.

The spark advance is 22° 24° corresponding to 2,30

2,45 mm before the top dead center.

the screw C

÷

÷

÷

5.9 Nuts and bolts

All nuts and bolts are equipped with locking

devices (lock nuts, self locking nuts, lock

washers). Nevertheless, check the tightening

periodically.

5.10 Wiring harness

See electric diagram:

6In the European mopeds: fig. 22 EU

6In the USA mopeds: fig. 22 US

5.1 Handlebar hook

The locking hook is secured by two springs (A-

fig.14). Before riding, be sure that both springs are

working properly.

The correct position of the hook is illustrated in

fig.14. If the hook goes out of adjustment (as

illustrated in fig.13 and 15), readjust as follows:

6loosen the screw (B) for a fraction of turn;

6turn the knurled eccentric ring (C) until the

hook assumes the position indicated in fig. 14;

6tighten again the screw (B)

5.2 Handlebar hinge

If the handlebar hinge feels loose, tighten the lock nut

(A-fig. 16) to take out the slack without

overtightening.

The handlebar stem must still swivel reasonable easy.

5.3 Brakes

The brakes may be adjusted at the handbrake levers

(F-fig. 12) and at the brake backing plate (A-fig.17)

After each adjustment tighten the correspondent nut.

With the brake levers in their normal position, the

wheels must turn freely.

To check the brake lining thickness, remove the

rubber plugs located in the brake backing plates (B-

fig. 17).

Fig. 13 Fig. 14 Fig. 15

A

BC

NO NOOK

Fig. 16 Fig. 17

A

A

B

B

7. SERVICING

7.1 Every 1000 km (600 miles)

6Lubricate with grease the speedometer drive

(B-fig.18) through the lubricating nipple.

6Clean the air filter and the carburetor;

7.2 Once a year

6Lubricate the cables (brakes,throttle,

speedometer) and the frame articulations with

a drop of light oil.

6Clean the starting gears and lubricate with

grease.

6Replace the rubber fuel line: after one year the

rubber tube becomes brittle and cracked and

this can cause fire when the engine is hot.

