Dialight L865 Medium Intensity Instruction manual

Document: 9100-127-2968-99

Revision C

Release Date: 11/27/19

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 1of 43

DO NOT let any supply cords touch hot

surfaces higher than cord ratings.

DO NOT mount near gas or electric heaters

Equipment should be mounted in locations

and at heights where it will not be subjected to

tampering by unauthorized personnel.

The use of accessory equipment not

recommended by the manufacturer may cause

unsafe conditions.

DO NOT use this equipment for other than

intended use.

DO NOT look into the Infrared (IR) LEDs.

These five IR LEDs on top of the unit (if

applicable) will not appear to be ON, but can

be verified using most digital cameras.

Pictures are required for

commissioning the install. Failure to

provide could VOID all warranties

SAVE THESE INSTRUCTIONS!!

The operation and maintenance must be carried

out by authorized personnel.

Repairs and Installation must only be carried

out by a qualified electrician.

Only genuine Dialight replacement parts must

be used when unforeseen repairs are required.

Observe the national safety rules and

regulations during installation!

Earth Grounding is required throughout the

install process. Failure to do so could void all

warranties!

No alterations should be done without the

agreement from Dialight Corp. Alterations other

than written in this manual will void all

warranties.

Instructions must be kept with the system installed

MediumIntensityQuickStartManual

READ AND FOLLOW ALL SAFETY INSTRUCTIONS

Document: 9100-127-2968-99

Revision C

Release Date: 11/27/19

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 2of 43

Included in this manual:

System overview

Installation Tips and

requirements

Environmental Specifications

System Descriptions

RS485 Communication

Connections

Installing the RS485 to additional

power supplies

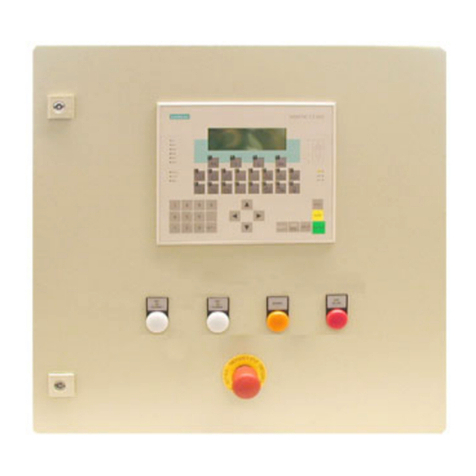

Controller layouts

Navigating the LCD Display

oLCD startup display

screens

oSetup Screens

(Configuration)

oMain Menu Screens

oManual Lighting inspection

test

Controller Status LED’s

Dry contact connections

Controller electrical

Parameters

Resetting, ext. sync option,

and serial numbers

Replacement part numbers

Display Events and Alarm

Descriptions

Alarm list and possible causes

Calibration of SideLights

Connection of the Photocell

Connection of the GPS Antenna

Event and Alarm Views and

Meanings

Introduction

This manual is for orientation and a quick guide to the installation process of the

controller, configuration and definitions of the Dual Strobe system or Dual Strobe +

Infrared (IR) system. There will be steps that are not detailed and the full installation

manual MUST be used for more in depth installation instructions.

Refer to the installation manual for the following information

Installing the Controller and the pre drilled holes

Dimensions of the Controller

Securing the cables to the structure

Connection of either AC or DC input voltages

Connection of the Sidelights and calibration

Photocell connections

Flash head connections for both the 4 conductor and the 8 conductor versions

Proper bonding of the Strobe cable

Mounting the Flash head

Document: 9100-127-2968-99

Revision C

Release Date: 11/27/19

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 3of 43

System Overview

Document: 9100-127-2968-99

Revision C

Release Date: 11/27/19

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 4of 43

Installation Tips and requirements

For the Mains cable, it is recommended that the electrician or installer calculate the wire

requirements based on the amount of Flash heads being installed. It is recommended

that no installation utilizes less than 16AWG wire with at least a 90ºC temperature

rating. See electrical parameters. Local Electric codes and wiring MUST followed.

