Page 2 of 9

WC17PS SERIES RESTROOM CONTROL

INSTALLATION INSTRUCTIONS

Page 1 of 9

WC17PS Series Restroom Control

INSTALLATION INSTRUCTIONS

Electrified Locks, Relays and Timers

1. GENERAL DESCRIPTION

The CX-WC17PS Restroom Control Kit allows access in and out of

a restroom with the ability to secure the door once inside. The Kit

also provides annunciation by including an Occupied light. The

designation of “PS” in the part number reects that this kit now

comes pre-wired in a metal enclosure with a power supply which

is ready to accept all eld wiring.

The CX-WC17PS Restroom Control Kit is controlled by Camden’s

advanced relay logic controller CX-33. The CX-WC17PS has two

modes. One is Mode 7 for a normally unlocked restroom and

the other is Mode 8 for a normally locked restroom. In Mode 7

when the exterior PUSH to OPEN column switch is pressed it will

trigger the door operator to open the door. In Mode 8 when the

exterior PUSH to OPEN column switch is pressed it will unlock the

strike and trigger the door operator to open the door. Once in

the restroom and the PUSH to LOCK column switch is pressed, it

will keep the door locked in either mode, and disable the exterior

PUSH to OPEN column switch, as well as, providing annunciation

with an Occupied light. When exiting the restroom, you can

either press the inside PUSH to OPEN column switch to unlock

the door and open the door or you can push the crash bar,

paddle or turn the knobset to break the door contact circuit,

which will also unlock the door and reset the system. The

Occupied light will turn o, signaling the restroom is available.

2. INSTALLATION

Operation at a Glance

When the exterior PUSH TO OPEN column switch is pressed it

will send a momentary closure to the outside PUSH TO OPEN

terminal on the CX-WC17PS allowing the door to swing open.

When the interior PUSH TO LOCK column switch is pressed it

will send a momentary closure to the to inside PUSH TO LOCK

terminal on the CX-WC17PS causing it to lock the restroom and

turn on the Occupied light. When the inside PUSH TO OPEN

column switch is pressed it will send a momentary closure to

the inside PUSH TO OPEN terminal on the CX-WC17PS causing it

to unlock the door and open it. The Occupied light will now turn

o signalling the restroom is now vacant. The restroom can also

be unlocked by opening the door from the inside which will break

the door contact circuit causing the CX-WC17PS to reset and

unlock the door.

Mounting

IMPORTANT: Do not apply power to the unit until you have fully

read the instructions and have made the required adjustments.

The CX-WC17PS cabinet should be mounted in a clean dry

location out of direct contact with the elements.

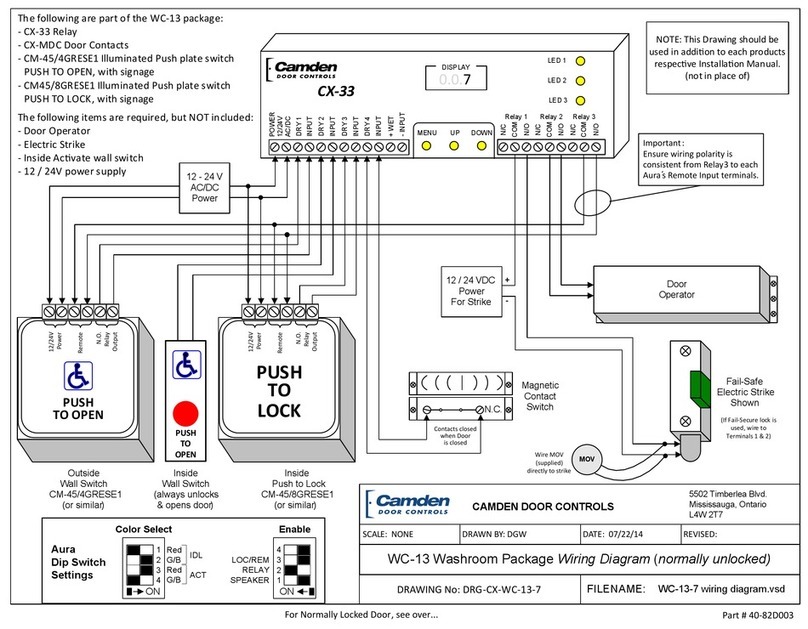

Wiring the CX-WC17PS Series Restroom

Control Kit is as follows:

The CX-WC17PS comes from Camden with the CX-33 pre-wired

to a labeled set of two terminal strips. This will make the wiring

of the push buttons easier since the wiring manual will no

longer need to be directly referenced for termination points. A

complete wiring diagram is adhered to the inside of the door

to provide a layout of the wiring as a reference when wiring the

eld devices to the kit.