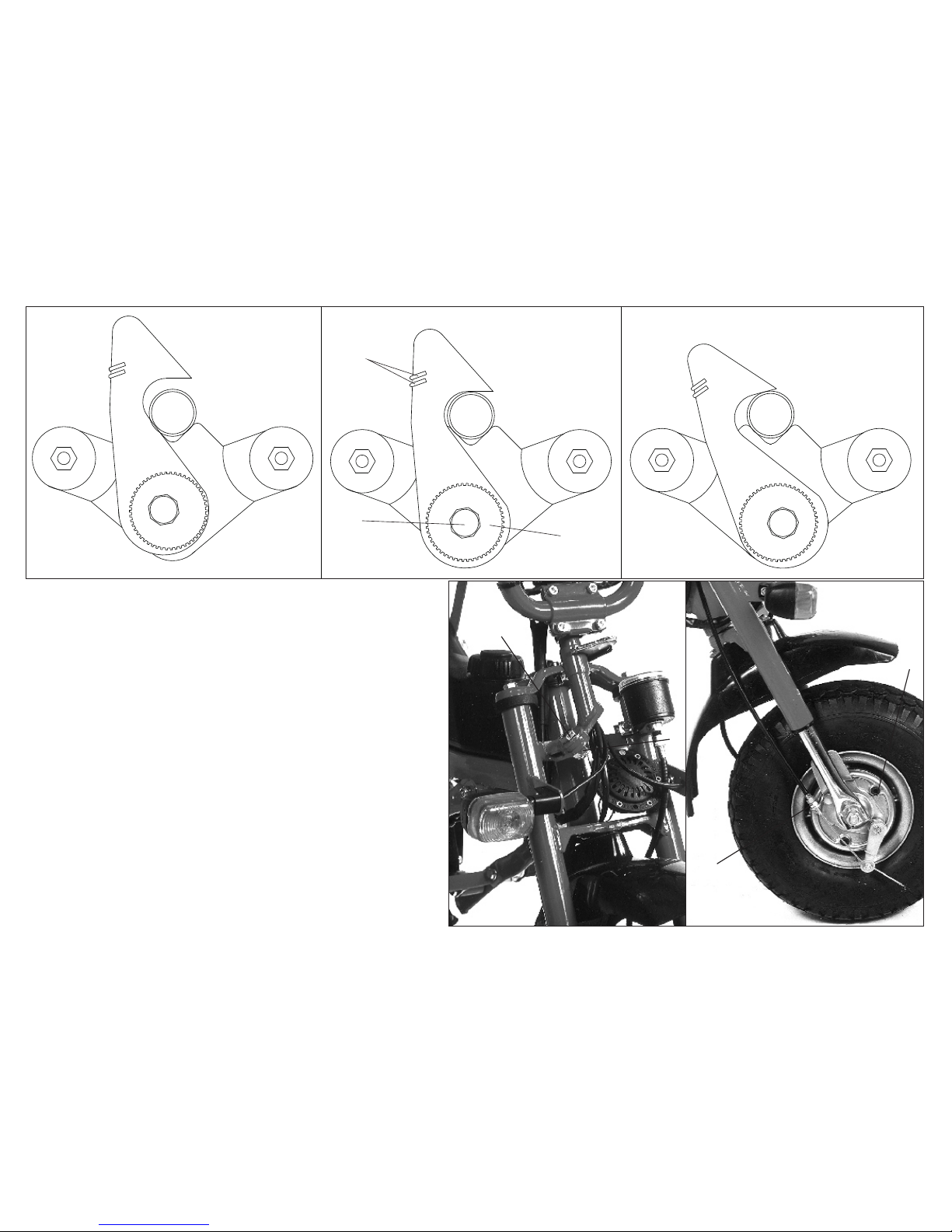

6.2 Expanding pulley / clutch (fig.18)

For disassembling:

6

6unscrew screw (T);

For assembling:

6add a drop of loctite (medium grade) in

the screw (T)

6tighten the screw (T) with a pneumatic

screwdriver or with a socket wrench while

holding the magnetowheel

For spare parts order see Fig. 21

Unscrew the three bolts (B1 - B2 - B3)

holding the belt guard.

6 DISASSEMBLIES

6.1 Rear wheel - reduction unit (fig. 18-19)

6Unscrew the lock nut of the screw (A) and

then the screw (A) at the bottom of the left

shock absorber.

6Rotate the left shock absorber on its top end so

to keep it removed from the belt guard.

6Unscrew the three bolts (B1 - B2 - B3) holding

the belt guard.

6Disconnect the brake cable from the brake

backing plate on the right hand side of the

wheel;

6While pulling forward the reduction unit arm

(C), remove the primary belt (D);

6Remove the screw head (G) through the hole

(H);

6Unscrew the nuts (L) holding the wheel to the

fork;

6Remove the wheel assembly from the fork;

6Disconnect the spring (M) at its end (N);

6Remove the arm (C) from its rotation pin

together with the timing belt;

6Remove the tap washer (P), unscrew the four

screws (Q) and remove the crown wheel.

For reassembling, the previous steps are to be

carried out in on the reverse.

6.3 Front wheel (fig.20)

6disconnect the brake cable at the brake

backing plate (A);

6disconnect the speedometer cable at the

speedometer drive (B);

6Unscrew the clamping nuts (C).

CAUTION: when reassembling the wheel,do not

turn (screwing or unscrewing) the fork tips (D).

Fig. 21

Fig. 18

B1

B2

B3

A

C

D

E

L

F

GH

T

Fig. 19 Fig. 20

N

M

QP

L

AB

CC

D

D

7. SERVICING

7.1 Every 1000 km (600 miles)

6Lubricate with grease the speedometer drive

(B-fig.18) through the lubricating nipple.

6Clean the air filter and the carburetor;

7.2 Once a year

6Lubricate the cables (brakes,throttle,

speedometer) and the frame articulations with

a drop of light oil.

6Clean the starting gears and lubricate with

grease.

6Replace the rubber fuel line: after one year the

rubber tube becomes brittle and cracked and

this can cause fire when the engine is hot.

6.2 Expanding pulley / clutch (fig.18)

For disassembling:

6

6unscrew screw (T);

For assembling:

6add a drop of loctite (medium grade) in

the screw (T)

6tighten the screw (T) with a pneumatic

screwdriver or with a socket wrench while

holding the magnetowheel

For spare parts order see Fig. 21

Unscrew the three bolts (B1 - B2 - B3)

holding the belt guard.

6 DISASSEMBLIES

6.1 Rear wheel - reduction unit (fig. 18-19)

6Unscrew the lock nut of the screw (A) and

then the screw (A) at the bottom of the left

shock absorber.

6Rotate the left shock absorber on its top end so

to keep it removed from the belt guard.

6Unscrew the three bolts (B1 - B2 - B3) holding

the belt guard.

6Disconnect the brake cable from the brake

backing plate on the right hand side of the

wheel;

6While pulling forward the reduction unit arm

(C), remove the primary belt (D);

6Remove the screw head (G) through the hole

(H);

6Unscrew the nuts (L) holding the wheel to the

fork;

6Remove the wheel assembly from the fork;

6Disconnect the spring (M) at its end (N);

6Remove the arm (C) from its rotation pin

together with the timing belt;

6Remove the tap washer (P), unscrew the four

screws (Q) and remove the crown wheel.

For reassembling, the previous steps are to be

carried out in on the reverse.

6.3 Front wheel (fig.20)

6disconnect the brake cable at the brake

backing plate (A);

6disconnect the speedometer cable at the

speedometer drive (B);

6Unscrew the clamping nuts (C).

CAUTION: when reassembling the wheel,do not

turn (screwing or unscrewing) the fork tips (D).

Fig. 21

Fig. 18

B1

B2

B3

A

C

D

E

L

F

GH

T

Fig. 19 Fig. 20

N

M

QP

L

AB

CC

D

D

8 DIAGNOSIS

8.2 The engine does not run normally

The reason can be:

6One of the reasons listed in sec. 8.1

6Carbon deposit at the piston and cylinder

head, at the cylinder exhaust port, in the

exhaust pipe;

6The spark plug or the cylinder head or the

induction manifold are not tightened.