For RS485 cabling, 3 cores of 18AWG, drain wire plus a shield and braid for adequate

grounding and signals are required. RS485 is only required for E1+1 and larger

structures where multiple Strobes are required.

Cable between the Flash head and the controller must be a minimum of 14AWG and 4

conductors with foil and braid (Supplied if a Kit P/N is ordered). Maximum distance

between the controller and the Flash head is 630feet.

NOTE: Failure to do any of the above could void all factory warranties. If in doubt

please contact your sales agent or representative or Dialight Tech support.

During installing on the tower proper grounding techniques should be utilized.

The system has built in Lightning and RF immunity at each section, but for it to

be effective proper ground connection techniques must be used. For more

details, contact your local sales rep.

USE PROPER METHODS OF LIFTINGAND CARRYINGTO PROTECT AGAINST INJURY.

FOLLOWTHE RECOMMENDATIONS BELOWTO ENSURE ENCLOSURESARE HANDLED

IN A SAFEMANNER:

BASED ON FACILITY SAFETY REQUIREMENTS DETERMINE IF THE

ENCLOSURE REQUIRES TEAM LIFTING

BEND AT THE KNEES AND MAKE SURE YOUR BACK IS STRAIGHT BEFORE

LIFTING

LIFT WITH YOUR LEGS AND NOT YOUR BACK

KEEP THE ENCLOSURE CLOSE TO YOUR BODYWHILE CARRYING

KEEP YOUR BACK STRAIGHT WHEN LOWERING

EnvironmentalSpecifications

Operating Temperature Range: -40°C to +55°C

IP66, Suitable for outdoor use

Pollution degree: P1

Equipment is intended to be installed at an altitude of 2000m or less

Document: 9100-127-2968-99

Revision C

Release Date: 11/27/19

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 5of 43

System Descriptions that are covered in the manual

D1RWCTR409

Gen5 dual red/white controller with AC input ,

48volt sidelights and 4 conductor flash head

cable required

D1RWCTR449

Gen5 dual red/white controller with 48VDC

input , 48volt sidelights and 4 conductor flash

head cable required

D1CWCTR409

Gen5 dual red/white + Infrared (IR) controller

with AC input , 48volt sidelights and 4

conductor flash head cable required

D1CWCTR409

Gen5 dual red/white + Infrared (IR) controller

with 48VDC input , 48volt sidelights and 8

conductor flash head cable required

D1RWCTR409GPS

Gen5 dual red/white + Infrared (IR) controller

with 48VDC input , 48volt sidelights and 8

conductor flash head cable required

D1RWFH409

Gen5 dual red/white 4 conductor Flash Head

D1CWFH409

Gen5 dual red/white + Infrared (IR) 4

conductor FlashHead

Connection of AC Mains Power

The Enclosure is supplied with 6 predrilled holes to accommodate the Main cord, the

RS485 communication cable, Photocell’s input, GPS antenna cable, the SideMarker

lights and relay outputs.

NOTE: Certain holes may not be required for all installation types thus all unused holes

must remain sealed with supplied blanking plugs and properly tightened to avoid water

or moisture entering the enclosure.

If additional holes are required then they can be located in any convenient location for

the user and installer. If installed outdoors water ingress must be considered.

NOTE: If there is existing AC and RS485 communication (when required) in the vicinity

of the Base Controller installation then these cables can be used if they meet the

requirements in this guide.

NOTE: Multiple grounding points are provided in the enclosure for protective and

functional Earth/Ground connections.

RS485 Communication Connections

NOTE: The below is common between all the controllers covered in the manual.

Document: 9100-127-2968-99

Revision C

Release Date: 11/27/19

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 6of 43

The connection of the RS485 cable is vitally important to the operation of the system.

This connection provides all the events and alarms to the Master controller that is being

used with the installation.

