3161 Governor Manual 03101

6 Woodward

Chapter 3.

Principles of Operation

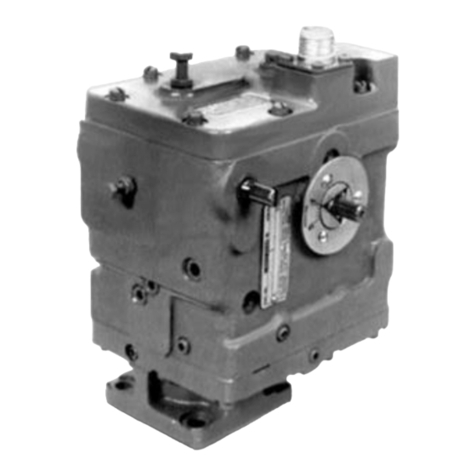

Component Description

Gerotor Oil Pump—The gerotor oil pump is located in the base of the governor.

The inner rotor of the pump is driven by a pin in the drive shaft, and carries the

outer rotor around in mesh, pumping oil to the accumulator piston.

Accumulator—A single accumulator, consisting of a piston and spring, acts as a

relief valve for the oil pump and provides a reservoir of high pressure oil for quick

servo movement. Oil is pumped to the accumulator by the governor pump, with

pressure increasing as the accumulator spring is compressed. When the

pressure builds to the predetermined level, oil is released back to sump through

relief ports in the piston wall.

Power Piston—The power piston is attached to the output shaft by a link and

lever assembly. The power piston is designed with a large area on the bottom

and a small area on top (differential piston). A small pressure increase on the

large area of the piston will move the piston up, causing the output shaft to rotate

in the “increase” direction. The piston can move down only when oil under the

piston is released to sump. Oil to or from the bottom of the power piston is

regulated by the ballhead pilot valve and ballhead pilot valve bushing.

Pilot Valve System

The pilot valve system consists of two components, the ballhead pilot valve

(rotating) bushing, and the ballhead pilot valve plunger. The bushing is rotated

relative to the pilot valve plunger to reduce friction between the two parts. The

control land of the pilot valve plunger regulates the flow of control oil through the

control ports of the ballhead bushing.

When the pilot valve plunger is lowered, high pressure oil moves through the

control port of the bushing, to the bottom side of the power piston, and the piston

moves up. When the pilot valve plunger is raised, the oil from the bottom of the

power piston is released to sump, and the higher pressure on top of the piston

moves the piston down. When the prime mover is running at steady state, the

control land of the pilot valve plunger covers the porting in the ballhead bushing

and the power piston does not move. The movement of the pilot valve plunger is

controlled by the ballhead assembly.

Ballhead Assembly

The ballhead system consists of a ballhead, fly-weights, speeder spring, thrust

bearing, and speeder plug. The ballhead, as part of the pilot valve bushing, is

rotated by the drive coupling and drive shaft.

As the ballhead rotates, the centrifugal force causes the flyweights to pivot

outward. At the same time, the speeder spring is forcing the thrust bearing down

on the flyweight toes opposing the centrifugal force of the flyweights. Pushing

down on the speeder plug increases the downward pressure on the speeder

spring, and the governor speed setting is increased. The prime mover then runs

at a higher speed to produce a higher centrifugal force on the flyweights to

overcome the speeder spring force and rebalance the system.

This document, and more, is available for download from Martin's Marine Engineering Page - www.dieselduck.net