8.3 Fouling at the electrodes

The reason can be a too poor carburation:

6Clean the carburetor, the cylinder exhaust

port, the exhaust pipe;

6Tighten the spark plug,the cylinder head, the

induction manifold;

6Make sure that fuel is a mixture of regular

fuel with 2% oil.

8.4 Jamming of the expanding pulley

Disassemble and clean.

8.5 Jamming of the reduction unit

Replace the V-belt.

8.1 The engine does not start

6Check if the fuel is not reaching the carburetor

because:

- The tank is low on fuel: place fuel tap in

reserve position (lever pointing up) and

then refuel;

- The fuel tap is closed;

- The fuel line is clogged (by an air bubble,

for instance);

- The carburetor or air filter is dirty.

6Check the ignition:

- With the spark plug removed and resting

with its metal portion lying on the fins of

the cylinder, check whether there is a

spark between the electrodes by

depressing the kick starter manually.

- Check whether the spark plug is dirty (in

this case clean it thoroughly) and check

whether the gap of the electrodes is

correct (0.3 0.4 mm );

- Check the spark plug cable and replace

if it is broken or poorly insulated;

- Check the electric wiring (see diagram

fig. 22). Make sure that the ground

connection between the engine and the

frame is efficient.

÷

A Orange

B White

C Blue

G Yellow

H Gray

M Brown

N Black

P Pink

R Red

V Green

X Ye l l o w -

Green

Z Violet

HRS Horn Switch

BLS Blinker Light Switch

ESS Engine Stop Switch

SLS Stop Light Switch

FRB Front Right Blinker

STB Stabilizer

COL Coil (2003)

MGN Magnetowheel (2002)

LGS Light Switch

HRN Horn

HLT Head Light

FLB Front Left Blinker

BLK Blinking Device

RLB Rear Light Blinker

RRB Rear Light Blinker

HRS

ESS

SLS

BLS

HRN

HLT

FLB FRB

STB

COL

MGN

RLB RRB

TLT

SLT

LGS

CAVPZ R

XRG

NM

H B

Fig. 22EU

BLSSLS LGS

HSS

HRN

HLT

ESS

FLB FRB

STB

COL

MGN

BLK RLB RRB

TLT

SLT

Z C A R HG V X

N B P

Fig. 22US

8 DIAGNOSIS

8.2 The engine does not run normally

The reason can be:

6One of the reasons listed in sec. 8.1

6Carbon deposit at the piston and cylinder

head, at the cylinder exhaust port, in the

exhaust pipe;

6The spark plug or the cylinder head or the

induction manifold are not tightened.

8.3 Fouling at the electrodes

The reason can be a too poor carburation:

6Clean the carburetor, the cylinder exhaust

port, the exhaust pipe;

6Tighten the spark plug,the cylinder head, the

induction manifold;

6Make sure that fuel is a mixture of regular

fuel with 2% oil.

8.4 Jamming of the expanding pulley

Disassemble and clean.

8.5 Jamming of the reduction unit

Replace the V-belt.

8.1 The engine does not start

6Check if the fuel is not reaching the carburetor

because:

- The tank is low on fuel: place fuel tap in

reserve position (lever pointing up) and

then refuel;

- The fuel tap is closed;

- The fuel line is clogged (by an air bubble,

for instance);

- The carburetor or air filter is dirty.

6Check the ignition:

- With the spark plug removed and resting

with its metal portion lying on the fins of

the cylinder, check whether there is a

spark between the electrodes by

depressing the kick starter manually.

- Check whether the spark plug is dirty (in

this case clean it thoroughly) and check

whether the gap of the electrodes is

correct (0.3 0.4 mm );

- Check the spark plug cable and replace

if it is broken or poorly insulated;

- Check the electric wiring (see diagram

fig. 22). Make sure that the ground

connection between the engine and the

frame is efficient.

÷

A Orange

B White

C Blue

G Yellow

H Gray

M Brown

N Black

P Pink

R Red

V Green

X Ye l l o w -

Green

Z Violet

HRS Horn Switch

BLS Blinker Light Switch

ESS Engine Stop Switch

SLS Stop Light Switch

FRB Front Right Blinker

STB Stabilizer

COL Coil (2003)

MGN Magnetowheel (2002)

LGS Light Switch

HRN Horn

HLT Head Light

FLB Front Left Blinker

BLK Blinking Device

RLB Rear Light Blinker

RRB Rear Light Blinker

HRS

ESS

SLS

BLS

HRN

HLT

FLB FRB

STB

COL

MGN

RLB RRB

TLT

SLT

LGS

CAVPZ R

XRG

NM

H B

Fig. 22EU

BLSSLS LGS

HSS

HRN

HLT

ESS

FLB FRB

STB

COL

MGN

BLK RLB RRB

TLT

SLT

Z C A R HG V X

N B P

Fig. 22US

Cod. 699 - R7 - Inglese - Ed 11.97

Table of contents