Factory connected wiring color code:

Boards are Labeled Description Color Code

Label “A”

Communications “A”

Grey

Common

Common for RS485

Yellow

Label “B”

Communications “B”

Blue

Option 1: RS485 consisting of 3 conductors, a drain wire and foil shield and braid.

Install Cable Connected to Description Color Code

Conductor 1

Label “A”

Communications “A”

Grey

Conductor 2

Common

Common for RS485

Yellow

Conductor 3

Label “B”

Communications “B”

Blue

Drain wire

Ground stud

Ground

Bare wire

Foil Shield and

Braid

Clamping terminal

Ground

Connected when

cable enters the

enclosure and must

be secured to the

plate

Option 2: RS485 consisting of 2 Conductors, a drain wire and either a shield or

braid is used.

Install Cable Connected to Description Color Code

Conductor 1

Label “A”

Communications “A”

Red

Drain Wire

Common

Common for RS485

Bare Wire

Conductor 2

Label “B”

Communications “B”

Black

Shield or Braid

Clamping Terminal

Ground

Connected when

cable enters the

enclosure and must

be connected to

plate

WARNING: For Color Codes not shown the installer must take note of the colors used

for these connections since it is required that all A, Common and B terminals be

connected the same throughout the system.

Installing the RS485 to additional power supplies

NOTE: For an E1 system there is no externally connected RS485.

Document: 9100-127-2968-99

Revision C

Release Date: 11/27/19

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 7of 43

NOTE: For structures lager than the above additional external communications need to

be added between the RS485 surge board and the translator boards ineach of the

additional power supplies.

NOTE: For systems larger than E2 daisy chaining between the translator boards is

required.

NOTE: Translator boards are located in power supply enclosures

NOTE: The controller translator board is to be set to zero.

E1+1,D1+1and A1+1

systems

RS485

Junction

Board

Translator

Board#1

Located in

power

supplies

E2,D2 and A2

systems

Translator

Board#1

Translator

Board#2

RS485

Junction

Board

RS485

Located in

Controller

Document: 9100-127-2968-99

Revision C

Release Date: 11/27/19

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 8of 43

Connection of the Marker Lights (L810’s) to the Side Light Monitoring Board

WARNING: DC Voltage L810’s are to be used for connecting to this system!

NOTE: Dialight Part number is RTO-1R18-001

LED Status Indicators on the Monitor Board

LED Label

Color

Status

PHOTO_FAULT

RED

ON = Photo cell is not connected orin fault

OFF = Photo cell is connected and working

W. DOG (Watchdog)

GREEN

BLINKING= Microcontroller is working

OFF = Microcontroller in fault

PWR_ON

GREEN

ON = Board is powered

OFF = Board is not powered or in fault

ISO_5V

GREEN

ON = 5 Volt DC rail is working

OFF = 5 Volt DC rail is in fault

5V

GREEN

ON = 5 Volt DC rail is working

OFF = 5 Volt DC rail is in fault

12V

GREEN

ON = 12 Volt DC rail is working

OFF = 12 Volt DC rail is in fault

TX (Transmit)

GREEN

BLINKING = Monitor Board is transmitting data

OFF = NOT transmitting data (Fault)

RX (Receive)

GREEN

BLINKING = Monitor Board is receiving data

OFF = NOT receiving data (Fault)

TX_EN (Transmit Enable)

GREEN

BLINKING= Monitor Board acknowledgetransmit

OFF = NO acknowledge of transmit (Fault)

OK# (RTO Output #)

GREEN

ON = RTOs are present and working

OFF = RTOs not present

FAULT# (RTO Output #)

RED

ON = RTOs are in fault (low current)

OFF = RTOs are working or not present

CAL# (Calibrate RTO Output #)

AMBER

ON = RTOs are ready to calibrate

OFF = RTOs are working, not present, or in fault

Document: 9100-127-2968-99

Revision C

Release Date: 11/27/19

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 9of 43

LED LOCATIONS

Calibration Steps for L810 Side Lights

Follow these steps to calibrate the Marker Light Monitor Boards located in the

Main Controller. These steps will allow the system to properly identify, power,

and monitor the RTO L810 side markers.