There are two terminal strips that mirror the locations on the

CX-33. The left strip is used for power to the CX-33, the PUSH

TO OPEN and PUSH TO LOCK column switch, the door position

switch, and the Wet trigger. The right strip is for the outputs to

drive the strike (Relay 1), door operator (Relay 2), Occupied light

(Relay3), and to provide VDC power for the door strike.

Once all eld devices are wired to the CX-WC17PS then AC

power can be wired in.

IMPORTANT: Conrm the electrical panels breaker you are

going to be using is currently o. Do not wire the primary

terminals of the transformer until the secondary terminals

are connected rst.

The supplied CX-TRX-5024 transformer will have its secondary

terminals wired to the terminals on the top of the left terminal

strip marked as “AC”. Next, wire the primary terminals to the AC

feed to be used. Conrm your connections and apply power by

turning on the electrical panels breaker.

Selecting a Mode

The CX-WC17PS has two restroom applications built in (Mode

7 & 8). The default mode for the CX-WC17PS is Mode 7

(normally unlocked).

Determining which mode is correct for you will be based on

whether the restroom will be normally unlocked (Mode 7) or

normally locked (Mode 8).

There are three LED displays that will allow you to see what mode

you have selected when advancing through the modes. To change

the mode of the CX-WC17PS simply press the MENU button once

and use the UP button to advance to the desired mode.

Editing the Settings for a Mode

Camden builds in typical times for lock release and door

operator activation and is ready to use without changing any

parameters. If you need to change the timing or delay for an

output, it can be done by pressing the “MENU” button within

the mode you selected. Once the option is selected you can

use the “UP or DOWN” buttons to select the timing needed.

The rst option (H & 1 ashing) will be how long relay 1 will be

activated for (0-50 seconds). The second option (d & 1 ashing)

will be how long to wait before activating relay 2 (0-15 seconds).

The third option (H & 2 ashing) will be how long relay 2 will be

activated for (0-50 seconds). The fourth option (d & 2 ashing)

will be how long to wait before activating relay 3 (0-15 seconds).

The fth option (H & 3 ashing) will be how long relay 3 will be

activated for (0-50 seconds). See chart below.

Factory Reset (Defaulting the CX-33)

To return the CX-33 back to its factory default settings you will

need to remove power, then hold down the “MENU” button

while powering up the CX-33. Once started you will see the

rmware version listed then a number “1” will be displayed.

Reconnect your power and press the “MENU” button once then

use the “UP” or “DOWN” button to advance to the desired mode.

Fully test the operation of the CX-WC11PS for proper functionality.

Display (M) Description ( Mode you are in) Parameters (1-15 )

H, then 1 Relay 1 Hold Time 0.0 to 50 seconds

d, then 1 Relay 2 Delay Time 0.0 to 15 seconds

H, then 1 Relay 2 Hold Time 0.0 to 50 seconds

d, then 1 Relay 3 Delay Time Depends on Mode

H, then 1 Relay 3 Hold Time 0.0 to 50 seconds

dSets the display ON or OFF during operating mode ON or OFF

AInput delay on Activate. If other than 0.0 is selected, the input must

be held in for the time period chosen before the CX-33 will activate. 0.0 to 10 seconds

1Set Dry Input 1 to activate on normally open or normally closed contact. N/O OR N/C

2Set Dry Input 2 to activate on normally open or normally closed contact. N/O OR N/C

3Set Dry Input 3 to activate on normally open or normally closed contact. N/O OR N/C

4Set Dry Input 4 to activate on normally open or normally closed contact. N/O OR N/C

5Set Dry Input 5 to activate on normally open or normally closed contact. N/O OR N/C

3. CM-AF503 MOUNT INSTALLATION

Flush Mount Installation

With the back box already roughed-in, position the CM-AF503 so that the holes on the faceplate line-up with the screw holes on

the back box and tighten with supplied #6-32 screws securely in place and completely tighten the #6-32 screws in place.

Wall

CM-AF503

515

16 ''

[150mm]

31

16''

[77mm]

13

16 ''

[21mm]

31

4''

[83mm]

31

2''

[89mm]