STEP 1 –CLEAR the Marker Light Monitor Board by holding down

buttons SW1-4 at same time.

STEP 2 –FAULT LEDs #1-4 will light up red.

STEP 3 –Press “RESET” button (SW7).

STEP 4 –Each output will auto configure within 15 seconds.

STEP 5 –Verify Each output is correct:

Green “OK” LED will illuminate green if RTO output is present.

“OK”, “FAULT”, and “CAL” LEDs will be off if RTO output is NOT present

WARNING: If calibration is NOT completed then the system will not log events or

Alarms for faulty Side lights.

NOTE: If calibration of the side lights is not performed the default is that the side lights

will turn ON at night but no events or alarms will be logged

Document: 9100-127-2968-99

Revision C

Release Date: 11/27/19

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 10 of 43

MARKER LIGHT MONITOR BOARD SHOWING BUTTONS AND SWITCH FOR

CONFIGURATION AND CALIBRATION

Document: 9100-127-2968-99

Revision C

Release Date: 11/27/19

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 11 of 43

Photocell Connection: Dialight P/N D256-600xPEC

Open supplied photocell enclosure. The Photocell requires 3 connections to be made to

the inside of the photocell enclosure itself and 3 inside the controller.

+V = 12Vdc (supplied from controller)

SIG. IN = Sense voltage relayed to controller

Return = Ground

Cable Requirements:

3 conductor, 18AWG

Maximum allowable distance is 500 feet from the controller

The photocell comes supplied with one end threaded for ¾” NPT conduit, which is

recommended for installing the photocell. If a cable without conduit is used in a

hazardous location installation then the cable at minimum MUST have either a shield or

braid that is properly connected to body of the photocell and to the enclosure of the

controller it is being installed to. Failure to properly ground or use a cable without the

Terminal blocks

inside Controller

labeled

“photocell input”

Document: 9100-127-2968-99

Revision C

Release Date: 11/27/19

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 12 of 43

shield or braid will void all warranties and the product could be subject to premature

failures.

When installed the Photocell must face north and have an unobstructed view of the

northern sky.

NOTE: For testing and troubleshooting purposes refer to the Photocell manual

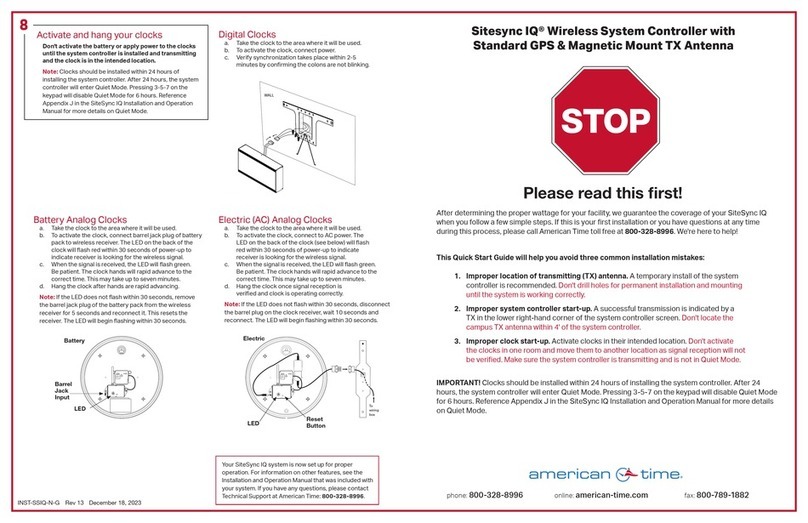

GPS Antenna Connection to the Controller

NOTE: REFER to GPS Antenna manual for mounting GPA Antenna to Photocell

Enclosure

Located in the controller mounted on top of the terminal blocks on the bottom left hand

side is a BNC connector that accepts the cable from the GPS antenna, Picture shown

below.

NOTE: This is the only connection required for the GPS inside the controller.

Photocell

Document: 9100-127-2968-99

Revision C

Release Date: 11/27/19

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 13 of 43

WARNING: The cable can NOT be cut or shortened in any way. Any extra cable that is

left because of the proximity of the antenna MUST be gathered, tie wrapped and stored

in the Controller. See picture below

Bundle excess GPS cable and store in bottom part of Enclosure

Document: 9100-127-2968-99

Revision C

Release Date: 11/27/19

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 14 of 43

D1xW-CTR-4x9Controller

Requirements

NOTE: See electrical parameters for power consumption

Attach output of Photocell to terminal blocks labeled “photocell”

Connect the RS485 to the terminal blocks labeled “RS485” when additional

power supplies are connected.

Document: 9100-127-2968-99

Revision C

Release Date: 11/27/19

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 15 of 43

D1xW-CTR-4x9GPS Controller

Requirements

NOTE: See electrical parameters for power consumption

Attach output of Photocell to terminal blocks labeled “photocell”

Connect the RS485 to the terminal blocks labeled “RS485” when additional

power supplies are connected.

Document: 9100-127-2968-99

Revision C

Release Date: 11/27/19

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 16 of 43

LCD Start up Display Screens

Once power is turned on the next 2 screens will be displayed automatically.

The Startup Screen displays:

NOTE: The Site manager and Installer should take a note of this screen including the

REV number and the Build number if any future troubleshooting is required. x’s indicate

revision levels and will appear as numbers on the display.

The Initializing Screen:

This screen shows a countdown for the initial 15 flashes for E and D type structures

For A red only systems the countdown starts at 45.

NOTE: In some cases this screen will go back to the Startup screen if synchronization

was faulty.

Setup Screens:

These screens are used for properly configuring system based on the structure type

that is being installed. By using the “UP” and “DWN” buttons the user or maintenance

personnel can view and edit the configuration as applicable by pressing the “ENTR”

button after the selecting the desired choice the next screen will be entered.

Configuration Type Screen:

A) To change configuration of controller go to ‘Config Type’ screen’ and press

“ENTR”. This will enable you to select either an “E” “A” or “D” tower type. Sub

categories such as E1, E2 etc. will be addressed later in the configuration

menu.

B) Use the “UP” and “DWN” buttons to scroll and select tower style A, D, or E.

Then press “ENTR”.

Dialight MI Ctrl

REV. x Build: xx

Initial 15 Flashes

In Process

CONFIG TYPE X

‘Enter to change’

Document: 9100-127-2968-99

Revision C

Release Date: 11/27/19

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 17 of 43

NOTE: If ‘Tower Style D’ is selected, the system will automatically proceed to

step F, skipping steps D and E since side markers (L810) are not used in D style

configurations. Any information previously in the system as indicated in omitted

steps will be changed to “0” if switched back to an E or A style configuration and

will have to be re-entered to match what is installed on the tower.

NOTE: System will reset when tower style is changed.

C) Select for the presence of an External GPS using the “UP” and “DWN” buttons,

“YES” indicates an external GPS is being used, “NO” is the standard

configuration without an external GPS. Press “ENTR” after selection.

For the D1RWCTR409GPSthefactory Default is YES.

D) Select the number of Side Marker (L810 or RTO) Tiers that are connected to

the system. 0 through 4 can be selected; the number input shall represent the

number of tiers present. Press “ENTR”.

E) Select the number of Side Marker s (L810’s, RTO’s) that will connected to P1

(Tier 1) 0 through 4 can be selected, then press “ENTR”

NOTE: Repeat for ports 2 through 4.

NOTE: Each port represents one tier.

F) Select the number of beacons (864/5’s) that will be connected to the system. 1

through 9 beacons can be supported. Press “ENTR”

Ext GPS = NO

u/d=chg, enter=done

Num of 810 TIERS=0

u/d=chg, enter=done

NUM 810 P1/T1= 0

u/d=chg, enter=done

Tower style = E

‘enter’ to change

Document: 9100-127-2968-99

Revision C

Release Date: 11/27/19

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 18 of 43

G) Select the number of side light boards that are connected to the system, 1

through 9 and the press “ENTR”.

NOTE: Additional sidelight monitor boards are available for special applications;

most configurations will only have one board and this will remain set to “1”

H) Select the status of sidelights. Use “UP” and “DWN” buttons to change from

STEADY, DISABLED and FLASHING, depending on what is needed of the

sidelights.

NOTE: This is a global change that will affect all tiers of sidelights; individual

tiers are not able to have statuses changed.

I) Select red mode flash rate of the beacons as well as the sidelights when

specified to be flashing as indicated in step H. Selections available are 20, 30,

and 40. Use “UP” and “DWN” buttons to change, and them press “ENTR”

NOTE: Factory default is 30fpm

NOTE: This is a global change that will affect all tiers of sidelights at once.

NOTE: This change will not affect white flashes.

Number of 864/5 = 1

u/d=chg, enter=done

Number of SD BDs=1

u/d=chg, enter=done

L810 stat = STEADY

u/d=chg, enter=done

Flash per min = 30

u/d=chg, enter=done

L810 stat = Disabled

u/d=chg, enter=done

L810 stat = Flashing

u/d=chg, enter=done

Document: 9100-127-2968-99

Revision C

Release Date: 11/27/19

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 19 of 43

J) If sidelights are to be calibrated at this time (if not calibrated as per the previous

section of this manual or the quantity or wiring of sidelights has changed since

previous calibration), use “UP” and “DWN” buttons to change from “NO” to

“YES”, and then press “ENTR.”The system will reset and the sidelight board

will perform its calibration sequence.

NOTE: This step should only be selected if all tiers of sidelights are fully installed

and connected to the controller.

K) If the Photocell mode transition alarm (18 hour alarm) is not needed as an

alarm this selection can disable it.

NOTE: Typically used where there long day or night operations.

Selecting YES: If the photocell does not detect day or night after 18 hours, the

system will alarm after 18 hours and will switch to Day mode. To clear this alarm the

system requires a local reset or a forced operation change locally or remotely.

Selecting NO: After 18 hours of not transitioning the system will log an event in the

log but the system will continue to operate normally based on light conditions. No

alarm via dry contact or mod bus will be generated.

Use “UP” and “DWN” buttons to change from “NO” to “YES”, and then press “ENTR.”

L) The Beacon can be made steady burn in Red night mode

Once the selection for the Beacon steady red Night is completed the next screen to be

displayed is the “Config Type”.

RECAL L810 = NO

u/d=chg, enter=done

Trans PEC Alrm = YES

u/d=chg, enter=done

Trans PEC Alrm = NO

u/d=chg, enter=done

BCN Steady RNite= NO

u/d=chg, enter=done

Document: 9100-127-2968-99

Revision C

Release Date: 11/27/19

1501 Route 34 South, Farmingdale, NJ 07727

Tel: (732) 919-3119 Fax: (732) 751-5778 www.dialight.com

Page 20 of 43

NOTE: Typically used outside of the US. FAA regulations require the beacon to be

flashing so most typical installation will have this selection set to “NO” to ensure a

flashing beacon.

After about 2 minutes the system will reset on its own to save the configured

information.

The Reset button located in the middle bottom of the board can also be pressed to reset

the system.

Resetting is required so the controller saves the configured information to throw alarms

on changes occurring during the operation of the system.

Main Menu Screens:

The next screens are paged through using the “UP” and “DWN” buttons. The user or

maintenance personnel can view and edit the configurations as applicable by pressing

the “ENTR” button to enter into each main menu screen.

Pressing the “CLR” in the selected screens takes the user back to the main screens.

Upon resetting or powering and powering up the system this is the first screen that is

displayed.

Status Screen –Config type:

Screen: Tower style:

This screen displays what the Base Controller has been configured for, if the amount of

beacons configured does not match what is actually connected then alarms will be

generated as “config” alarms. Only powered fixtures and fixtures connected to the

RS485 will be detected. The “B y” in second line will indicate the firmware level of main

controller.

NOTE: If the installer selects 3 beacons and only 1 is powered AL1 (config ERR) will be

lit and recorded in the alarm log.

CONFIG TYPE X

‘Enter to change’

CONFIG TYPE X

‘Enter to change’

Tower Style: X

X 86X ,X 810 B y

This manual suits for next models

1

Table of contents

Popular Controllers manuals by other brands

ARAG

ARAG Bravo 3 Series ADDITION TO INSTRUCTION BOOKLET

Murphy

Murphy Cascade CD101 Installation and operation manual

Hach

Hach sc200 user manual

Automated Logic

Automated Logic M4106nx Technical instructions

KMC Controls

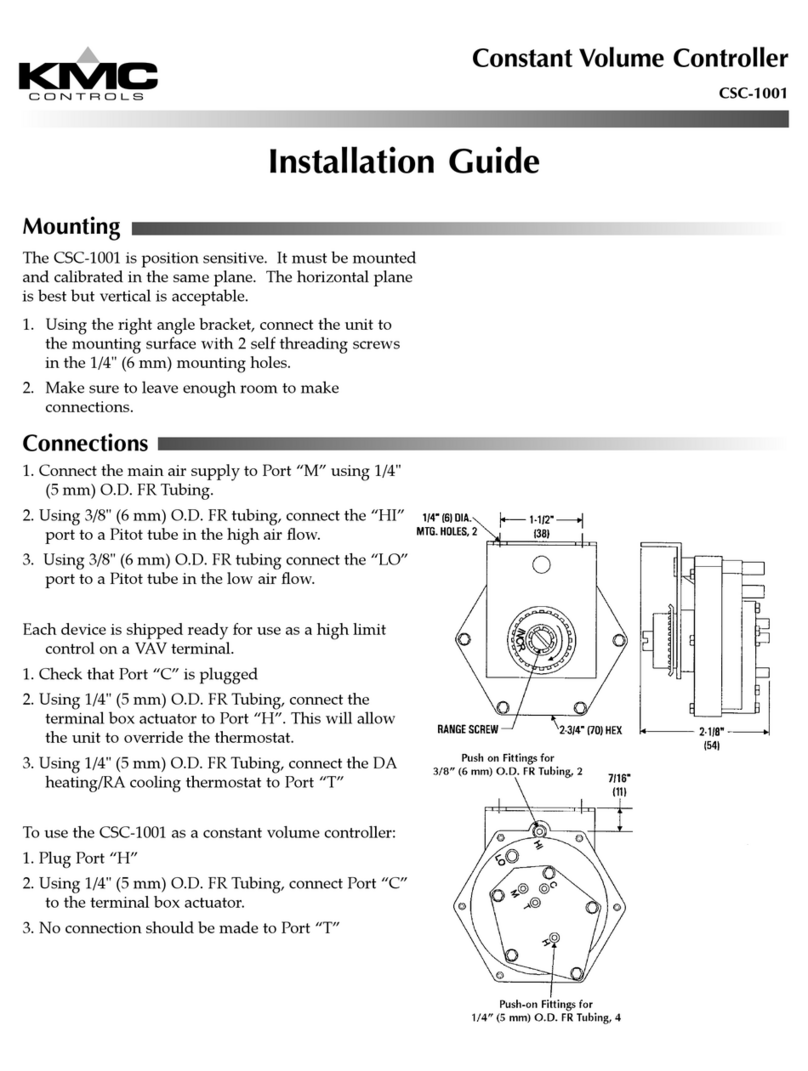

KMC Controls CSC-1001 installation guide

Multiplex

Multiplex MULTIcont BL-20 SD instructions